Zoomerang | OPV International Lifetime Summit Results Overview

Zoomerang | OPV International Lifetime Summit Results Overview

Zoomerang | OPV International Lifetime Summit Results Overview

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Zoomerang</strong> | <strong>OPV</strong> <strong>International</strong> <strong>Lifetime</strong> <strong>Summit</strong>: <strong>Results</strong> <strong>Overview</strong><br />

<strong>OPV</strong> <strong>International</strong> <strong>Lifetime</strong> <strong>Summit</strong><br />

<strong>Results</strong> <strong>Overview</strong><br />

Date: 7/9/2008 6:31 AM PST<br />

Responses: Completes<br />

Filter: No filter applied<br />

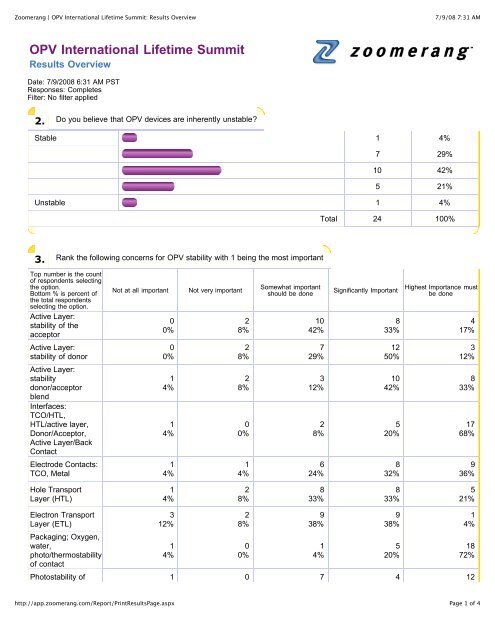

2.<br />

Do you believe that <strong>OPV</strong> devices are inherently unstable?<br />

Stable 1 4%<br />

http://app.zoomerang.com/Report/Print<strong>Results</strong>Page.aspx<br />

7 29%<br />

10 42%<br />

5 21%<br />

Unstable 1 4%<br />

3.<br />

Rank the following concerns for <strong>OPV</strong> stability with 1 being the most important<br />

Top number is the count<br />

of respondents selecting<br />

the option.<br />

Bottom % is percent of<br />

the total respondents<br />

selecting the option.<br />

Active Layer:<br />

stability of the<br />

acceptor<br />

Active Layer:<br />

stability of donor<br />

Active Layer:<br />

stability<br />

donor/acceptor<br />

blend<br />

Interfaces:<br />

TCO/HTL,<br />

HTL/active layer,<br />

Donor/Acceptor,<br />

Active Layer/Back<br />

Contact<br />

Electrode Contacts:<br />

TCO, Metal<br />

Hole Transport<br />

Layer (HTL)<br />

Electron Transport<br />

Layer (ETL)<br />

Packaging; Oxygen,<br />

water,<br />

photo/thermostability<br />

of contact<br />

Not at all important Not very important<br />

0<br />

0%<br />

0<br />

0%<br />

1<br />

4%<br />

1<br />

4%<br />

1<br />

4%<br />

1<br />

4%<br />

3<br />

12%<br />

1<br />

4%<br />

2<br />

8%<br />

2<br />

8%<br />

2<br />

8%<br />

0<br />

0%<br />

1<br />

4%<br />

2<br />

8%<br />

2<br />

8%<br />

0<br />

0%<br />

Somewhat important<br />

should be done<br />

10<br />

42%<br />

7<br />

29%<br />

3<br />

12%<br />

2<br />

8%<br />

6<br />

24%<br />

8<br />

33%<br />

Total 24 100%<br />

Significantly Important<br />

8<br />

33%<br />

12<br />

50%<br />

10<br />

42%<br />

5<br />

20%<br />

8<br />

32%<br />

8<br />

33%<br />

7/9/08 7:31 AM<br />

Highest Importance must<br />

be done<br />

Photostability of 1 0 7 4 12<br />

9<br />

38%<br />

1<br />

4%<br />

9<br />

38%<br />

5<br />

20%<br />

4<br />

17%<br />

3<br />

12%<br />

8<br />

33%<br />

17<br />

68%<br />

9<br />

36%<br />

5<br />

21%<br />

1<br />

4%<br />

18<br />

72%<br />

Page 1 of 4

<strong>Zoomerang</strong> | <strong>OPV</strong> <strong>International</strong> <strong>Lifetime</strong> <strong>Summit</strong>: <strong>Results</strong> <strong>Overview</strong><br />

http://app.zoomerang.com/Report/Print<strong>Results</strong>Page.aspx<br />

7/9/08 7:31 AM<br />

<strong>OPV</strong> active layers 4% 0% 29% 17% 50%<br />

Temperature<br />

Illumination source<br />

type/spectrum<br />

Pattern of<br />

Illumination,<br />

cycling/intermittency<br />

Applied Load<br />

5.<br />

0<br />

0%<br />

0<br />

0%<br />

0<br />

0%<br />

0<br />

0%<br />

3<br />

12%<br />

5<br />

22%<br />

8<br />

35%<br />

5<br />

21%<br />

How stable do you believe current encapsulated <strong>OPV</strong> devices are?<br />

100 hours 2 9%<br />

500 hours 1 4%<br />

1000 hours 9 39%<br />

5000 hours 7 30%<br />

10,000 hours 4 17%<br />

7<br />

29%<br />

11<br />

48%<br />

9<br />

39%<br />

15<br />

62%<br />

9<br />

38%<br />

6<br />

26%<br />

6<br />

26%<br />

2<br />

8%<br />

Total 23 100%<br />

6. To your knowledge do any meaningful and appropriate standards currently exist for <strong>OPV</strong> stability/lifetime?<br />

none 6 25%<br />

initial stages 13 54%<br />

developed 1 4%<br />

adequate 2 8%<br />

well developed 2 8%<br />

8.<br />

What metrics do you believe should be incorporated into the standards for <strong>OPV</strong> stability?<br />

Top number is the count<br />

of respondents selecting<br />

the option.<br />

Bottom % is percent of<br />

the total respondents<br />

selecting the option.<br />

Degree of lost<br />

efficiency (where<br />

should the start<br />

point in efficiency<br />

be?)<br />

Time over which a<br />

device is measured<br />

(is there a<br />

Total 24 100%<br />

least important 2 3 4 most important<br />

1<br />

4%<br />

0<br />

0%<br />

0<br />

0%<br />

0<br />

0%<br />

4<br />

17%<br />

5<br />

22%<br />

5<br />

21%<br />

10<br />

43%<br />

5<br />

21%<br />

1<br />

4%<br />

0<br />

0%<br />

2<br />

8%<br />

14<br />

58%<br />

8<br />

35%<br />

Page 2 of 4

<strong>Zoomerang</strong> | <strong>OPV</strong> <strong>International</strong> <strong>Lifetime</strong> <strong>Summit</strong>: <strong>Results</strong> <strong>Overview</strong><br />

minimum?)<br />

Temperature<br />

Relative Humidity<br />

Light Intensity<br />

Spectrum<br />

Constant<br />

Illumination<br />

Devices kept under<br />

a specific load<br />

Outdoor<br />

Measurement<br />

0<br />

0%<br />

1<br />

4%<br />

0<br />

0%<br />

0<br />

0%<br />

1<br />

4%<br />

0<br />

0%<br />

0<br />

0%<br />

http://app.zoomerang.com/Report/Print<strong>Results</strong>Page.aspx<br />

0<br />

0%<br />

0<br />

0%<br />

0<br />

0%<br />

3<br />

14%<br />

2<br />

9%<br />

2<br />

9%<br />

2<br />

9%<br />

13 Responses<br />

6<br />

25%<br />

3<br />

12%<br />

5<br />

21%<br />

3<br />

14%<br />

6<br />

26%<br />

8<br />

36%<br />

5<br />

23%<br />

9. Should a round robin validation using stabilized and identical devices be done?<br />

Not Necessary 2 8%<br />

8<br />

33%<br />

7<br />

29%<br />

10<br />

42%<br />

11<br />

50%<br />

12<br />

52%<br />

10<br />

45%<br />

7<br />

32%<br />

2 8%<br />

3 12%<br />

10 40%<br />

Mandatory 8 32%<br />

10.<br />

Which techniques are the most important for determining diffusion rates for encapsulation?<br />

Top number is the count<br />

of respondents selecting<br />

the option.<br />

Bottom % is percent of<br />

the total respondents<br />

selecting the option.<br />

Mocon<br />

Ca diffusion<br />

Inference from<br />

encapsulated device<br />

stability vs 'glove<br />

box' devices<br />

Mass-spectrometry<br />

Radioactive method<br />

Total 25 100%<br />

Not very useful 2 3 4 Very useful<br />

1<br />

6%<br />

0<br />

0%<br />

2<br />

11%<br />

0<br />

0%<br />

0<br />

0%<br />

2<br />

13%<br />

2<br />

11%<br />

3<br />

19%<br />

7<br />

44%<br />

2<br />

13%<br />

1<br />

6%<br />

8<br />

50%<br />

4<br />

25%<br />

7<br />

47%<br />

8<br />

44%<br />

2<br />

12%<br />

7/9/08 7:31 AM<br />

10<br />

42%<br />

13<br />

54%<br />

9<br />

38%<br />

5<br />

23%<br />

2<br />

9%<br />

2<br />

9%<br />

8<br />

36%<br />

4<br />

25%<br />

4<br />

27%<br />

5<br />

28%<br />

3<br />

19%<br />

1 4 4 2 2<br />

Page 3 of 4

<strong>Zoomerang</strong> | <strong>OPV</strong> <strong>International</strong> <strong>Lifetime</strong> <strong>Summit</strong>: <strong>Results</strong> <strong>Overview</strong><br />

Radioactive method<br />

http://app.zoomerang.com/Report/Print<strong>Results</strong>Page.aspx<br />

7/9/08 7:31 AM<br />

8% 31% 31% 15% 15%<br />

12. Should NREL create a centralized database for sharing stability information?<br />

No 1 4%<br />

1 4%<br />

Maybe 7 28%<br />

6 24%<br />

Yes 10 40%<br />

13.<br />

Would you be willing to contribute to such a database?<br />

Total 25 100%<br />

No 0 0%<br />

1 4%<br />

Depends 11 48%<br />

2 9%<br />

Yes 9 39%<br />

Products & Services | About Us | Support/Help | <strong>Zoomerang</strong> Forums<br />

© 2008 Copyright MarketTools Inc. All Rights Reserved. | Privacy Policy | Terms Of Use<br />

Total 23 100%<br />

Page 4 of 4

Major Concerns (Raw Data)<br />

encapsulant stability - long term yellowing of flexible packaging<br />

Stability of the morphology; contact issues at electrode due to delamination,<br />

diffusion of ions (from e.g. PEDOT) through the layer<br />

Electron transport is the difficult part in organic photovoltaics<br />

Delamination and dark spot formation are major concerns.<br />

Module specific issues: reverse bias testing due to partially shadowing<br />

I believe that the biggest problem facing <strong>OPV</strong> reliability is the lack of detailed<br />

mechanisms for each type of failure. It's difficult to fix something you don't<br />

understand.<br />

Moisture & O2 permeation<br />

Differentiate between intrinsic and extrinsic effects. For conventional Si<br />

technology, intrinsic issues do not play an important role over the live of the<br />

solar cell. The Si wafer is stable. For <strong>OPV</strong>, we need to study both intrinsic<br />

and extrinsic stability<br />

Other issues are: effect of shadowing, reverse bias, wind, hail, salt, sand,<br />

thermal cycles, connection with balance of system.<br />

Perhaps also discuss the application area, since the stability requirements<br />

depend on the application (consumer electronics, telecommunication,<br />

camping equipement, stand alone PV systems, grid connected & building<br />

integrated PV systems, large scale power plants)<br />

UV stability. Reliance on the packaging to solve stability problems when<br />

experience has shown that samples must be moisture insensitive.<br />

film morphology and device architecture, e.g., transparent and tandem <strong>OPV</strong><br />

devices<br />

The uniformity of the <strong>OPV</strong> active layers and how the interaction of the layers<br />

affect each layers stability<br />

Morphology of donor/acceptor blends; integrity of donor and acceptor phase<br />

and interface<br />

What Standards Exist?

As a starting point the standards from silicon and thin film devices are<br />

being applied (85/85). I do not believe they are meaningful as there is no<br />

data to indicate that the acceleration factors from these other technologies<br />

will be at all applicable. Furthermore, it is not clear that these are the<br />

most important root cause of degradation in <strong>OPV</strong>.<br />

1 sun intensity and 80 degrees. conditions should be either Jcs, Voc, or<br />

maximum power point.<br />

Some measure is desperately needed. perhaps several levels of testing. A<br />

short test that can be useful for screening materials and a longer one that<br />

should be viewed as the real litmus test for stability. The most recent issue<br />

of SOLMAT has some papers detailing stability and methods. Most notably<br />

accelerated testing is not a reliable method<br />

some tests derived from IEC protocols for x-Si are carried out. If these are<br />

adequate depends totally on the foreseen type of applications<br />

Why not use the standards that have been developed for amorphous<br />

silicon?<br />

At the moment people select isolated tests from existing IEC standards to<br />

identify critical stress factors. Some parties are starting to develop prenormative<br />

test protocols which fit better to their product (flexible) and final<br />

application (low-tomedium power applications)<br />

<strong>OPV</strong> devices should be held to the same standards as those made from<br />

other more traditional PV materials.<br />

Adapt IEC test. The operating conditions of the product should determine<br />

standards, not the shortcomings of the material.<br />

IEC thin-film qualification test. question 3 was answered if subjected to<br />

85C/85% RH how long will last. Not on shelf at room temperature.Question<br />

6 - IEC test a minimum. Need to understand degradation to determine if<br />

it is enough.<br />

there is no standard yet<br />

ASTM E1171-04<br />

ASTM E2236-05a<br />

IEC61215<br />

they include implicit assumptions about starting technology

Initial NREL guidance but not adequate yet<br />

Degree of Lost Efficiency<br />

It might be reasonable to report the start point as either the starting<br />

efficiency (after encapsulated, if there is any encapsulation) or after the<br />

device efficiency has stabilized (but then this might need to be defined). I<br />

would borrow the level to which a Si or thin film cell is allowed to degrade<br />

in their quoted lifetimes.<br />

with at least a 5 percent device<br />

The degree of loss is important. Do not test this for mediocre devices, only<br />

for those that reach a reasonable (e.g 3% or more) efficiency. Otherwise<br />

you will get the answers to quateuons that are not important.<br />

I don't understand this - why talk about "losing efficiency"?<br />

To make things clear, degree of lost effieciency should always be<br />

mentioned. Importance of starting point: dpeends on application<br />

The value of stable efficiency will be important.<br />

set of data required<br />

scientific model/understanding<br />

deduce, understand & confirm acceleration factors<br />

start with outdoor tests already at initial stage of stability studies<br />

To the point like amorphous silicon. The stabilized efficiency is after an<br />

initial transient.<br />

starting point is "as rated" - in aSi they condition cell first or rate low to<br />

compensate.<br />

Output power under load is most relevant parameter<br />

Minimum Time for Device Measurement

minimum of 500 hours<br />

At least 1000 hrs, but some studies should also be done at 5000 hrs.<br />

As above maybe two layers are needed<br />

one for testing materials<br />

one for testing complete modules/devices for applications<br />

If a sample that is measured twice in succession gives two different<br />

values, the measurement reflects the speed with which the measurement<br />

is completed, and, clearly, is not relevant to real use<br />

People use 1000 hours as a minimum since this is mostly used in current<br />

IEC lifetime tests for PV.<br />

As long as it takes to eliminate hysteresis. if you meant exposed<br />

minimum 100 hrs.<br />

may depend on the application<br />

You need to correlate short aggressive environment with longer term<br />

typical environment so that accelerate testing can be done.<br />

5-10 min<br />

Temperature Standard<br />

Are we trying to develop an accelerated degradation standard, "rooftop"<br />

conditions, or something else?<br />

80 degrees. but at least defined<br />

The stability needs to be measured at a temperature that can predict the<br />

stability under real-use conditions.<br />

Various temperatures are important to determine acceleration factors.<br />

Development of standards should also be based on a scientific basis<br />

Same as conventional flat plate.<br />

85C<br />

65

Humidity Standards<br />

Relative humidity is important, but studies should be done both in<br />

presesnce and absecnce of water vapor<br />

The stability needs to be measured at a humidity that can predict the<br />

stability under real-use conditions.<br />

Extremely important to test quality of encapsulants. This is regarded as<br />

one of the most important test in current PV<br />

Seems to be a significant cause of degradation.<br />

standard testing with encapsulated or as-sold product<br />

Light Intensity<br />

There may be intensity dependent degradation. Changing the intensity<br />

may be a way of changing the acceleration factor.<br />

1 sun<br />

1 sun<br />

The stability needs to be measured at an illumination that can predict the<br />

stability under real-use conditions.<br />

In order to accelerate the number of turnovers, it is wise to go for 1 sun<br />

equivalent illumination<br />

1-sun<br />

standard (STC,AM 1.5G)<br />

100 mW/cm2<br />

Spectrum<br />

There needs to be a systematic study of what frequencies adversely<br />

affect <strong>OPV</strong> devices. This may vary from material to material or even<br />

donor:acceptor system to system. It may be possible that UV<br />

degradation studies can be done independently from a studies with<br />

spectrum that is relatively well matched to the EQE. I would think<br />

continuous lamp spectra would be more meaningful than ones from<br />

lamps with many strong lines.<br />

am1<br />

In my view less important, altough UV may detriorate HTL and oxides<br />

used.

Not particularly important, but the issue is how much, if any, UV should<br />

be filtered by the packaging.<br />

The stability needs to be measured under a spectrum that can predict the<br />

stability under real-use conditions.<br />

Presence of UV in the light source might be important.<br />

UV acceleration minimal. UV light expected to damage polymers.<br />

STC<br />

AM1.5G<br />

Continuous Illumination<br />

There may be some healing effect as observed in a-Si, if the sample is<br />

shuttered periodically.<br />

Yes, to save time.<br />

There are many examples of devices improving with a period in the dark.<br />

It may thus be useful to simulate night/day cycles<br />

The use of constant, instead of intermittent, illumination is likely to be a<br />

matter of convenience.<br />

Yes, to accelerate the number of turnovers<br />

Have to be done for accelerated testing<br />

Loading<br />

Keeping a device under the MPP for most of the time, seems to be the<br />

most reasonable "real-world" condition. It may not matter though.<br />

For sure at maximum power point, but SC and OC conditions are also<br />

intersting as they may help to resolvethe mechanisms<br />

Some devices especially the ZnO devices exhibit a memory effect<br />

whereby the load that the device has experience affects the response.<br />

the load should be stated and is sometimes important in what result that<br />

is obtained<br />

The only operating load of importance is that which gives the maximum<br />

power point in the device.<br />

The bias condition is known to affect degradation rates of many devices;<br />

it is likely that it will be important in at least some <strong>OPV</strong> designs

Only if demonstrated different failures in the dark at Voc versus the light<br />

at Pmax or dark biased to Pmax. Secondary problem as long as so<br />

sensitive to air.<br />

Outdoor measurements<br />

Outdoor measurements will be among the most accessible to many, and<br />

if successful, will be very useful for convincing skeptics without more<br />

rigorous lab testing available.<br />

eventually a necessity<br />

Not very useful scientifically, but nice for demonstration issues<br />

Difficult to use as a standard.<br />

The relevance of test procedures should be verified using outdoor<br />

exposure.<br />

Extermely important to strat with field tests as soon as possible,<br />

offcourse depending on the robustness of the system.<br />

Only after can survive 100 hours of 85% RH/ 85 C.<br />

Encapsulation Measurement Techniques<br />

ellipsometry<br />

Need another rapid meaniful technique that to my knowledge has not<br />

been identified yet.<br />

I have yet to see "stabilized identical devices" in organic PV. Most of<br />

differences in organic PV efficiency may not revealed by "round robin"<br />

since the biggest issue seems to be what do you call the area and was an<br />

aperture used. If round robin on identical devices is to be conducted lets<br />

do one with stable filtered Si reference cells.<br />

Comments for the organizers for the meeting<br />

This is a lot to address in two days (especially if there are close to 100<br />

different opinions at the beginning).<br />

None<br />

Having a database already on hand, with early entries, would facilitate<br />

discussion. That might be difficult to get done in time...

try to invite some people from the fields of lifetime testing x-Si PV and<br />

organic LED<br />

Have you arranged for someone to show up with existing standards that<br />

were developed for a-Si and other technologies? Why should you create<br />

new standards? Why not use existing standards?<br />

In my view there are different separate topics to discuss<br />

- intrinsic stability issues: do we need fundamental understandig of the<br />

degradation mechanisms. How can we do this most efficiently? Maybe<br />

invite somebody from the polyLED/Lighting field who has experience with<br />

this.<br />

- Extrinisc issues: packaging, what are requirements for which<br />

application<br />

- Development of IEC type of standards: For this discussion the<br />

photoactive layer itself is not that important. This should be a more<br />

general discussion. We should talk about development of tests that are<br />

specific for a certain product (flexible vs. rigid) or for specific type of<br />

applications (low power, mdeium power, highpower). It is good to invite<br />

peole who are allready commercializing flexible inorganic PV for charging<br />

applications for instance and how they deal with test standards which are<br />

not existing yet. And invite people from certification labs (for instance<br />

ISE, NREL, TUV, etc) who knows what is needed to come to<br />

standardatization.<br />

stability / lifetime testing is difficult, time consuming and receives only<br />

little attention. In the end it is as important as obtaining high efficiencies.<br />

However, typically, stability papers claiming record values do not receive<br />

as much attention as papers claiming record efficiencies. This is just to<br />

indicate that research in stability does not receive the attention as it<br />

deserves. Perhaps a conserted action could help.<br />

A special session on <strong>OPV</strong> stability at the E-MRS might be a good idea,<br />

similarly at a US conference. However, an update once a year should be<br />

sufficient.<br />

A two track long term research programme on generating (intrinsic and<br />

extrinsic) stability data using measurement protocols could serve a trial<br />

and error method to improve stability. In a different track one could build<br />

up a knowledge base on chem. structure-property&morphology-stability<br />

relation. Hopefully leading to a scientific understanding of processes<br />

influencing device lifetime.<br />

Perhaps a conserted action among institutes/universities/companies<br />

could help to us the limited resources efficiently.<br />

Perhaps Michael Köhl from Fraunhofer could give valuable input from<br />

testing protocols. Also strengthening the relations with other organic

electronic communities maybe helpful.<br />

What would be the killer applications for <strong>OPV</strong><br />

Viable Packaging Options<br />

No entirely my field. I think that imprtant questions still exist, even if<br />

encapsulation would be perfect. My largest concern is the long-term<br />

stability of the morphology and the integretity of the layer stack and its<br />

interfaces.<br />

I think we should develop <strong>OPV</strong>s that do not need<br />

encapsulation/protection against oxygen/water<br />

Thin glass should not be ignored for early implementation.<br />

glass<br />

I think you need to understand the degradation mechanisms and<br />

engineer around them rather than trying to solve the problems with<br />

encapsulation. The encapsulation should give physical protection and<br />

protection from puddles of water, but the devices should be able to<br />

survive small exposures.<br />

The packaging will depend on the application<br />

Don't count on the package to solve stability issues. Cells that degrade<br />

in seconds in air can not be made stable by low cost low temperature<br />

package solutions. At present glass / glass packaging on option that has<br />

a chance of protection.<br />

<strong>OPV</strong> cells sealed with glass may be used as standard reference device