electric boat news | september 2011 - Electric Boat Corporation

electric boat news | september 2011 - Electric Boat Corporation

electric boat news | september 2011 - Electric Boat Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SEPTEMBER <strong>2011</strong><br />

INSIDE<br />

Earned Hours Incentive Program<br />

Heads into the Fourth Quarter • 2<br />

New Hires • 3<br />

Kesselring Site Office<br />

Successfully Completes MARF<br />

Prototype Extended Shutdown • 4<br />

Mississippi Sailor Selected<br />

as “Service Person of the Month” • 5<br />

Health Matters • 6<br />

Breast Cancer and Early Detection:<br />

A First Person Account<br />

from Kristin Fletcher • 7<br />

Marine News Roundup • 9<br />

Service Awards • 10<br />

Ethics • 11<br />

Retirees • 11<br />

Safety Performance • 12<br />

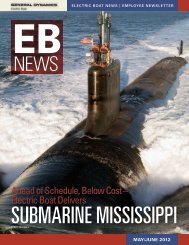

WITH CONSTRUCTION START ON SSN-787,<br />

SUBMARINE PRODUCTION RATE<br />

INCREASES TO TWO PER YEAR<br />

With the start of construction on the unnamed SSN-<br />

787 earlier this month, the Navy’s submarine program<br />

marked a significant and long-awaited milestone<br />

– the production of two Virginia-class ships per year.<br />

“The last time two submarines of the same class started construction<br />

in the same year was 22 years ago,” said John Holmander,<br />

VP – Virginia Program.<br />

This milestone is very important to the submarine program<br />

and <strong>Electric</strong> <strong>Boat</strong>,” he said. “It will bring a level of stability to the<br />

Groton waterfront that we haven’t seen in many years.”<br />

<strong>Electric</strong> <strong>Boat</strong> and its construction partner, Huntington Ingalls,<br />

continued on page 3<br />

The Virginia-class<br />

submarine California (SSN-<br />

781) gets under way from<br />

Naval Station Norfolk to<br />

conduct weapons systems<br />

acceptance trials earlier<br />

this month. California is<br />

the eighth Virginia-class<br />

submarine and is scheduled<br />

to be commissioned Oct. 29.<br />

(U.S. Navy photo)

EARNED HOURS<br />

INCENTIVE<br />

PROGRAM<br />

HEADS INTO THE<br />

FOURTH QUARTER<br />

As <strong>Electric</strong> <strong>Boat</strong> begins the final quarter of <strong>2011</strong>, the company<br />

is running behind its Earned Hours Incentive Program goal<br />

by 205,000 hours.<br />

Now in its 11th year, the program has a baseline goal for <strong>2011</strong> of 18.7<br />

million earned hours. If this goal is achieved, eligible employees will<br />

receive $500, minus withholdings.<br />

If the stretch goal of 19.6 million hours is achieved, each employee<br />

will receive another $250, for a total potential incentive reward of<br />

$750.<br />

The earned hours measurement is a tool the company employs to<br />

track its cost and schedule performance. By using this tool, the company<br />

can determine its progress toward the annual goal on a month-tomonth<br />

basis.<br />

“The Earned Hours Incentive Program is important to the company,<br />

but it also benefits employees by providing them with the opportunity<br />

to share in <strong>Electric</strong> <strong>Boat</strong>’s financial success,” said Kevin Carroll,<br />

director of Program Finance, Contracts and Estimating. “Everyone<br />

has the chance to come out ahead.”<br />

To be eligible for the incentive, employees must:<br />

P Work 1,000 hours during <strong>2011</strong> (excluding absences of any kind).<br />

P Be on the payroll as of Dec. 1, <strong>2011</strong>, with the following exceptions:<br />

n Employees who retiree in <strong>2011</strong> must work at least eight<br />

hours in <strong>2011</strong>.<br />

n Employees who are laid off in <strong>2011</strong> must work at least<br />

1,000 hours in <strong>2011</strong>.<br />

“To reach this year’s earned hours goal, we need to support the Ohio-<br />

Replacement Program and the ramp-up of the Moored Training Ship<br />

program within the engineering business area, and continue our support<br />

of the Navy shipyards and the drive to deliver the Mississippi<br />

(SSN-782) early next year,” said Carroll.<br />

2 | ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong>

WELCOME TO ELECTRIC BOAT<br />

PLEASE HELP WELCOME THE FOLLOWING EMPLOYEES,<br />

WHO HAVE RECENTLY JOINED THE COMPANY<br />

272 Wayne Carpenter<br />

433 Gregory Hew<br />

644 Samara Russell<br />

Dan Barrett, Editor<br />

330 Kenneth Ferguson<br />

341 Julie Dupont-Woody<br />

404 James Ivey<br />

410 Marcos Quintana<br />

411 Jonathan Nikodem<br />

438 Perrilea Phoenix<br />

445 Michael Audette<br />

449 Andrew Donihe<br />

James Stumme<br />

Tin Truong<br />

463 David Skidmore<br />

663 David Borkenhagen<br />

670 Clea Duffy<br />

Anthony McDonald<br />

Joseph Sakmar<br />

702 Jason Lamp<br />

Bob Gallo, Gary Slater,<br />

Gary Hall, Photography<br />

<strong>Electric</strong> <strong>Boat</strong> News<br />

is published monthly by the<br />

Public Affairs Department,<br />

75 Eastern Point Road,<br />

Groton, CT 06340<br />

413 Matthew Noll<br />

472 Tammie Patterson<br />

Phone (860) 433-8202<br />

415 Amanda Chen<br />

502 Kayti Poplaski<br />

Fax (860) 433-8054<br />

416 Robert Brouillier<br />

419 David Steere<br />

429 Nathan Clark<br />

431 Dylan Alexander<br />

505 Richard Chapman<br />

Frank DeCaro<br />

545 Diane M. Levreault<br />

626 Christine Burns<br />

Email dbarrett@gdeb.com<br />

2 SUBS PER YEAR<br />

continued from page 1<br />

have been preparing for the production increase for several<br />

years, Holmander said. These preparations have included a $124<br />

million capital investment allocated to production-improvement<br />

projects at the Quonset Point modular construction facility and<br />

the Groton shipyard, where final assembly and test is performed,<br />

he said.<br />

“We’re going to continue our efforts to improve construction<br />

efficiencies so that Virginia-class submarines are more affordable<br />

for our customer,” said Holmander, noting that affordability<br />

is the linchpin to continuing the two-per-year production rate.<br />

“To get to this important point, our Navy/industry shipbuilding<br />

team executed a very successful design for affordability program<br />

that yielded significant cost savings and has allowed the<br />

Navy to increase production in a fiscally-responsible manner,”<br />

said Rear Adm. David Johnson, program executive officer for<br />

submarines.<br />

“A great deal of our success comes from increasing construction<br />

efficiencies; our last two submarines were delivered in 65<br />

months, which is eight months early to their contract delivery<br />

date and we are well on our way to getting that number down to<br />

60 months for our two fiscal year 2012 authorized <strong>boat</strong>s (SSN-<br />

788 and SSN-789),” Johnson said.<br />

According to Holmander, the next ship and the ninth of the<br />

class, Mississippi (SSN-782), is tracking to be delivered 12<br />

months ahead of schedule and more than $50 million under contract<br />

target budget.<br />

The design for affordability program involved redesigning<br />

portions of the Virginia Class to reduce costs and construction<br />

time. The program has yielded significant cost savings for the<br />

Virginia Class, reducing its per-submarine acquisition costs by<br />

nearly 20 percent while shortening their construction span from<br />

84 months to 60. These efforts significantly contributed to the<br />

increased production rate.<br />

“Our team has been diligently driving down the cost and construction<br />

time of these submarines to get to this key two per year<br />

milestone,” said Rear Adm. (sel.) Michael Jabaley, the Navy’s<br />

Virginia-class program manager. “Building two submarines per<br />

year is the most economical way to procure these <strong>boat</strong>s and will<br />

help ensure that our submarine force has the platforms it needs<br />

to carry out its various missions.”<br />

Connecticut Congressman Joe Courtney, D-2nd District,<br />

praised <strong>Electric</strong> <strong>Boat</strong> as construction began on SSN-787. “This<br />

milestone is the culmination of years of hard work by many people,<br />

especially the men and women of <strong>Electric</strong> <strong>Boat</strong>,” he said.<br />

Two more Virginia-class program events will be held later this<br />

year – the California (SSN-781) will be commissioned in Nor-<br />

folk, Va., on Oct. 29, and Mississippi (SSN-782) will be christened<br />

at the Groton shipyard on Dec. 3.<br />

ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong> | 3

KESSELRING SITE OFFICE SUCCESSFULLY COMPLETES<br />

MARF PROTOTYPE EXTENDED SHUTDOWN<br />

E<br />

lectric <strong>Boat</strong>’s Kesselring Site Office (KSO) recently completed its<br />

assignment as the Lead Maintenance Activity for the MARF Prototype<br />

<strong>2011</strong> Extended Shutdown (XSD). MARF is an acronym for Modifications<br />

and Additions to Reactor Facilities.<br />

All work was completed on schedule and under budget, allowing the<br />

MARF plant to be returned to its purpose as a training platform for the U.S.<br />

Navy. The successful completion of this major project was the result of a<br />

combined effort by <strong>Electric</strong> <strong>Boat</strong>, Knolls Atomic Power Laboratory (KAPL),<br />

continued<br />

All work was completed on schedule and under budget, allowing the MARF<br />

plant to be returned to its purpose as a training platform for the U.S. Navy.<br />

From left, Lt. Cmdr. Jesse<br />

Stoffel, MARF executive<br />

officer; Rich Reichard,<br />

plant manager, KAPL<br />

(MARF) Nuclear Prototype<br />

Training Unit in Ballston<br />

Spa, N.Y.; Adm. Kirkland H.<br />

Donald, director of Naval<br />

Nuclear Propulsion; and<br />

Mike Crimmins, <strong>Electric</strong><br />

<strong>Boat</strong>’s MARF Extended<br />

Shutdown project<br />

manager.<br />

4 | ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong>

MISSISSIPPI SAILOR<br />

SELECTED AS “SERVICE<br />

PERSON OF THE MONTH”<br />

A letter of thanks and appreciation from Director of Naval<br />

Reactors K.H. Donald, Admiral, U.S. Navy, sent to the members<br />

of the MARF XSD Team.<br />

and Naval personnel led by <strong>Electric</strong> <strong>Boat</strong> MARF XSD<br />

Project Manager Mike Crimmins and KAPL MARF<br />

Plant Manager Rich Reichard.<br />

Adm. Kirkland Donald, director of Naval Nuclear Propulsion,<br />

later toured the MARF Plant and recognized<br />

Crimmins, Reichard and the MARF XSD Team with an<br />

Admiral’s “Four Star Letter” for a job well done.<br />

The <strong>Electric</strong> <strong>Boat</strong>/KSO effort received significant support<br />

from personnel throughout company, many of whom<br />

travelled to the Kesselring Site to assist in the deck-plate<br />

execution of the work or perform independent technical or<br />

program reviews before and during the XSD.<br />

Asailor assigned to the submarine Mississippi<br />

(SSN-782) has been named “Service Person<br />

of the Month” for September by the Southeastern<br />

Connecticut Chamber of Commerce and other<br />

organizations for his support and efforts in the local<br />

community.<br />

The award recipient, Machinist’s Mate 1st Class<br />

(SS/SW) James Pearson, serves as the volunteer coor-<br />

dinator for Mississippi. He was honored for his work<br />

at a luncheon at the Groton Inn & Suites.<br />

“My overall plan for Mississippi all along has been<br />

to inform the local community about the U.S. Navy,<br />

and in particular, PCU Mississippi,” said Pearson.<br />

“I think more sailors should volunteer in their local<br />

communities to really gain an appreciation for the<br />

community.”<br />

The Ledyard Rotary Club presented the Service<br />

Person of the Month award to Pearson. This program<br />

provides community recognition of outstanding<br />

active-duty enlisted personnel stationed in the Groton-New<br />

London area. The program is coordinated<br />

by the Southeastern Connecticut Chamber of Commerce<br />

in cooperation with local active-duty military<br />

organizations.<br />

Since mid-2010, sailors aboard Mississippi have<br />

assisted with projects from cooking for veterans in<br />

the local area; educating students about the military<br />

at John B. Stanton Elementary School; conducting<br />

repairs at the New London Homeless Hospitality Center<br />

to packing boxes for deployed Connecticut service<br />

members.<br />

“Since becoming the community service coordinator<br />

in July 2010, he has recruited 55 crew members of<br />

PCU Mississippi to participate in the community ser-<br />

vice program,” said Cmdr. John McGrath, commanding<br />

officer of PCU Mississippi. “These dedicated volunteers<br />

have donated over 90 hours of cumulative<br />

community service per month.”<br />

Pearson said their volunteer program was created<br />

to emphasize their interest in Connecticut, and their<br />

desire to offer assistance wherever necessary. The<br />

program has impacted more than 10,000 people.<br />

“PCU Mississippi is extremely proud of Petty Officer<br />

Pearson and because of his hard work, dedication,<br />

and volunteer spirit. As a result of his efforts,<br />

the command enjoys a strong and vibrant relationship<br />

with the citizens, government, and civic organizations<br />

of New London County,” said McGrath.<br />

ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong> | 5

HEALTH<br />

MATTERS<br />

Bob Hurley, M.D.<br />

Medical Director<br />

BREAST<br />

CANCER<br />

Over the course of their lives,<br />

women face a one-in-eight<br />

chance that they will receive<br />

a diagnosis of breast cancer.<br />

Ductal and Lobular are the two main<br />

types. Ductal carcinoma starts in the<br />

tubes (ducts) that move milk from the<br />

breast to the nipple. Most breast cancers<br />

are of this type. Lobular carcinoma<br />

starts in the parts of the breast, called lobules,<br />

that produce milk. In rare cases,<br />

breast cancer can start in other areas of<br />

the breast. Breast cancer may be invasive<br />

or noninvasive. Invasive means the cancer<br />

spreads from the milk duct or lobule<br />

to other tissues in the breast. Noninvasive<br />

means it has not yet invaded other breast<br />

tissue and is called “in situ.” Thus, ductal<br />

carcinoma in situ (DCIS), or intraductal<br />

carcinoma, is breast cancer in the lining<br />

of the milk ducts that has not yet invaded<br />

nearby tissues. If left untreated, it may<br />

progress to invasive cancer. Lobular car-<br />

cinoma in situ (LCIS) has a tendency to<br />

progress to invasive cancer in the same or<br />

both breasts.<br />

Some cancers have estrogen receptors on<br />

the surface of their cells. They are called<br />

estrogen receptor-positive cancer or ERpositive<br />

cancer. In the presence of estrogen<br />

these HER2-positive breast cancers<br />

are encouraged to grow. When cells<br />

(including cancer cells) have too many<br />

copies of this gene, they grow faster.<br />

Experts think that women with HER2-<br />

positive breast cancer have a more aggressive<br />

disease and a higher risk that the disease<br />

will return than women who do not<br />

have this type.<br />

Another genetic marker, BRCA1 and<br />

BRCA2, are genes that direct the production<br />

of proteins that protect you from<br />

cancer. If a parent passes you a defective<br />

gene, you have an increased risk for breast<br />

cancer. Women with one of these defects<br />

have up to an 80 percent chance of getting<br />

breast cancer sometime during their life.<br />

Prevention<br />

So what can one do to reduce the chance<br />

of contracting breast cancer There are<br />

some general recommendations but since<br />

the exact triggering mechanism of this<br />

disease is uncertain there are no specific<br />

actions shown to be preventative. There<br />

are also traits that can’t be changed such<br />

as age and gender. Although breast cancer<br />

is not exclusive to women, female gender<br />

and age are two significant risk factors.<br />

A family history of breast cancer may<br />

raise your risk by 20 to 30 percent. Your<br />

genetic makeup and age of first menstruation<br />

as well as menopause all influence<br />

your risk profile.<br />

As for what you can control, we do know<br />

that breast implants, using antiperspirants,<br />

wearing underwire bras or other mechanical<br />

trauma do not raise one’s risk. There<br />

also is inconclusive evidence that pesticides<br />

have a direct causal link to the disease.<br />

Whether one chooses to have children<br />

or not is associated with risk. Women<br />

who have never had children or who had<br />

them only after age 30 have an increased<br />

risk for breast cancer.<br />

Being pregnant more than once or becoming<br />

pregnant at an early age reduces your<br />

risk of breast cancer. Having taken DES<br />

(diethylstilbestrol) to prevent a miscar-<br />

riage has been linked to increased risk as<br />

has hormone replacement therapy with<br />

estrogen for several years or more. If you<br />

received radiation therapy as a child or<br />

young adult to treat cancer of the chest<br />

area, you have a much higher risk for<br />

developing breast cancer.<br />

One controllable behavior is diet. For<br />

example, some data suggests obesity is<br />

linked to breast cancer as this produces<br />

extra estrogen. That having been said,<br />

so far the best advice is to eat a well-balanced<br />

diet and avoid focusing on one<br />

“cancer-fighting” food<br />

The American Cancer Society’s dietary<br />

guidelines for cancer prevention recommend<br />

that people:<br />

P Choose foods and portion sizes that<br />

promote a healthy weight.<br />

P Choose whole grains instead of refined<br />

grain products.<br />

6 | ELECTRIC BOAT NEWS | September <strong>2011</strong>

P Eat five or more servings of fruits and<br />

vegetables each day.<br />

P Limit processed and red meat in the<br />

diet.<br />

P Limit alcohol consumption to one to<br />

two drinks per day (women with high<br />

risk should consider not drinking at<br />

all).<br />

Symptoms<br />

It would be helpful if early breast cancer<br />

had symptoms, but it usually doesn’t.<br />

That’s why prevention, screening and<br />

early detection programs are so important.<br />

Regular breast exams are important. As<br />

the cancer grows, symptoms may include<br />

findings that you might be able to discern<br />

such as:<br />

P Breast lump or lump in the armpit that<br />

is hard, has uneven edges, and usually<br />

does not hurt<br />

P Change in the size, shape, or feel of<br />

the breast or nipple, for example, you<br />

may have redness, dimpling, or puckering<br />

that looks like the skin of an<br />

orange<br />

P Fluid coming from the nipple; it may<br />

be bloody, clear to yellow, green, and<br />

look like pus<br />

Men can get breast cancer, too. Symptoms<br />

include breast lump and breast pain and<br />

tenderness. Advanced breast cancer may<br />

include:<br />

P Bone pain<br />

P Breast pain or discomfort<br />

P Skin ulcers<br />

P Swelling of one arm (next to the breast<br />

with cancer)<br />

P Weight loss<br />

Breast Screening Recommendations<br />

There are no consensus recommendations<br />

and with updates and revisions, the lay<br />

public often questions what the best way to<br />

screen for breast cancer is. My recommendation<br />

is to review the recommendations<br />

BREAST CANCER AND EARLY DETECTION:<br />

A FIRST PERSON ACCOUNT<br />

FROM KRISTIN FLETCHER<br />

Editor’s note: Earlier this year, Vice<br />

President and Chief Information Officer<br />

Kristin Fletcher was diagnosed with breast<br />

cancer. She wrote the following article to<br />

help raise awareness of the disease and to<br />

stress the importance of early detection.<br />

I am a sleepy head. I hate getting up.<br />

I love to sleep … not a morning person.<br />

Thursday, March 31st, I had pressed the<br />

“snooze” button for the umpteenth time.<br />

My husband was long gone to work. I rolled<br />

over, knowing my time was up if I was<br />

going to make it to my first meeting, and felt something funny in<br />

my right breast. Small. Hard. First thought – it’s probably nothing. I<br />

rolled back over. Thirty seconds later, I was trying to find it again. I<br />

stood up and found it again.<br />

I called my husband, and then the doctor’s office. I knew the doctor’s<br />

office wouldn’t be open for several hours, but I was afraid that<br />

if I waited until later in the day, I wouldn’t do it. This thing was<br />

tiny – pea sized – and I was certain I was being a hypochondriac.<br />

The rest is history. Several weeks later, I was diagnosed with<br />

breast cancer. It didn’t make sense – I was up to date on my mammograms;<br />

another mammogram was performed the week after<br />

I found my lump, and my tumor is not visible on that shot, even<br />

though it was being targeted. I had two independent breast exams<br />

by highly qualified physicians during the three months prior to<br />

finding this lump myself … but no doctor knows my body as well<br />

as I do.<br />

As a result of early detection – I am incredibly fortunate. My<br />

medical team has options for treatment. My treatment is multifaceted.<br />

I have great care. Just a few months after feeling something<br />

unusual in my breast, my treatment is well along and the most dif-<br />

ficult aspects are expected to be completed in a relatively short<br />

period of time. I am certainly not in a position to declare victory,<br />

but I do have reason to be very optimistic regarding my prognosis.<br />

I have told my son that I will be around to haunt him for 40 more<br />

years.<br />

As far as I’m concerned, it doesn’t matter whether you do it<br />

clockwise or counterclockwise, on the first day of the month, the<br />

last, or on the full moon. What does matter is that you know your<br />

body, and when something doesn’t feel right, you follow up on it...<br />

as quickly as possible.<br />

Thanks for reading,<br />

Kristin<br />

continued on page 8<br />

ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong> | 7

It would be helpful<br />

if early breast<br />

cancer had<br />

symptoms, but it<br />

usually doesn’t.<br />

That’s why<br />

prevention,<br />

screening and<br />

early detection<br />

programs are<br />

so important.<br />

HEALTH MATTERS / BREAST CANCER<br />

continued from page6<br />

below, speak with a trusted medical provider,<br />

and then decide which course is right for you.<br />

The American College of Obstetricians and<br />

Gynecologists currently continues to recommend<br />

the following services:<br />

P Screening mammography every one to<br />

two years for women from ages 40 to 49<br />

P Screening mammography every year for<br />

women age 50 or older<br />

P Breast Self Examination (BSE) has the<br />

potential to detect palpable breast cancer and<br />

can be recommended<br />

The American Cancer Society recommends:<br />

P Annual mammography beginning<br />

at age 40<br />

P Annual Clinical Breast exam (CBE)<br />

after the age of 40<br />

P Breast MRI is not recommended for<br />

women at average risk for breast<br />

cancer<br />

P There is insufficient evidence to<br />

recommend breast self examination<br />

( BSE)<br />

The American Medical Association (2002)<br />

and the National Comprehensive Cancer Network<br />

(2009) recommend actions similar to<br />

those of the American Cancer Society, with<br />

an exception – they recommend breast self<br />

examination..<br />

The American Academy of Family Physicians<br />

has endorsed the U.S. Preventative Ser-<br />

vices Task Force (USPSTF) recommendations<br />

on breast cancer screening in the past.<br />

The American College of Physicians recommended<br />

in 2007 that screening mammography<br />

decisions in women from ages 40 to<br />

49 should be based on individualized assessment<br />

of risk for breast cancer; that clinicians<br />

should inform women from ages 40 to<br />

49 about the potential benefits and harms of<br />

screening mammography; and that clinicians<br />

should base screening mammography decisions<br />

on benefits and harms of screening, as<br />

well as on a woman’s preferences and breast<br />

cancer risk profile.<br />

The USPSTF recommends against routine<br />

screening mammography in women from<br />

ages 40 to 49 years. The decision to start<br />

regular, biennial screening mammography<br />

before the age of 50 should be an individual<br />

one and take patient context into account,<br />

including the patient’s values regarding specific<br />

benefits and harms.<br />

P The USPSTF recommends biennial<br />

screening mammography for women<br />

from ages 50 to 74 years.<br />

P The USPSTF recommends against<br />

teaching breast self-examination<br />

(BSE).<br />

Calling Your Health Care Provider<br />

Regardless of which guidelines you and your<br />

provider choose to follow, there are some<br />

absolutes. You should contact your health<br />

care provider for an appointment if:<br />

P You have a breast or armpit lump<br />

P You have nipple discharge<br />

Also call your health care provider if you<br />

develop symptoms after being treated for<br />

breast cancer, such as:<br />

P Nipple discharge<br />

P Rash on the breast<br />

P New lumps in the breast<br />

P Swelling in the area<br />

P Pain, especially chest pain,<br />

abdominal pain, or bone pain<br />

For more information, there are multiple<br />

on-line sites such as the National Cancer<br />

Institute, which provides an online tool to<br />

help you figure out your risk of breast<br />

cancer. See: www.cancer.gov/bcrisktool, or<br />

go to www.myuhc.com.<br />

8 | ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong>

MARINE SYSTEMS NEWS<br />

<strong>Electric</strong> <strong>Boat</strong> Supports Submarine Repair<br />

Work at Norfolk Naval Shipyard<br />

<strong>Electric</strong> <strong>Boat</strong> has been awarded a $23 million work order by<br />

the U.S. Navy to support submarine repair work at Norfolk Naval<br />

Shipyard (NNSY) in Virginia.<br />

The work order is part of a Basic Ordering Agreement awarded<br />

to <strong>Electric</strong> <strong>Boat</strong> in September 2010 to support U.S. Navy submarine<br />

repair work.<br />

Under this work order, <strong>Electric</strong> <strong>Boat</strong> trades employees will be<br />

assigned to maintenance activities on USS Newport News (SSN-<br />

750) and USS West Virginia (SSBN-736). The work is scheduled<br />

to be completed by September 2012.<br />

<strong>Electric</strong> <strong>Boat</strong> Receives $33 Million<br />

Contract to Procure Virginia-class<br />

Submarine Photonics Masts<br />

<strong>Electric</strong> <strong>Boat</strong> has been awarded a $32.9 million contract modification<br />

by the U.S. Navy to procure three backup photonics masts<br />

for Virginia-class submarines.<br />

In Virginia-class submarines, traditional periscopes have been<br />

supplanted by photonics masts – non-hull-penetrating masts that<br />

do not extend physically into the control room. Information is<br />

digitally recorded by cameras in the mast, transmitted through<br />

fiber optics into the ship and processed with on-board image processors.<br />

Each photonics mast has an HDTV digital color camera,<br />

an infrared camera and a laser rangefinder.<br />

General Dynamics to Acquire Metro Machine<br />

FALLS CHURCH, Va<br />

General Dynamics has entered an agreement to acquire Metro<br />

Machine Corp., a leading East Coast surface-ship repair company<br />

that supports the U.S. Navy fleet in Norfolk, Va. The value of the<br />

cash transaction, which is expected to be accretive to General<br />

Dynamics’ earnings beginning in 2012, has not been disclosed.<br />

The transaction is subject to normal regulatory approvals and is<br />

expected to close in November.<br />

Metro Machine Corp. is a privately held company that employs<br />

approximately 400 workers. It has been conducting U.S. Navy ship<br />

repair and conversions since 1972. Metro Machine Corp. is a prime<br />

contractor in Norfolk for multi-ship, multi-option (MSMO) contracts<br />

for combat and support ships for the U.S. Navy, including frigates<br />

(FFGs), dock landing ships (LSDs) and amphibious transport ships<br />

(LPDs). MSMO contracts provide for maintenance, modernization<br />

and repair to all ships of a class in specific homeport areas.<br />

Metro Machine Corp. will become part of the shipbuilding and<br />

repair operations of General Dynamics NASSCO. NASSCO, the<br />

largest shipbuilding and repair company on the West Coast, is a<br />

prime contractor for MSMO contracts for Navy combat and support<br />

ships, including FFGs, LSDs, LPDs and amphibious assault<br />

(LHA/LHD) ships. The company employs 3,400 people.<br />

“With its Norfolk location, Metro Machine Corp. will extend<br />

the reach of NASSCO’s ship-repair operations to a key East Coast<br />

naval port,” said NASSCO President Fred Harris. “This move<br />

will enhance General Dynamics’ ability to deliver cost-effective<br />

maintenance and repair services to the U.S. Navy, helping the<br />

Navy to maximize the life of in-service ships and better serve the<br />

ship-repair needs of the entire U.S. fleet.”<br />

BIW Awarded $1.8 Billion for Construction<br />

of Two DDG-1000 Destroyers<br />

BATH, Maine – The U. S. Navy has awarded Bath Iron Works<br />

a $1.8 billion contract for the construction of DDG -1001 and<br />

DDG -1002, the next two ships in the Zumwalt-class program.<br />

DDG -1001 is scheduled to be delivered in December 2015 and<br />

DDG- 1002 is scheduled to be delivered in February 2018.<br />

“This contract enables us to maintain a strong base of quality<br />

shipbuilding jobs in Maine and continue our contributions to sus-<br />

taining the U.S. Navy fleet,” said Jeff Geiger, president of Bath<br />

Iron Works. “It provides Bath Iron Works with a healthy back-<br />

log of work and reflects the Navy’s continued commitment to the<br />

DDG-1000 program, as well as their confidence in our ability to<br />

build and deliver all three ships of this class.<br />

“Winning this work is a result of our commitment to opera-<br />

tional excellence and to finding more efficient, affordable ways to<br />

operate in every part of our business. It gives us the opportunity<br />

to continue introducing new and innovative ways to build capable<br />

ships for the Navy,” Geiger said.<br />

“We appreciate all the support the Maine Congressional delega-<br />

tion has provided to this program. Their commitment to national<br />

defense and their advocacy on behalf of the workers of Maine has<br />

been a crucial factor,” he said.<br />

The first ship in the class, DDG-1000, is more than 50 percent<br />

complete and is scheduled to be delivered in 2014. The DDG-<br />

1000 Zumwalt-class destroyer is the U.S. Navy’s next-generation,<br />

guided-missile destroyer, leading the way for a new generation of<br />

advanced multi-mission surface combat ships. The ships will fea-<br />

ture a low radar profile, an integrated power system and a total<br />

ship computing environment infrastructure. Armed with an array<br />

of weapons, the Zumwalt-class destroyers will provide offensive,<br />

distributed and precision fires in support of forces ashore.<br />

“This contract award demonstrates the Navy’s commitment<br />

to balancing cost, capability and industrial base considerations<br />

to improve the affordability of this shipbuilding program,” Sean<br />

Stackley, assistant secretary of the Navy, said in a statement.<br />

“This is a great example of putting in place should-cost targets to<br />

meet validated warfighting requirements.”<br />

Work is already under way at the Bath, Maine, shipyard on<br />

DDG-1001 and DDG- 1002. Congress previously approved fund-<br />

ing for advanced procurement and initial construction of these<br />

ships. Bath Iron Works is the lead designer and builder for the<br />

program which employs approximately 5,400 people.<br />

ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong> | 9

SERVICE AWARDS H H H H H H H H H H H H<br />

55 Years<br />

412 Samuel J. Grills<br />

45 Years<br />

413 James B. Segar<br />

40 Years<br />

243 Ronald Reed<br />

431 Paul J. Kazlauskas<br />

35 Years<br />

100 Dennis S. Triba<br />

229 David B. Pelletier<br />

229 Richard M. Romyns<br />

230 Carmine F. Penza<br />

230 Stephen E. Rolfe<br />

242 Michael D. Adams<br />

242 Thomas Daniewicz<br />

242 Alan C. White<br />

243 Michael D. Finnigan<br />

243 Gerald S. Poirier<br />

244 Brian P. Chesna<br />

252 Timothy P. Lloyd<br />

252 Gerard W. Manville<br />

252 Benjamin R. Mattos<br />

252 Bruce L. Stefanelli<br />

272 Tommie R. Parr<br />

323 Kevin G. Pincins<br />

355 Raymond P. Arpin<br />

355 Joseph Giorgianni<br />

355 Robert H. Gordy Jr.<br />

406 Harold J. Robb<br />

411 Gara B. Eastman<br />

424 David M. West<br />

452 Michael E. Bessette<br />

459 Clyde T. Britt Jr.<br />

496 Frank A. Laudone III<br />

501 Joseph G. Houle Jr.<br />

553 Jeffrey T. Izzo<br />

601 Robert H. Nardone<br />

642 Lester B. Ahern<br />

691 Elizabeth A. Peterson<br />

795 Gary M. Beaudoin<br />

900 Anthony J. Moniz<br />

901 Thomas G. Blanchette Sr.<br />

902 Paul E. Cagnon Jr.<br />

904 Donald T. Wilsey<br />

915 George P. Cain<br />

915 Robert J. Chabot<br />

921 James P. Hague<br />

921 Murray F. McGrady Jr.<br />

921 Lon W. Planz Jr.<br />

950 Stephen J. Defalco<br />

950 William G. Harford Jr.<br />

950 Sally A. Johanson<br />

950 Raymond G. Schultheiss<br />

957 Barry J. Houston<br />

970 Paul A. Cirillo<br />

30 Years<br />

100 Scott D. McNickle<br />

242 Scott G. Dawson<br />

242 William P. Grohocki Jr.<br />

242 Michael A. Malone<br />

456 Daniel J. Panucci<br />

459 Richard H. Sampson<br />

460 Willard F. Reavis<br />

495 Harold C. Branstrom Jr.<br />

601 Kim R. Shaffer<br />

604 Daniel L. Williams<br />

915 David A. Jackson<br />

25 Years<br />

210 Glenn I. Erickson<br />

341 Raymond J. Albert<br />

409 Mary Hallisey<br />

454 Christopher M. Giordano<br />

456 Virginia L. Payne<br />

467 Alan P. Callaghan<br />

901 John S. Camboia<br />

950 Oscar W. Stone<br />

20 Years<br />

403 David Phoenix<br />

452 Robert T. Hill<br />

453 Stephen A. Payne<br />

455 Cynthia L. Mello<br />

467 Richard E. Murphy<br />

915 Franklin O. Lockwood<br />

10 | ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong>

Retirees<br />

201 Randy J. Williams<br />

32 years<br />

Operations Supervisor<br />

230 Donald E. Greene<br />

33 years<br />

Crane Operator 1/C<br />

274 John R. Bosse<br />

27 years<br />

Elec Tech Nuc/Sy 1/C<br />

355 Richard H. Vescovi<br />

25 years<br />

Prod Planner<br />

400 Herbert C. Rattley, Jr.<br />

35 years<br />

Director of Eng - <strong>Electric</strong>al<br />

423 George H. Gilmore Jr.<br />

27 years<br />

Manager of Quality<br />

452 Paul L. Olivier<br />

37 years<br />

Design Tech-Piping<br />

452 Richard A. Strand<br />

46 years<br />

Piping Sr Designer<br />

452 James R. Willie<br />

41 years<br />

Vent Sr. Designer<br />

459 Christine Dupont<br />

33 years<br />

Arrgt Sr Designer<br />

459 Edward S. Freeman<br />

38 years<br />

Struct Sr Designer<br />

545 Thomas E. Smotherman<br />

36 years<br />

Scrap Matl Sorte W/L<br />

604 Paul P. Macko<br />

37 years<br />

IMS Spec Sr<br />

741 Leon N. Lefevre<br />

46 years<br />

Superintendent-Site<br />

915 Edward M. Ellis<br />

38 years<br />

M/T Tech II<br />

924 Thomas S. Capirchio<br />

27 years<br />

M/T Tech II<br />

972 Walter J. Morris<br />

33 years<br />

Prod Supp Tech I<br />

EB BUSINESS<br />

ETHICS<br />

AND CONDUCT<br />

WORKPLACE VIOLENCE<br />

We do not tolerate violent<br />

behavior at any workplace or<br />

company-sponsored gathering,<br />

whether committed by or against<br />

an employee. The following<br />

behaviors are prohibited:<br />

P Making threatening remarks<br />

P Causing physical injury to<br />

someone else<br />

P Intentionally damaging<br />

someone else’s property<br />

P Acting aggressively in a way<br />

that causes someone else to be<br />

intimidated or fear injury<br />

Always use good judgment and<br />

promptly inform your supervisor,<br />

manager, union steward,<br />

Human Resources or Security<br />

representatives if you observe<br />

behavior that could be dangerous<br />

or violent.<br />

<strong>Electric</strong> <strong>Boat</strong> Ethics Director<br />

Frank Capizzano (860-433-1278)<br />

is available to confidentially assist<br />

anyone with questions or issues<br />

that may relate to ethical decision<br />

making. The General Dynamics<br />

Ethics Hotline is available 24/7<br />

and may be reached at 800-<br />

433-8442 or 770-613-6315 for<br />

international callers who wish to<br />

report an ethical violation. Online<br />

access to the Hotline is available<br />

at www.gd.ethicspoint.com.<br />

Remember – When in doubt,<br />

always ask.<br />

ELECTRIC BOAT NEWS | SEPTEMBER <strong>2011</strong> | 11

STANDARD PRESORT<br />

U.S. POSTAGE<br />

PAID<br />

GROTON, CT<br />

PERMIT NO. 392<br />

ELECTRIC BOAT<br />

SAFETY<br />

PERFORMANCE<br />

YEAR TO DATE<br />

SEPTEMBER <strong>2011</strong>