Pull-Action Latch Clamps

Pull-Action Latch Clamps

Pull-Action Latch Clamps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DE-STA-CO Products for Rotational Molders<br />

Hold-Down <strong>Clamps</strong><br />

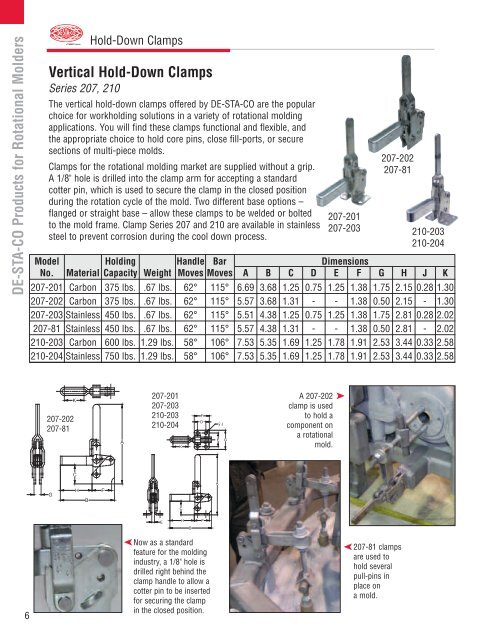

Vertical Hold-Down <strong>Clamps</strong><br />

Series 207, 210<br />

The vertical hold-down clamps offered by DE-STA-CO are the popular<br />

choice for workholding solutions in a variety of rotational molding<br />

applications. You will find these clamps functional and flexible, and<br />

the appropriate choice to hold core pins, close fill-ports, or secure<br />

sections of multi-piece molds.<br />

<strong>Clamps</strong> for the rotational molding market are supplied without a grip.<br />

A 1/8" hole is drilled into the clamp arm for accepting a standard<br />

cotter pin, which is used to secure the clamp in the closed position<br />

during the rotation cycle of the mold. Two different base options –<br />

flanged or straight base – allow these clamps to be welded or bolted<br />

to the mold frame. Clamp Series 207 and 210 are available in stainless<br />

steel to prevent corrosion during the cool down process.<br />

Model<br />

No.<br />

207-201<br />

207-202<br />

207-203<br />

207-81<br />

210-203<br />

210-204<br />

Material<br />

Carbon<br />

Carbon<br />

Stainless<br />

Stainless<br />

Carbon<br />

Stainless<br />

Holding<br />

Capacity<br />

375 lbs.<br />

375 lbs.<br />

450 lbs.<br />

450 lbs.<br />

600 lbs.<br />

750 lbs.<br />

Weight<br />

.67 lbs.<br />

.67 lbs.<br />

.67 lbs.<br />

.67 lbs.<br />

1.29 lbs.<br />

1.29 lbs.<br />

Handle<br />

Moves<br />

62°<br />

62°<br />

62°<br />

62°<br />

58°<br />

58°<br />

Bar<br />

Moves<br />

115°<br />

115°<br />

115°<br />

115°<br />

106°<br />

106°<br />

A<br />

6.69<br />

5.57<br />

5.51<br />

5.57<br />

7.53<br />

7.53<br />

B<br />

3.68<br />

3.68<br />

4.38<br />

4.38<br />

5.35<br />

5.35<br />

C<br />

1.25<br />

1.31<br />

1.25<br />

1.31<br />

1.69<br />

1.69<br />

D<br />

0.75<br />

-<br />

0.75<br />

-<br />

1.25<br />

1.25<br />

207-201<br />

207-203<br />

Dimensions<br />

E F<br />

1.25<br />

-<br />

1.25<br />

-<br />

1.78<br />

1.78<br />

1.38<br />

1.38<br />

1.38<br />

1.38<br />

1.91<br />

1.91<br />

207-202<br />

207-81<br />

G<br />

1.75<br />

0.50<br />

1.75<br />

0.50<br />

2.53<br />

2.53<br />

H<br />

2.15<br />

2.15<br />

2.81<br />

2.81<br />

3.44<br />

3.44<br />

210-203<br />

210-204<br />

J<br />

0.28<br />

-<br />

0.28<br />

-<br />

0.33<br />

0.33<br />

K<br />

1.30<br />

1.30<br />

2.02<br />

2.02<br />

2.58<br />

2.58<br />

207-202<br />

207-81<br />

K<br />

A<br />

207-201<br />

207-203<br />

210-203<br />

210-204<br />

K<br />

F<br />

D<br />

E<br />

ÿJ<br />

G<br />

A 207-202<br />

clamp is used<br />

to hold a<br />

component on<br />

a rotational<br />

mold.<br />

➤<br />

C<br />

G<br />

H<br />

B<br />

F<br />

A<br />

C<br />

E<br />

H<br />

B<br />

F<br />

6<br />

➤<br />

Now as a standard<br />

feature for the molding<br />

industry, a 1/8" hole is<br />

drilled right behind the<br />

clamp handle to allow a<br />

cotter pin to be inserted<br />

for securing the clamp<br />

in the closed position.<br />

➤<br />

207-81 clamps<br />

are used to<br />

hold several<br />

pull-pins in<br />

place on<br />

a mold.