Muhammad Pervej Jahan - University of Arkansas

Muhammad Pervej Jahan - University of Arkansas

Muhammad Pervej Jahan - University of Arkansas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

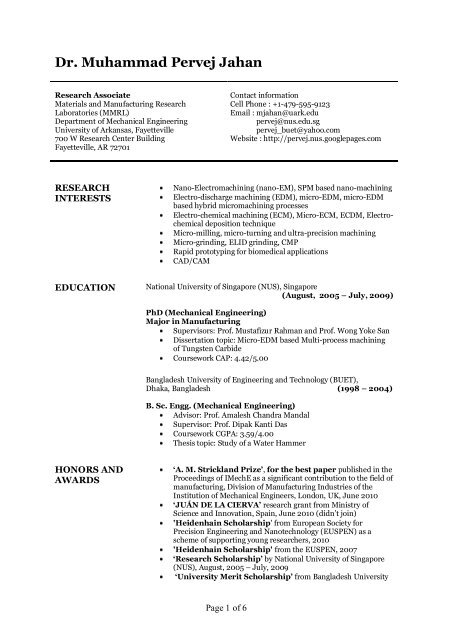

Dr. <strong>Muhammad</strong> <strong>Pervej</strong> <strong>Jahan</strong><br />

Research Associate<br />

Materials and Manufacturing Research<br />

Laboratories (MMRL)<br />

Department <strong>of</strong> Mechanical Engineering<br />

<strong>University</strong> <strong>of</strong> <strong>Arkansas</strong>, Fayetteville<br />

700 W Research Center Building<br />

Fayetteville, AR 72701<br />

Contact information<br />

Cell Phone : +1-479-595-9123<br />

Email : mjahan@uark.edu<br />

pervej@nus.edu.sg<br />

pervej_buet@yahoo.com<br />

Website : http://pervej.nus.googlepages.com<br />

RESEARCH<br />

INTERESTS<br />

Nano-Electromachining (nano-EM), SPM based nano-machining<br />

Electro-discharge machining (EDM), micro-EDM, micro-EDM<br />

based hybrid micromachining processes<br />

Electro-chemical machining (ECM), Micro-ECM, ECDM, Electrochemical<br />

deposition technique<br />

Micro-milling, micro-turning and ultra-precision machining<br />

Micro-grinding, ELID grinding, CMP<br />

Rapid prototyping for biomedical applications<br />

CAD/CAM<br />

EDUCATION<br />

National <strong>University</strong> <strong>of</strong> Singapore (NUS), Singapore<br />

(August, 2005 July, 2009)<br />

PhD (Mechanical Engineering)<br />

Major in Manufacturing<br />

Supervisors: Pr<strong>of</strong>. Mustafizur Rahman and Pr<strong>of</strong>. Wong Yoke San<br />

Dissertation topic: Micro-EDM based Multi-process machining<br />

<strong>of</strong> Tungsten Carbide<br />

Coursework CAP: 4.42/5.00<br />

Bangladesh <strong>University</strong> <strong>of</strong> Engineering and Technology (BUET),<br />

Dhaka, Bangladesh (1998 2004)<br />

B. Sc. Engg. (Mechanical Engineering)<br />

Advisor: Pr<strong>of</strong>. Amalesh Chandra Mandal<br />

Supervisor: Pr<strong>of</strong>. Dipak Kanti Das<br />

Coursework CGPA: 3.59/4.00<br />

Thesis topic: Study <strong>of</strong> a Water Hammer<br />

HONORS AND<br />

AWARDS<br />

, for the best paper published in the<br />

Proceedings <strong>of</strong> IMechE as a significant contribution to the field <strong>of</strong><br />

manufacturing, Division <strong>of</strong> Manufacturing Industries <strong>of</strong> the<br />

Institution <strong>of</strong> Mechanical Engineers, London, UK, June 2010<br />

research grant from Ministry <strong>of</strong><br />

Science and Innovation, Spain, June 2010 <br />

'Heidenhain Scholarship' from European Society for<br />

Precision Engineering and Nanotechnology (EUSPEN) as a<br />

scheme <strong>of</strong> supporting young researchers, 2010<br />

'Heidenhain Scholarship' from the EUSPEN, 2007<br />

by National <strong>University</strong> <strong>of</strong> Singapore<br />

(NUS), August, 2005 July, 2009<br />

from Bangladesh <strong>University</strong><br />

Page 1 <strong>of</strong> 6

<strong>of</strong> Engineering and Technology (BUET), 1998 -2003<br />

from BUET, 1998-2003<br />

from Dhaka Education Board, 1995-1997<br />

from Govt. <strong>of</strong> Bangladesh, 1992-1994<br />

from Govt. <strong>of</strong> Bangladesh, 1989-1991<br />

RESEARCH AND<br />

WORK<br />

EXPERIENCES<br />

Working as Research Associate, August, 10 Present<br />

Worked as R&D Engineer in Makino, August, 09 July 10<br />

Worked as Research Scholar in NUS, August, 2005 July, 2009<br />

Worked in two research projects <strong>of</strong> Makino, July August, 2009<br />

Guided 6 Final year B. Eng. Students in 2007, 2008 and 2009<br />

Worked as Engineer (Internship) in Bangladesh Machine<br />

Tools Factory Limited (BMTF Ltd.), 2002<br />

PREVIOUS<br />

RESEARCH<br />

PROJECTS<br />

Glass micro-grinding using on-machine fabricated PCD tool by<br />

means <strong>of</strong> micro-EDM: Hybrid micromachining (2010)<br />

Fabrication <strong>of</strong> high-aspect-ratio micro-structures and microholes<br />

using hybrid machining (2008-2009)<br />

Vibration assisted micro-EDM <strong>of</strong> WC (2008-2009)<br />

Powder mixed micro-EDM <strong>of</strong> WC (2008-2009)<br />

Sinking and Milling micro-EDM for machining <strong>of</strong> WC (2008).<br />

Fine-finish die-sinking micro-EDM <strong>of</strong> WC (2007-2008).<br />

Machinability evaluation <strong>of</strong> WC-Co against SUS 304 in micro-<br />

EDM drilling (2007-2008).<br />

Performance <strong>of</strong> Transistor and RC-type pulse generator for the<br />

micro-EDM <strong>of</strong> WC (2006).<br />

Effects <strong>of</strong> different machining parameters (both for Transistortype<br />

and RC-type) on performance <strong>of</strong> the micro-EDM <strong>of</strong> tungsten<br />

carbide: Basic parametric study (2006).<br />

ACADEMIC<br />

SERVICES<br />

Reviewer. Proceedings <strong>of</strong> the Institution <strong>of</strong> Mechanical<br />

Engineers, Part B: Journal <strong>of</strong> Engineering Manufacture<br />

Reviewer, International Journal <strong>of</strong> Advanced Manufacturing<br />

Technology (IJAMT), Springer<br />

Reviewer, Journal <strong>of</strong> Materials Processing Technology (JMPT),<br />

Elsevier Science<br />

PROFESSIONAL<br />

AFFILIATIONS<br />

Member <strong>of</strong> IES, Singapore , Since 2005<br />

Member <strong>of</strong> EUSPEN, Since 2005<br />

Member <strong>of</strong> GSS, NUS, Since 2005<br />

Member and founding member <strong>of</strong> Advisory students from<br />

postgraduate <strong>of</strong> BSS, NUS, Since 2007<br />

Members <strong>of</strong> OC-IEB, Singapore (applied)<br />

POSTGRADUATE<br />

COURSES<br />

Modeling <strong>of</strong> machining processes<br />

Linear systems<br />

Abrasive and non-conventional machining processes<br />

Engineering Plastics and Composites Materials<br />

Materials characterization<br />

Corrosion <strong>of</strong> materials<br />

Mechanical Engineering Oil & Gas Technology<br />

Graduate English Course (Intermediate level)<br />

Graduate English Course (Advanced level)<br />

Page 2 <strong>of</strong> 6

TRAINING AND<br />

WORKSHOPS<br />

Safety training in NUS, 2005<br />

Risk assessment workshop, 2008<br />

Scientific Writing Course, 2008<br />

Mechanics <strong>of</strong> Nanoscale Engineered & Biological Materials<br />

Summer Course, 8 - 9 July 2008, Singapore-MIT Alliance (SMA)<br />

TECHNICAL<br />

EXPERTISE<br />

CNC machines (Milling, Turning, Sinker EDM, WEDM)<br />

Optical Microscopes (Keyence, Nomarski, Mitutoyo)<br />

Taylor-Hobson surface roughness tester<br />

Scanning Electron Microscope (SEM)<br />

Energy Dispersive X-ray (EDX)<br />

Atomic Force Microscopy (AFM)<br />

COMPUTER<br />

SKILLS<br />

Programming Language: C++<br />

S<strong>of</strong>tware & Packages: Mat Lab, AutoCAD, Solid works, MS Office<br />

Operating system: Windows 98, Windows XP<br />

EXTRA-<br />

CURRICULAR<br />

ACTIVITIES<br />

Organized and participated in functions and cultural activities<br />

Hobbies: Indoor games, Reading, Traveling<br />

PUBLICATIONS<br />

Book Chapter:<br />

1. M.P. <strong>Jahan</strong>, A.B.M.A. Asad, M. Rahman, Y.S. Wong, T. Masaki,<br />

Micro-Electro Discharge Machining (micro-EDM), Chapter 10,<br />

-<br />

in Dec, 2010)<br />

Journals (Peer-Reviewed):<br />

1. M.P. <strong>Jahan</strong>, T. Saleh, M. Rahman, Y.S. Wong, Development,<br />

modeling and experimental investigation <strong>of</strong> low frequency<br />

workpiece vibration assisted micro-EDM <strong>of</strong> tungsten carbide,<br />

Transaction <strong>of</strong> ASME: Journal <strong>of</strong> Manufacturing Science and<br />

Engineering, 2010 (accepted, in press).<br />

2. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, Modeling and experimental<br />

investigation on the effect <strong>of</strong> nanopowder mixed dielectrics in finefinish<br />

micro-EDM <strong>of</strong> tungsten carbide, Proceedings <strong>of</strong> the Institution<br />

<strong>of</strong> Mechanical Engineers, Part B: Journal <strong>of</strong> Engineering<br />

Manufacture, 2010 (available online).<br />

3. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, Study on the nano-powder<br />

mixed sinking and milling micro-EDM <strong>of</strong> WC-Co, International<br />

Journal <strong>of</strong> Advanced Manufacturing Technology (online).<br />

4. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, L. Fuhua, On-machine<br />

fabrication <strong>of</strong> high-aspect-ratio microelectrodes and application in<br />

vibration-assisted micro-EDM drilling <strong>of</strong> tungsten carbide,<br />

Proceedings <strong>of</strong> the Institution <strong>of</strong> Mechanical Engineers, Part B:<br />

Journal <strong>of</strong> Engineering Manufacture (available online).<br />

Page 3 <strong>of</strong> 6

5. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman, A comparative experimental<br />

investigation <strong>of</strong> deep-hole micro-EDM drilling capability for<br />

cemented carbide (WC-Co) against austenitic stainless steel (SUS<br />

304), International Journal <strong>of</strong> Advanced Manufacturing Technology<br />

Volume 46, Numbers 9-12 / February, 2010.<br />

6. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman, A Comparative Study on the<br />

Performance <strong>of</strong> Sinking and Milling micro-EDM for Nan<strong>of</strong>inishing<br />

<strong>of</strong> Tungsten Carbide, International Journal <strong>of</strong> Nanomanufacturing<br />

(accepted, in press).<br />

7. M.P. <strong>Jahan</strong>, M.M. Anwar, Y.S. Wong, M. Rahman, Nan<strong>of</strong>inishing <strong>of</strong><br />

hard materials using micro-EDM, Proceedings <strong>of</strong> the Institution <strong>of</strong><br />

Mechanical Engineers, Part B: Journal <strong>of</strong> Engineering Manufacture,<br />

Vol. 223, No. 9, pp. 1127-1142, 2009 . Announced as one <strong>of</strong> three<br />

most highly commended papers in 2009 in Proc IMechE part B: JEM<br />

8. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman, A study on the fine-finish diesinking<br />

micro-EDM <strong>of</strong> Tungsten Carbide using different electrode<br />

materials, Journal <strong>of</strong> Materials Processing Technology, Vol. 209,<br />

Issue 8, pp. 3956-3967, 2009. Ranked#11 in the Science Direct Top<br />

25 Hottest Articles (Materials Science), April June 2009;;<br />

Ranked#23 in July - September 2009.<br />

9. M.P. <strong>Jahan</strong>, Y.S. Wong, and M. Rahman, A study on the quality<br />

micro-hole machining <strong>of</strong> Tungsten Carbide by micro-EDM process<br />

using Transistor and RC-type pulse Generator, Journal <strong>of</strong> Materials<br />

Processing Technology, Vol. 209, Issue 4, pp. 1706-1716, 2009.<br />

Ranked#14 in the Science Direct Top 25 Hottest Articles (Materials<br />

Science), January March 2009.<br />

10. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman, A.B.M.A. Asad, An experimental<br />

investigation on the surface characteristics <strong>of</strong> Tungsten Carbide for<br />

the fine-finish Die-sinking and Scanning micro-EDM, International<br />

Journal <strong>of</strong> Abrasive Technology, Vol. 2, No. 3, pp. 223-244,<br />

2009 (invited paper).<br />

11. M.P. <strong>Jahan</strong>, Y.S. Wong and M. Rahman, Effect <strong>of</strong> non-electrical and<br />

gap control parameters in the micro-EDM <strong>of</strong> WC-Co, Journal <strong>of</strong><br />

Machining & Forming Technologies, Nova Science (USA), Vol. 1/2,<br />

pp. 51-78, 2009.<br />

12. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman, A Comparative Study <strong>of</strong><br />

Transistor and RC Pulse Generators for Micro-EDM <strong>of</strong> Tungsten<br />

Carbide, International Journal <strong>of</strong> Precision Engineering and<br />

Manufacturing, Vol. 9, No. 4, pp. 3-10, 2008.<br />

13. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, Migration <strong>of</strong> materials during<br />

finishing micro-EDM <strong>of</strong> tungsten carbide, Key Engineering<br />

Materials, Vol. 443, pp. 681-686, 2010.<br />

14. M.P. <strong>Jahan</strong>, T. Saleh, M. Rahman, Y.S. Wong, Study <strong>of</strong> Micro-EDM<br />

<strong>of</strong> Tungsten Carbide with Workpiece Vibration, Advanced Materials<br />

Research (in press).<br />

15. Asma Perveen, M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong;; Cutting Force<br />

Analysis <strong>of</strong> On-Machine Fabricated PCD Tool during Glass Micro-<br />

Grinding, Advanced Materials Research (in press).<br />

Page 4 <strong>of</strong> 6

16. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, Experimental Investigations<br />

into the Migration <strong>of</strong> Materials and its Effect on Surface<br />

Characteristics during Fine-finish Micro-EDM <strong>of</strong> Cemented<br />

Tungsten Carbide, Materials and Manufacturing Processes (invited<br />

paper, submitted).<br />

17. Asma Perveen, M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong;; Microgrinding<br />

<strong>of</strong> glass using on-machine fabricated PCD tool, International<br />

Journal <strong>of</strong> Advanced Manufacturing Technology (under review).<br />

18. M. Rahman, M.P. <strong>Jahan</strong>, Y.S. Wong, A review on the current<br />

research trends <strong>of</strong> electro-discharge machining (EDM) and micro-<br />

EDM <strong>of</strong> difficult-to-cut Tungsten Carbide, International Journal <strong>of</strong><br />

Automation Technology, Fuji press, Japan (invited paper, to be<br />

submitted)<br />

19. M.P. <strong>Jahan</strong>, T.W. Lieh, Y.S. Wong and M. Rahman, An experimental<br />

investigation into the electro-discharge machining behavior <strong>of</strong> p-<br />

type silicon (to be submitted).<br />

20. M.P. <strong>Jahan</strong>, T.W. Liang, Y.S. Wong and M. Rahman, Micro-EDM<br />

Process Development for Machining <strong>of</strong> Micro-punch Array (to be<br />

submitted).<br />

International Conferences:<br />

1. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong;; Migration <strong>of</strong> Materials during<br />

Finishing Micro-EDM <strong>of</strong> Tungsten Carbide;; APCMP2010 - The 9th<br />

Asia-Pacific Conference on Materials Processing, 7-10 June 2010,<br />

Sydney, Australia.<br />

2. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, Modeling and experimental<br />

study <strong>of</strong> vibration-assisted micro-EDM <strong>of</strong> cemented carbide, euspen<br />

10 th International Conference;; Delft, Netherlands;; May 31 st -4 th June,<br />

2010.<br />

3. M.P. <strong>Jahan</strong>, M. Rahman, Y.S. Wong, L. Fuhua, Fabrication <strong>of</strong> highaspect-ratio<br />

EDM microelectrodes using on-the-machine tool<br />

fabrication techniques, The 8th International Conference <strong>of</strong><br />

Mechanical Engineering (ICME2009), 26-28 December, 2009,<br />

BUET, Dhaka, Bangladesh.<br />

4. M.P. <strong>Jahan</strong>, Y.S. Wong and M. Rahman, A study on fine-finish<br />

micro-EDM <strong>of</strong> tungsten carbide in nanopowder-mixed dielectric,<br />

3rd International Conference <strong>of</strong> Asian Society for Precision<br />

Engineering and Nanotechnology (ASPEN) 2009, November 11 th -13 th ,<br />

2009, Japan.<br />

5. Asma Perveen, M.P. <strong>Jahan</strong>, Y.S. Wong and M. Rahman, Cutting force<br />

analysis <strong>of</strong> on-machine fabricated PCD tool during glass microgrinding,<br />

AMPT 2009, 26 - 29 October, 2009, Kuala Lumpur,<br />

Malaysia.<br />

6. M.P. <strong>Jahan</strong>, T. Saleh, Y.S. Wong and M. Rahman, Study <strong>of</strong> micro-<br />

EDM <strong>of</strong> tungsten carbide with workpiece vibration, Advances in<br />

Materials and Processing Technologies conference (AMPT 2009), 26<br />

- 29 October, 2009, Kuala Lumpur, Malaysia.<br />

7. M.P. <strong>Jahan</strong>, Y.S. Wong and M. Rahman, A comparative study on the<br />

performance <strong>of</strong> sinking and milling micro-EDM for nan<strong>of</strong>inishing <strong>of</strong><br />

Page 5 <strong>of</strong> 6

tungsten carbide, 6th International Symposium on Nano<br />

Manufacturing (ISNM-6), 12-14 November, 2008, Athens, Greece<br />

(CD ROM proceedings).<br />

8. M.P. <strong>Jahan</strong>, M.M. Anwar, Y.S. Wong, M. Rahman, Generation <strong>of</strong><br />

nano-level surface finish in the micro-EDM <strong>of</strong> hard tool/die<br />

materials using RC-generator, The 1st International Conference on<br />

Nanomanufacturing (nanoMan 2008), SMU, Singapore, July 14-16 ,<br />

2008, pp. 342 (CD ROM proceedings).<br />

9. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman, A.B.M.A. Asad, An experimental<br />

investigation on the surface characteristics <strong>of</strong> Tungsten Carbide for<br />

the fine-finish Die-sinking and Scanning micro-EDM, The 7th Asia<br />

Pacific Conference on Materials Processing (APCMP), Guangzhou-<br />

Guilin, China, June 15-20, 2008, pp. 612-617 (CD ROM proceedings).<br />

10. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman;; A comparative study on the<br />

performance <strong>of</strong> Transistor and RC type Pulse generator with focus<br />

in obtaining best quality micro-hole during the micro-EDM <strong>of</strong><br />

Tungsten Carbide--24 March, 2007 NITJ-INDIA,<br />

(CD ROM proceedings).<br />

11. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman;; Towards Fine-finish micro-<br />

EDM <strong>of</strong> Tungsten Carbide using RC-Generator;; In Proceedings <strong>of</strong><br />

-30 November 2007',<br />

Nagoya, Japan, pp. 252-257.<br />

12. M.P. <strong>Jahan</strong>, Y.S. Wong, M. Rahman;; Identification <strong>of</strong> operating<br />

parameters for improved performance <strong>of</strong> micro-EDM <strong>of</strong> Tungsten<br />

Carbide<br />

Bremen, Germany;; May 20th--339.<br />

REFERENCES<br />

Ajay P. Malshe, Ph.D., FInstP, FASME<br />

21st Century Endowed Chair Pr<strong>of</strong>essor <strong>of</strong> Materials,<br />

Manufacturing and Integrated Systems<br />

Director, Materials and Manufacturing Research Laboratories<br />

(MMRL)<br />

Mechanical Engineering, MEEG 204<br />

<strong>University</strong> <strong>of</strong> <strong>Arkansas</strong><br />

Fayetteville, AR 72701<br />

Tel (479) 575-6561<br />

Email apm2@uark.edu<br />

Dr Mustafizur RAHMAN<br />

Pr<strong>of</strong>essor, National <strong>University</strong> <strong>of</strong> Singapore<br />

Dept. <strong>of</strong> Mechanical Engineering<br />

Phone: +65-6516-2168 ;; Fax: +65-6516-1459<br />

E-mail: mpemusta@nus.edu.sg<br />

Homepage: http://serve.me.nus.edu.sg/musta<br />

Dr WONG Yoke San<br />

Pr<strong>of</strong>essor, National <strong>University</strong> <strong>of</strong> Singapore<br />

Dept. <strong>of</strong> Mechanical Engineering<br />

Phone: +65-6516-2221 ;; Fax: +65-6516-1459<br />

E-mail: mpewys@nus.edu.sg<br />

Homepage: http://serve.me.nus.edu.sg/wongys/index.htm<br />

Page 6 <strong>of</strong> 6