RALLY April 26 - May 1, 2010 - Turbo Diesel Register

RALLY April 26 - May 1, 2010 - Turbo Diesel Register

RALLY April 26 - May 1, 2010 - Turbo Diesel Register

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EDITORS<br />

Robert Patton<br />

Bob Vallier Jeannette Vallier<br />

CONTRIBUTORS THIS ISSUE<br />

Jim Anderson Mark Barnes<br />

Kevin Cameron Joe Donnelly<br />

John Holmes Polly Holmes<br />

Sam Memmolo Andy Mikonis<br />

Andy Redmond Steve St. Laurent<br />

Bill Stockard G.R. Whale<br />

ILLUSTRATOR<br />

Bob Pierce<br />

OFFICE STAFF<br />

Tina Bean<br />

GENO’S GARAGE<br />

Robin Patton<br />

Andy Bishop Brandon Parks<br />

Wendy Poole Scott Sinkinson<br />

ALL DIFFICULT WORK<br />

Pam Rose<br />

A MEMBERSHIP/SUBSCRIPTION TO THE TURBO<br />

DIESEL REGISTER IS $35.00 PER SUBSCRIPTION.<br />

PLEASE SEND ALL SUBSCRIPTION INFORMATION,<br />

CORRESPONDENCE, LETTERS, RENEWALS, ADDRESS<br />

CHANGES, ETC., TO:<br />

TDR<br />

1150 samples industrial drive<br />

cumming, GA 30041<br />

THE TDR IS PUBLISHED QUARTERLY BY DIESEL<br />

REGISTRY, INC. DISTRIBUTION TO MEMBERS<br />

VIA PERIODICAL POSTAGE IS IN THE MONTHS OF<br />

FEBRUARY, MAY, AUGUST AND NOVEMBER.<br />

ARTICLES ARE WELCOMED FROM ALL SUBSCRIBERS.<br />

LET US HEAR FROM YOU! WE RESERVE THE RIGHT<br />

TO EDIT ANY SUBMITTED MANUSCRIPTS. WE WILL<br />

ACCEPT MANUSCRIPTS IN IBM ASCII TEXT FILES OR<br />

FROM ANY POPULAR IBM WORD PROCESSORS, ON<br />

COMPUTER DISK, OR SCRIBBLED ON A RESTAURANT<br />

NAPKIN.<br />

THE TURBO DIESEL REGISTER IS NOT AFFILIATED<br />

WITH CHRYSLER CORP., CUMMINS INC., OR ANY OF<br />

THEIR SUBSIDIARIES. ADVERTISING OF PRODUCTS<br />

OR SERVICES IN THE PUBLICATION DOES NOT<br />

CONSTITUTE ENDORSEMENT OR APPROVAL. WE<br />

ARE NOT RESPONSIBLE FOR DAMAGES, ACCIDENTS,<br />

INJURIES, INVALIDATION OF WARRANTY, FAILURE<br />

TO PASS EMISSION STANDARDS OR SAFETY<br />

INSPECTIONS AND WILL NOT BE HELD ACCOUNTABLE<br />

IN ACTIONS RELATING TO OR RESULTING FROM ANY<br />

SUCH SITUATION.<br />

COPYRIGHT © <strong>2010</strong>. ALL RIGHTS RESERVED.<br />

REPRODUCTION IN WHOLE OR PART WITHOUT<br />

PERMISSION IS PROHIBITED.<br />

POSTMASTER: Send address change to TDR, 1150<br />

Samples Industrial Drive, Cumming, GA 30041.<br />

USPS number 014234<br />

ISSN number 10888241<br />

4 Tailgating<br />

Letter from the Editor<br />

6 Letter Exchange Your Letters<br />

Responses from the Readers<br />

8 Member2Member Dash Cover<br />

Members’ Solutions to Members’ Questions<br />

10 10 Back Issue 27 – We Survived Y2K<br />

A Look Back Ten Years Ago in the TDR Magazine<br />

12 First Generation Fuel Gauge/Prescriptions For Power<br />

Owner-Specific Articles on the ’89-’93 Trucks<br />

14 12-Valve Engines Remove and Install<br />

Owner-Specific Articles on the ’94-’98.5 12-Valve Trucks<br />

18 24-Valve Engines Transfer Case/Quick Connects/Wiring<br />

Owner-Specific Articles on the ’98.5-’02 24-Valve Trucks<br />

24 5.9 HPCR Injectors/APPS/Leaks<br />

Owner-Specific Articles on the ’03-’07 5.9 HPCR Trucks<br />

30 6.7 HPCR SEMA and Performance Enhancements/Absurd<br />

Owner-Specific Articles on the ’07.5 and Newer Trucks<br />

38 Blowin’ in the Wind Chrysler’s Plans<br />

Industry News<br />

42 Technical Topics EPA/CARB and Deja Vu Again, Again<br />

Service/Parts Updates<br />

46 TDReview The <strong>2010</strong> Ram Heavy Duty Truck<br />

An Article or Product Review<br />

58 Four Whaling Not a Truck/Common Sense<br />

Journalist G.R. Whale talks about all things <strong>Diesel</strong><br />

60 Motor Minded Where Are the Keys/Getting Older<br />

Reflections on the Human Side with Psychologist Mark Barnes<br />

62 Idle Clatter Review of Problems<br />

A Review of Frequently Asked Questions by Jim Anderson<br />

66 Ranch Dressing <strong>2010</strong> Ram HD/Trailer Topics<br />

Esoteric Dissertations on Manure Shoveling by John Holmes<br />

72 Polly’s Pickup Maintenance<br />

A Feminine Perspective by Polly Holmes<br />

74 Celebrity Column The Cummins Show<br />

The Shadetree Mechanic/Sam Memmolo<br />

76 Have Ram Will Travel Performance Clutches/NV5600 Rebuild<br />

Joe Donnelly’s Truck and Travel Stories<br />

88 Chapter News Local Contacts<br />

Happenings at Local Chapters<br />

90 Outstanding in the Field <strong>May</strong> Madness <strong>2010</strong><br />

Upcoming Local Chapter Events<br />

92 TDR/R/R Referrals/High Mileage<br />

Referral/Recognition/Reward<br />

95 Earn Your Stripes Horsepower Recognition<br />

Recognizing Big Horsepower<br />

96 Travel Companion The Helpful Spirit<br />

Anonymous Listing of Helpful Members<br />

98 Backfire Swelling Oil<br />

Corrections, Clarifications, Crow Eating<br />

100 TDRV Towing/Storage/Wiring<br />

<strong>Turbo</strong> <strong>Diesel</strong> Perspective on RVs<br />

106 Shop Floor Problems Solved<br />

Tips From <strong>Turbo</strong> <strong>Diesel</strong> Repair Shops<br />

112 Product Showcase Edge’s Color Touch Screen<br />

Featured Products<br />

116 TDRelease New Products<br />

Vendor Press Releases<br />

118 Exhaust Note Smoke – The <strong>Diesel</strong> Lobby<br />

Thought-Provoking Discussions with Kevin Cameron<br />

122 Advertiser Index How to Contact<br />

TDR 67 www.turbodieselregister.com 3

THEME FOR ISSUE 67<br />

What did I ask our writers to talk about in Issue 67 Defining this<br />

issue’s theme deserves a few words of background. Therefore<br />

let me share the contents of a memo I sent our writers in early<br />

November, announcing an innovation that will enhance the<br />

information resources of our publication, and also alerting them to<br />

how we’ll put it into practice.<br />

This was my memo: “The staff has diligently worked to put Issues<br />

40 – 66 on the web site in digital format for access by any TDR<br />

member. The strength that this publication has always been its<br />

credibility and consistency. If you have a link/reference to a previous<br />

TDR article, please list it in your writing.<br />

“I told Joe Donnelly that he would be the picked-on example. In<br />

his Issue 66 article (specifically page 104), he wrote about water<br />

pumps. He did not tell the audience about coolant. Item 6 on page<br />

104 [an insertion about coolants] is the editor adding to the text.<br />

“So, the theme for Issue 67 is ‘Give a man a fish and you have<br />

fed him for a day. Teach a man to fish and you have fed him for a<br />

lifetime.’ Let’s teach ‘em to fish and use examples where you’ve<br />

(we’ve) taught the lesson many times before.<br />

There we have it, good reader: those were my editorial instructions<br />

to writers, which provided them their theme for Issue 67, and a<br />

watchword for TDR readers. For the past couple of years I have<br />

tirelessly beat the drum, calling on writers to cite specific material<br />

printed in previous issues of the magazine where we have published<br />

additional information about a topic. Now the task of providing for<br />

digital access to Issue 40 through the present issue is complete.<br />

In-depth articles are waiting for those with a thirst for knowledge.<br />

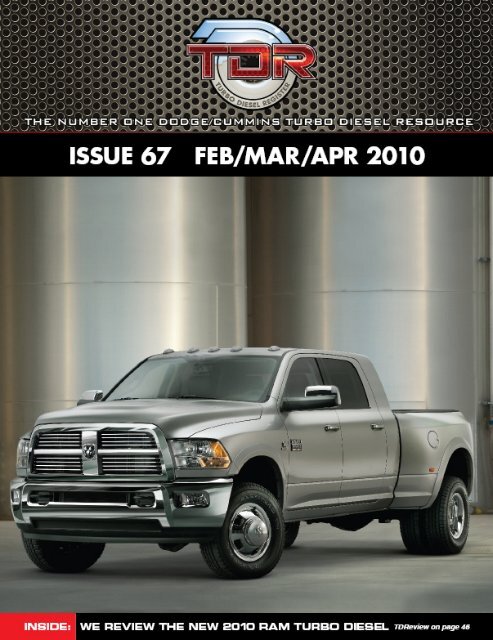

COVER OF THE TDR<br />

Since Issue 60 we’ve featured the artwork of Bob Pierce and Kelly<br />

Snyder on the cover of the TDR. Our project—TDR members having<br />

portraits of their trucks painted by Bob and Kelly and then featured<br />

on the cover—has proven to be popular. We’ve got two member<br />

trucks waiting to go on the cover, belonging to Shannon Garrison<br />

and to Mike Colosky.<br />

Are we in a holding pattern for getting your truck onto the cover<br />

Yes, as a matter of fact: holding. For this issue we have taken a<br />

time-out in the continuity of the popular artwork program, and are<br />

featuring a timely picture of the exciting new <strong>2010</strong> Ram Heavy Duty<br />

truck. You’ll read the enthusiastic reviews of this truck starting on<br />

page 46. Motor Trend has named it Truck of the Year. It is fitting to<br />

have the <strong>2010</strong> truck on the cover of Issue 67.<br />

ASK THE ENGINEER<br />

December 8, 2009, was a red-letter day in <strong>Turbo</strong> <strong>Diesel</strong> cyberspace.<br />

TDR hosted an online event, billed as “Ask the Engineer,” a live<br />

session wide open for an hour and a half to TDR members and<br />

their guests. Conceived by Dodge’s advertising agency, BBDO<br />

Detroit, this event gave our members and guests an opportunity<br />

to ask questions about the new <strong>2010</strong> Ram Heavy-Duty truck and<br />

get authoritative answers from professional engineers at Cummins<br />

and Dodge.<br />

The session was a huge success, getting such avid participation<br />

that for a week after the event itself, Dodge and Cummins<br />

personnel were still busy responding to questions. The magnitude<br />

of participation is a credit to everyone involved. As I pen these lines<br />

just before press time for this issue, TDR has received an e-mail<br />

from executives at BBDO expressing their appreciation for our role<br />

in the event: “Your forum,” they wrote, “is out of control…the level<br />

of activity rivals that of a traditional Jeep event, which usually outperforms<br />

Dodge (the pre “Ram” brand)…. TDR Forum members<br />

are incredible.” My thanks go out to everyone who worked behind<br />

the scenes dealing with a maze of technical issues to put the event<br />

together.<br />

The timing of “Ask the Engineer” placed the event after the deadline<br />

for proper reporting in this Issue. This is both bad and good.<br />

It’s bad because I would have liked to synopsize the responses<br />

from the “Ask the Engineers” session.<br />

But the good side is that I will have ample time to give you the<br />

full account in Issue 68, in the running story on the new <strong>2010</strong><br />

Ram truck. In the meantime, particularly if you are urgently in the<br />

market for a new truck, go to the TDR website and read the “Ask<br />

the Engineer” responses. TDR writer commentary begins on page<br />

46. Or you can cut to the chase and get down to your Ram dealer<br />

and drive that truck.<br />

<strong>2010</strong> TDR CALENDAR ERROR<br />

Yes, there is a Memorial Day in <strong>May</strong>. No it is not as listed in your<br />

<strong>2010</strong> TDR Calendar. Memorial Day is not 5/24. Please correct<br />

your calendar to read 5/31. Our apologies for the error. The other<br />

holiday dates in the calendar are correct.<br />

Robert Patton<br />

TDR Editor<br />

4 www.turbodieselregister.com TDR 67

THAT’S WHAT IT’S ALL ABOUT!<br />

I wanted to write and thank the TDR’s members for sharing their<br />

experiences with fuel transfer pumps. Specifically, I own a ’04.5<br />

truck with the transfer pump on the side of the fuel filter housing,<br />

and the articles in Issue 56 and 60 were the key to keeping me on<br />

the road.<br />

I was using my truck to move a trailer-load of household items to<br />

my Kansas City destination. The truck’s fuel pump started acting up<br />

on Interstate 70 outside of Columbia, Missouri. With a replacement<br />

pump in hand (I was ready for the inevitable with a Carter FPD<br />

4089602 in my “boonie box” of spare parts) and directions for the<br />

repair from Issue 60, I was able to continue my travels with only a<br />

minor interruption.<br />

I work in airline maintenance for UPS. At the age of 61 I did not find<br />

hanging over the engine to be a fun project, it took me about 1.5<br />

hours. However, the money and time saved were substantial.<br />

Thanks for the heads-up and the how-to instructions.<br />

Mark Hatfield<br />

Platte City, MO<br />

APRIL <strong>2010</strong> CALENDAR PHOTO<br />

Thank you so much for using my photo as the picture for <strong>April</strong> in<br />

the <strong>2010</strong> TDR Calendar.<br />

When I got Issue 66 in the mailbox, I felt like Ralphie from “Christmas<br />

Story” opening the mail. I was frantically ripping the plastic off looking<br />

for the calendar. The first thing I did was look at the back cover. I<br />

didn’t see it there, so now I knew it was all or nothing from that point.<br />

Then, there it was on the month of <strong>April</strong>. I’ve been talking about it<br />

to my family and smiling all weekend.<br />

I’ve never done anything such as this before. The dealership that<br />

owns the truck was very happy. They couldn’t believe it either. I<br />

took the calendar to show them and they had the old rig on the lift<br />

installing all new suspension bushings. They plan to keep it for a<br />

long time.<br />

Neil Costello<br />

Clinton, IN<br />

WANDERING ABOUT SECOND GENERATION<br />

I just purchased a ’01 Dodge dually, 4x4. The truck has 173,000<br />

miles on the clock. There is a lot of play in the steering and some<br />

wandering. I read the article about “Second Generation Alignment<br />

and Techniques” in Issue 53 but I’m still confused. I know you folks<br />

are not a repair shop, but thought maybe someone there might have<br />

an idea or experience with this issue. I thought about a Luke’s Link<br />

or even the Borgeson shaft. Before I sink a bunch of money into it<br />

I wanted to research my options. Thanks in advance for any ideas<br />

or suggestions.<br />

Ken Trissel<br />

Logan, OH<br />

Ken, there are many components that make the steering<br />

function correctly. I reread the Issue 53 article by Andy<br />

Redmond, and I can understand the questions that you have.<br />

But a problem with front suspension and steering needs to be<br />

addressed based on an inspection of the components. In other<br />

words, there is not a one-size-fits-all solution.<br />

I would start by putting the truck up in the air and inspecting<br />

then ordering replacement parts accordingly. I can note that<br />

the BD Steering Stabilizer is a good building block to reinforce<br />

the entire steering system.<br />

I am sorry this does not directly answer your question, but<br />

45 minutes with your truck in the air (and a friend helping<br />

you find what is sloppy and what is tight) is the key to a cost<br />

effective repair.<br />

However, the money and time<br />

saved were substantial.<br />

Thanks for the heads-up<br />

and the how-to instructions.<br />

6 www.turbodieselregister.com TDR 67

I think you will agree with me when I categorize <strong>Turbo</strong> <strong>Diesel</strong> owners<br />

as independent people who are not afraid to try something new.<br />

You are an ingenious membership who reinvents and improves<br />

a product to make it better serve your needs. You show a strong<br />

willingness to share your shadetree solutions. With your input each<br />

quarter, we publish the “Member2Member” exchange to give you a<br />

forum to tell other members how you solved a problem.<br />

SECOND GENERATION DASH COVER<br />

After watching the dash on my 2000 Ram slowly crack apart, I<br />

was interested in the dash cover offered by Geno’s Garage. After<br />

receiving the new dash cover and reading the vendor’s directions,<br />

I decided to improve the instructions by adding a couple of extra<br />

steps.<br />

THIRD GENERATION SEATBELT CHIME (REVISITED)<br />

Elsewhere in this issue you will read about the new <strong>2010</strong> trucks.<br />

As a part of the ride-and-drive experience I was reacquainted with<br />

the annoying seat belt chime. You see, using the directions from<br />

our Issue 62 magazine (page 9), the chime was turned off in my<br />

’07.5 truck.<br />

To save you searching for the instructions on how to turn the chime<br />

off, I will reprint the article:<br />

Somewhere between my old ’03 truck and my new ’07.5, the<br />

Chrysler engineers programmed an annoying seatbelt chime. It is<br />

annoying to me because I know that I’ll get the seatbelt fastened<br />

before I hit the road. But when I’m driving around to hook-up the<br />

trailer or putzing through the shopping center/subdivision, the<br />

seatbelt chime is bothersome.<br />

How do you turn the chime off TDR writer John Holmes was helpful<br />

and he put me in touch with his technician friends at Carson Dodge.<br />

The following is the turn-off procedure.<br />

• Close all doors to the truck<br />

• Insert key into ignition switch—leave key in the “off” position<br />

• Buckle the driver’s seatbelt<br />

• Turn the key to the “on” position<br />

• Wait for the seatbelt warning light to turn off<br />

• Start the vehicle. You now have about 30 seconds to perform<br />

the next series of steps to program the chime-off.<br />

• Within 10 seconds, unbuckle and buckle the seatbelt at least<br />

three times ending up with the seatbelt in the buckled position.<br />

• Turn off the engine and a single chime will let you know that<br />

you’ve silenced the chime.<br />

Robert Patton<br />

TDR Staff<br />

Tools and supplies that are needed.<br />

First, because of the extensive cracking in my dash, the cracks which<br />

were accessible were repaired with JB Weld “Kwik.” This product<br />

is exactly what it says, quick, so be ready when you mix it. I did my<br />

repairs with three small batches rather than one large one.<br />

8 www.turbodieselregister.com TDR 67

Member 2 Member . . . . Continued<br />

Third, dry-fit the cover to the original dash and be prepared to do<br />

some minor trimming with a box knife or sandpaper to obtain the<br />

best fit.<br />

Fourth, for better adhesion, lightly sand the areas where adhesive<br />

is to be applied, and then follow with window cleaner. This applies<br />

to both the original dash and the new cover.<br />

Fifth, apply the adhesive supplied with the cover and follow the<br />

manufacturer’s instructions. I used several bricks to hold the cover<br />

down during curing of the adhesive. Masking tape can be used to<br />

secure the edges.<br />

I was very pleased with the results. It is not often that a product<br />

exceeds your expectations, but this was definitely the case for me.<br />

Second, a ½” diameter hole saw was used to make access holes<br />

in the new cover where the factory screws hold the original dash<br />

to the body just below the windshield. If you ever have to remove<br />

the dash in the future, this will be time well spent.<br />

David A. Pratt<br />

Bardstown, KY<br />

TDR 67 www.turbodieselregister.com 9

I have often lamented that as a society we don’t properly honor the<br />

inventiveness and achievement of our elders. So let us give that<br />

bygone achievement some proper and regular observance in our<br />

pages in the “10 Back” column.<br />

In each installment of the “10 Back” column I will reprise the<br />

accomplishments of TDR trailblazers by recalling an article still as<br />

relevant in today’s <strong>Turbo</strong>-<strong>Diesel</strong> world as it was the day it was written.<br />

Ten-year-old article reprints will then be posted in the magazine<br />

archives section of the TDR web site.<br />

So, without further ado, we present our look back at February 2000.<br />

My, how time flies!<br />

Issue 27 – February, March, <strong>April</strong> 2000<br />

Wait. Hold on. It is February 2000. From the looks of TDR Issue<br />

27 we made it past the Y2K debacle unscathed. Wow, that was<br />

close.<br />

All cynicism aside, do media outlet(s) ever take responsibility for<br />

the misguided information that they parade around as news<br />

Wait. Hold on. It is “10 Back,” and this is a technical journal for<br />

<strong>Turbo</strong> <strong>Diesel</strong> owners. Focus, focus.<br />

• On the cover was TDR member Jim Carney’s First Generation<br />

truck. The photograph was taken by TDR writer G.R. Whale at<br />

the TDR Nationals in Columbus, Indiana. Jim’s truck is featured<br />

in the First Generation column and writer Whale reminds us<br />

that without the enthusiasm of the First Generation owner we<br />

would not be ushering-in the G4 truck, nor would there be a<br />

TDR magazine.<br />

• TDR writer Andy Mikonis was one of the first to tour the Walter<br />

P. Chrysler museum at Chrysler’s headquarters in Auburn Hill,<br />

Michigan. The museum opened on October 5, 1999. Should<br />

you be in the metro Detroit area, the museum is well worth<br />

your time.<br />

• John Holmes writes in to report his discovery of how to make a<br />

4x4 into a 4x2 in low gear (disable the front axle lock up when<br />

in 4 LOW). We’ve got aftermarket kits that do exactly as John<br />

suggested way back when. He also gave us the heads-up on<br />

using a throttle feather-switch to activate an exhaust brake on<br />

the 24-valve engines. The factory “on” for the new 24-valve<br />

engine was to wire into the throttle position switch circuitry.<br />

This method causes a two-second time delay in the activation<br />

of the brake. With the feather-switch you get instant on.<br />

• The magazine was seeing more and more reports of<br />

performance diesels and diesel drag racing. Long-time TDR<br />

member Chris Timochko and supporting vendor Auto Wurks<br />

<strong>Diesel</strong> (Mike Primamore, Caldwell, NJ, www.autowurksdiesel.<br />

com) sent in a report about their trip to the US <strong>Diesel</strong> Truckin’<br />

Nationals at the drag strip in Englishtown, NJ. Chris logged-in<br />

a 15.54 second run and Mike a 12.73. Jeff Prince, Chapman<br />

Ranch, Texas, was racing in Texas and doing 12.98 seconds<br />

in his 3500 <strong>Turbo</strong> <strong>Diesel</strong> truck.<br />

There are formulas one can use to calculate the horsepower<br />

needed to move “x” pounds down the ¼-mile in a given time:<br />

Using Elapsed Time Using Miles Per Hour<br />

HP = weight HP = (mph ÷ 234) 3 x weight<br />

(ET÷5.825) 3<br />

Doing the math, Mike was at 605hp, Chris at 456hp, and Jeff<br />

at 587hp. Ten years ago these were (and still are) impressive<br />

numbers for 12-valve engines.<br />

• Writer Scott Dalgleish was busy making modifications to his ’98<br />

truck with the 12-valve engine. A Dr. Performance fuel pump<br />

was added (good for 358 horsepower at the rear wheels) and<br />

a McLeod clutch was installed.<br />

• As is the norm, a new TDR member was having trouble<br />

understanding the sermon about performance enhancements<br />

and warranty. So, repeat after me, a modification to your vehicle<br />

and/or engine does not invalidate your warranty; however, it<br />

does put your rights to warranty in serious jeopardy.<br />

The owner was concerned that his ’98 truck with a GCW of<br />

21,000 pounds was slowing down too much on steep grades.<br />

Remember back then the automatic trucks offered 180hp/420<br />

torque. We used a Cummins computer program to simulate<br />

the load and show that the maximum speed on a 5% grade<br />

was 39mph in third gear. If you have an Issue 27 close by the<br />

“TDResource” column is an interesting reread.<br />

• Jim Anderson files a report on his first travel adventure to<br />

Alaska. If you’ve considered a trip to Alaska you may want<br />

to read about Jim’s first trip (the ’99 travels in Issue 27) and<br />

second trip (his ’03 travels in Issue 42). Alternately, Jim will<br />

correspond with you at his e-mail address j.t.anderson@<br />

worldnet.att.net. (Same address as it was in 2000, don’t you<br />

appreciate stability)<br />

The last comment on stability kind of sums-up the TDR<br />

experience—a consistent message that you can count on.<br />

Robert Patton<br />

TDR Staff<br />

10 www.turbodieselregister.com TDR 67

Coverage of the ’89 through ’93 Model Trucks.<br />

Web Site Correspondence Edited by Bill Stockard<br />

and additional Q&A written by Joe Donnelly.<br />

INJECTION PUMP FUEL LEAK<br />

There is a small, but persistent, fuel leak on the back side of the<br />

injection pump near the timing plug on my ’93 <strong>Turbo</strong> <strong>Diesel</strong> D250.<br />

On the back side of the injection pump, in between the six injector<br />

lines, is a big fitting with a smaller plug in the middle of it. There is a<br />

leak around this fitting and it is not coming from the injector lines.<br />

I removed the small plug and replaced the brass washer, but it didn’t<br />

stop the leak. Has anyone removed the big fitting and what seals<br />

it to the injection pump<br />

Mad Max, Peyton, CO<br />

My injection pump was leaking from there too. If you don’t have the<br />

special tool, one of the large gator grip sockets will remove it.<br />

It is sealed with an O-ring and the fitting can be removed without<br />

parts falling out while the injection pump remains on the engine. I<br />

resealed all the main parts of the injection pump with a seal kit from<br />

Bosch, including that one, and it solved my problem.<br />

pepecat, Sacramento, CA<br />

I used a slightly modified 12 point socket and tightened it to 55<br />

ft-lbs torque.<br />

Greenleaf, Ashland, OH<br />

ERRATIC FUEL GAUGE<br />

The fuel gauge on my ’93 <strong>Turbo</strong> <strong>Diesel</strong> D250 has become erratic<br />

after 253,000 miles. The indicator does not go past the full mark<br />

as previously, moves around more, and appears to settle after<br />

about 15-20 miles after the tank is filled. All other electrical gauges<br />

perform normally.<br />

Is the fuel sender in the tank How difficult is it to replace What<br />

should I check first<br />

Bluebird, San Bernardino CA<br />

The fuel sender is part of the fuel tank module and is located in<br />

the fuel tank. There are two ways to access the fuel tank module.<br />

Either remove the pickup box or lower the tank. Removing the box<br />

makes it easier to see the fuel lines to remove them from the fuel<br />

tank module, which can be difficult. Also, when removing the box,<br />

it isn’t necessary to drain the fuel tank before attempting to lower<br />

it. Disconnect the fuel lines and the wires at the connecting plug.<br />

Remove the big lock ring by unscrewing it and remove the module<br />

with the sender. The module holds fuel in the bottom half.<br />

While the module is out, it’s a good time to check the strainers for<br />

debris and clean them. One fuel screen is clipped on the bottom<br />

and one is inside the module.<br />

You can continue to drive the truck without a fuel gauge as long<br />

as you keep up with the mileage between fills. I replaced mine<br />

because I was going on a trip and wanted to know how much fuel<br />

was in the tank.<br />

PToombs, Minoa, NY<br />

SMOKE FROM THE STEERING COLUMN<br />

The air conditioner in my ’92 <strong>Turbo</strong> <strong>Diesel</strong> has been running almost<br />

constantly this summer. Recently, I noticed smoke from the steering<br />

column and the bottom cover was very hot. I traced the overheated<br />

wiring to the ignition switch supply wires, which are the 12-gauge<br />

red and the pink wire with black tracer. There is a 12-gauge black<br />

wire with pink tracer that powers the A/C blower motor and power<br />

window circuit through the ignition switch.<br />

In order to lower the current draw on the ignition switch power feed<br />

wires, I disconnected the black/pink tracer wire from the connector at<br />

fuse number 11 and 12. I soldered on a signal wire and connected<br />

it to a relay I mounted under the hood. I connected a 10-gauge wire<br />

to the relay output and connected that to the fuse terminal to power<br />

fuse number 11 and 12. I used a 10-gauge wire with a 30-amp inline<br />

fuse from battery to power the relay. With this change, the ignition<br />

switch signals the relay, and the switch and wiring are not overloaded<br />

powering the A/C blower motor and the power windows.<br />

Thanks to TDR member Philip for help in locating the schematic of<br />

the A/C blower motor power feed on page 8w-53 of the ’92 Factory<br />

Service Manual.<br />

Greenleaf, Ashland, OH<br />

DASH LIGHT BULB COVERS<br />

I’ve replaced several burned out dash light bulbs on my ’93 <strong>Turbo</strong><br />

<strong>Diesel</strong> D250. One of the bulb covers has been slightly burned from<br />

heat and the plastic has shrunk and won’t remain on the bulb. I<br />

cannot find these covers at the auto parts stores. Is this a dealer<br />

only part I don’t want to search the salvage yards unless it’s a<br />

last resort.<br />

BarlowCummins, Boise, ID<br />

The bulb covers are available at Radio Shack in various colors.<br />

KOG<br />

A good paint pen or magic marker will color the bulbs permanently<br />

and won’t fall off.<br />

JLEONARD, Torrington, CT<br />

12 www.turbodieselregister.com TDR 67

FIRST GENERATION . . . . Continued<br />

FUEL TANK FITTINGS<br />

When replacing all of the steel brake lines and hoses on my ’91<br />

<strong>Turbo</strong> <strong>Diesel</strong>, I removed the fuel tank in order to replace the brake<br />

line behind the tank. After removing the tank, I discovered that the<br />

steel supply and return fuel lines were rusted and decided to replace<br />

those also. On the top of the fuel tank module, the supply line fitting<br />

is plastic and is a quick-disconnect type fitting that appears to be<br />

in good condition. However, the return line fitting is metal and is<br />

rusted beyond recognition.<br />

NO WASTEGATE PRESCRIPTIONS FOR POWER<br />

I recently purchased a ‘93 <strong>Turbo</strong> <strong>Diesel</strong> with 155,000 miles which is<br />

very low on power. Recently on a long trip I could barely hear the<br />

turbocharger. I checked the air cleaner element for induction leaks<br />

or a stuck-open wastegate, except there is no wastegate! How is<br />

turbo boost regulated I see a small hose that runs from the head<br />

to what appears to be a diaphragm housing on top of the injection<br />

pump. Is that how it’s done<br />

WHendrix, Monroe, GA<br />

The line from the head to the injection pump is the boost reference<br />

line for the aneroid valve to control low/no boost smoke. If the<br />

line has a leak or there is a pinhole in the diaphragm, it will feel<br />

sluggish because boost never builds to increase fueling. Start with<br />

the aneroid, star wheel adjustment and fuel pin adjustment and see<br />

if that makes a difference.<br />

cerberusiam, McDonough, GA<br />

A ‘93 <strong>Turbo</strong> <strong>Diesel</strong> uses an 18.5-cm turbine housing which should<br />

make 14-16 psi of boost. A ‘92 will have a 21-cm housing which<br />

will make 13-15 psi of boost. A smaller 16-cm housing will add 1.5<br />

to 2 psi of boost over the 18.5-cm and about 3 psi over the 21-cm<br />

housing. I prefer a 14-cm housing for best overall performance.<br />

Check that little air line from the head to the Air Fuel Control (AFC).<br />

If it has a leak, the power will be down.<br />

glhs, Cheyenne, WY/Brighton, CO<br />

Is the return fitting available from the dealer If not, is there a<br />

suitable aftermarket replacement<br />

ro23j, MD<br />

To remove the rusty one, push in on the plastic piece on the end<br />

to release it. While pushing the fitting on, push the release clip<br />

in, and pull out. Go to the junkyard and purchase a replacement<br />

plastic fitting which are the same for a Dodge Caravan, Jeep, and<br />

gasoline powered trucks. Check the size for either ¼-inch or 5/16<br />

-inch. The newer fittings will have a square hole on each side for the<br />

clip to release, but should hook right up. However, you may need to<br />

purchase new clips for them. New replacement fittings are available<br />

at automotive parts stores. I saw them at my local CARQUEST and<br />

they looked the same as yours.<br />

PToombs, Minoa, NY<br />

CRANKSHAFT SENSOR<br />

I need to replace the crankshaft sensor on my ’93 <strong>Turbo</strong> <strong>Diesel</strong><br />

W250. I’ve checked all the local automotive parts stores, AutoZone,<br />

NAPA, Parts Plus, Advanced, and Auto Value. Many did not have<br />

the part listed and a couple tried to sell me the wrong part. The<br />

Dodge dealer can get me one for $140, which I thought was a lot<br />

for such a simple sensor.<br />

MOstrowski, Bath, MI<br />

Try a Cummins dealer. The original Cummins part number was<br />

3920360. It’s been changed to 3924432.<br />

Shadrach, Edmonton, AB<br />

Editor’s note: Often the new owner of a used First Generation<br />

truck is overlooked in the pages of the TDR. I could spend<br />

pages explaining all of the reasons, but I will refrain and stick<br />

to the subject. Back in Issue 42 the late TDR member Bob<br />

Coe wrote an 8 page article with everything that a new First<br />

Generation owner would want to know. Since Issue 42 is no<br />

longer available in print (it is in your web site TDR archives),<br />

we’ve added that 8 page article to the <strong>Turbo</strong> <strong>Diesel</strong> Buyer’s<br />

Guide that is also found at the TDR’s web site. The evergreen/<br />

updated Buyer’s Guide book is now over 200 pages. The article<br />

to look for is appropriately titled “Prescriptions for Power.”<br />

FAN CLUTCH<br />

What is the best way to remove the fan clutch from my <strong>Turbo</strong> <strong>Diesel</strong><br />

without the factory recommended tool I think the threads are lefthanded.<br />

I have tried using a crescent wrench and a hammer, but<br />

is there a way to hold the pulley<br />

BIGTOMMY<br />

To hold the pulley, I used a large set of channel locks on two of<br />

the bolts. Or, you can use a strap wrench on the pulley. I tried the<br />

crescent wrench and hammer without success. I thought it must<br />

be seized. After I purchased the proper wrench from Snap On for<br />

about $60, it came off easily without the need for a hammer. Save<br />

yourself the headache and get the wrench. I have heard that there<br />

is also a fan clutch wrench that you can purchase at NAPA and it<br />

is supposedly less expensive.<br />

DonPeterson<br />

TDR 67 www.turbodieselregister.com 13

Coverage of the ’94 to ’98 Model Trucks (12-valve engines).<br />

Web Site Correspondence Edited by Bill Stockard<br />

and additional Q&A by Joe Donnelly<br />

OIL PAN DRAIN PLUG AND DUALLY VALVE STEM<br />

EXTENSION ADVICE<br />

The oil pan drain plug on my ’97 <strong>Turbo</strong> <strong>Diesel</strong> 3500 is leaking. Does<br />

anyone use the Fumoto “finger touch” oil drain plug I don’t want<br />

to continue to remove the plug to drain oil in case the threads in<br />

the pan have become worn.<br />

Also I need valve stem extensions for my dual rear wheels. I have<br />

a double sided long stem tire gauge and air hose chuck, but it is<br />

difficult getting into the inner wheel with the trim rings and hub caps<br />

in the way. Is anyone using them<br />

Dave M, Ahwahnee, CA<br />

I installed the Fumoto oil drain plug in 2001 and have had no<br />

problems with it.<br />

Gene Arnold, Boise, ID<br />

I used the brass EZ Change oil drain on my ‘03 <strong>Turbo</strong> <strong>Diesel</strong> and<br />

the oil was changed at least 40 times. It was still working well when<br />

I sold the truck. It made oil sampling easy. It also has a lower profile<br />

than the Fumoto finger touch drain. The drawbacks were that it cost<br />

more than the Fumoto drain plug and I had to keep up with the drain<br />

hose. Overall I was happy with the EZ Change.<br />

GaryOwen, Knoxville, TN<br />

I have a Fumoto finger touch drain plug from Geno’s. It has worked<br />

flawlessly for somewhere around 100 oil changes. For this plug<br />

to drain the pan completely, it is necessary to drill the threads so<br />

that all the oil will drain from the pan; otherwise about a quart will<br />

not drain. Remove the factory plug and wait for all the oil to drain.<br />

Find the four drain holes in the threaded nut that is inside the pan<br />

which allows the oil to completely drain. Mark the bottom of the pan<br />

where the holes are located and install the new finger touch plug,<br />

tightening it to specification. Mark the new plug with the location<br />

of the holes and remove it. Cross drill the threads to correspond<br />

to the holes and install the new plug again. You will never need to<br />

remove a drain plug again.<br />

I use valve stem extensions on my dual rear wheels too. The<br />

extensions you use are not as important as replacing the original<br />

equipment rubber valve stems with metal stems. The rubber stems<br />

flex with an extension attached and will fail while going down the<br />

road.<br />

GAmes, Killeen, TX<br />

BLUE-WHITE EXHAUST SMOKE<br />

While driving my ’95 <strong>Turbo</strong> <strong>Diesel</strong> I noticed blue-white smoke from<br />

the exhaust when I slowed for a stop light. When I took off from<br />

the stop light, I expected to see black smoke, but the smoke was<br />

light colored again. On the drive home I noticed a continuous light<br />

colored smoke/haze from the tail pipe. Does this indicate a blown<br />

head gasket<br />

tmassey, Central CA<br />

Have an assistant “blip” the throttle with the engine running while<br />

parked. Stand near the tailpipe and smell the exhaust to determine<br />

if it’s oil, fuel or antifreeze causing the smoke. Fuel will make a rich<br />

stinky cold diesel smell, oil will smell like burning oil, and we all<br />

know the stench of antifreeze.<br />

When my ‘98 <strong>Turbo</strong> diesel began hazing light smoke from the<br />

exhaust pipe, I had someone put the automatic transmission in<br />

Drive while holding the brake and give it a little throttle while I stood<br />

outside to do a smell test. The exhaust gas smelled like burning oil<br />

mixed with normal diesel engine exhaust. The smoke was caused<br />

by a defective turbo bearing.<br />

Vaughn MacKenzie, Tri-Cities, WA<br />

I found the problem. It was a leaking turbo caused by too much<br />

turbo end play which damaged the seal.<br />

tmassey, Central CA<br />

PLACING THE CYLINDER HEAD BACK ON THE BLOCK<br />

When I removed the cylinder head from my ’98 <strong>Turbo</strong> <strong>Diesel</strong> 2500<br />

with a cherry picker and a screw type leveling bar with a chain<br />

attached to the factory lift tabs, the head came out with the back of<br />

the head dragging along the block. What method can I use to get<br />

the head to go in level and get it under the cowl<br />

LVJUNIOR, Las Vegas, NV<br />

I had a friend help me. One on each side and set it down straight.<br />

It’s not easy because of the weight.<br />

hsmith, Texas Hill Country<br />

Use a chain wrapped around the exhaust manifold all the way to<br />

the back and the other end on the factory lift bracket on the front.<br />

Pick it up at an angle with the back down.<br />

<strong>Diesel</strong>demon, Montague, CA<br />

I used ratchet straps. They are easy to adjust and can easily handle<br />

the weight. Once I got the head in position, I set a couple of head<br />

bolts just into the threads and used them as guides to lower it on<br />

the block to avoid scuffing the gasket.<br />

McCRam, Central MT<br />

14 www.turbodieselregister.com TDR 67

12-VALVE ENGINES . . . . Continued<br />

LEAKING HEADGASKET<br />

I am replacing the headgasket on my ‘94 <strong>Turbo</strong> <strong>Diesel</strong> with over<br />

315,000 miles on it. My truck is a daily driver and I don’t need a big<br />

increase in power. I’ve owned the truck since it was new and the<br />

engine has never been opened up. What work should I consider<br />

doing to the engine while the head is off<br />

dstafford<br />

I would have the head checked for cracks, flatness, and a valve<br />

job. Make sure they can resurface the head surface to the proper<br />

smoothness.<br />

hsmith, Texas Hill Country<br />

From my experience, I’d do nothing inside the engine. I’d make sure<br />

the mating surfaces are flat. Install new valve seals and heavy duty<br />

valve springs if you are planning on adding some performance to<br />

the engine by using a P7100 fuel pump and a Governor Spring Kit.<br />

I doubt that a valve regrind is needed, but it wouldn’t hurt. Anything<br />

else is optional.<br />

GAmes, Killeen, TX<br />

ENGINE SUDDENLY DIES AND STARTER DOESN’T WORK<br />

As I was driving my ’96 <strong>Turbo</strong> <strong>Diesel</strong> 3500 into the garage, the<br />

engine suddenly died like I had turned the key off. There was no<br />

sputtering like out of fuel, and there was plenty of fuel in the tank.<br />

When I turned the key to run, all systems were functioning normally,<br />

but when I turned the ignition switch to start, there was no sound from<br />

the starter. No service work has been done on the truck recently<br />

and the engine has been running normally for a long time.<br />

LWilliams, Beckville, Texas<br />

If the starter isn’t turning, check the starter relay and fuse in power<br />

distribution center (PDC). Usually when an engine dies suddenly,<br />

it is because the fuel shut off solenoid has failed. It is pretty easy<br />

to check.<br />

Missouri Mule, Winter Park, FL<br />

Connect a battery charger on the batteries for a few hours and see<br />

if anything changes.<br />

SRadke, Corvallis, OR<br />

Accidentally, I discovered the problem. I sat in the seat and tilted<br />

the steering wheel all the way down and turned the ignition switch<br />

to start. The starter cranked and the engine started and ran. I tilted<br />

the steering wheel up and the engine died. Under the steering<br />

wheel below the key switch is a wire harness connection. I found<br />

two wires had broken from tilting the steering wheel over the years.<br />

The wires would touch when the steering wheel is tilted down and<br />

pull apart when the wheel tilted up. It was an easy fix to connect<br />

the wires and plug them into the connector.<br />

LWilliams, Beckville, Texas<br />

I also had a mysterious electrical problem. I discovered a tiny wire<br />

protruding from under the steering wheel. I removed the knee board<br />

and the steering column cover and there were two wires broken<br />

off at a multi-wire junction of about eight wires, on the right side<br />

just behind the steering wheel. This junction plugs into a receiver<br />

about three inches long. I pushed the pins out, reattached the wires,<br />

plugged it back together, and everything works again.<br />

It was an easy fix but all the wires alongside the steering column<br />

are showing wear which appears to be caused by the tilt steering<br />

wheel. I found where the dealer had fixed a couple of problems<br />

back when the truck was still in warranty. They used the blue wire<br />

clips that are good for a quick repair, but will eventually fail. I may<br />

be replacing the wire harness.<br />

Al Smith, Marietta, GA<br />

REMOVING THE ENGINE<br />

What is the best way to remove the engine in my ’98 <strong>Turbo</strong> <strong>Diesel</strong><br />

4X4 Is it necessary to lift the cab<br />

love-horsepower, Des Moines, IA<br />

No, it isn’t necessary to lift the cab. You should get a Clymer or Chilton<br />

repair manual, if you do not have one. Disconnect the batteries, label<br />

the engine to chassis wiring, and disconnect. Remove the radiator<br />

for extra clearance. If it has an auto transmission, remove the flex<br />

plate to torque convertor bolts. Disconnect the exhaust pipe, remove<br />

the starter, intake, heater hoses, fuel lines, throttle cable, etc.<br />

JDKammin<br />

Remove the front bumper and radiator and it will come right out.<br />

Place jacks on the frame under the cab for oil pan clearance.<br />

champspa, Chester, VA<br />

REMOVE ROLLOVER VALVE<br />

While working on a hard-to-start problem on my son’s ’96 <strong>Turbo</strong><br />

<strong>Diesel</strong>, we went through the entire fuel delivery system and fixed<br />

all the leaks following TDR member Joe George’s instructions. The<br />

scope of work included both supply and return lines, pre-heater, prefilter,<br />

hose-on-pump, and inside the fuel tank. We tried to remove<br />

the rollover valve and could not get it out and now it leaks fuel when<br />

tank is filled. I am hesitant to try to seal it. How do I remove the<br />

rollover valve from the fuel tank<br />

Al Fischer, Fresno, CA<br />

You will need two screwdrivers and four hands to pry it up. It is<br />

difficult, but it will come out. When you had the fuel tank module<br />

out, did you check the fuel lines in it When I had a hard start and<br />

low power at high RPM, I found that one of the screws that hold the<br />

module halves together had rubbed a hole in the fuel pick-up line.<br />

Check it closely since the hole is hard to see.<br />

ata, Sandlake, OR<br />

We never succeeded in removing the rollover valve after pulling and<br />

prying. We were afraid of breaking it. We will order a replacement<br />

valve and grommet from the dealer and will replace it when we drop<br />

the tank. The truck runs fine with no more hard starting problems<br />

and only leaks fuel if the tank is topped off.<br />

Al Fischer, Fresno, CA<br />

Editor’s note: Hard-to-start problems are often difficult to trace.<br />

But, thankfully, the TDR membership has chronicled many of the<br />

problems and solutions. For an excellent review of the fuel-toengine/low<br />

pressure part of the fuel system please reference the<br />

<strong>Turbo</strong> <strong>Diesel</strong> Buyer’s Guide at the TDR web site. The evergreen/<br />

updated book is now over 200 pages. The six-page article to<br />

look for is “Low Pressure Fuel System Problems.”<br />

TDR 67 www.turbodieselregister.com 15

12-VALVE ENGINES . . . . Continued<br />

VALVE JOB<br />

I have 110,000 miles on my engine and the cylinder head is off<br />

and at a shop. I plan to have it checked for cracks and resurfaced.<br />

The shop recommends that I get a valve job also. What is your<br />

advice<br />

Cody Sanders<br />

I recommend getting a valve job. You will probably find that the<br />

intake valves have pounded into the seats, and the exhaust valve<br />

faces have pitting. You could run the engine longer with the original<br />

valve facings, but your engine will benefit (and give more power)<br />

from a quality valve job. Be sure the surface on the head is as<br />

smooth as it was from the factory or it won’t seal. You should not<br />

need O-rings or fire rings to seal with moderate timing (up to 20<br />

degrees) and boost (under 60 psi). Just get a new stock head gasket<br />

(stock .060” thick is 3283335; .070” is 3283337; .080” is 3283339)<br />

and be sure the block surface is super clean, and the bolt holes<br />

have been mopped out with Q tips so nothing will be forced onto the<br />

deck when you screw in the bolts (lightly oiled). If the head is flat<br />

(less than .002” warp) and there is no erosion at the cylinder sealing<br />

bead areas, it doesn’t need to be resurfaced. If you are planning to<br />

replace the governor springs on the P7100 to get more rpm, have<br />

the shop install the 60 psi valve springs (on all 12 valves). These<br />

springs are available for exhaust brake usage from Cummins, BD<br />

Power, and PacBrake.<br />

Joe Donnelly<br />

AFC BREAK-OFF SCREW SIZES<br />

What are the thread sizes and lengths of these screws When I<br />

adjust my AFC I want to get button head Allen screws to replace<br />

them. Thanks,<br />

CTD12V<br />

The screw holding the stamped steel cover is M6 x 1.0 x 8 mm. The<br />

screws for the halves of the AFC at the diaphragm can be replaced<br />

with M6 x 1.0 x 12 or 14 mm. The break-off screw holding the AFC<br />

to the pump governor is M6 x 1.0 thread, 16 mm long. You can use<br />

an 18 mm long screw there if you want.<br />

Joe Donnelly<br />

P7100 INJECTION PUMP STARTING PROBLEM<br />

My father’s 1995 <strong>Turbo</strong> <strong>Diesel</strong> will not start unless I use starting<br />

fluid. It runs okay once it starts. Cracking open a line gives fuel<br />

but it doesn’t seem to be high enough pressure to pop the injectors.<br />

Is the P7100 pump failing<br />

TBurow<br />

Check the shutdown solenoid. If it is not pulling the lever on the<br />

side of the pump to full open, you may not be getting enough fuel<br />

to start the engine. TST offers a fitting that replaces the bleeder<br />

screw on top of the fuel filter. You can thread a compression fitting<br />

adapter into it to use a pressure gauge, such as a boost gauge, to<br />

check lift pump pressure. You will not be able to tell the pressure<br />

of the fuel being forced into the injector when you open a line and<br />

check that way.<br />

Joe Donnelly<br />

HOW TO FIX INCORRECTLY MACHINED<br />

FIRE RING GROOVES<br />

I measured the fire ring grooves cut by the machine shop, and found<br />

that the diameters varied and were all too large. Groove widths<br />

also varied +/- 0.005” from the correct width. How can I salvage<br />

my brand new ported head<br />

LVJUNIOR<br />

Probably the best fix would be to mill the head as needed to remove<br />

the grooves; about .020” to .030” deep is probably needed. Use<br />

the Cummins 3283339 gasket which is .020” thicker, either a stock<br />

gasket or a Haisley fire ring gasket. It is okay to sink the valves a<br />

little and to reface them to get maybe another .010” valve inset if<br />

need be. You would like to keep at least .060”, and .080” or more<br />

valve-to-piston clearance (at top dead center, overlap cam lobe<br />

position). Stock valve inset is about .050” to .055” from the head<br />

surface. If you choose another fire ring gasket, get the grooves cut<br />

to meet Haisley’s specifications. I suggest Kells Automotive in Las<br />

Vegas, since you live there. They also know how fine a finish you<br />

need on the head surface. Most shops use far too rough a surface<br />

finish and often the gasket won’t seal well.<br />

Joe Donnelly<br />

P7100 FUEL SHUTDOWN<br />

How does the fuel shutdown shaft on the P7100 actually work,<br />

internal to the pump<br />

KEdenfield<br />

Internally, the shutdown lever takes the fueling rack to zero travel.<br />

At this point, the plungers are rotated to stop fueling through the<br />

barrels to the injection lines.<br />

Joe Donnelly<br />

SLOW CRANKING<br />

The engine cranks over slowly. I have replaced the starter<br />

contacts.<br />

MDEVENS<br />

It is likely that either your starter is having more problems, or one<br />

battery is dead (often the passenger side).<br />

Joe Donnelly<br />

BAD HARMONIC BALANCER<br />

My harmonic balancer is separating at the rubber ring. What years<br />

of balancers will fit my 1996 <strong>Turbo</strong> <strong>Diesel</strong><br />

TBurow<br />

There were two stock 12-valve dampers (balancers). The 215hp<br />

engines use a larger diameter one. Any 12-valve engine can use<br />

the big one; the crank sensor can be moved into position for either<br />

size.<br />

Joe Donnelly<br />

16 www.turbodieselregister.com TDR 67

12-VALVE ENGINES . . . . Continued<br />

TURBO INTERCHANGE<br />

Can the stock turbocharger from a 2005-2007 <strong>Turbo</strong> <strong>Diesel</strong> be<br />

fitted to a modified 1996 <strong>Turbo</strong> <strong>Diesel</strong> and give better spool up or<br />

reduced EGT<br />

GUY SILVEIRA<br />

This swap is not practical for several reasons. First, the later<br />

turbocharger is not enough of an upgrade to be useful for your<br />

application. Second, the compressor outlet is 2.75” and set up for<br />

a hose, whereas your compressor outlet is 3” and set up for an<br />

aluminum elbow, O-ring seal, and V-band clamp retention. Third,<br />

the exhaust outlet is much larger than yours. Yours is 3” OD and<br />

the late turbo outlet is near 5” OD. You would need to work up an<br />

adapter and elbow to use with your 3” exhaust pipe.<br />

Joe Donnelly<br />

AUTOMATIC TRANSMISSION SHIFTING PROBLEM<br />

I purchased a 1997 <strong>Turbo</strong> <strong>Diesel</strong> two months ago. The truck<br />

works well in reverse but it goes forward in 3rd gear; no first<br />

gear, overdrive, or lockup. The truck will take off in 2nd if you<br />

manually shift it. A transmission shop replaced the solenoids and<br />

powertrain computer module. What else can I try to fix the problem<br />

Chris Pulice<br />

Do your tachometer, air conditioning, and charging system work If<br />

not, usually it is a bad crank sensor. If they work, the crank sensor<br />

is okay. Then check the vehicle speed sensor, and the transmission<br />

output sensor.<br />

Joe Donnelly<br />

TDR 67 www.turbodieselregister.com 17

Coverage of the ’98.5 to ‘02 Model Trucks (24-valve engines).<br />

Web Site Correspondence Edited by Bill Stockard<br />

and additional Q&A by Joe Donnelly<br />

BALL JOINT REPLACEMENT TIP<br />

I recently replaced the ball joints on my ’01 <strong>Turbo</strong> <strong>Diesel</strong> 2500.<br />

The left side had never been replaced. I tried everything I could to<br />

remove it. Since the ball joint was worn out, I decided to use my<br />

reciprocating saw to cut the studs. In about three minutes, I had<br />

the studs cut and the hub and steering knuckle on the ground.<br />

I cut blocks of wood to support the knuckle off the ground so I could<br />

hammer straight down, and with no obstructions to bounce off of,<br />

it fell right out. Obviously this method of removal is good only if the<br />

ball joints are worn and are being replaced.<br />

Jim Norton, Columbia City, IN<br />

ENVIROGUARD INSTALLATION<br />

Has anyone installed a Fleetguard Enviroguard How do I remove<br />

the frost plug in the port boss located on the pan rail on my <strong>Turbo</strong><br />

<strong>Diesel</strong><br />

DFontaine<br />

I got part of the lip up, but could not get a hold of the plug. I took my<br />

truck to a friend who works at Midas. They put it up on the rack and<br />

used a very long crowbar and the plug finally popped out. There<br />

was a small lip under the rim. Other members have used a bolt<br />

screwed into the plug and used the bolt for better leverage to pry it<br />

out. Sometimes it comes out on the first try; however, some seem<br />

to take forever to remove. Others have pushed the plug down into<br />

the pan for later recovery.<br />

KKohagen, Santa Clarita, CA<br />

Try threading a 6-mm or 8-mm bolt about 1 to 1½-inches long into<br />

the plug and use a nail bar to pop it out. The plug is soft.<br />

Silver_Ram, Riverton, UT<br />

FILTER MINDER QUESTIONS<br />

When my ’02 <strong>Turbo</strong> <strong>Diesel</strong> 2500 is running, does the filter minder<br />

indicator pull down and stay there until I hit the reset button The<br />

little disk is always at the top and never seems to move. I change<br />

the air filter with a new Fleetguard about every 15,000 to 20,000<br />

miles. Could that be why I am not seeing it move<br />

chazj, Carson City, NV<br />

Without any engine modifications and the frequent air filter changes<br />

you are probably not going be able to get it to register anything.<br />

I changed the air filter every second or third oil change. As a test<br />

for the indicator, I decided to leave the air filter in until the filter<br />

minder indicator moved. It took a long time before it registered a<br />

restriction.<br />

kenny61, NY<br />

You are replacing your air filter too often. This may sound counterintuitive,<br />

but as an air filter gets dirtier it filters better. You are<br />

throwing away a better filter than the one you are putting in. The<br />

reason is the filter has various size holes in the media. The larger<br />

holes have the less resistance and therefore most air goes through<br />

them; as they start to fill up, it forces the air to go through smaller<br />

holes. Our large equipment and trucks come with instructions not<br />

to over service the air cleaner for this reason. Change the filter by<br />

the filter minder indicator.<br />

CKelley1<br />

TRANSFER CASE POPS OUT OF GEAR WHILE TOWING<br />

While hauling a load of gravel and towing a tractor on a trailer (a<br />

gross weight of 19,000 pounds) the transfer case on my ‘98 <strong>Turbo</strong><br />

<strong>Diesel</strong> 3500 with 182,000 miles on the odometer kept popping into<br />

Neutral. The transfer case popped out one time while unloaded.<br />

It only does it when in 4th gear. I checked the linkage and it does<br />

not appear to be binding or hitting anything. Ideas<br />

JPulliam<br />

I had the same thing happen to my ‘02 <strong>Turbo</strong> <strong>Diesel</strong> and my friend’s<br />

’99. I replaced the shift fork in the transfer case. There are plastic<br />

inserts on the fork tips which wear and cause some play. Also while<br />

you have it apart, increase the spring tension on the shifter detent<br />

approximately 0.25-inch. Make a spacer to put behind the spring<br />

to increase the tension, but too much and you won’t be able to shift<br />

the transfer case. My transfer case no longer pops out of gear.<br />

JMcKee<br />

I had the same thing happen with the transfer case popping out<br />

of high range into Neutral which was caused by a severely worn<br />

range fork. A new fork solved the problem and it’s not that hard<br />

to replace.<br />

RLHannink<br />

I removed and disassembled the transfer case. The pads on the<br />

mode fork were worn and one was cracked. The sliding clutch and<br />

stop ring have some damage from the gear grinding under load.<br />

The input shaft bearing came out in pieces. Nothing else seemed<br />

damaged, but I replaced the thrust washers in the planetary just<br />

in case. All I needed to disassemble the transfer case was a set<br />

of sockets and a good pair of snap ring pliers. It came right apart.<br />

I have not had any more problems and it shifts better than ever for<br />

only $285 in parts.<br />

JPulliam<br />

18 www.turbodieselregister.com TDR 67

24-VALVE ENGINES . . . . Continued<br />

47RE TRANSMISSION LINE DISCONNECT<br />

How do I disconnect these transmission cooler lines on my ’02 <strong>Turbo</strong><br />

<strong>Diesel</strong> I removed the brass clip thinking the line would pull apart.<br />

Do I need a special tool<br />

I disconnected a line recently using a short piece of ½-inch of PVC<br />

rigid water pipe that I had in the garage. I cut it length wise down<br />

the middle, slid each piece into each side of the coupler, and it<br />

popped right off.<br />

damar, Deming, NM<br />

FUEL SUCTION LINE AT TANK<br />

I’m trying to install an aftermarket fuel lift pump on my ’00 <strong>Turbo</strong><br />

<strong>Diesel</strong> 3500 and I can’t get the fuel line off of the fitting at the tank.<br />

It’s difficult to access with the bed on the truck. The instructions<br />

say to pinch the tabs on the sides of the fitting and it will come off<br />

which I’ve tried, but it won’t come off. Am I missing something or<br />

do I have a stuck fuel line<br />

LarryM, Callahan, FL<br />

I had a lot of difficulty in disconnecting the fuel line when dropping<br />

my tank for the first time, but once I understood how it worked; I<br />

can remove or install the connector in a second. It went on and off<br />

so easily that I was amazed it doesn’t leak or suck air!<br />

dspoon, Winston Salem, NC<br />

There is a special tool made to remove them. I bought a set at an<br />

automotive parts store in different sizes. The tool looks like half of<br />

a piece of tubing in different diameters. Slide them into the fitting<br />

and it releases the connector. There are more expensive metal<br />

tools available, but the plastic tools I purchased are inexpensive<br />

and work fine for the occasional user.<br />

Allnew2Me, Bay Area, CA<br />

The connector is similar to the drawing below. The ears marked “1”<br />

are part of the inner retainer I pinched and it does not slide off the<br />

nipple. The outer part marked “2” is what moves to the right in the<br />

drawing as the retainer ears are pressed in. Once you finally get it<br />

off, you’ll be amazed how simple it works.<br />

Most automotive parts stores sell a cheap kit similar to this:<br />

JLandry, Shoreline, WA<br />

It worked. I was trying to pinch inside the little square holes. I didn’t<br />

see the tabs on the end. Thank you.<br />

LarryM, Callahan, FL<br />

DFerverda, Northern IN<br />

If you want to do it the cheap way, use two small screw drivers one<br />

on either clip and pull the line apart. However, I don’t recommend<br />

it unless you are in the middle of nowhere and need to get the<br />

job done.<br />

BGuilty, Long Island, NY<br />

TDR 67 www.turbodieselregister.com 19

24-VALVE ENGINES . . . . Continued<br />

REPLACING THE CAM AND CRANKSHAFT SENSOR<br />

The tachometer stopped working and the check engine light on<br />

my ’01 <strong>Turbo</strong> <strong>Diesel</strong> came on and then went off. I checked the<br />

diagnostic trouble code (DTC) and it shows 1693. How do I replace<br />

the cam sensor Do I need special tools<br />

MDSlover<br />

No special tools are needed to replace the sensor; however, you<br />

will need the ability to contort your arms and hands under the<br />

Bosch VP44 fuel injection pump to reach the camshaft position<br />

sensor. It’s held in place by a single female Allen head bolt. Once<br />

the bolt is removed, the sensor may be firmly stuck in the hole and<br />

could require tugging or careful prying with a small screwdriver to<br />

remove. It’s difficult since it can only be reached with one hand<br />

and it isn’t visible.<br />

EXPENSIVE DRIVESHAFT<br />

Recently, I noticed a bad vibration in my ‘02 <strong>Turbo</strong> <strong>Diesel</strong> 2500<br />

at about 70 mph. I slowed down a little and it went away. The<br />

vibration came back at each speed I slowed down to. I thought I<br />

was about to lose a U-joint. Suddenly, there was the loud bang. I<br />

got out and expected to see the rear driveshaft hanging down. But<br />

what I saw was automatic transmission fluid under my truck from<br />

a split transfer case.<br />

After $1200 and a rebuilt case from Blumenthal’s, I was ready for<br />

a test drive, but it still had the vibration. I returned to my shop and<br />

discovered the front double carden joint was defective. I didn’t notice<br />

it when I removed it to replace the transfer case. I think that a $300<br />

driveshaft just cost me almost $1600! Will the defective double<br />

carden joint put enough stress on the transfer case to break it<br />

ichoplin, Claremore, OK<br />

I’ve seen a defective U-joint destroy a transfer case, break a<br />

transmission case, and bend an output shaft.<br />

Huff N Puff, Springfield, VA<br />

ENGINE OIL LEAK<br />

There is engine oil leaking from the area of the injection pump on<br />

my ’00 <strong>Turbo</strong> <strong>Diesel</strong> 3500. While looking for the leak, I found a nut<br />

on top of the vacuum pump that appears to be from the injection<br />

pump on the block side. I can’t get in there to see where the nut<br />

came from. Could it be the source of the oil leak The injection<br />

pump was changed about 14 months ago by my dealer; however,<br />

he is no longer in business.<br />

MFarruggia<br />

JLandry, Shoreline, WA<br />

Thanks for the drawings. It helps to know what to look for.<br />

MDSlover<br />

Using a flashlight and a small mirror, look under the base of the<br />

injection pump towards the front of the engine. The nut is probably<br />

from the bottom stud that holds the injection to the timing case. Use<br />

a long extension with a swivel end with 14-mm socket, if I remember<br />

correctly. Tip: place a piece of paper across the socket and insert<br />

the nut, which helps keep the nut from dropping out of the socket<br />

while fishing the socket into place. Check the other mounting nuts,<br />

including the bracket to the block bolts.<br />

Joe Mc, Levittown, PA<br />

20 www.turbodieselregister.com TDR 67

24-VALVE ENGINES . . . . Continued<br />

LIFT PUMP POWER LOSS<br />

I recently installed a fuel pressure gauge on my <strong>Turbo</strong> <strong>Diesel</strong>.<br />

I relocated the lift pump and, for an indicator of power to the lift<br />

pump, I use the light in the gauge. I have a problem with intermittent<br />

electric power to the lift pump. When this happens at highway<br />

speeds, the fuel pressure drops to zero and the engine will start<br />

missing and hesitating. If I pull off the road and turn the ignition<br />

switch off for a few seconds, the power to the lift pump returns.<br />

Is there a relay that powers the lift pump or does the power come<br />

directly from the engine control module (ECM) Is it possible to wire<br />

the lift pump to run constantly from the ignition switch<br />

RCamp<br />

There are no relays for the lift pump external to the ECM. The<br />

ECM supplies power directly to the lift pump without anything in<br />

between. So assuming there aren’t wire harness problems, then<br />

the ECM is the problem.<br />

Yes, a separate relay can be used to power the lift pump when the<br />

ignition key is turned to the run position. Other members have done<br />

this in similar situations. Be sure you add fuses to the circuits to<br />

protect the wiring in case of an accidental short.<br />

JLandry, Shoreline, WA<br />

Here are the ECM connector pin outs which might help you locate<br />

the correct wire:<br />

Engine Control Module C1 (<strong>Diesel</strong>)<br />

For the lift pump (switched) side of the relay, if possible, take power<br />

directly from the battery. Install a 15-amp fuse prior to the relay,<br />

because according to the Factory Service Manual, the lift pump<br />

normally draws 12-amps.<br />

I had the same problem a few years ago. The lift pump had no<br />

power to it. In the Power Distribution Center (PDC) near the driver<br />

side battery, there is a relay marked “Fuel Circuit,” “Pump Relay,”<br />

or similar. I changed it out with the relay from the fog light circuit<br />

which restored power to the lift pump and it has been fine since<br />

then. Other members said that should not have fixed it, but it did.<br />

Try it and see if it works for you.<br />

Ram4Sam, Redlands, CA<br />

Other members have lost proper functioning of the lift pump circuit<br />

without the rest of the ECM being affected.<br />

A good place to drive a relay for the lift pump would be the same<br />

circuit the ECM uses to turn the VP44 fuel injection pump relay on<br />

and off. To do this, you’ll need to find the 18 gauge Brown/White<br />

tracer wire running between pin 36 of the ECM and the PDC. Tap<br />

that wire, and for safety, insert a low amperage fuse before the<br />

relay. Ground the other side of the relay. When the ignition key<br />

is turned on, the ECM will provide current to the relay, which will<br />

switch it on. See the attached wiring schematic.<br />

I changed it out with the relay<br />

from the fog light circuit which restored<br />

power to the lift pump and it has<br />

been fine since then.<br />

JLandry, Shoreline, WA<br />

TDR 67 www.turbodieselregister.com 21

24-VALVE ENGINES . . . . Continued<br />

INJECTION PUMP DRIVE GEAR<br />

I am preparing to replace the failed Bosch VP44 fuel injection pump<br />

on my ’01 <strong>Turbo</strong> <strong>Diesel</strong> 2500. What kind of gear puller do I need to<br />

remove the pump drive gear<br />

sleddog, Stanwood, WA<br />

A standard disc-type steering wheel puller works well. It’s<br />

inexpensive and readily available at many automotive parts<br />

stores.<br />

Editor’s note: TDR writers and members have removed and<br />

installed the VP44 fuel injection pump many times. The most<br />

recent article is in Issue 51, page 96, and it is available at the<br />

TDR’s web site magazine archives. Also, Joe’s VP44 removal<br />

and installation tips are found in Issue 47, page 40, and Issue<br />

42, page 48.<br />

CRUISE CONTROL<br />

The cruise control will engage on my ’01 <strong>Turbo</strong> <strong>Diesel</strong> 3500, but<br />

will not disengage when I press the brake pedal. The only way I<br />

can disengage the cruise control is with the on-off switch on the<br />

steering wheel.<br />

olebum, Aztec, NM<br />

Check to see if the brake lights function. The cruise control<br />

disengages from a signal from the brake lights. You may have a<br />

defective brake light switch or a blown fuse.<br />

Shelby Griggs, Prineville, OR<br />

JLandry, Shoreline, WA<br />

Get a short 3 or 4-inch piece of 1½-inch x 1½-inch x ¼-inch angle<br />

iron. Measure the spacing of the screw holes in the gear and drill two<br />

matching holes on 1½-inch centers in the angle iron. Go to NAPA<br />

and buy two high grade bolts marked SKS with about 1½-inches of<br />

threads. On my truck the pump shaft cleared the front of the timing<br />

cover just enough that I did not need to use spacers between the<br />

puller and the shaft. Use a couple of flat washers on each bolt so<br />

the bolt will turn easily against the puller. Lubricating the washers<br />

helps. With the pump still mounted to the timing gear cover, tighten<br />

the bolts and tap the puller where it meets the shaft.<br />

It’s probably the brake light switch, and if it is, do not be tempted<br />

to push the little button on the new replacement switch. The<br />

switch comes in a plastic bag with installation instructions. The<br />

instructions warn: Do not push the button on the replacement<br />

switch until installed.<br />

Joe Mc, Levittown, PA<br />

HARD TO SHIFT NV5600 SIX-SPEED TRANSMISSION<br />

I replaced the clutch, pressure plate, pilot bearing and had the<br />

flywheel resurfaced. After a while I started to have difficulty getting<br />

the transmission into gear after coming to a complete stop. We<br />

replaced the clutch slave cylinder but had trouble bleeding the<br />

system. I noticed an immediate improvement in ease of shifting<br />

but after a week, the gear selection problem returned.<br />

DLangford<br />

Either get the complete hydraulics from Mopar, or the heavy duty<br />

hydraulics from South Bend Clutch. The latter gives more travel and<br />

a light pedal effort. Hard shifting is caused by incomplete release<br />

of the clutch. Continued forcing into gear will result in worn and<br />

possibly broken synchronizers.<br />

Joe Donnelly<br />

GRINDING, RUMBLING NOISE IN FRONT END<br />

SNOKING, Shelter Bay, WA<br />

I have used a Snap-On Tool Number SP504 on well over a<br />

dozen injection pump changes without a problem. It’s a perfectly<br />

designed tool.<br />

dclassens, Traverse City, MI<br />

I hear the noise at and above 60mph. I can also feel a little vibration<br />

in the floorboard. Besides that, my truck seems to drive and handle<br />

as it always has. The noise is worse when going straight. I get the<br />

noise in both 5th and 6th gear, as well as neutral, with the clutch<br />

in or out.<br />

Telliott<br />

Check the hub bearings (4x4) or wheel bearings (4x2) in addition to<br />

the ball joints for play. I suspect that bad hub bearings are causing<br />

the noise.<br />

Joe Donnelly<br />

22 www.turbodieselregister.com TDR 67

24-VALVE ENGINES . . . . Continued<br />

KILLER DOWEL PIN IN A 2001<br />

What is the likelihood of having problems with the dowel pin inside<br />

the gear case for a late 24-valve engine Do I need to make this<br />

possible repair as a preventive measure<br />

TMorgan1<br />

In my experience, a minority of dowel pins never move, and a minority<br />

of those come out at relatively low mileage (below something like<br />

80,000 miles). The rest slowly move out and will eventually fall out<br />

unless you have the updated gear case with a restricted hole in it<br />

to retain the dowel pin in case it moves. Movement is faster with<br />

the greater vibrations of the P7100 injection pump used from 1994<br />

to 1998 in 12-valve engines. I have heard of a few instances of late<br />

24-valve engines losing the dowel pin and having the early gear<br />