You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cylinder liners<br />

The steadily rising demands on internal combus<br />

tion engines require also in the area of cylinder<br />

working surfaces continuous improvements.<br />

The precise matching of the honed cylinder liners<br />

with the pistons and piston rings, leads to im -<br />

proved results in the engine. For cylinder liners<br />

made from gray cast iron, it is therefore necessary<br />

to create optimum surfaces that contribute<br />

to lower oil consumption and blow-by, produce<br />

less wear particles and allow shorter running-in<br />

times and therefore a longer service life.<br />

<strong>MAHLE</strong> manufactures cylinder liners for international<br />

engine manufacturers for series production<br />

and the aftermarket – always according to the<br />

same strict quality standards. We manufacture<br />

our cylinder liners with very strict tolerances.<br />

There by ensuring, among other things, that the<br />

cylinder liners can be optimally fitted into the<br />

engine block. Additional important quality characteristics<br />

of our cylinder liners are the materials,<br />

the structure and the surface quality. In close<br />

co operation with engine manufacturers, we de -<br />

ter mine the composition of the melt, the treatment<br />

of the melt and the machining process.<br />

Materials<br />

In addition to aluminum, cast iron alloys are used<br />

as materials for cylinder liners. Lamellar graphite<br />

cast iron is alloyed with phosphorus. Additional<br />

alloy materials improve the wear properties and<br />

can strengthen the matrix due to bainite and very<br />

fine perlite formations.<br />

Honing methods<br />

Good honing has a positive effect on piston ring<br />

wear, particle emission, oil consumption and friction.<br />

With further developments and innovations<br />

in the honing of cylinder liners, it is attempted to<br />

keep the running-in phase of the cylinder<br />

(engine) as short as possible and to achieve<br />

improved tribological properties. An important<br />

prerequisite for good and regular honing of the<br />

cylinder liners is high material quality. This<br />

means, cast material free of voids, with homoge -<br />

neous structure and uniform hardness as well<br />

as suitable pre-machining of the bore.<br />

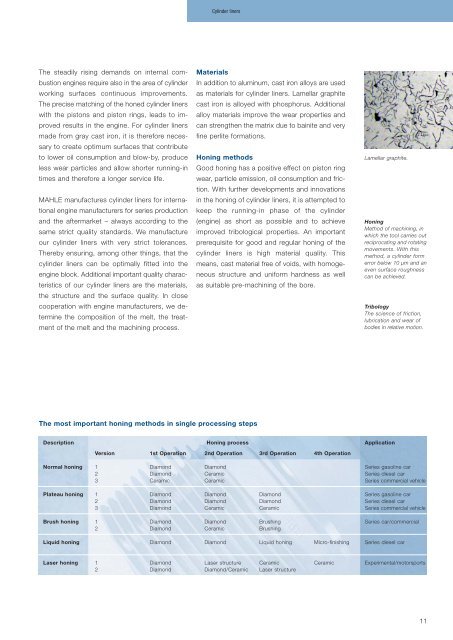

Lamellar graphite.<br />

Honing<br />

Method of machining, in<br />

which the tool carries out<br />

reciprocating and rotating<br />

movements. With this<br />

method, a cylinder form<br />

error below 10 μm and an<br />

even surface roughness<br />

can be achieved.<br />

Tribology<br />

The science of friction,<br />

lubrication and wear of<br />

bodies in relative motion.<br />

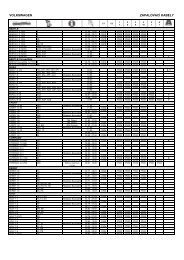

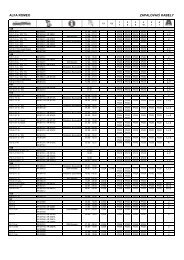

The most important honing methods in single processing steps<br />

Description<br />

Honing process<br />

Application<br />

Version<br />

1st Operation<br />

2nd Operation<br />

3rd Operation<br />

4th Operation<br />

Normal honing<br />

1<br />

2<br />

3<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Diamond<br />

Ceramic<br />

Ceramic<br />

Series gasoline car<br />

Series diesel car<br />

Series commercial vehicle<br />

Plateau honing<br />

1<br />

2<br />

3<br />

Diamond<br />

Diamond<br />

Diamond<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Series gasoline car<br />

Series diesel car<br />

Series commercial vehicle<br />

Brush honing<br />

1<br />

2<br />

Diamond<br />

Diamond<br />

Diamond<br />

Ceramic<br />

Brushing<br />

Brushing<br />

Series car/commercial<br />

Liquid honing<br />

Diamond<br />

Diamond<br />

Liquid honing<br />

Micro-finishing<br />

Series diesel car<br />

Laser honing<br />

1<br />

2<br />

Diamond<br />

Diamond<br />

Laser structure<br />

Diamond/Ceramic<br />

Ceramic<br />

Laser structure<br />

Ceramic<br />

Experimental/motorsports<br />

11