phoenix_wdi_2014summer-1.compressed

phoenix_wdi_2014summer-1.compressed

phoenix_wdi_2014summer-1.compressed

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

M<br />

NON-DURABLE<br />

HERBALIFE<br />

www.her b alife.com / Net s ales $4.8 : billion / Hea dq ua r ter s : Los Angeles / Emplo y ees : 7,000 / S pecia l ty: Nutrition products<br />

/ R ich Goud is , CO O “We : never cross the goal line, we just continue to move the ball down the field.”<br />

Herbalife is one of the w orld’ s leading direct sales<br />

comp anies, and continues to grow .<br />

A H e a l t hy F ut ur e<br />

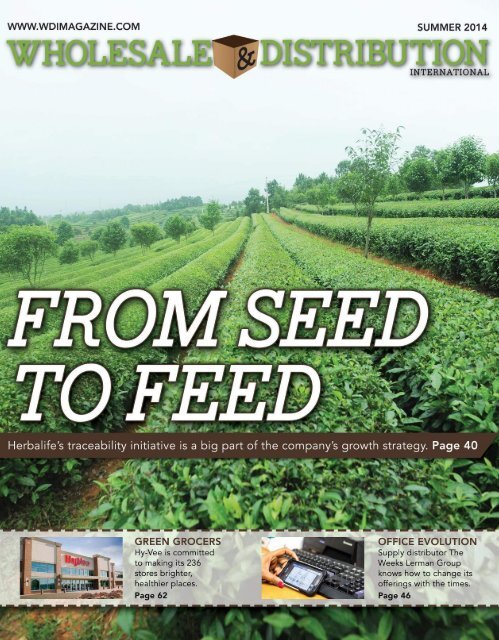

Herbalife’ s ‘ seed-to-feed’ supply chain strategy is at the center of the direct<br />

marketing giant’ s efforts to double its siz e by 2 0 2 0 . BY J IM HARRIS<br />

i l l i o n s o f p e o p l e h a Instead v e of just staying the course and<br />

maintaining its business at its current<br />

levels, Herbalife continues to grow and<br />

expand not only in terms of its global<br />

footprint, but also its internal operations.<br />

“We have a philosophy that we<br />

looked to Herbalife to help<br />

them live healthier and more<br />

active lives for more than 3 0 years. With<br />

3 million-plus independent members<br />

and distributors of its food, nutrition<br />

and personal care products in more than<br />

9 0 countries and many more millions of<br />

daily consumers, the L os Angeles-based<br />

company has grown to become one of<br />

the world’s leading direct sales companies<br />

since founder Mark Hughes sold his<br />

first protein shake in 1 9 8 0.<br />

can always build it better,” COO R ich<br />

Goudis says. “We never cross the goal<br />

line, we just continue to move the ball<br />

down the field.”<br />

Ongoing technology, manufacturing<br />

and supply chain investments are helping<br />

Herbalife meet its goal of doubling<br />

in size by 2020, which the company refers<br />

to as its “decade plan.”<br />

‘ SEED TO F EED ’<br />

One key component of Herbalife’s<br />

growth strategy is its “seed-to-feed” initiative,<br />

which addresses the traceability<br />

of it ingredients, and the manufacturing<br />

and quality of its products. “We believe<br />

that as we grow over the next 1 0 years,<br />

food safety will be a important strategic<br />

initiative in order to create confidence<br />

among our members and their consum-<br />

40 www.<strong>wdi</strong>magazine.com Summer 2014

HERBALIFE<br />

ers,” Goudis says. “We want complete<br />

traceability of our products throughout<br />

the entire supply chain.”<br />

To achieve this, the company recently<br />

made two significant facility investments.<br />

A botanical extraction facility<br />

in Changsha, Hunan Province, China,<br />

processes botanical extracts such as<br />

teas, guarana, chamomile, broccoli and<br />

bilberry for use in many of the company’s<br />

products. These extracts are<br />

produced from botanicals purchased<br />

directly from known farms in Hunan<br />

Province and other regions in China,<br />

processed in Changsha and then sent to<br />

Herbalife’s manufacturing facilities in<br />

S uzhou, China, and L ake F orest, Calif.,<br />

as well as its contract manufacturers.<br />

Changsha, the capital of Hunan Province,<br />

is home to many of the world’s nutritional<br />

herbs and botanicals. Herbalife<br />

Herbalife recently invested in a botanical ex traction facility<br />

in C hina to p rocess ex tracts for multip le p roducts.<br />

also protects their ingredient pipeline<br />

by sourcing key materials from world<br />

leading suppliers such as vitamins and<br />

minerals from D S M ( formerly R oche V i-<br />

tamins) , soy from D uPont and AD M and<br />

fructose from Tate & L yle and D uPont,<br />

among other sources, the company says.<br />

The 1 6 5 ,000-square-foot, $1 1 million<br />

facility, which opened in early 201 3 ,<br />

can process roughly 2,000 metric tons<br />

of raw materials annually through extraction,<br />

purification and drying methods.<br />

The facility also houses Herbalife’s<br />

quality control center of excellence,<br />

which routinely retests all products<br />

manufactured worldwide.<br />

The new $1 3 0 million Herbalife Innovation<br />

and Manufacturing ( HIM)<br />

facility in Winston-S alem, N.C., which<br />

opened in May, will also enhance the<br />

company’s ability to make quality products<br />

and, with added capacity, meet the<br />

growing needs of the company. The<br />

5 8 0,000-square-foot plant – the largest<br />

facility directly operated by Herbalife<br />

– will house manufacturing operations<br />

as well as product development and<br />

quality laboratories.<br />

The facility will create an estimated<br />

5 00 jobs in manufacturing, packaging,<br />

warehousing, engineering, quality<br />

control and other areas. Products<br />

manufactured in the Winston-S alem<br />

plant will be exported into more than<br />

5 0 countries, to many of the company’s<br />

more than 7 00 member access points<br />

worldwide, the company notes.<br />

The new facilities will be linked to<br />

Herbalife’s other factories and distribution<br />

centers around the world through<br />

the Oracle information systems platform.<br />

The North American market is<br />

served by hub distribution centers in<br />

Memphis and L os Angeles and 1 0 other<br />

smaller regional sales centers.<br />

“Any factory we directly operate runs<br />

Oracle’s manufacturing module as its<br />

core operating system,” Goudis says,<br />

noting that all the company’s manufacturing<br />

data is backed up in a cloud infrastructure<br />

housed in Austin, Texas. “E very<br />

factory runs the same metrics and analytics,<br />

which we can monitor centrally,<br />

and all products are planned using Oracle’s<br />

Advanced S upply Planning mod-<br />

Summer 2014 www.<strong>wdi</strong>magazine.com 41

Q<br />

HERBALIFE<br />

Herbalife says its use of an Oracle management<br />

system gives it a high degree of control.<br />

ule.” In addition, the company uses Oracle’s Agile PL M system<br />

as its repository and “one source of truth” for product formulations,<br />

specifications and labels Oracle’s warehouse management<br />

system to run their largest regional distribution centers.<br />

“Oracle helps us run a global company with even greater<br />

ease and most importantly, gives us the level of control over<br />

our proprietary data that we require,” Goudis adds.<br />

Herbalife’s other technology partners include IPTI, which<br />

provides its pick to light hardware; Interroll, which provides<br />

pallet flow racking; and TWG, which provides the conveyor<br />

systems used in the company’s warehouses and factories.<br />

“ W e want comp l et e<br />

t r aceab il it y of ou r<br />

p r odu ct s .”<br />

– Rich Goudis<br />

UA LITY CONTR OLS<br />

The seed-to-feed program establishes a number of quality<br />

controls that Herbalife applies to its manufacturing, warehousing<br />

and distribution practices.<br />

Incoming materials are tested for identity, the presence of<br />

heavy metals, microbiology and pesticides. In addition, the<br />

42 www.<strong>wdi</strong>magazine.com Summer 2014

HERBALIFE<br />

identity of key herbal ingredients is<br />

verified through the company’s botanical<br />

identification program, which established<br />

a “fingerprint” for botanical<br />

ingredients that all incoming materials<br />

are compared against. “When we specify<br />

a botanical ingredient, we want to<br />

make sure we are getting the right kind<br />

of botanical every time,” Goudis notes.<br />

Products go through at least five<br />

rounds of testing during the procurement<br />

to production process. That includes<br />

testing the products extensively<br />

to ensure they meet what is claimed<br />

on their labeling.<br />

In addition to testing, Herbalife<br />

assures quality by maintaining appropriate<br />

climates for its products to<br />

avoid spoilage. The temperature and<br />

humidity can be tracked electronically<br />

as they move through the shipping<br />

process. “As our products journey<br />

through the logistics and warehousing<br />

environment, they’re all kept under<br />

strict temperature monitoring and<br />

humidity controls,” Goudis says, noting<br />

that products are shipped to countries<br />

in five distinct climate zones.<br />

“We want to understand the environment<br />

our products will be in, so we can<br />

understand the nature of, and make<br />

changes to avoid any member or consumer<br />

complaints we might receive.”<br />

// CRB USA // CRB teamed with Herbalife to provide Design/Build services for their multi-product<br />

nutritional supplement production facility located in Winston-Salem, North Carolina. Working with the<br />

Herbalife Team, CRB was responsible for overall project management, facility architecture, process<br />

utilities, mechanical, electrical, plumbing/fire protection, I&C design and construction management<br />

services. This Design/Build project went from concept to commissioning in 18 months.<br />

by its members, that can vary in size<br />

and scope from commercial spaces to<br />

homes. Instead of investing in weeks’<br />

worth of products, customers pay a<br />

few dollars a day to enter the club and<br />

enjoy a single shake, tea and aloe. The<br />

JOIN THE CLUB<br />

Herbalife’s $200 million investment<br />

in its single-instance Oracle platform<br />

also provides the company with the<br />

capacity to open up to five or six new<br />

markets a year. Much of the company’s<br />

growth in recent years does not come<br />

from new markets, but instead is a<br />

result of a transformation in its sales<br />

model from having customers periodically<br />

buying large quantities of Herbalife<br />

products to a daily consumption<br />

model, where consumers essentially<br />

purchase by the serving, Goudis says.<br />

In this model, customers typically<br />

visit “Nutrition Clubs” established<br />

Summer 2014 www.<strong>wdi</strong>magazine.com 43

T<br />

F<br />

HERBALIFE<br />

the marketplace, and also have a robust<br />

scientific advisory team that includes<br />

some of the leaders and influencers in<br />

areas such as obesity, heart health and<br />

nutritional supplements,” Goudis says.<br />

“We react to this input while sticking to<br />

our core product category offerings.”<br />

lower price point opens up a larger market<br />

of people who can afford to buy our<br />

products, he adds.<br />

The daily consumption model started<br />

more than 1 0 years ago in Mexico,<br />

which is now the second largest country<br />

in Herbalife’s portfolio.<br />

In addition to shaping the company’s<br />

he comp any tests all incoming materials to ensure<br />

they are the right botanicals for the p roducts.<br />

business model, consumers and members<br />

also play a role in helping the company<br />

develop new products and fl avors.<br />

The majority of the company’s research<br />

and development efforts take place<br />

close to local markets.<br />

“We get a lot of input from our members<br />

on what they would like to see in<br />

LEA D ING CHA NG E<br />

Herbalife’s growth and traceability<br />

strategies are driven by a management<br />

team that was hired specifically<br />

with the D ecade Plan in mind. “F or us,<br />

growth is not just a matter of finding a<br />

warehouse or acquiring a company, it’s<br />

about investing in a management team<br />

to execute a core strategy that will create<br />

a competitive advantage for years to<br />

come,” Goudis says.<br />

Goudis joined Herbalife in 2004 , initially<br />

as the company’s CF O. In 201 0<br />

he became COO, and today, Herbalife<br />

employs 1 8 executives from Goudis’<br />

past two companies – R exall S undown<br />

and GNC. This group of industry leading<br />

executives includes executive vice<br />

president D avid Pezzullo, senior vice<br />

presidents Gerry Holly, Mark E vans<br />

and Gary S wanson and vice presidents<br />

Mike L ocke, J im B arton, Q un Y i Z heng<br />

and K uei Tu Chang. L eading executives<br />

who joined the team from other industry-leading<br />

companies include senior<br />

vice presidents J oseph Plunkett, B ill<br />

rankos and Pradip Mukerji.<br />

Herbalife’s management and other<br />

personnel all excel at handling the<br />

complexity of a global business’ manufacturing<br />

and distribution operations<br />

in an efficient manner, Goudis adds.<br />

“We recently had an investor visit, and<br />

he asked me what I thought our most<br />

valuable assets are. I said, ` Our products<br />

and distribution,’ but what creates real<br />

value here is our culture,” Goudis says.<br />

“When you visit one of our facilities,<br />

you will find people who are passionate<br />

about nutrition and want to help others,<br />

and there’s a real sense here of embracing<br />

and leading change.” <br />

44 www.<strong>wdi</strong>magazine.com Summer 2014