AS-3640

AS-3640

AS-3640

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>AS</strong>-<strong>3640</strong><br />

ADRESS PRINTER<br />

User Manual

Products presented in this guide are conform to<br />

requirements of directives nbr 2006/42/EG and<br />

2004/108/EG.<br />

Neopost has implemented a program for the<br />

recycling of worn machines and machines at<br />

the end of their lifetime. Contribute in a responsible<br />

way to the environmental protection<br />

by consulting your retailer internet site, or<br />

by contacting him. He will inform you of the<br />

collection and treatment processes of these<br />

machines.

Pos: 3 /[Allgemeines]/0.0a_Note_Trademarks+Manufacturer Address NEOPOST @ 1\mod_1256739001883_912.doc @ 7153 @<br />

Pos: 4 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/0.0_Revision level_<strong>AS</strong>-OrbitBase 3.1 @ 3\mod_1302187161916_912.doc @ 31186 @<br />

Pos: 5 /[Allgemeines]/0.2_Inhaltsverzeichnis @ 0\mod_1242731641668_912.doc @ 1625 @<br />

a<br />

Copyright<br />

© Copyright 2011<br />

All rights reserved. No part of this manual may be reproduced or transmitted in any form or<br />

by any means, copied onto electronic media or translated into any language without the<br />

manufacturer's express written permission.<br />

The manufacturer is not liable for any damage resulting either from incorrect use or from<br />

repairs and modifications carried out by a third unauthorized party. This manual was<br />

produced with great care. However, liability for any errors which it may contain is excluded.<br />

The manufacturer reserves the right to make any technical or design changes to the<br />

equipment during the development process. All specified values are purely nominal.<br />

Consequently, any legal claims made on the basis of this manual cannot be enforced.<br />

The manufacturer is not liable for any damage or disturbance resulting from the use of<br />

options or accessories which are not original products or do not have the express approval<br />

of the manufacturer.<br />

Brands:<br />

HP is a registered brand name of the Hewlett-Packard Company.<br />

Microsoft and Windows are registered brand names of the Microsoft Corporation.<br />

FlexMail is a registered brand name of Flex Systems B.V.<br />

Bulk Mailer is a registered brand name of Satori Software Inc.<br />

Manufacturer Address<br />

Neopost Industrie<br />

ZI Tivoli<br />

72800 Le Lude<br />

France<br />

www.neopost.com<br />

Revision level<br />

Version Change description Released<br />

3.0 New document for graphic display and<br />

firmware version 4.7<br />

3.1<br />

• Added descriptions for new USB 2.0<br />

and TCP/IP interface<br />

• Changed description to firmware<br />

version 4.8<br />

• Added Device Class A note<br />

• Corrected description for emergency<br />

stop interface “EXTERN”<br />

November 2010<br />

April 2011<br />

User Manual Version 3.1 3

Table of Contents<br />

1 Introduction .............................................................................11<br />

1.1 Pictograms ............................................................................11<br />

1.2 Notes for use of this manual.....................................................11<br />

1.3 Terms and abbreviations .........................................................12<br />

1.4 System requirements ..............................................................12<br />

2 Safety notes .............................................................................13<br />

2.1 General safety notes ...............................................................13<br />

2.2 Ink safety notice.....................................................................15<br />

2.3 Location of the printer .............................................................15<br />

2.4 Disposal ................................................................................15<br />

3 Scope of delivery and assembly................................................16<br />

3.1 Scope of delivery ....................................................................16<br />

3.2 Delivery ................................................................................17<br />

3.3 Device overview .....................................................................18<br />

3.4 Assembly ..............................................................................19<br />

3.5 How to assemble the print system ............................................20<br />

3.5.1 Control unit shelf............................................................... 20<br />

3.5.2 Print unit connections ........................................................ 20<br />

3.5.3 How to mount the Paper Guide Kit ....................................... 21<br />

3.5.4 Connecting the power cable ................................................ 23<br />

3.5.5 Neopost FD-13/FD-15/ Feeder (optional) .............................. 23<br />

3.5.6 Additional devices.............................................................. 23<br />

4 Description of device ................................................................24<br />

4.1 Application range....................................................................24<br />

4.2 Description of functions ...........................................................24<br />

4.3 The Operator Panel .................................................................25<br />

4.3.1 Key panel......................................................................... 26<br />

4.3.2 Main Display ..................................................................... 28<br />

4.4 Interfaces..............................................................................32<br />

4.5 Emergency stop connection......................................................34<br />

4.5.1 Stand-alone operation........................................................ 34<br />

4.5.2 Operation with one additional Neopost device........................ 34<br />

4.5.3 Operation with several additional Neopost devices ................. 34<br />

4.5.4 Operation with other, non-Neopost devices ........................... 35<br />

4 User Manual Version 3.1

4.5.5 How to activate the emergency stop function ......................... 35<br />

5 Initial start-up of the device .................................................... 36<br />

5.1 How to power-on the device..................................................... 36<br />

5.2 How to install the ink cartridges ............................................... 37<br />

5.3 How to position the paper sensor.............................................. 38<br />

5.4 How to adjust the printer to the material thickness ..................... 40<br />

5.5 How to position the material (print media) ................................. 41<br />

5.6 How to adjust the paper guide kit ............................................. 41<br />

5.7 How to position the print units ................................................. 42<br />

5.8 How to measure the print media size ........................................ 43<br />

5.9 How to set the print direction (orientation)................................. 43<br />

5.10 How to perform a test print ................................................ 44<br />

6 Printer menu (firmware V4.8).................................................. 46<br />

7 How to connect the printer to the PC ..................................... 109<br />

7.1 How to install the printer driver .............................................. 109<br />

7.1.1 Windows XP and Windows Vista ......................................... 109<br />

7.1.2 Windows 7...................................................................... 110<br />

7.2 How to use the USB interface................................................. 113<br />

7.3 How to use the Ethernet interface........................................... 113<br />

7.3.1 Adding a TCP/IP port to a printer driver .............................. 114<br />

7.3.2 Connecting the printer to a local area network ..................... 116<br />

7.3.3 Direct Ethernet connection between the printer and the PC .... 119<br />

8 Service ................................................................................... 122<br />

8.1 Maintenance and support....................................................... 122<br />

8.1.1 How to clean the printer ................................................... 122<br />

8.1.2 How to clean an ink cartridge ............................................ 123<br />

8.1.3 How to clean the pen board contacts .................................. 125<br />

8.1.4 How to reset the printer.................................................... 126<br />

8.2 Troubleshooting ................................................................... 127<br />

8.2.1 The conveyor transport doesn’t work .................................. 127<br />

8.2.2 No or only very weak printout with new ink cartridges........... 128<br />

8.2.3 Ink on transport belt after test print ................................... 129<br />

8.2.4 Emergency system cannot be released................................ 129<br />

8.2.5 The printer doesn't detect a connected Feeder ..................... 130<br />

8.2.6 The products slip unjustified onto the conveyor .................... 130<br />

8.2.7 White streaks in printed text or graphic .............................. 131<br />

User Manual Version 3.1 5

8.2.8 White streak in printed text or graphics (in between cartridges)...<br />

.....................................................................................132<br />

8.2.9 The printed ink doesn’t dry on the substrate ........................133<br />

8.3 Error Messages..................................................................... 134<br />

8.3.1 How to read an error message entry ...................................134<br />

8.4 Warning Messages ................................................................ 153<br />

8.4.1 How to read a warning message entry.................................153<br />

8.4.2 Additional Error Messages..................................................160<br />

8.5 Technical Support ................................................................. 164<br />

9 Consumables and Accessories ................................................ 165<br />

9.1 Consumables ....................................................................... 165<br />

9.1.1 Standard inks for Neopost address printers ..........................165<br />

9.1.2 Cleaning Towels ...............................................................166<br />

9.2 Accessoires.......................................................................... 167<br />

9.2.1 Additional print unit for Neopost /<strong>AS</strong>-<strong>3640</strong> ...........................167<br />

9.2.2 Keyboard support kit ........................................................167<br />

9.2.3 Paper guide kit Neopost <strong>AS</strong>-<strong>3640</strong> / CSV-810 / ......................168<br />

9.2.4 Tower Lamp ....................................................................168<br />

10 Technical Specifications ......................................................... 169<br />

11 Appendix ................................................................................ 171<br />

11.1 How to completely remove printer drivers from Windows Vista<br />

and Windows 7 .......................................................................... 171<br />

11.2 How to completely remove printer drivers from Windows XP and<br />

Windows 2000 ........................................................................... 172<br />

11.3 How to use a pre-installed printer driver ............................. 173<br />

11.3.1 USB connection................................................................173<br />

11.3.2 Ethernet connection..........................................................174<br />

11.3.3 How to identify the USB port used by the printer ..................175<br />

11.4 How to test the Ethernet connectivity ................................. 176<br />

11.4.1 Sample settings for Ethernet connection ..............................178<br />

11.5 How to create a print file .................................................. 181<br />

11.6 How to update the flashware............................................. 182<br />

11.6.1 How to update the flashware..............................................182<br />

11.7 How to position the print unit guide bars ............................ 186<br />

11.8 How to position the paper sensor guide bar......................... 187<br />

11.9 How to position the encoder wheel mounting....................... 190<br />

11.10 Mounting two print units on one mounting bar..................... 191<br />

6 User Manual Version 3.1

Pos: 6 /[Allgemeines]/0.3_Abbildungsverzeichnis [Figure] @ 0\mod_1250599665953_912.doc @ 2745 @<br />

11.11 Determining the minimal possible paper format................... 192<br />

11.12 How to connect the FD-13/FD-15 Feeder ............................ 193<br />

11.13 How to adjust the Neopost FD-13/FD-15 Feeder to the medium..<br />

.................................................................................... 194<br />

11.14 Additional display texts .................................................... 197<br />

11.15 Ink package ID number ................................................... 198<br />

11.15.1 ID: 6030206 ................................................................... 199<br />

11.16 Declaration of conformity ................................................. 200<br />

12 Glossary ................................................................................. 202<br />

13 Index ..................................................................................... 208<br />

User Manual Version 3.1 7

Table of Figures<br />

Figure 1: Base conveyor belt Neopost <strong>AS</strong>-<strong>3640</strong> .......................................................... 18<br />

Figure 2: Control Unit front...................................................................................... 18<br />

Figure 3: Control Unit backplane .............................................................................. 18<br />

Figure 4: Print Unit................................................................................................. 19<br />

Figure 5: <strong>AS</strong>-<strong>3640</strong> with mounted control unit shelf...................................................... 20<br />

Figure 6: Print unit connections................................................................................ 21<br />

Figure 7: Mounting the paper guide kit I.................................................................... 22<br />

Figure 8: Mounting the paper guide kit II................................................................... 22<br />

Figure 9: The operator panel ................................................................................... 25<br />

Figure 10: Main display ........................................................................................... 28<br />

Figure 11: Interfaces Control unit ............................................................................. 32<br />

Figure 12: Interfaces Base conveyor ......................................................................... 33<br />

Figure 13: Inserting the ink cartridge into the pen stall................................................ 37<br />

Figure 14: Lock the restraining lever......................................................................... 37<br />

Figure 15: Positioning of paper sensor (schematically)................................................. 39<br />

Figure 16: Print unit, height adjustment .................................................................... 40<br />

Figure 17: Area of vacuum suction (schematical) ........................................................ 41<br />

Figure 18: Positioning of the print units, top view (example with two print units)............. 42<br />

Figure 19: Test print............................................................................................... 45<br />

Figure 20: Keep Alive function ................................................................................. 56<br />

Figure 21: Distances between TOF sensor (LS) and U1-U4 ........................................... 58<br />

Figure 22: DIST. TOF-U1 service test page ................................................................ 59<br />

Figure 23: Distances between the units U1-U4 ........................................................... 59<br />

Figure 24: Adjustment of encoder necessary .............................................................. 61<br />

Figure 25: Encoder Adjustment ................................................................................ 61<br />

Figure 26: Adjusted encoder .................................................................................... 62<br />

Figure 27: PRINT CORR.PATT. for systems with two print units (6 cartridge positions)...... 63<br />

Figure 28: Horizontal alignment U1-U2...................................................................... 64<br />

Figure 29: Regular print / Direction Nor..................................................................... 67<br />

Figure 30: Mirrored print / Direction Nor.................................................................... 67<br />

Figure 31: Regular print / Direction Rev .................................................................... 67<br />

Figure 32: Mirrored print / Direction Rev ................................................................... 67<br />

Figure 33: Order of print units ................................................................................. 70<br />

Figure 34: Difference Nor/Rev.................................................................................. 87<br />

Figure 35:LEFT MARGIN, transport direction............................................................... 88<br />

8 User Manual Version 3.1

Figure 36: Encoder Pattern .................................................................................... 100<br />

Figure 37: Simult. PrintUnits service print................................................................ 101<br />

Figure 38: Overlapping service print ....................................................................... 101<br />

Figure 39: Pattern A ............................................................................................. 102<br />

Figure 40: Pattern A with defects............................................................................ 103<br />

Figure 41: Cartridge contacts................................................................................. 103<br />

Figure 42: Pattern B ............................................................................................. 104<br />

Figure 43: Pattern C ............................................................................................. 104<br />

Figure 44: Sample character set print ..................................................................... 105<br />

Figure 45: Sample setting dump print ..................................................................... 105<br />

Figure 46: Sample Input Buffer Dump print.............................................................. 106<br />

Figure 47: New Hardware Wizard ........................................................................... 110<br />

Figure 48: Recommended install procedure.............................................................. 110<br />

Figure 49: Properties of unspecified device .............................................................. 112<br />

Figure 50: Update the printer driver........................................................................ 112<br />

Figure 51: Update Driver Software Wizard ............................................................... 112<br />

Figure 52: Select the driver source ......................................................................... 112<br />

Figure 53: Ferrite with plastic case ......................................................................... 113<br />

Figure 54: Adding TCP/IP Port................................................................................ 114<br />

Figure 55: TCP/IP Printer Port Wizard...................................................................... 114<br />

Figure 56: IP address of the printer ........................................................................ 114<br />

Figure 57: Custom settings.................................................................................... 115<br />

Figure 58: Custom settings of printer port ............................................................... 115<br />

Figure 59: Address printer port settings................................................................... 116<br />

Figure 60: DHCP Table on server ............................................................................ 118<br />

Figure 61: Test of fix IP (ping test on server) ........................................................... 119<br />

Figure 62: Local Area Connection Properties............................................................. 121<br />

Figure 63: TCP/IPv4 settings.................................................................................. 121<br />

Figure 64: Cleaning the nozzle plate ....................................................................... 124<br />

Figure 65: Nozzle plate and contacts....................................................................... 124<br />

Figure 66: Pivoted print unit .................................................................................. 124<br />

Figure 67: Pen board contacts................................................................................ 125<br />

Figure 68: White streaks in text ............................................................................. 131<br />

Figure 69: White streaks in between two cartridges................................................... 132<br />

Figure 70: New hardware detected ......................................................................... 174<br />

Figure 71: Found New Hardware Wizard .................................................................. 174<br />

User Manual Version 3.1 9

Pos: 7 /Bedienungsanleitungen/Geräte neutral/1.0_Ü1_Einführung_allgemein @ 0\mod_1242731723794_912.doc @ 1634 @ 1<br />

Figure 72: Device Manager .................................................................................... 176<br />

Figure 73: Device Properties - Details ..................................................................... 176<br />

Figure 74: Command Prompt reply OK .................................................................... 177<br />

Figure 75: Command Prompt reply NOT OK ............................................................. 177<br />

Figure 76: Print dialog window ............................................................................... 181<br />

Figure 77: Print to file dialog.................................................................................. 181<br />

Figure 78: Printer port properties ........................................................................... 182<br />

Figure 79: Paper sensor ........................................................................................ 188<br />

Figure 80: Teach-in modes, rotary switch ................................................................ 188<br />

Figure 81: Position of the encoder wheel on the belt (schematical) .............................. 190<br />

Figure 82: Two print units on one mounting bar ....................................................... 191<br />

Figure 83: Serial connection between printer and feeder............................................ 193<br />

Figure 84: Separator system ................................................................................. 194<br />

Figure 85: Feeder adjustment I.............................................................................. 194<br />

Figure 86: Feeder adjustment II............................................................................. 194<br />

Figure 87: Feeder adjustment III............................................................................ 194<br />

Figure 88: Adjusting the paper feed ramp and the slide, side view ............................. 195<br />

Figure 89: Filing the stack with a fanned out pile, side view....................................... 195<br />

10 User Manual Version 3.1

Pos: 8 /Bedienungsanleitungen/Geräte neutral/1.1_Ü2_Piktogramme_allgemein @ 0\mod_1242731723997_912.doc @ 1638 @ 2<br />

Pos: 9 /Bedienungsanleitungen/Geräte neutral/1.2_Ü2_Hinweise zum Gebrauch dieses Handbuches @ 0\mod_1249459443010_912.doc @ 2613 @ 2<br />

Pos: 10 /Bedienungsanleitungen/Geräte spezifisch/Drucker/1.3_Ü2_Terms and abbreviations @ 1\mod_1260869177556_912.doc @ 8380 @ 2<br />

1 Introduction<br />

In order to ensure both long service life of the <strong>AS</strong>-<strong>3640</strong> and its<br />

components, as well as safe conditions of use, we recommend that<br />

you read carefully and comply with the operating instructions and<br />

safety notes. Always be aware of all warnings and notes that are<br />

affixed to or printed on the machine itself.<br />

All persons who are to handle this machine must also be familiar with the operating manual.<br />

Store this manual in a safe place where it is easily accessible for future reference at any<br />

time.<br />

1.1 Pictograms<br />

General warnings<br />

Warning of danger from electricity or electrical shock<br />

Warning of possible fire<br />

Information / Note indicating important information regarding<br />

the handling of the machine.<br />

1.2 Notes for use of this manual<br />

This manual is structured chronologically, and therefore ordered sequentially from the<br />

receipt of the machine packed up to its ready-for-use state.<br />

If you are unfamiliar with the machine, it is best to read through the manual from beginning<br />

to end, where you can follow easy step by step instructions to allow you to fully and<br />

correctly operate the machine.<br />

If you are already familiar with the <strong>AS</strong>-<strong>3640</strong>, it will make things easy if you to use this<br />

manual as a reference work.<br />

User Manual Version 3.1 11

Pos: 11 /Bedienungsanleitungen/Geräte spezifisch/Drucker/1.4_Ü2_System requirements_ONLY_619 @ 2\mod_1272530190780_912.doc @ 17229 @ 2<br />

Pos: 12 /Bedienungsanleitungen/Geräte neutral/2.0_Ü1_Sicherheitshinweise @ 0\mod_1242735234414_912.doc @ 1664 @ 1<br />

1.3 Terms and abbreviations<br />

This User Manual uses the following terms and abbreviations related to the Neopost <strong>AS</strong>-<br />

<strong>3640</strong>:<br />

• cartridge = Crt = C, C1, C2, C3<br />

• print unit = Unit = U, U1, U2<br />

A print unit always consists of three ink cartridges.<br />

• print media width = expansion of the print media in transport direction.<br />

• print media height = expansion of the print media across the transport direction.<br />

1.4 System requirements<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> is designed to be used in connection with a PC. To connect the <strong>AS</strong>-<br />

<strong>3640</strong> to the PC one free USB port or one free Ethernet (TCP/IP) port is required. The PC<br />

should be an up-to-date model and must have enough processing power and free disk space<br />

to run the Neopost Addressing Solutions Software.<br />

We recommend using one of the following operating systems:<br />

• Microsoft Windows 2000 (SP4)<br />

• Microsoft Windows XP (SP3)<br />

• Microsoft Windows Vista (SP2) (32- or 64-bit)<br />

• Microsoft Windows 7 (32- or 64-bit)<br />

12 User Manual Version 3.1

Pos: 13 /Bedienungsanleitungen/Geräte neutral/2.1a_Ü2_Allgemeine Sicherheitshinweise_Handbuch @ 0\mod_1249563586836_912.doc @ 2673 @ 2<br />

Pos: 14 /Bedienungsanleitungen/Geräte neutral/2.1c_Allgemeine Sicherheitshinweise_Aufstellen des Gerätes @ 0\mod_1242736827044_912.doc @ 1710 @<br />

Pos: 15 /Bedienungsanleitungen/Geräte neutral/2.1e_Allgemeine Sicherheitshinweise_Elektrische Gefahren_ZWEIPOLIG @ 0\mod_1242736827372_912.doc @ 1718 @<br />

Pos: 16 /Bedienungsanleitungen/Geräte neutral/2.1f_Allgemeine Sicherheitshinweise_Betriebssicherheit/Reinigung/Service @ 0\mod_1242736827200_912.doc @ 1714 @<br />

2 Safety notes<br />

Prior to initial operation, please carefully read the following instructions for the sake of both<br />

your own safety and the printer operating safety. Always observe any warnings and<br />

instructions directly attached to the device. Keep this manual available in order to be able to<br />

check back at any time.<br />

Disregarding this manual may cause<br />

• electric shock,<br />

• injury by being drawn into the transport belt or transport rollers,<br />

• damage to the equipment.<br />

2.1 General safety notes<br />

Caution!<br />

Please read these notes with care.<br />

Keep this manual for future reference.<br />

All notes and warnings found on the machine are to be followed.<br />

Setting up the<br />

machine<br />

A safe, level position is necessary, when installing the machine.<br />

Injuries may be caused by tipping, rolling away or falling.<br />

The machine is to be protected from moisture.<br />

The machine is not suitable for outdoor use.<br />

Electrical<br />

Hazards<br />

The power cable must only be connected to a socket with protective<br />

grounding contact! The protective effect must not be compromised by<br />

the use of an extension cable without a protective grounding<br />

conductor. All interruptions of the protective grounding conductor,<br />

within or outside of the machine, are prohibited.<br />

When fuse failure occurs, electrical machine parts can still carry<br />

voltage.<br />

When making the connection to the mains power, be aware of the<br />

connection values on the rating plate.<br />

Run the power cable in such a way, that no one can trip over it. Do<br />

not place any objects on the power cable.<br />

When the machine is not in use over a long period of time, it should<br />

be disconnected from the power supply in order to avoid any damage<br />

in the event of a voltage surge.<br />

Protect the device from moisture. When moisture enters the machine,<br />

there is a danger of electrical shock.<br />

Never open the machine. For reasons of electrical safety, the machine<br />

should only be opened by authorized service personnel.<br />

User Manual Version 3.1 13

Pos: 17 /Bedienungsanleitungen/Geräte neutral/2.1g_Allgemeine Sicherheitshinweise_Ersatzteile/Reparaturen/Umbauverbot @ 0\mod_1249462580902_912.doc @ 2637 @<br />

Pos: 18 /Bedienungsanleitungen/Geräte neutral/2.1h_Allgemeine Sicherheitshinweise_Hinweis Service @ 0\mod_1242737415895_912.doc @ 1746 @<br />

Pos: 19 /Bedienungsanleitungen/Geräte spezifisch/Drucker/2.2_Ü2_Ink safety notice @ 1\mod_1260870536312_912.doc @ 8392 @ 2<br />

Operating<br />

safety<br />

Cleaning the<br />

machine<br />

Machine<br />

inspections<br />

only by<br />

authorized<br />

Service<br />

Partners!<br />

Never put your hands inside the machine when it is running!<br />

There is a danger that injuries can occur through being pulled in and<br />

being crushed on the transport belt or the rotating rollers. In addition,<br />

keep long hair and parts of loose clothing away from the machine<br />

while it is in operation.<br />

In order to prevent damage to the machine, only factory authorized<br />

accessory parts should be used.<br />

Prior to cleaning the machine, it should be disconnected from the<br />

power outlet. When cleaning the machine, do not use liquid or spray<br />

cleaners, but only a cloth dampened with water.<br />

Additional information concerning the cleaning of the device can be<br />

found in chapter „Maintenance and support“.<br />

In the following cases, you should unplug the machine from the<br />

power outlet and contact an authorized service technician:<br />

• When the power cable or its plug is worn or damaged.<br />

• When water or other liquid has entered the device.<br />

• When the device has been dropped/knocked over or the housing is<br />

damaged.<br />

• When there is a significant change in the performance of the<br />

machine.<br />

Spare parts<br />

Repairs<br />

Modification is<br />

not permitted<br />

When repair work is carried out, only original spare parts or spare<br />

parts approved by the manufacturer may be used.<br />

Do not disassemble the machine any further than it is described in<br />

this manual. The opening of the machine by unauthorized personnel<br />

is not permitted. Repairs may only be carried out by authorized<br />

service personnel.<br />

For safety reasons, your own reworking and modifications to the<br />

machine are not permitted.<br />

Please contact your authorized Neopost dealer or service partner, for<br />

all questions relating to service and repair. In this way, you ensure<br />

the operational safety of your machine.<br />

14 User Manual Version 3.1

Pos: 20 /Bedienungsanleitungen/Geräte neutral/2.3_Ü2_Location of the device @ 0\mod_1242737912401_912.doc @ 1759 @ 2<br />

Pos: 21 /Bedienungsanleitungen/Geräte neutral/2.4_Ü2_Entsorgung @ 0\mod_1242738502378_912.doc @ 1762 @ 2<br />

Pos: 22 /Bedienungsanleitungen/Geräte neutral/3.0_Ü1_Scope of delivery and assembly @ 0\mod_1242739012009_912.doc @ 1765 @ 1<br />

2.2 Ink safety notice<br />

Keep ink cartridges away from children. If you get into skin contact<br />

with the ink, immediately clean off the ink under running water. In case<br />

ink has entered your eye, immediately rinse it with plenty of water.<br />

• The ink cartridge should not be shaken, dropped or hit against the palm or hard<br />

surfaces.<br />

• Install the ink cartridge immediately after removing the protective tape. The cartridge<br />

may not be used after date of expiry!<br />

• Do not try to open or refill a cartridge. This can damage the printer and reduce the<br />

print quality.<br />

• For further information regarding the cleaning of the ink cartridge, please see chapter<br />

8.1.2, on page 123.<br />

2.3 Location of the printer<br />

Be aware when installing the machine that it must stand on a smooth and level surface that<br />

is larger than the printer.<br />

When placing the machine, make sure that there is enough clearance around it, so that you<br />

can access all connections easily.<br />

The floor space for the printer must be sufficiently stable. The tipping over or falling of the<br />

machine can lead to injuries, as well as damage to the machine.<br />

When selecting the installation or storage location for the printer, keep in mind that it must<br />

be protected from strong temperature and humidity changes, direct sunlight and excessive<br />

heat.<br />

The printer must not be subject to vibrations or shocks.<br />

Install the printer near a power outlet, so that the power cable can be disconnected troublefree<br />

at all times.<br />

2.4 Disposal<br />

The printer may not be disposed of in the conventional manner of household waste. Please<br />

dispose the printer in accordance with the regulations in force.<br />

User Manual Version 3.1 15

Pos: 23 /Bedienungsanleitungen/Geräte neutral/3.1_Ü2_Scope of delivery @ 0\mod_1250854288313_912.doc @ 2837 @ 2<br />

Pos: 24 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/3.1_Ü2_Lieferumfang_<strong>AS</strong>-OrbitBase_ONLY_619 @ 2\mod_1265645028788_912.doc @ 11647 @<br />

Pos: 25 /Bedienungsanleitungen/Geräte neutral/3.2_Ü2_Delivery @ 0\mod_1242739526953_912.doc @ 1770 @ 2<br />

3 Scope of delivery and assembly<br />

3.1 Scope of delivery<br />

• 1x Neopost <strong>AS</strong>-<strong>3640</strong> print system<br />

• 1x control unit<br />

• 1x control unit shelf<br />

• 1x vacuum conveyor belt with<br />

1x mounted encoder wheel,’<br />

1x mounted paper sensor (TOF = Top of form sensor) and<br />

1x, 2x, 3x or 4x mounted print units* (Standard or Centaur**)<br />

• 1x, 2x, 3x or 4x SCSI-3 cable*<br />

• 1x Addressing Solution software CD-ROM<br />

• 2x power cables<br />

• 1x belt motor control cable<br />

• 1x paper guide kit<br />

• 1x grounding cable flat/flat<br />

• 1x grounding cable eye/flat<br />

• 3x strapping plugs for emergency-stop INTERN/EXTERN<br />

• 1x strapping plug for emergency-stop OUT<br />

• 1x 5-pin emergency-stop cable for external devices<br />

• 3x, 6x, 9x or 12x Black Dye ink cartridges*<br />

• 1x, 2x, 3x or 4x Inxdinx ink cartridge boxes*<br />

• 1x USB connection cable<br />

• 1x Network cable<br />

• 1x Ferrit<br />

* The number depends on the chosen <strong>AS</strong>-<strong>3640</strong> model. The <strong>AS</strong>-<strong>3640</strong> can be equipped with<br />

one, two, three or four print units in a row.<br />

** Centaur is an optional ink supply system, which requires an additional ink control unit<br />

and special ink cartridges. The standard print units are equipped with standard HP TIJ 2.5<br />

Cartridges.<br />

16 User Manual Version 3.1

Pos: 26 /Bedienungsanleitungen/Geräte spezifisch/Drucker/3.2_Warning: transportation locks_<strong>AS</strong>-OrbitBase/2060/Base @ 2\mod_1265645243882_912.doc @ 11663 @<br />

Pos: 27 /Bedienungsanleitungen/Geräte neutral/3.2_Delivery_mit Transportsicherung_<strong>AS</strong>-960/990/OrbitBase/3060A/2060/Base @ 2\mod_1271945715904_912.doc @ 16957 @<br />

Pos: 28 /Bedienungsanleitungen/Geräte neutral/3.3_Ü2_Device overview @ 0\mod_1250854288578_912.doc @ 2841 @ 2<br />

3.2 Delivery<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> is delivered in appropriate packaging so that it reaches its destination<br />

without damage via a regular mode of transport.<br />

Transportation and storage should be carried out in suitable condition. That means an<br />

ambient temperature between +10°C and +31°C at 20-80% relative humidity (noncondensing).<br />

Conditions outside of these ranges may harm the machine. Damages from<br />

wrong transportation and storage conditions may not be visible on the packaging.<br />

Transportation locks<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> is fixed to the transport pallet by<br />

transportation locks, which are mounted to the four feet. Loosen<br />

these locks and roll the printer off the pallet cautiously. Do not lift the<br />

printer by hand.<br />

If the printer has to be shipped again, please store the transportation locks and the<br />

packaging. In case the packaging is no longer needed, please dispose it in an<br />

environmentally suitable manner.<br />

User Manual Version 3.1 17

Pos: 29 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/3.3_Geräteübersicht_<strong>AS</strong>-OrbitBase_ONLY_619 @ 2\mod_1269851845762_912.doc @ 14033 @<br />

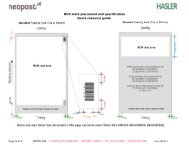

3.3 Device overview<br />

1<br />

2 3 4<br />

Figure 1: Base conveyor belt Neopost <strong>AS</strong>-<strong>3640</strong><br />

8<br />

7<br />

6<br />

5<br />

1 Slider for suction area 8 Power input module Base<br />

2 Emergency stop button<br />

Base<br />

9 Emergency stop button<br />

Control unit<br />

3 Transport belt 10 Green emergency release button<br />

Control unit<br />

4 Green emergency release button<br />

Base<br />

11 Main Display<br />

5 Interfaces Base (backplane) 12 Control panel / Key panel<br />

6 Height adjustable feet 13 Connectors for print units U1-U4<br />

7 Main switch on/off vacuum<br />

suction<br />

14 Main switch on/off Control unit<br />

9 10 11 12 13<br />

14<br />

Figure 2: Control Unit front<br />

Figure 3: Control Unit backplane<br />

18 User Manual Version 3.1

Pos: 30 /Bedienungsanleitungen/Geräte neutral/3.3_Ü2_Assembly @ 1\mod_1264168442358_912.doc @ 10763 @<br />

Pos: 31 /Bedienungsanleitungen/Geräte spezifisch/Transportbänder/CSV-810 (Base)/5.1_Aufstellen_Base2.0 @ 0\mod_1254121426488_912.doc @ 3793 @<br />

Pos: 32 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/3.3.2_Ü3_Shelf, Electrical Connections mounting/connection @ 2\mod_1265888855615_912.doc @ 11906 @ 233<br />

15 Print unit guide bar 18 Print bar hinge<br />

16 Clamp lever 19 Print unit<br />

17 Scaled adjustment wheel 20 Ink cartridge<br />

17<br />

18<br />

16<br />

15<br />

19<br />

20<br />

Figure 4: Print Unit<br />

3.4 Assembly<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> is shipped pre-assembled and can be easily positioned due to its<br />

mounted transport wheels.<br />

Please ensure that the device stands in a secure and level position. Please fix the pedestals<br />

by locking the nuts.<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> may only be used with mounted and reeled-out<br />

pedestals.<br />

The height level of the conveyor is adjustable in a range between 810<br />

mm – 915 mm (31.9 – 36.0”).<br />

User Manual Version 3.1 19

3.5 How to assemble the print system<br />

3.5.1 Control unit shelf<br />

How to mount<br />

the shelf<br />

• Use the enclosed screws to fix the shelf to the conveyor belt (see<br />

Figure 5).<br />

• Put the control unit onto the shelf.<br />

Figure 5: <strong>AS</strong>-<strong>3640</strong> with mounted control unit shelf<br />

3.5.2 Print unit connections<br />

Electrical<br />

connections<br />

The cables for the print units, the paper sensor (Top of form sensor) and<br />

the encoder wheel are pre-assembled and have to be connected to the<br />

control unit.<br />

Do not turn the device on yet!<br />

Fix all cable connections with the safety screws of the cables.<br />

Please see chapter 4.4 Interfaces, on page 34 for a detailed description<br />

of the connection interfaces of the <strong>AS</strong>-<strong>3640</strong>.<br />

• Connect all print units to the control unit (see Figure 6). Use the<br />

safety screws to lock the connection.<br />

• Connect the paper sensor (TOF) cable to the control unit.<br />

• Connect the encoder wheel cable to the control unit.<br />

• Connect the conveyor belt and the control unit with the use of the<br />

belt motor control cable.<br />

• Connect the emergency stop cable between the control unit and<br />

the conveyor belt (see chapter 4.5 Emergency stop connection, on<br />

page 36 for additional information).<br />

20 User Manual Version 3.1

Pos: 33 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-2060/3.3.2_Ü3_Mounting_the_paper_guide_kit_<strong>AS</strong>-OrbitBase/Base @ 2\mod_1278332983547_912.doc @ 23833 @ 3<br />

Connection<br />

cable<br />

Control unit<br />

on shelf<br />

Encoder wheel<br />

Paper sensor<br />

Figure 6: Print unit connections<br />

Fixing of cables<br />

For a reliable operation of the printer, the safety screws of the cables<br />

between the print units and the control unit have to be fixed firmly.<br />

Do not interrupt this connection while the printer is powered<br />

on! Otherwise electronic parts can get damaged.<br />

Please be aware of the correct order of the print units and the paper<br />

sensor. The products have to pass the paper sensor before passing<br />

the print units (see Figure 6)!<br />

3.5.3 How to mount the Paper Guide Kit<br />

The paper guide kit supports an aligned feeding of the materials onto the transport belt. To<br />

mount the paper guide kit onto the Neopost <strong>AS</strong>-<strong>3640</strong>perform the following steps:<br />

• Place the two metal plates over the designated holes on the <strong>AS</strong>-<strong>3640</strong> (see Figure 8.).<br />

• Fix each plate with two screws.<br />

• Place the two bars with the guides into the metal plates (see Figure 8).<br />

• Move the two guides to the most outer positions, so that they do not yet interfere<br />

with the material flow when setting up the machine.<br />

User Manual Version 3.1 21

Pos: 34 /Bedienungsanleitungen/Geräte neutral/3.3.1_Ü3_Connecting the power cable @ 1\mod_1264168527578_912.doc @ 10766 @ 3<br />

Screws<br />

Transport direction<br />

Screws<br />

Figure 7: Mounting the paper guide kit I<br />

Clamp to fix guide<br />

Transport direction<br />

Figure 8: Mounting the paper guide kit II<br />

22 User Manual Version 3.1

Pos: 35 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/3.3.1_Warnhinweis Netzkabel @ 2\mod_1265888781005_912.doc @ 11903 @<br />

Pos: 36 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-3060A/Ü3_3.3.3_Neopost_FD-13_Feeder_(optional)_<strong>AS</strong>-3060_<strong>AS</strong>-2060 @ 1\mod_1264412362375_912.doc @ 10834 @ 3<br />

Pos: 37 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/3.3.5_Ü3_Additional devices @ 2\mod_1265908772620_912.doc @ 11996 @ 3<br />

Pos: 38 /Bedienungsanleitungen/Geräte neutral/4.0_Ü1_Description of device @ 0\mod_1246003073544_912.doc @ 1919 @ 1<br />

3.5.4 Connecting the power cable<br />

Power cable<br />

Attention!<br />

The device may only be used in connection to power outlets with<br />

integrated protective conductor (earthing)!<br />

Make sure that the on/off switch off both the control unit and the<br />

conveyor is set to off.<br />

Plug the power cables into the power inputs of both devices connect<br />

the cables to the power outlet.<br />

3.5.5 Neopost FD-13/FD-15/ Feeder (optional)<br />

For a detailed instruction on how to use the Neopost <strong>AS</strong>-<strong>3640</strong> together with the optional<br />

Neopost FD-13/FD-15 Feeder, please see chapter 11.12 on page 191 of this manual.<br />

3.5.6 Additional devices<br />

Please connect all upstream and downstream devices like the Neopost FD-13/FD-15 Feeder,<br />

IR dryer or additional conveyor belts to the control unit of the <strong>AS</strong>-<strong>3640</strong>. Please see chapter<br />

4.5.3 on page 36.<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> has a emergency stop connection that assures a safe and convenient<br />

stop of all connected devices, if a emergency stop button is pressed. Please see chapter 4.5<br />

Emergency stop connection, on page 36 for additional information.<br />

Grounding of all connected devices<br />

Connect all upstream and downstream devices (e.g. feeder) with the<br />

enclosed grounding cables.<br />

Paper separation and transport may lead to electrostatic charging of<br />

the devices, which can destroy electronics parts of the <strong>AS</strong>-<strong>3640</strong>.<br />

User Manual Version 3.1 23

Pos: 39 /Bedienungsanleitungen/Geräte neutral/4.2_Ü2_Application range @ 0\mod_1250854288985_912.doc @ 2849 @ 2<br />

Pos: 40 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/4.2_Anwendungsgebiet_<strong>AS</strong>-OrbitBase/<strong>AS</strong>-2060 @ 2\mod_1267112631341_912.doc @ 12541 @<br />

Pos: 41 /Bedienungsanleitungen/Geräte neutral/4.3_Ü2_Description of functions @ 0\mod_1250854288782_912.doc @ 2845 @ 2<br />

Pos: 42 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/4.3_Funktionsbeschreibung_<strong>AS</strong>-OrbitBase @ 2\mod_1265645244991_912.doc @ 11683 @<br />

Pos: 43 /Bedienungsanleitungen/Geräte neutral/4.4_Ü2_The Operator Panel @ 0\mod_1250854289204_912.doc @ 2853 @ 2<br />

4 Description of device<br />

4.1 Application range<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> is an inkjet printer with high font quality. Up to four print units can be<br />

connected to cover a wide print area.<br />

The main field of application is the printing of mass mailings with addresses, graphics and<br />

postal elements. However, the application is not limited to this purpose.<br />

The device may be applied both in stand-alone and in inline operation. The print media<br />

feeding must be executed in a separated manner in inline mode.<br />

4.2 Description of functions<br />

The Neopost <strong>AS</strong>-<strong>3640</strong> printer is a inkjet print system, that is designed for industrial and<br />

professional printing with high throughput. The printer can be combined with different<br />

feeders and can be integrated into inline production systems.<br />

The device can be used in connection with an IBM compatible PC and a vary of software<br />

running under Microsoft Windows operation systems.<br />

Each of the print units (U1, U2, U3, U4) of the Neopost <strong>AS</strong>-<strong>3640</strong> are provided with three HP<br />

ink cartridges (C1, C2, C3). During the printing the units stay motionless, therefore the<br />

device is called a Fixed Head printer. The alignment of the printed text should be parallel to<br />

the paper transport direction.<br />

Each print unit covers an area of 762 x 38 mm (30.0 x 1.5"). This corresponds to nine text<br />

lines at a font size of 12 pt. A highly durable transport belt, supported by vacuum suction,<br />

ensures a constant product flow.<br />

For further specifications please see chapter 10 Technical Specifications, on page 170.<br />

24 User Manual Version 3.1

Pos: 44 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4_Operator_Panel @ 2\mod_1265967728349_912.doc @ 12018 @<br />

Pos: 45 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.1_Ü3_Key Panel_Fixed Head <strong>AS</strong>-Orbit/OrbitBase @ 1\mod_1261137318681_912.doc @ 9011 @ 3<br />

4.3 The Operator Panel<br />

Figure 9: The operator panel<br />

The operator panel is used to easily activate often required functions and select information<br />

from the main display. The operator panel is also used to navigate within the printer menus,<br />

in order to change printer and layout settings, run test modes and look up specific printer<br />

statistics.<br />

The four LEDs (light-emitting diode) on the panel indicate the status of the printer.<br />

LED<br />

Green Online<br />

Blue Offline<br />

Orange Warning<br />

Red Error<br />

Status indication<br />

Printer is Online<br />

Printer is Offline<br />

Printer displays a warning message<br />

Printer displays an error message<br />

Online and Offline<br />

Only when the printer is Offline you can make changes to printer<br />

settings, use the secondary functions of the arrow key or open printer<br />

menus.<br />

Please note, that when the printer is Online (= able to receive print<br />

data from the PC), the only key that can be used is the Cancel<br />

(Offline) key. The Cancel (Offline) key will turn the printer Offline<br />

(= not able to receive print data from the PC).<br />

User Manual Version 3.1 25

4.3.1 Key panel<br />

Below is an explanation of how the different keys of the panel work:<br />

Key<br />

Ok (Online)<br />

Cancel (Offline)<br />

Home<br />

Quick<br />

Arrow up (Test Print)<br />

Arrow right (Paper Length)<br />

Main key function<br />

Turns the printer online and confirms a selection in a<br />

menu<br />

Turns the printer offline and exits the current menu<br />

level.<br />

Opens the main menu of the printer<br />

Opens the quick menu of the printer<br />

Upwards navigation in menus and increasing values in<br />

menus<br />

Navigation to the right<br />

Arrow down (Clean Heads) Downwards navigation in menus and decreasing<br />

values in menus<br />

Arrow left (Run Paper)<br />

Navigation to the left<br />

The four arrow keys have secondary functions, which can be executed by pressing one of<br />

the arrow keys and the Quick key together.<br />

Secondary key functions<br />

Please note, that the secondary key functions will work slightly<br />

different depending on how long you press the keys.<br />

(Short) = pressing the two buttons just briefly<br />

(Long) = pressing the two keys, hold them for approx. 3 seconds<br />

26 User Manual Version 3.1

Pos: 46 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.2_Ü3_Main_Display @ 1\mod_1261142768887_912.doc @ 9017 @<br />

Below is an explanation of how the different secondary functions of the arrow keys work:<br />

Quick key + Secondary key function<br />

Arrow up (Test Print)<br />

Arrow right (Paper Length)<br />

Arrow down (Clean Heads)<br />

The printer will ask you from which source you want<br />

to supply material for the test print. You have to<br />

choose between Manual, Feeder and Cancel.<br />

(Short) The printer will display Test and print the test<br />

pattern once, using the current printer setting (e.g.<br />

print quality).<br />

(Long) The printer will display Test and print the test<br />

pattern continuously, using the current printer setting<br />

(e.g. print quality). To stop, hit the Cancel (Offline)<br />

key.<br />

The printer will ask you from which source you want<br />

to supply material for the measurement. You have to<br />

choose between Manual, Feeder and Cancel.<br />

(Short) The printer will display PAPER WIDTH: , feed<br />

one page and measure the size of the page. The<br />

measured size will be shown in the display.<br />

(Long) The printer will display PAPER WIDTH: (L),<br />

feed one page and measure the size of the page. The<br />

measured size will be shown in the display. The (L)<br />

indicates that the measured page size will be locked in<br />

the printer, so that the page size cannot be changed<br />

from a PC program.<br />

The printer will ask you from which source you want<br />

to supply material for the test print. You have to<br />

choose between Manual, Feeder and Cancel.<br />

The printer will feed one page and print a pattern of<br />

bars, using the currently set page size.<br />

Arrow left (Run Paper)<br />

(Short) The printer will display PapRUN and feed one<br />

page and transport it, using the current printer setting<br />

(e.g. transport speed).<br />

(Long) The printer will display PapRUN and feed and<br />

transport pages continuously, using the current<br />

printer setting (e.g. transport speed). To stop hit the<br />

Cancel (Offline) key.<br />

This is an useful function to check if, the separation<br />

and the material transport of the printer, are setup<br />

correctly.<br />

User Manual Version 3.1 27

Pos: 47 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.3_Main_Display_Fixed_Head_6_cartridges_<strong>AS</strong>3060A/OrbitBase/960/990_ONLY 619 @ 3\mod_1301663239066_912.doc @ 31022 @<br />

4.3.2 Main Display<br />

The main display shows you the most important information about your current print job at<br />

one glance.<br />

J ob Current :1234 5 6 7 ←1<br />

Costs/ 1000 Pg 1 . 5 5 € ←2<br />

M eter/Secon d : 0. 5 4 0 ←3<br />

Pages/ h : 10 5 0 0 ←4<br />

BLA CK DYE<br />

←5<br />

█ █ █ █ █ █ 6x6 d p i ←6<br />

█ █ █ █ █ █ Nor ←7<br />

█ █ █ █ █ █ O n l i n U S B ←8<br />

↑ ↑ ↑ ↑ ↑ ↑<br />

999999<br />

Figure 10: Main display<br />

Items per display line<br />

Please note, that there are display lines which contain more that one<br />

item to display. To cycle through all items, select a line (e.g. line 1<br />

counters) with the arrow up or arrow down keys and then hit the<br />

arrow left or arrow right key to show the other items of this line.<br />

Display lines and data<br />

1: Counters This line shows one of the following counters:<br />

Job Current: Shows the number of printed pages<br />

from the current print job (= send from the PC).<br />

Job Power On: Shows the total number of printed<br />

pages from all print jobs, since the printer was turned<br />

on.<br />

TotalService: Shows the number of service pages<br />

printed (e.g. Clean Heads), since the printer was<br />

turned on.<br />

Tot.Power On: Shows the total number of pages<br />

printed, since the printer was turned on. All Print job<br />

pages + all service pages.<br />

To reset one of the counters to zero pages, select this<br />

line and use the arrow right or arrow left key to<br />

show the counter you want to reset and hit the Ok<br />

key. Confirm the reset by selecting Yes and hitting the<br />

Ok key again.<br />

28 User Manual Version 3.1

2: Ink costs and ink range This line shows one of the following information:<br />

InkCosts/Job: Calculates and shows the cost of ink<br />

for the current print job in the set currency.<br />

Costs/1000Pg: Calculates and shows the cost of ink<br />

per 1,000 pages of the current print job.<br />

Pages/Cartr.: Calculates and shows the number of<br />

pages you can print, of the current print job, with the<br />

remaining amount of ink in the cartridge.<br />

Please consider that the information above are<br />

calculated average values only. Therefore the<br />

accuracy of the values will increase as more pages are<br />

printed.<br />

To show information in this line, you first have to set<br />

a cost per cartridge greater than zero. To do this,<br />

select this line and hit the Ok key. Or you can open<br />

the main menu of the printer and select the following<br />

menu: PRINTER CONFIG. > INK > INK COST CONFIG.<br />

3: Transport speed This line shows the currently set transport speed. To<br />

change the speed select this line and use the arrow<br />

right or arrow left key to change the speed.<br />

Please note that the speed you can select is limited by<br />

the set print quality (see line 6). With a print quality<br />

of 6 x 6 dpi, the maximum speed you can set is 0.540<br />

meter/second.<br />

4: Throughput This lines shows one of the following information:<br />

Pages/h: Shows the current throughput of the<br />

machine, calculated from the last few pages.<br />

JOB Pages/h: Shows the average through since the<br />

beginning of this print job. This is a valuable<br />

information to measure the actual productivity of the<br />

machine.<br />

5: Ink type This line shows the currently set ink type.<br />

6: Print quality This lines shows the currently set print quality. To<br />

change the quality select this line and use the arrow<br />

right or arrow left key to change the quality.<br />

Please note that the selected print quality determines<br />

the maximum speed of the machine.<br />

This setting can be locked, so that a print quality<br />

setting, send from the PC is ignored. To lock this<br />

setting, select this line and press the Ok key for<br />

four seconds. A symbol appears next to the quality<br />

setting, showing that it is locked now.<br />

To unlock the setting select this line again and press<br />

the Ok key for four seconds. The symbol<br />

disappears again.<br />

User Manual Version 3.1 29

7: Print direction This line shows the set print direction.<br />

Nor The print layout is printed in normal direction.<br />

Rev The print layout is printed 180° turned.<br />

Please refer to the section “Printer Menu” of this<br />

manual, to get more detailed information about print<br />

direction (JOB PARAMETERS > LAYOUT ><br />

ORIENTATION).<br />

This setting can be locked, so that a print direction<br />

setting, send from the PC is ignored. To lock this<br />

setting, select this line and press the Ok key for<br />

four seconds. A symbol appears next to the<br />

direction setting, showing that it is locked now.<br />

To unlock the setting select this line again and press<br />

the Ok key for four seconds. The symbol<br />

disappears again.<br />

8: Status This line shows the printer status and the used<br />

interface.<br />

OnlinUSB The printer is ready to receive print data<br />

from the PC via the USB interface. No changes to<br />

printer settings via a printer menu can be made when<br />

the printer is Online.<br />

OnlinTCP The printer is ready to receive print data<br />

from the PC via the Ethernet interface. No changes to<br />

printer settings via a printer menu can be made when<br />

the printer is Online.<br />

Offline The printer menus can be accessed and<br />

changes to settings can be made when the printer is<br />

Offline.<br />

Changing from OnlinUSB or OnlinTCP to Offline: Hit<br />

the Cancel key.<br />

Changing from Offline to Online: Select this line<br />

(line 8) in the main menu (see Figure 10) by hitting<br />

the Cancel key or using the arrow down key and<br />

then hit the Ok key.<br />

30 User Manual Version 3.1

Pos: 48 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.3_Additional Display Texts_Error_Warning_MSG_HINWEIS_Systeme @ 2\mod_1275402249272_912.doc @ 17861 @<br />

Pos: 49 /Bedienungsanleitungen/Geräte neutral/4.6_Ü2_Interfaces @ 0\mod_1254127277720_912.doc @ 3816 @ 2<br />

9: Ink level cartridge The height of the bars, shows the amount of ink left<br />

per cartridge.<br />

To see the exact percentage of ink left, select one of<br />

the bars with the arrow left key. To manually<br />

change the amount of ink left in the cartridge, change<br />

the value with the arrow up or arrow down keys.<br />

You can access the cartridge menu by selecting one of<br />

the bars with the arrow left key and hitting the Ok<br />

key. In this menu you can reset the amount of ink<br />

to 100% or change the ink type.<br />

Note:<br />

The number of bars shown, depends on your printer<br />

model and its configuration.<br />

Additional display texts<br />

Under certain circumstances additional texts may be shown in the<br />

display. Please see chapter 11.14 Additional display texts, on page<br />

195<br />

Error and warning messages<br />

Under certain circumstances error or warning messages may be<br />

shown in the display. Please see chapter 8.4.2 on page 160 and<br />

chapter 8.4 on page 152 for a complete overview of all messages.<br />

User Manual Version 3.1 31

Pos: 50 /Bedienungsanleitungen/Geräte spezifisch/Drucker/<strong>AS</strong>-OrbitBase/4.6a_Ü3_Anschlüsse_<strong>AS</strong>-OrbitBase_ONLY_619 @ 2\mod_1269851044039_912.doc @ 14020 @<br />

4.4 Interfaces<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18<br />

Figure 11: Interfaces Control unit<br />

1 F635 / 2700<br />

2 18 F<br />

3 AF 500<br />

4 AUX<br />

Connection (Start/Stop) for a<br />

Streamfeeder 2007 or a<br />

RENA Dreamfeeder version before<br />

2007 (max. 100mA)<br />

Connection (Start/Stop) for a<br />

FBM 18 F Feeder<br />

(max. 42V / 500mA)<br />

Connection (Start/Stop) for AF 500<br />

(max. 42V / 500mA)<br />

Feeder connection (Start/Stop)<br />

(max. 42V / 500mA)<br />

5 Relay 1 / 2<br />

Relay outputs for controlling<br />

external devices (e.g. batch kicker<br />

or feeder) (max. 42V / 1A)<br />

10 TOF<br />

11 Encoder<br />

Connection for the paper sensor<br />

(Top of form)<br />

Connection for the encoder wheel<br />

12 Statuslight<br />

13 USB<br />

Connection for Neopost signal<br />

lamp (optical signal lamp) (see<br />

section Consumables and<br />

Accessories for more details)<br />

USB 2.0 interface to the PC for<br />

sending print data<br />

14 Conveyor<br />

Serial interface (start, stop &<br />

speed) to a Neopost CSV-810<br />

(conveyor)<br />

32 User Manual Version 3.1

Pos: 51 /Bedienungsanleitungen/Geräte neutral/4.6b_Ü2_(Ü3)_Emergency stop connection @ 0\mod_1254129198454_912.doc @ 3831 @ 2<br />

6 Input 1 / 2<br />

Signal inputs that can be used to<br />

send information to the printer<br />

(e.g. is the upstream device<br />

running)<br />

7 Emergency Stop<br />

Interfaces for emergency stop<br />

system (see next section for a<br />

detailed description)<br />

8 Servo Control<br />

Not used<br />

9 Belt Motor<br />

Connection for the Base conveyor<br />

belt motor<br />

15 Control<br />

16 Centaur<br />

17 Feeder<br />

18 TCP/IP<br />

Serial interface to the PC for<br />

control command, status feedbacks<br />

and service purposes. Cannot be<br />

used to send print data to the<br />

printer.<br />

Serial interface to the Neopost<br />

Centaur bulk ink system<br />

Serial interface to the Neopost<br />

feeder (start, stop, speed and gap<br />

determination)<br />

Ethernet (TCP/IP) interface for<br />

sending print data<br />

Belt Motor<br />

Connection for the <strong>AS</strong>-<strong>3640</strong> Control unit belt motor<br />

Emergency Stop<br />

Interface for the emergency stop connection (see chapter 4.5<br />

Emergency stop connection, on page 36).<br />

Interface Conveyor<br />

Not used<br />

EXT In/Out<br />

Not used<br />

Figure 12: Interfaces<br />

Base conveyor<br />

User Manual Version 3.1 33

Pos: 52 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.6b_Sicherheitsschaltung Vorwort_Drucker @ 1\mod_1260879100054_912.doc @ 8462 @<br />

Pos: 53 /Bedienungsanleitungen/Geräte neutral/4.6b_Ü3_(Ü4)_Emergency stop connection_modes_CORRECTED @ 3\mod_1297862150511_912.doc @ 30360 @ 3333<br />

4.5 Emergency stop connection<br />

If the Neopost <strong>AS</strong>-<strong>3640</strong> printer is used in connection with other Neopost devices like the<br />

Neopost CSV-810conveyor, the Neopost FD-13/FD-15 Feeder or even with upstream or<br />

downstream inline devices from other non-Neopost manufacturers, the machines can be<br />

connected to ensure a simultan emergency stop.<br />

According to the chosen machine combination, the different emergency stop wirings are<br />

explained here.<br />

Emergency stop connection via serial connection<br />

If this Neopost printer is connected to another Neopost device via a<br />

serial connection, this connection will act as an emergency stop<br />

connection as well.<br />

But it is recommended to always connect the devices with the<br />

emergency stop wirings as explained here.<br />

4.5.1 Stand-alone operation<br />

Strapping plug ‘Out’<br />

4141957N<br />

Strapping plug ‘In/Extern’<br />

4141958P<br />

Strapping plug ‘In/Extern’<br />

4141958P<br />

4.5.2 Operation with one additional Neopost device<br />

Strapping plug<br />

‘In/Extern’<br />

4141958P<br />

Strapping plug ‘In/Extern’ 4141958P<br />

Connection cable<br />

4141959Q<br />

Strapping plug<br />

‘In/Extern’<br />

4141958P<br />

Strapping plug<br />

‘Out’<br />

4141957N<br />

4.5.3 Operation with several additional Neopost devices<br />

Strapping plug<br />

‘In/Extern’<br />

4141958P<br />

2 x Connection cable<br />

4141959Q<br />

2 x Strapping plug ‘In/Extern’<br />

4141958P<br />

Strapping plug<br />

‘In/Extern’<br />

4141958P<br />

Strapping plug<br />

‘Out’<br />

4141957N<br />

34 User Manual Version 3.1

Pos: 54 /Bedienungsanleitungen/Geräte neutral/4.6c_Ü3_How to activate the emergency stop function @ 2\mod_1268668633269_912.doc @ 13473 @ 3<br />

Pos: 55 /Bedienungsanleitungen/Geräte neutral/4.6d_HINWEIS_emergency stop function_Drucker @ 2\mod_1268724307638_912.doc @ 13493 @<br />

Pos: 56 /Bedienungsanleitungen/Geräte neutral/5.0_Ü1_Initial start-up of the device @ 0\mod_1246014198984_912.doc @ 1931 @ 1<br />

4.5.4 Operation with other, non-Neopost devices<br />

Strapping plug<br />

‘Out’<br />

4141957N<br />

Strapping plug<br />

‘In/Extern’<br />

4141958P<br />

Open 5-pin connection cable 9200561S<br />

The devices works only when the input to pin 1 and pin 2<br />

are closed. The input signal must be potential-free (dry<br />

contact only, no voltage).<br />

In case of an emergency stop, the device will close the relay<br />

contact 3 and 4 (max. 48V, 500mA).<br />

The print system should always be the first device in the emergency<br />

connection chain.<br />

4.5.5 How to activate the emergency stop function<br />

Emergency<br />

stop function<br />

If an unexpected error occurs, you can stop the printer by hitting the red<br />

emergency stop button. All devices connected within the emergency loop<br />

will instantly stop and the green release button will start to flash fast.<br />

If there is no emergency stop loop connection (Stand-alone operation),<br />

only the affected device will stop.<br />

The emergency stop function does not disconnect the device<br />

from the mains power!<br />

Do not open or try to repair the device while in emergency<br />

stop mode. Unplug the device from the wall outlet before<br />

performing any service.<br />

Restart the<br />

device<br />

To restart the device, unlock the red emergency button by turning it<br />

clockwise and then press the green emergency release button.<br />

Now the device can be started normally again.<br />

If the emergency stop function gets activated while printing, the<br />

printer will stop instantly within the print job. The affected page<br />

impression will get lost, but the rest of the print job may be resumed.<br />

To stop and pause the print job in a more controlled way, please use<br />

the Cancel button.<br />

User Manual Version 3.1 35

Pos: 57 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.0_print_first_test_page @ 1\mod_1263302633152_912.doc @ 10181 @<br />

Pos: 58 /Bedienungsanleitungen/Geräte neutral/5.2d_Ü2_How to power-on the device @ 0\mod_1250856526091_912.doc @ 2869 @ 2<br />

Pos: 59 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.2d_Power-on the device_<strong>AS</strong>-OrbitBase @ 2\mod_1265969207771_912.doc @ 12022 @<br />

Pos: 60 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.2_Ü2_How to install the ink cartridges _ MEHRERE PATRONEN @ 1\mod_1260880358807_912.doc @ 8482 @ 2<br />

5 Initial start-up of the device<br />

This section describes all the necessary steps to print the first test page with your Neopost<br />

<strong>AS</strong>-<strong>3640</strong>.<br />

5.1 How to power-on the device<br />

Turn on the control unit with the on/off switch located on the<br />

Afterwards turn on the vacuum suction of the conveyor belt.<br />

rear side of the device.<br />

The printer will start an initialization and present the following messages (from top to<br />

bottom):<br />

Message<br />

Loader -01<br />

Version#1.1.xx#<br />

STARTING APPLICATION<br />

Version 4.7.xx –PPC<br />

Printer<br />

Initialization<br />

EMERGENCY BUTTON SHOULD BE<br />

RELE<strong>AS</strong>ED!<br />

CODE: 49<br />

Note<br />

Initialization of the monitor software. The version<br />

number may differ.<br />

Initialization of the printer firmware. The version<br />

number may differ.<br />

Initialization of the printer functions.<br />

Press the green emergency release button of the<br />

control unit. If the message does not disappear; check<br />

the emergency connections and the strapping plugs.<br />

Please wait...<br />

CHECK CARTRID1,2,3U1<br />

INSERT ALL CARTRIDG!<br />

CODE: 25<br />

If a Neopost feeder is connected<br />

and turned on:<br />

Feeder online at serial interface<br />

If no Neopost feeder is<br />

connected and turned on:<br />

No device connected at serial<br />

interface<br />

Initialization.<br />

This notification is only shown when no cartridges are<br />

inserted in the printer.<br />

This notification will only be displayed if a Neopost FD-<br />

13/FD-15 feeder is connected to the printer and<br />

turned on.<br />

This notification will only be displayed if the Neopost<br />

FD-13/FD-15 feeder is not connected to the printer .<br />

Proceed by pressing the Ok key. The printer will switch to the Online mode and the<br />

display will show the main view.<br />

36 User Manual Version 3.1

Pos: 61 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.2b_How to install the ink cartridge_Allgemein @ 1\mod_1261387630600_912.doc @ 10024 @<br />

5.2 How to install the ink cartridges<br />

Cartridge mounting<br />

The restraining lever ensures a safe contact between the ink cartridge<br />

and the electronics of the <strong>AS</strong>-<strong>3640</strong>.<br />

Please do not force the ink cartridge to its final position by hand<br />

To avoid connection problems and damage, please install the<br />

cartridge as seen in Figure 13 and Figure 14.<br />

Figure 13: Inserting the ink cartridge into<br />

the pen stall<br />

Figure 14: Lock the restraining lever<br />

Installing the<br />

ink cartridge<br />

Please put the cartridge into the mounting (pen stall), by cautiously<br />

pushing it downwards in a straight movement. Do not force or press the<br />

cartridge back into its pen stall by hand.<br />

The cartridge should be in a slightly inclined position. The restraining<br />

lever then tilts the cartridge into its final position.<br />

• Open the restraining lever completely.<br />

• Take the ink cartridge out of the packaging and remove the<br />

protection tape from the print nozzles.<br />

• Insert the ink cartridges one after another with the print nozzles<br />

facing downwards - do not push in the direction of the restraining<br />

lever.<br />

• Lock the lever in direction of the arrow as shown in Figure 14.<br />

Thus, the ink cartridge is tilted into its final position, and the<br />

contact is established correctly.<br />