2 - The International Resource Journal

2 - The International Resource Journal

2 - The International Resource Journal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DT HiLoad<br />

www.dthiload.com

DT HiLoa

SUPPORTING INDUSTRY<br />

d<br />

A<br />

better mousetrap2<br />

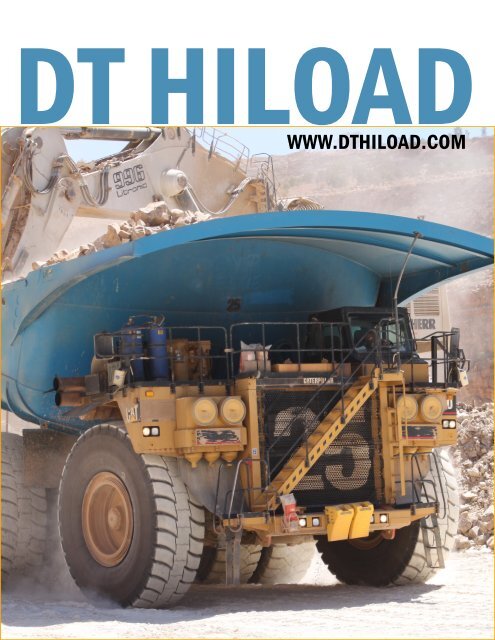

DT HiLoad Australia specialises in the design and manufacture of the<br />

Hercules dump truck body – a better mousetrap for mine site hauling

4 SupportiNG industrY DT HiLoad<br />

DT HiLoad’s solution for mining equipment is<br />

the Hercules – an engineered tray for off-road,<br />

rear-tipping, mining and quarry trucks. <strong>The</strong> patented<br />

curved design is made from a flexible,<br />

hard-wearing steel plate and the innovation has<br />

proved its ability to improve mining efficiency and<br />

productivity through an increased payload advantage<br />

and lower downtime.<br />

Richard Lang, chief executive officer, reckons<br />

that the designed body carries around an extra<br />

10 per cent payload on every trip. Multiply that by<br />

every day for a truck doing a cycle every hour and<br />

that adds up to a substantial amount of extra<br />

material. A standard truck body will carry some<br />

210 tonnes, but the lighter-weight Hercules can<br />

carry 244 tonnes. In addition, because of the<br />

lightweight design, a mining company uses less<br />

fuel per tonne of ore moved.<br />

<strong>The</strong> original concept was born in Chile, when<br />

family-run DT HiLoad in South America began experimenting<br />

with a better design for trucking material<br />

on site. Since 2003, Perth-based DT HiLoad<br />

Australia has taken on the business and patents,<br />

and the entire production process is completed<br />

at its workshop facilities. <strong>The</strong>re are 1,200 Hercules<br />

trays in use globally and some 300 in Australia.<br />

<strong>The</strong> most important element, says Lang, is<br />

the curved tray design, which means that canopy<br />

loading becomes a thing of the past. <strong>The</strong> problem<br />

with canopy loading is that material heaped on<br />

the canopy of a body changes the distribution of<br />

load on the truck tyres, and small changes in load<br />

compared to the rated load of the tyre result in<br />

disproportionate loss of tyre life. This has been a<br />

particularly relevant issue in recent years, which<br />

has found miners needing to resort to all sorts of<br />

tricks to preserve them in a global tyre shortage.<br />

Moreover, the curved design reduces hang<br />

up, a real nuisance when dealing with sticky clay.<br />

“<strong>The</strong> curved nature of the body is integral to<br />

the design and that is where a lot of the strength<br />

comes from, which is also why the lighter weight<br />

is possible while still retaining heavy-duty capability,”<br />

explains Lang.<br />

And although there is a general design, DT can<br />

customise trays at its workshop to exact specifications<br />

for any individual mine. By looking at<br />

the rated payload of the truck and the loose bulk<br />

density of material being shifted, the company<br />

can work out what volume of tray a mine should<br />

have. That can result in faster tipping times –<br />

fitted circuitry limits the tipping angle and the<br />

angle can be calibrated to the relevant material<br />

and locked by a supervisor.<br />

Driving change<br />

Implementing operational change can be a tall<br />

order for mine sites. Lang points out that most

MAY 2012 <strong>The</strong> <strong>International</strong> <strong>Resource</strong> <strong>Journal</strong><br />

5<br />

<strong>The</strong> solution to your wear problems<br />

Harder and tougher than ever: XAR ® .<br />

<strong>The</strong>se exceptional properties make the wear-resistant special structural steel XAR ® an uncompromising material.<br />

Whether it’s in mining and handling of solid rock or in the rough climatic conditions of oil sands mining,<br />

XAR ® masters every challenge. And despite its high hardness XAR ® can easily be cold formed and welded.<br />

For dump bodies that last up to fi ve times longer and cope with everything that life throws at them.<br />

For more information:<br />

Phone +49 (0)203 52-75604 · roland.riesbeck@thyssenkrupp.com<br />

http://plate.thyssenkrupp-steel-europe.com<br />

ThyssenKrupp Steel Europe<br />

Thinking the future of steel

6 SupportiNG industrY DT HiLoad<br />

of the necessary detailed knowledge is often<br />

found at the superintendent level or below and<br />

that effecting change may require a coalition of<br />

supporters from different disciplines across the<br />

organisation. A team should include people who<br />

can crunch the numbers, know the maintenance<br />

requirements and understand the operational<br />

trucking flow existing at the site.<br />

<strong>The</strong> timing is certainly on DT HiLoad’s side. In<br />

a recent report, Deloitte points out that while the<br />

issues facing mining companies appear familiar<br />

every year, the factors influencing the industry<br />

are moving to a new level of extremity. This is just<br />

as true with cost-control measures.<br />

<strong>The</strong> winning argument in favour of assembling<br />

a team is that adopting the Hercules tray on site

MAY 2012 <strong>The</strong> <strong>International</strong> <strong>Resource</strong> <strong>Journal</strong><br />

7<br />

can pay itself off in less than a year if implemented<br />

properly. However, teams within larger companies<br />

can face barriers, particularly if there are existing<br />

international deals with key suppliers in place.<br />

“Maybe it’s just that old habits die hard.<br />

We have had a very good response from our<br />

customers, so there is no way that I could complain<br />

generally about the attitude of people that<br />

we deal with. Contractors have probably been<br />

the most nimble and the very big international<br />

companies are probably the least in our experience,”<br />

Lang says.<br />

www.dthiload.com

AS SEEN IN THE MAY 2012 ISSUE<br />

OF THE INTERNATIONAL RESOURCE JOURNAL