Camfil Farr Product Catalog - Texas Air Products

Camfil Farr Product Catalog - Texas Air Products

Camfil Farr Product Catalog - Texas Air Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Air</strong> Filter Technology<br />

<strong>Product</strong> Performance Barometers<br />

ASHRAE Standard 52.2-2007<br />

In ASHRAE Standard 52.2-2007, an air filter’s performance is<br />

determined by measuring the particle counts on both the upstream and<br />

the downstream of the air filter device being tested. The filter user is<br />

then provided capture efficiency values throughout a range of particle<br />

sizes, allowing them to be specific in selecting a filter that has the best<br />

efficiency for the contaminant they want to remove.<br />

If a user wants to remove paper dust in a bill processing facility, they<br />

can select a filter with a high efficiency specific to the relatively large<br />

size of that contaminant. If the contaminant of concern is tobacco or<br />

welding smoke, they can select a filter specific to the much smaller size<br />

of that contaminant. Each manufacturer should be able to provide a<br />

graph for each product that shows that product’s capture efficiency<br />

through the twelve individual particle size ranges of the test.<br />

To simplify filter selection, the Standard defines a minimum efficiency<br />

reporting value (MERV). The MERV is a single number that simplifies the<br />

filter selection process by providing the specifier, or the user, a single<br />

value of specification for filter selection. For most filters that use<br />

mechanical principles of filter operation, this number will most likely be a<br />

minimum value at installation and throughout the life of the filter.<br />

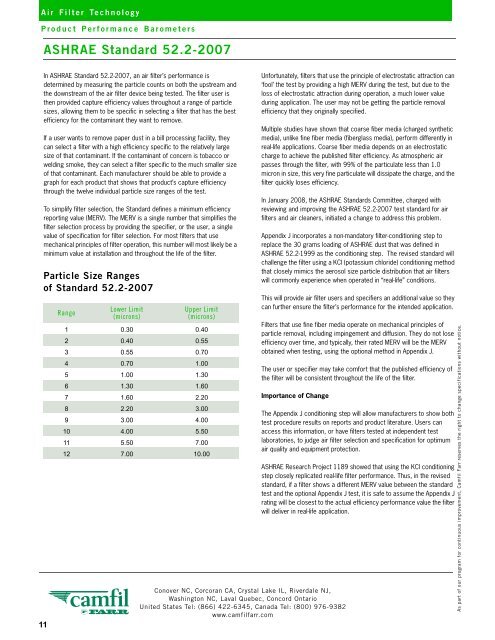

Particle Size Ranges<br />

of Standard 52.2-2007<br />

11<br />

Range<br />

Lower Limit<br />

(microns)<br />

Upper Limit<br />

(microns)<br />

1 0.30 0.40<br />

2 0.40 0.55<br />

3 0.55 0.70<br />

4 0.70 1.00<br />

5 1.00 1.30<br />

6 1.30 1.60<br />

7 1.60 2.20<br />

8 2.20 3.00<br />

9 3.00 4.00<br />

10 4.00 5.50<br />

11 5.50 7.00<br />

12 7.00 10.00<br />

Conover NC, Corcoran CA, Crystal Lake IL, Riverdale NJ,<br />

Washington NC, Laval Quebec, Concord Ontario<br />

United States Tel: (866) 422-6345, Canada Tel: (800) 976-9382<br />

www.camfilfarr.com<br />

Unfortunately, filters that use the principle of electrostatic attraction can<br />

‘fool’ the test by providing a high MERV during the test, but due to the<br />

loss of electrostatic attraction during operation, a much lower value<br />

during application. The user may not be getting the particle removal<br />

efficiency that they originally specified.<br />

Multiple studies have shown that coarse fiber media (charged synthetic<br />

media), unlike fine fiber media (fiberglass media), perform differently in<br />

real-life applications. Coarse fiber media depends on an electrostatic<br />

charge to achieve the published filter efficiency. As atmospheric air<br />

passes through the filter, with 99% of the particulate less than 1.0<br />

micron in size, this very fine particulate will dissipate the charge, and the<br />

filter quickly loses efficiency.<br />

In January 2008, the ASHRAE Standards Committee, charged with<br />

reviewing and improving the ASHRAE 52.2-2007 test standard for air<br />

filters and air cleaners, initiated a change to address this problem.<br />

Appendix J incorporates a non-mandatory filter-conditioning step to<br />

replace the 30 grams loading of ASHRAE dust that was defined in<br />

ASHRAE 52.2-1999 as the conditioning step. The revised standard will<br />

challenge the filter using a KCl (potassium chloride) conditioning method<br />

that closely mimics the aerosol size particle distribution that air filters<br />

will commonly experience when operated in “real-life” conditions.<br />

This will provide air filter users and specifiers an additional value so they<br />

can further ensure the filter’s performance for the intended application.<br />

Filters that use fine fiber media operate on mechanical principles of<br />

particle removal, including impingement and diffusion. They do not lose<br />

efficiency over time, and typically, their rated MERV will be the MERV<br />

obtained when testing, using the optional method in Appendix J.<br />

The user or specifier may take comfort that the published efficiency of<br />

the filter will be consistent throughout the life of the filter.<br />

Importance of Change<br />

The Appendix J conditioning step will allow manufacturers to show both<br />

test procedure results on reports and product literature. Users can<br />

access this information, or have filters tested at independent test<br />

laboratories, to judge air filter selection and specification for optimum<br />

air quality and equipment protection.<br />

ASHRAE Research Project 1189 showed that using the KCl conditioning<br />

step closely replicated real-life filter performance. Thus, in the revised<br />

standard, if a filter shows a different MERV value between the standard<br />

test and the optional Appendix J test, it is safe to assume the Appendix J<br />

rating will be closest to the actual efficiency performance value the filter<br />

will deliver in real-life application.<br />

As part of our program for continuous improvement, <strong>Camfil</strong> <strong>Farr</strong> reserves the right to change specifications without notice.