Bus Chassis Leaflet - Buses - Tata Motors

Bus Chassis Leaflet - Buses - Tata Motors

Bus Chassis Leaflet - Buses - Tata Motors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The complete range<br />

of bus platforms<br />

SFC 410 BS III<br />

LPO 1512 BS III<br />

LPO 1613 CNG BS IV<br />

LP 909 CNG BS IV

STARBUS<br />

ULTRA<br />

DIVO<br />

Designed with the use of the most superior technology, bus chassis from<br />

<strong>Tata</strong> <strong>Motors</strong> have definitely established a benchmark for performance<br />

and reliability in the bus industry. These chassis are best suited for providing<br />

the level of comfort and suspension required for various applications.<br />

They comply with BS III and BS IV norms, and are available as diesel and<br />

CNG vehicles.<br />

Read on to know more about the wide range of chassis from <strong>Tata</strong> <strong>Motors</strong>.

Attractive Advantages<br />

<strong>Tata</strong> 497 engine<br />

• Higher power-to-weight ratios and torque, for better acceleration, pulling & gradeability<br />

• Optimal power, for higher fuel efficiency & lowest NVH<br />

• Electronic diesel control, for better diagnostics<br />

<strong>Tata</strong> 3.8 SGI engine & <strong>Tata</strong> 5.7 SGI engine<br />

• Multi-point gas injection, for individual cylinders for better fuel control<br />

• Deceleration fuel cut-off & skip firing strategy of cylinders, to save fuel<br />

• Full electronic control with onboard diagnostics<br />

Cummins 6BT 5.9 - 135 engine<br />

• Optimum power with higher torque, for best pulling with highest fuel efficiency<br />

• 4 valves/cylinder for better fuel combustion & mileage<br />

• Superior Cummins mechanically driven engine, for continuous heavy duty operation<br />

& easy maintenance<br />

• Higher flat torque curves, for better acceleration & mileage<br />

Cummins 6BT 5.9 - 180 - 30 engine<br />

• 4 valves per cylinder for better fuel combustion and higher fuel efficiency<br />

• Higher power & torque, for better pulling & direct drive AC operation<br />

• Superior Cummins mechanically driven engine, for continuous heavy duty operation<br />

& easy maintenance<br />

Voith hydrodynamic retarder<br />

• Greatly enhanced tyre & brake liner life<br />

• Superior braking distances, for high speed applications<br />

• Higher safety on highways<br />

• Minimal driver fatigue<br />

GBS 27 Gearbox<br />

• Compact gearbox with side PTO<br />

• High torque carrying capacity<br />

GBS 40 Gearbox<br />

• Compact gearbox with high torque carrying capacity<br />

• More first gear torque<br />

• Less dense gear ratio, for higher speed<br />

GBS 550 Gearbox<br />

• Lightweight 6-speed gearbox with overdrive,<br />

for better mileage & higher maximum speed<br />

• Double cone steel synchroniser gives 30% more life<br />

• Available in direct, remote & cable shift mechanism option<br />

G-600 Gearbox with OD<br />

• Maximum geared speed with optimised gear ratios<br />

• Better fuel efficiency & acceleration with overdrive feature<br />

• High first gear torque, for better pulling capacity<br />

Warranty<br />

LCV Range (407, 410 & 712)<br />

Engine - 3 years/3 lakh km, whichever is earlier<br />

Driveline - 3 years/3 lakh km, whichever is earlier<br />

ICV Range (909, 912)<br />

Engine - 3 years/3 lakh km, whichever is earlier<br />

Driveline - 3 years/3 lakh km, whichever is earlier<br />

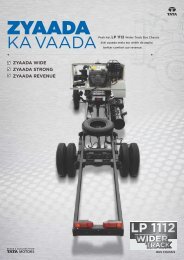

ICV Range (1112)<br />

Engine - 2 years/2 lakh km, whichever is earlier<br />

Driveline - 2 years/2 lakh km, whichever is earlier<br />

MCV Range (1512 Ex, 1612 Ex, 1613 & 1618)<br />

Engine - 2 years/2 lakh km, whichever is earlier<br />

Driveline - 1.5 years/1.5 lakh km, whichever is earlier

SL # TYPE Engine Clutch Gearbox Steering Suspension Brakes Tyres Fuel Tank Options Available<br />

Power Torque Description Clutch Dia Type WB (mm) ROH (mm) FOH (mm) Length (mm) Width (mm) GVW (kg) Min. TCD (m)<br />

SFC 410 100 HP @ 300 Nm @ G-380 Semi-elliptical Hydraulic brake 2750 1000 665 / 745 4415 / 4495 2092 / 1976 4800 11<br />

1<br />

Diesel BS III 2800 rpm 1400-1500 rpm<br />

<strong>Tata</strong> 4 SP TCIC 280 mm<br />

5 + 1<br />

Variable ratio<br />

Leaf Spring (F&R) with EEB fitment<br />

7.00 R x 16-12 PR 60 ltrs<br />

3100 1000 665 / 745 4765 / 4845 2092 / 1976 5300 12<br />

LP 407<br />

Vacuum-assisted<br />

2 CNG<br />

85 HP @ 270 Nm @<br />

<strong>Tata</strong> 3.8 SGI 280 mm<br />

GBS-27 Hydraulic Semi-elliptical<br />

dual circuit<br />

7.50 x 16-16 PR 310 ltrs - 4<br />

3400 1940 1275 6615 2140 6520 12.3<br />

BS IV<br />

2500 rpm 1200-1500rpm 5 + 1 power-assisted Leaf Spring (F&R)<br />

hydraulic<br />

Radial Cylinders<br />

LP 410<br />

Vacuum-assisted<br />

3 Diesel<br />

100 HP @ 300 Nm @<br />

<strong>Tata</strong> 4 SP TCIC 280 mm<br />

GBS-27<br />

Variable ratio<br />

Semi-elliptical<br />

dual circuit 7.50 x 16-16 PR 60 ltrs 3400 1940 1275 6615 2140 6520 12.3<br />

BS III<br />

2600 rpm 1400-1500 rpm 5 + 1 Leaf Spring (F&R)<br />

hydraulic<br />

LP 410<br />

Vacuum-assisted<br />

4 Diesel<br />

100 HP @ 300 Nm @<br />

<strong>Tata</strong> 497 TCIC 280 mm<br />

GBS-550 Hydraulic Semi-elliptical<br />

dual circuit 7.50 x 16-16 PR 60 ltrs 3400 1940 1275 6615 2140 6520 12.3<br />

BS IV<br />

2600 rpm 1300-1800 rpm 6 + 1 power-assisted Leaf Spring (F&R)<br />

hydraulic<br />

Ambulance<br />

<strong>Chassis</strong> 100 HP @ 300 Nm @ G-380 Variable ratio Parabolic Spring Vacuum-assisted<br />

5 <strong>Tata</strong> 4 SP TCIC 280 mm<br />

7.00 R 16-12 PR 60 ltrs 3100 1000 665 4765 2092 4350 12<br />

SFC 410 2800 rpm 1400-1500 rpm 5 + 1 (F&R) dual circuit<br />

Diesel BS III<br />

Dual circuit<br />

LP 712 Variable 3400 1750 1275 6425 2140 7490 12.3<br />

125 HP @ 400 Nm @ GBS-40 Semi-elliptical<br />

full air S-Cam<br />

6 Diesel<br />

<strong>Tata</strong> 497 TCIC 310 mm (power option<br />

7.50 x 16-16 PR 160 ltrs 3800 2050 1275 7125 2140 7490 13.5<br />

2400 rpm 1300-1500 rpm 5 + 1 Leaf Spring (F&R)<br />

brake with<br />

BS III<br />

for 42 WB)<br />

4200 2270 1275 7745 2140 7490 14.6<br />

EEB fitment<br />

hydraulic<br />

7<br />

Dual circuit<br />

3400 2050 1180 / 1275 6330 / 6425 2020 / 2140 7490 12.3<br />

LP 712 125 HP @ 400 Nm @ GBS-550 Semi-elliptical<br />

full air S-Cam<br />

<strong>Tata</strong> 497 TCIC 310 mm Power-assisted 7.50 x 16-16 PR 160/120 ltrs 3800 2050 1180 / 1275 7030 / 7025 2020 / 2140 7490 13.5<br />

Diesel BS IV 2400 rpm 1300-1500 rpm 6 + 1 Leaf Spring (F&R)<br />

brake with<br />

4200 2280 1275 7745 2020 / 2140 7490 14.6<br />

EEB fitment<br />

Dual circuit<br />

8<br />

LP 912 125 HP @ 400 Nm @ GBS-40 Semi-elliptical full air S-Cam 8.25 x 16-16 PR<br />

<strong>Tata</strong> 497 TCIC 310 mm Power-assisted<br />

Diesel BS III 2400 rpm 1300-1500 rpm 5 + 1 Leaf Spring (F&R) brake with<br />

cross ply std<br />

160 ltrs 4920 1275 2700 8895 2100 9000 17.5<br />

EEB fitment<br />

9<br />

LP 912 125 HP @ 400 Nm @ GBS-550 Semi-elliptical<br />

full air S-Cam<br />

<strong>Tata</strong> 497 TCIC 310 mm Power-assisted<br />

Diesel BS IV 2400 rpm 1300-1500 rpm 6 + 1 Leaf Spring (F&R)<br />

brake with<br />

8.25 x 16-16 PR 160 ltrs 4920 2700 1275 / 1430 8897 2140 / 2200 9000 17.5<br />

EEB fitment<br />

10<br />

LP 909 85 HP @ 270 Nm @ GBS-27 Semi-elliptical<br />

full air S-Cam 8.25 x 16-16 PR 480 ltrs/<br />

<strong>Tata</strong> 3.8 SGI 280 mm Power steering<br />

CNG BS IV 2500 rpm 1500-1800 rpm 5 + 1 Leaf Spring (F&R)<br />

brake with<br />

390 ltrs<br />

4920 1275 2700 8895 2140 9400 17.5<br />

EEB fitment<br />

310 mm for 3600 & Dual circuit<br />

Variable steering 3600 1730 1275 6605 2270 10500 14.8<br />

LP 1112 125 HP @ 400 Nm @ 4200 WB 330 mm GBS-40 Semi-elliptical<br />

full air S-Cam<br />

11 <strong>Tata</strong> 497 TC TCIC Power steering 8.25 x 20-14 PR 160 ltrs<br />

4200 2100 1275 7575 2270 10500 16.6<br />

Diesel BS III 2400 rpm 1300-1500 rpm for 4855 WB<br />

5 + 1 Leaf Spring (F&R)<br />

brake with<br />

for 4855 WB 4855 2913 1185 8953 2434 12670 19<br />

EEB fitment<br />

Dual circuit<br />

Dual circuit<br />

Dual circuit, 4225 1970 1185 7380 2560 14860 16.8<br />

G-600 Integral hydraulic Semi-elliptical Leaf Spring brake with<br />

160 ltrs/ 5195 3115 1185 9495 2560 16200 20.3<br />

12 LP/LPO 1512 Ex 135 HP @ 490 Nm @ CUMMINS<br />

with Overdrive power-assisted (F&R) Weveller suspension option 10 R 20-16 PR<br />

352 mm EEB fitment<br />

250 ltrs 5334 3200 1785 9716 2560 14860 20.1<br />

Diesel BS III 2400 rpm 1400-1600 rpm 6BT 5.9 TC<br />

6 + 1 steering Pneumatic suspension option (New Generation<br />

5545 3325 1775 10645 2560 16200 20.83<br />

LP/LPO 1613 130 HP @ 430 Nm @ <strong>Tata</strong> 697 G-40 Hydraulic Front - Semi-elliptical Leaf Spring; Dual circuit full 5195 3115 1185 9495 2560 16200 20.3<br />

13<br />

Diesel BS IV 2500 rpm 1350-1800 rpm TCIC BS IV<br />

330 mm<br />

5 + 1 power steering Rear - Leaf Spring air S-Cam<br />

10 R 20-16 PR 250 ltrs<br />

5545 3325 1775 10645 2560 16200 20.83<br />

Front - Semi-elliptical Leaf Spring; Dual circuit full 4 CNG cylinders<br />

14<br />

LPO 1613 130 HP @ 405 Nm @ <strong>Tata</strong> 5.7<br />

330 mm<br />

G-40 Hydraulic<br />

Rear - Leaf Spring/ air S-Cam 11 R 22.5-16 PR of 135 ltrs each &<br />

5545 3325 1775 / 2250 10645 / 2434 16200 20.4<br />

CNG BS IV 2500 rpm 1250-1500 rpm SGI BS IV 5 + 1 power steering<br />

Pneumatic Suspension NGT brake one cylinder of 110 ltrs<br />

11120<br />

Dual circuit<br />

15<br />

G-600 Integral hydraulic Semi-elliptical Leaf Spring (F&R)<br />

LPO 1612 Ex 135 HP @ 490 Nm @ CUMMINS 6 BT<br />

full air S-Cam brake<br />

352 mm with Overdrive power-assisted Weveller suspension option<br />

Diesel BS III 2400 rpm 1400-1600 rpm 5.9-180-30; TC<br />

(New Generation<br />

6 + 1 steering Pneumatic suspension option<br />

modified brakes)<br />

10 R 20-16 PR 250 ltrs 6200 3400 2250 11850 2434 16000 23.66<br />

LPO 1618 180 HP @ 675 Nm @ CUMMINS 6 BT G-600 Hydraulic Front - Semi-elliptical Leaf Spring; Dual circuit full 2434 for Face<br />

16 Diesel BS III 2500 rpm 1400 rpm 5.9-180-30; 352 mm with Overdrive power steering Rear - Pneumatic Suspension air S-Cam brake 11 R 22.5-16 PR 250 ltrs 6200 3400 2250 11850 & 2580 for 16200 23.66<br />

*TCIC - Turbo-charged, Inter-cooled | SGI - Sequential Gas Injection<br />

full air S-Cam<br />

modified brakes)<br />

4855 2285 1185 8325 2560 14860 19<br />

5845 3510 1755 11110 2560 16200 21.7<br />

BS III; TC 6 + 1 w/o Face

<strong>Bus</strong> Body Building Guidelines<br />

It is important to ensure that the body is fitted to the vehicle chassis in such a way that the load imposed is transmitted evenly. At the same time, the rigidly mounted<br />

body must flex with the frame. Care should be taken to ensure that the body and the vehicle chassis are compatible. An example of bad selection would be a<br />

construction in which a short body is made on a long wheel base. In this case, it becomes necessary to shorten the chassis rear overhang to accommodate the body. As<br />

a result, the centre of gravity moves forward, and a load greater than what is desirable, is imposed on front axle.<br />

It is also essential to give careful consideration to the movement or modification of the various parts of the vehicle. These include electrical wiring, electrical equipment,<br />

brake connections, brake piping, frame modification like chassis extension and other chassis components - to ensure good performance in operation.<br />

Apart from the above recommendations, you should always follow the tips given below, to get the best performance from your vehicle.<br />

1. Keep body weight minimum by selecting proper design and materials. This will save fuel and increase tyre life.<br />

2. Use curved window glass, avoid sharp corners and protruding destination boards, to reduce air resistance.<br />

3. Ensure that body dimensions, seating space and gangway width comply with current government regulations.<br />

4. Ensure ease of removal and assembly of various aggregates like gearbox, suspension, battery, spare wheel, etc. Also provide flaps/cut outs for servicing.<br />

5. De-rust, phosphate and apply primer to the body skeleton before fixing panels.<br />

6. Use zinc plated hardware of standard quality, for various body joints.<br />

7. While carrying out structural work, protect instrument panel, steering wheel, driver's/co-driver's seats, brake fluid containers, hoses etc. from damage.<br />

8. Do not drill or weld chassis frame or remove any rivet. Do not use chassis or leaf spring as the earthing point during welding.<br />

9. Do not clamp bus body cross bearers to chassis cross member.<br />

10. No body mountings should foul with any chassis aggregate or frame cross member.<br />

11. Avoid practice of cutting chassis cross member for mounting of 'U'<br />

bolts.<br />

12. Do not extend chassis rear overhang. If required, contact us.<br />

13. Avoid eccentric mounting of cross bearers.<br />

14. Do not use balata packing more than 6 mm thick for cross bearer mounting. This will result in premature perishing and damage to the chassis long member. In case<br />

thicker packing is required, use steel plates to compensate along with 6 mm balata packing.<br />

15. Avoid ' U ' bolts touching the chassis long members. This should be done by using aluminum alloy packing between ' U ' bolt bottom radius and long member<br />

bottom flange.<br />

16. As far as possible, avoid post location over wheel arch.<br />

17. Do not modify the front side of the cowl in a way that it would restrict the air flow to the radiator and air cleaner. Reducing the height/width of the centre flap or<br />

closing the louvres provided on the cowl front face are to be avoided.<br />

18. No restriction should be placed beneath the remote mounted air filter. Provide sufficient clearance for fitment and removal of the air cleaner.<br />

19. The air intake hoses are not to be distributed during body building. However, if hoses are removed for any reason, cover the turbocharger and intake manifold<br />

openings with suitable plastic caps to avoid foreign dust particles entry, till the time the hoses are connected back. The clamps should be properly tightened<br />

during this operation.<br />

20. The service indicator fitted on the air cleaner outlet pipe should not be tampered with, by way of painting etc.<br />

21. Always close the mouth of the air intake to turbo charger when the air filter is removed during body building.<br />

22. Do no reroute air intake, coolant and fuel lines.<br />

23. Do not keep the radiator open so as to avoid contamination of coolant with dust and foreign material.<br />

24. Disconnect battery and alternator connections before starting any electrical wielding on chassis/body.<br />

(Avail Recon Unit Exchange for<br />

Engine Long Block & Components)<br />

Enroll Today!<br />

(Annual Maintenance Contract Facility)<br />

For more information, please call our Toll-free no. 1800 209 7979, visit our website:<br />

www.buses.tatamotors.com or email us at businfo@tatamotors.com.<br />

You can also contact our Sales Office: <strong>Tata</strong> <strong>Motors</strong> Limited, 20th Floor, Tower 2, One<br />

Indiabulls Centre, 841, Senapati Bapat Marg, Mumbai 400 013. Tel: 91 22 6658 6000;<br />

Fax: 91 22 6658 6010.<br />

CAUTION: Accessories shown in the picture or elsewhere do not constitute standard fitment. The specifications are<br />

merely indicative. Due to continuous product improvements, these specifications are liable to change without notice.