Runout compensation - Bosch-Diagnostics OES

Runout compensation - Bosch-Diagnostics OES

Runout compensation - Bosch-Diagnostics OES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

41.151_SSD2_Newsl_Felge_GB 11.09.2006 11:45 Uhr Seite 1<br />

<strong>Runout</strong> <strong>compensation</strong><br />

<strong>Bosch</strong> information<br />

09/2006<br />

In connection with optical wheel alignment systems, which cover the entire rim circumference, the question arises<br />

as to whether rim runout <strong>compensation</strong> is still necessary.<br />

<strong>Bosch</strong> commissioned a study to clarify this issue. The results are contained in this document.<br />

What is rim runout<br />

Rim runout is the side runout of a rim perpendicular to the plane of rotation. Rim runout can also be designated<br />

as the maximum form error of an ideally flat disk. Rim runout results from production tolerances and is increased<br />

during service life by mechanical deformation, e.g. by driving onto a curbstone or, in some cases, during a tire<br />

change.<br />

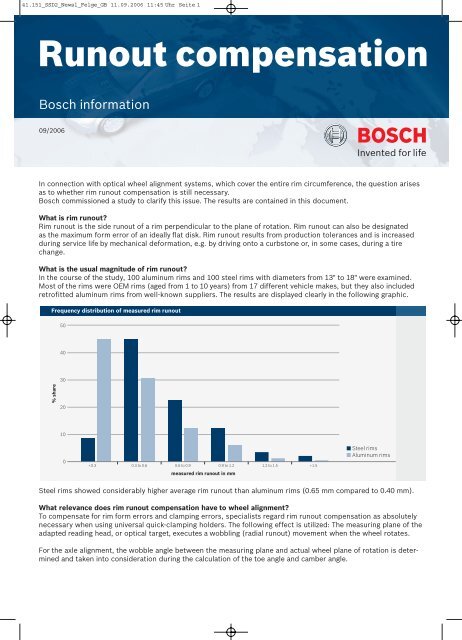

What is the usual magnitude of rim runout<br />

In the course of the study, 100 aluminum rims and 100 steel rims with diameters from 13" to 18" were examined.<br />

Most of the rims were OEM rims (aged from 1 to 10 years) from 17 different vehicle makes, but they also included<br />

retrofitted aluminum rims from well-known suppliers. The results are displayed clearly in the following graphic.<br />

Frequency distribution of measured rim runout<br />

50<br />

40<br />

30<br />

% share<br />

20<br />

10<br />

0<br />

< 0.3 0.3 to 0.6 0.6 to 0.9 0.9 to 1.2 1.2 to 1.5 > 1.5<br />

measured rim runout in mm<br />

Steel rims<br />

Aluminum rims<br />

Steel rims showed considerably higher average rim runout than aluminum rims (0.65 mm compared to 0.40 mm).<br />

What relevance does rim runout <strong>compensation</strong> have to wheel alignment<br />

To compensate for rim form errors and clamping errors, specialists regard rim runout <strong>compensation</strong> as absolutely<br />

necessary when using universal quick-clamping holders. The following effect is utilized: The measuring plane of the<br />

adapted reading head, or optical target, executes a wobbling (radial runout) movement when the wheel rotates.<br />

For the axle alignment, the wobble angle between the measuring plane and actual wheel plane of rotation is determined<br />

and taken into consideration during the calculation of the toe angle and camber angle.

41.151_SSD2_Newsl_Felge_GB 11.09.2006 11:45 Uhr Seite 2<br />

<strong>Runout</strong> <strong>compensation</strong><br />

<strong>Bosch</strong> information<br />

If no rim runout <strong>compensation</strong> is carried out, this wobble angle is added as an additional error to the actual measurement<br />

error of the axle alignment system.<br />

The above-displayed rim runout initially does not act directly as an angle error. This depends on the rim size and the<br />

distribution of the form errors over the rim circumference. With adapter-free wheel alignment systems, mathematical<br />

methods are used to calculate a measurement plane from a large number of surface points, which compensates<br />

for the smaller form errors spread over the circumference. However, this is still not sufficient to eliminate the basic<br />

rim runout and thus the wobble angle.<br />

In the course of the study, form error measurements were made on each rim at 12 measuring points and this was used to<br />

calculate the related wobble angles.<br />

This following is an example of a 17" aluminum rim with a rim runout of 0.65 mm and a wobble angle of 4.5 angular minutes<br />

(4.5’) viewed from two different perspectives:<br />

<br />

x: x-coordinates of the wheel y: y-coordinates of the wheel z: Form error in mm : Wobble angle between compensating and wheel plane of rotation (=4.5’)<br />

Measured form error Compensating plane of form error Wheel plane of rotation<br />

What do the results of the study mean for wheel alignment<br />

Making allowance for varying distribution of form error and different rim sizes, an average deviation of 0.1 to 0.2 mm<br />

would correspond a wobble angle of 1°.<br />

With most of the examined rims, i.e. approx. 75 % of the steel rims and approx. 40 % of the aluminum rims, disregarding<br />

the rim runout would lead to an additional angle error of more than 2’.<br />

The maximum angle error for steel rims was determined to be 12’ and 8’ for aluminum rims.<br />

Summary<br />

The study demonstrates convincingly that rim runout <strong>compensation</strong> is absolutely necessary, even for adapter-free<br />

or touchless wheel alignment systems, and is thus a basic prerequisite for precise setting of toe and camber.<br />

The study confirms the view held by <strong>Bosch</strong> that rim runout <strong>compensation</strong> continues to be necessary in wheel alignment.<br />

This is why automatic multi-point <strong>compensation</strong> has been integrated in the measurement process for the<br />

KDS New Generation.<br />

Contact<br />

Robert <strong>Bosch</strong> GmbH<br />

Diagnostic Products<br />

73207 Plochingen<br />

Internet: www.bosch-diagnostics-oes.de<br />

E-Mail: sales.diagnostics-oes@de.bosch.com