Preparing Your Laboratory to Certify or Accredit Under ISO 15189

Preparing Your Laboratory to Certify or Accredit Under ISO 15189

Preparing Your Laboratory to Certify or Accredit Under ISO 15189

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Preparations and Considerations<br />

When Seeking <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong><br />

<strong>Accredit</strong>ation <strong>Under</strong> <strong>ISO</strong> <strong>15189</strong><br />

Particular Requirements f<strong>or</strong> Quality and<br />

Competence<br />

Presenter: Greg Cooper<br />

Manager, Clinical Standards and Practices<br />

Bio-Rad Lab<strong>or</strong>a<strong>to</strong>ries

Introduction<br />

• International consensus document<br />

– Harmonized standard<br />

• Countries wishing <strong>to</strong> establish standards<br />

• Labs wishing <strong>to</strong> validate quality<br />

• Clinical lab focus<br />

– <strong>ISO</strong> 17025<br />

• Good f<strong>or</strong> research and industrial lab<strong>or</strong>a<strong>to</strong>ries<br />

• Does not address unique structure, operation<br />

and needs of a medical/clinical lab<strong>or</strong>a<strong>to</strong>ry

Course Objectives<br />

• Be able <strong>to</strong> explain the difference between certification and<br />

accreditation.<br />

• <strong>Under</strong>stand the fundamentals necessary <strong>to</strong> prepare f<strong>or</strong> an <strong>ISO</strong><br />

certification <strong>or</strong> f<strong>or</strong> accreditation under an <strong>ISO</strong> standard (e.g. <strong>ISO</strong><br />

<strong>15189</strong>).<br />

• <strong>Under</strong>stand the difference between a quality operating procedure<br />

(QOP), a standard operating procedure (SOP) and a w<strong>or</strong>k desk<br />

instruction (WDI).<br />

• <strong>Under</strong>stand the difference between a policy, a process and a procedure<br />

and the relationship <strong>to</strong> <strong>ISO</strong> terms QOP, SOP and WDI.<br />

• Become familiar with the fundamentals of a quality system under <strong>ISO</strong>.<br />

• Gain general familiarity with the content of <strong>ISO</strong> <strong>15189</strong>.

Certification Versus <strong>Accredit</strong>ation<br />

• Certification<br />

– Third party <strong>or</strong>ganization (<strong>or</strong> agency) attests that<br />

product, process <strong>or</strong> service conf<strong>or</strong>ms <strong>to</strong> specified<br />

requirements<br />

• <strong>ISO</strong> 9000<br />

• <strong>Accredit</strong>ation<br />

– Third party <strong>or</strong>ganization (<strong>or</strong> agency) with auth<strong>or</strong>ity<br />

f<strong>or</strong>mally recognizes competence <strong>to</strong> perf<strong>or</strong>m a<br />

task(s)<br />

• Third party<br />

– Totally independent and unbiased

<strong>Accredit</strong>ation<br />

• Requirements<br />

– Is unique <strong>to</strong> the <strong>or</strong>ganization<br />

– May be based <strong>ISO</strong> 17025, <strong>ISO</strong> <strong>15189</strong> <strong>or</strong><br />

CLIA (US)<br />

• Considered minimums<br />

• <strong>Accredit</strong>ing <strong>or</strong>ganization may require a higher<br />

standard of perf<strong>or</strong>mance

Preparation:<br />

F<strong>or</strong>m A Steering Group<br />

• Include representatives from lab<br />

supervision and management<br />

– All departments, all shifts (w<strong>or</strong>k hours)<br />

• Aids acceptance<br />

• <strong>ISO</strong> is a collab<strong>or</strong>ative/participative scheme<br />

• May use video tapes, teleconferencing as<br />

inclusion mechanisms

Steering Group: Purpose<br />

• Write the quality policy<br />

– Brief description: what lab is about, why it exists,<br />

overall objectives<br />

– General not prescriptive<br />

• “XYZ Hospital <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> is committed <strong>to</strong> producing<br />

reliable patient test results in a manner necessary <strong>to</strong><br />

insure appropriate and timely patient care. The<br />

lab<strong>or</strong>a<strong>to</strong>ry will strive <strong>to</strong> produce reliable patient test<br />

results by combining processes that promote efficiency<br />

with technology that is appropriate <strong>to</strong> the lab<strong>or</strong>a<strong>to</strong>ry<br />

mission and operated by staff that is both trained and<br />

competent <strong>to</strong> perf<strong>or</strong>m the w<strong>or</strong>k.”

Steering Group: Purpose<br />

• Offer guidance, direction and supp<strong>or</strong>t<br />

– Provide adequate resources <strong>to</strong> develop and maintain a<br />

quality system<br />

• Convene w<strong>or</strong>king groups <strong>to</strong> write quality procedures<br />

– Discourage “<strong>to</strong>p down” development<br />

– Can be f<strong>or</strong>med acc<strong>or</strong>ding <strong>to</strong> lab<strong>or</strong>a<strong>to</strong>ry specialty<br />

• Coagulation<br />

• Immunohema<strong>to</strong>logy<br />

• Etc.<br />

– Include all lab staff<br />

• Use email, teleconferencing, videotapes <strong>to</strong> aid communication<br />

and exchange of ideas

Steering Group: Purpose<br />

• Oversee development of the quality manual<br />

– Identifies lab<strong>or</strong>a<strong>to</strong>ry management by name,<br />

position<br />

– Defines the rep<strong>or</strong>ting structure (<strong>or</strong>ganizational<br />

chart)<br />

– Provides general description of the lab<strong>or</strong>a<strong>to</strong>ry<br />

operation<br />

– States the quality policy<br />

– Contains a compendium of high level quality<br />

procedures

Quality Manger:<br />

Responsibilities<br />

• Insure the components of the quality system are current and<br />

relevant.<br />

• Insure the quality system is audited at regular intervals.<br />

• Keep lab<strong>or</strong>a<strong>to</strong>ry management inf<strong>or</strong>med of all activities and<br />

findings of the quality system.<br />

• Insure that all staff are committed <strong>to</strong> and actively involved in the<br />

quality system, adhere <strong>to</strong> its policies, and document system<br />

failures <strong>or</strong> non-conf<strong>or</strong>mances (deviations from the accepted<br />

n<strong>or</strong>m).<br />

• Facilitate introduction of new quality system procedures <strong>or</strong><br />

modifications <strong>to</strong> existing procedures.<br />

• Act as liaison between the lab<strong>or</strong>a<strong>to</strong>ry and other interfacing<br />

departments of the hospital and internally between various<br />

departments within the lab<strong>or</strong>a<strong>to</strong>ry itself.

Steering Group: Purpose<br />

• Name a quality manager<br />

– Full time <strong>or</strong> part-time<br />

– Good communica<strong>to</strong>r<br />

– Good negotia<strong>to</strong>r

Types of Quality Procedures<br />

• QOP (Quality Operating Procedure)<br />

– Can be optional<br />

– Developed f<strong>or</strong> each element of the quality<br />

system<br />

– Set lab<strong>or</strong>a<strong>to</strong>ry policy<br />

– Can be m<strong>or</strong>e than one<br />

– Supp<strong>or</strong>ts the Quality Policy

Types of Quality Procedures<br />

• SOP (Standard Operating Procedure)<br />

– Developed by the w<strong>or</strong>king groups<br />

– Provides general instructions<br />

– Assigns responsibility f<strong>or</strong> each element<br />

– Are general, not prescriptive<br />

• Describes the overall process <strong>to</strong> complete a<br />

task<br />

– Supp<strong>or</strong>ts the QOP

Types of Quality Procedures<br />

• WDI (W<strong>or</strong>k Desk Instruction)<br />

– Commonly referred <strong>to</strong> as procedure<br />

– Is a step-by step instruction<br />

• Is prescriptive<br />

• Describes how <strong>to</strong> perf<strong>or</strong>m a single specific task <strong>or</strong> activity<br />

– Usually developed by staff familiar with the<br />

lab<strong>or</strong>a<strong>to</strong>ry specialty <strong>or</strong> procedure in particular<br />

• Can be product inserts, instrument manuals, <strong>or</strong> <strong>or</strong>iginal<br />

material

Guidance F<strong>or</strong> Writing QOPs,<br />

SOPs, and WDIs<br />

• NCCLS GP 26 Application of a Quality<br />

System Model f<strong>or</strong> <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> Services<br />

• QOP = policy<br />

– Statement of policy specifying intent and direction<br />

• SOP = process<br />

– Process used <strong>to</strong> transf<strong>or</strong>m the intent in<strong>to</strong> action<br />

• WDI = procedure<br />

– Specific directions f<strong>or</strong> a specific task

Example 1<br />

• (QOP) The lab<strong>or</strong>a<strong>to</strong>ry shall implement and use an internal<br />

quality control program designed <strong>to</strong> detect those analytical<br />

err<strong>or</strong>s, which can invalidate the reliability of patient test results.<br />

• (SOP) <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> testing personnel shall use Westgard rules<br />

and biological variation limits f<strong>or</strong> all quantitative tests <strong>to</strong> moni<strong>to</strong>r<br />

the analytical quality of the testing procedure (examination).<br />

• (WDI) The w<strong>or</strong>k desk instruction(s) supp<strong>or</strong>ting this SOP would<br />

give specific directions f<strong>or</strong> moni<strong>to</strong>ring analytical quality including<br />

but not limited <strong>to</strong>:<br />

– Setting Westgard rules.<br />

– Interpreting violations.<br />

– Setting biological variation limits.

Example 2<br />

• (QOP) The lab<strong>or</strong>a<strong>to</strong>ry shall implement and use an internal<br />

quality control program designed <strong>to</strong> detect those analytical<br />

err<strong>or</strong>s, which can invalidate the reliability of patient test results.<br />

• (SOP) <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> staff shall test quality control materials at an<br />

interval and in combinations suitable <strong>to</strong> detect analytical err<strong>or</strong>.<br />

• (WDI)The w<strong>or</strong>k desk instructions would give specific directions<br />

about:<br />

– When <strong>to</strong> test quality control materials.<br />

– Which concentrations of the control material <strong>to</strong> test (n<strong>or</strong>mal,<br />

abn<strong>or</strong>mal low and/<strong>or</strong> abn<strong>or</strong>mal high).

QUALITY SYSTEM HIERARCHY<br />

<strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong><br />

QUALITY<br />

POLICY<br />

<strong>ISO</strong> ELEMENT<br />

POLICY (QOP)<br />

<strong>ISO</strong> <strong>15189</strong> has 23 Elements<br />

PROCESS (SOP)<br />

PROCESS (SOP)<br />

PROCESS (SOP)<br />

PROCEDURE (WDI) PROCEDURE (WDI) PROCEDURE (WDI)<br />

PROCEDURE (WDI)<br />

PROCEDURE (WDI)<br />

PROCEDURE (WDI)

<strong>ISO</strong> <strong>15189</strong> Quality System<br />

Elements<br />

• 23 quality system elements<br />

– Each may have a QOP<br />

– Each must have at least one SOP and one<br />

<strong>or</strong> m<strong>or</strong>e WDIs.

<strong>ISO</strong> <strong>15189</strong>: Element 4.1<br />

Organization and Management<br />

• Legally identifiable.<br />

• Free of any financial <strong>or</strong> political conflicts of interest.<br />

• Lab management is responsible:<br />

– F<strong>or</strong> design, implementation and maintenance of the quality<br />

system.<br />

• Accomplished through policies and procedures.<br />

• Granting auth<strong>or</strong>ity and responsibility.<br />

– To provide adequate resources.<br />

• Financial, educational and human.<br />

– To appoint a quality manager.<br />

• A c<strong>or</strong>e requirement

<strong>ISO</strong> <strong>15189</strong>: Element 4.2<br />

Quality Management System<br />

• Document all policies, programs and<br />

procedures<br />

• Communicate <strong>to</strong> all lab staff<br />

• Have a quality policy<br />

• Have and maintain a quality manual<br />

• A c<strong>or</strong>e requirement

<strong>ISO</strong> <strong>15189</strong>: Element 4.3<br />

Document Control<br />

• Definition<br />

– “inf<strong>or</strong>mation (meaningful data) and its supp<strong>or</strong>ting<br />

medium” (<strong>ISO</strong> 9000-2000)<br />

– “An item of a factual <strong>or</strong> inf<strong>or</strong>mative nature”<br />

(NCCLS NRSCL8))<br />

– General rule:<br />

• Something not written upon except f<strong>or</strong> an auth<strong>or</strong>izing<br />

signature, stamp <strong>or</strong> official seal<br />

– Examples:<br />

• QOPs, SOPs, WDIs, product inserts, MSDS sheets,<br />

research papers, journal articles

<strong>ISO</strong> <strong>15189</strong>: Element 4.3<br />

Document Control<br />

• Approved and controlled<br />

• Reviewed at regular intervals f<strong>or</strong><br />

relevancy<br />

– Procedure f<strong>or</strong> amendments <strong>or</strong> changes<br />

• Found on a Master List of documents<br />

– Obsolete documents<br />

• A c<strong>or</strong>e requirement

<strong>ISO</strong> <strong>15189</strong>: Element 4.4<br />

Review of Contracts<br />

• Review contracts at regular intervals f<strong>or</strong><br />

services delivered by lab<strong>or</strong>a<strong>to</strong>ry <strong>to</strong><br />

clients<br />

– Sufficient resources:staff and knowledge<br />

base<br />

– Appropriate methods<br />

– Proper w<strong>or</strong>k environment <strong>to</strong> meet<br />

obligations<br />

• Can be f<strong>or</strong>mal <strong>or</strong> inf<strong>or</strong>mal

Type of <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong><br />

Hospital-Based<br />

Remote <strong>or</strong> Clinic-Based<br />

Reference Lab<strong>or</strong>a<strong>to</strong>ries<br />

Potential cus<strong>to</strong>mers<br />

Emergency<br />

Infection control<br />

Intensive care units<br />

Medical school (if part of institution)<br />

Medical staff<br />

Nursing administration<br />

Outpatients<br />

Pharmacy<br />

Radiology<br />

Referring clinicians<br />

Research lab<strong>or</strong>a<strong>to</strong>ries (if part of institution)<br />

Suppliers/Vend<strong>or</strong>s<br />

Utilization review<br />

Community<br />

Main <strong>or</strong> parent lab<strong>or</strong>a<strong>to</strong>ry<br />

Medical staff<br />

Referring clinicians<br />

Suppliers/Vend<strong>or</strong>s (not always-depends on<br />

au<strong>to</strong>nomy)<br />

Clinicians<br />

Governments (military possibly)<br />

Pharmaceutical companies<br />

Referring lab<strong>or</strong>a<strong>to</strong>ries<br />

Suppliers/Vend<strong>or</strong>s<br />

University-based research entities

<strong>ISO</strong> <strong>15189</strong>: Element 4.5<br />

Examination By Referral Lab<strong>or</strong>a<strong>to</strong>ries<br />

• Outside services<br />

– Referral lab<strong>or</strong>a<strong>to</strong>ries<br />

• Procedure f<strong>or</strong> evaluating and selecting<br />

– Require quality system in place<br />

» Certification/accreditation<br />

• On-going moni<strong>to</strong>r of referral lab<strong>or</strong>a<strong>to</strong>ries<br />

– Blind specimens, perf<strong>or</strong>mance on EQA

<strong>ISO</strong> <strong>15189</strong>: Element 4.6<br />

External Services and Supplies<br />

• Policies and procedures f<strong>or</strong>:<br />

– Selecting outside vend<strong>or</strong>s<br />

– Verifying purchased services meet lab<br />

requirements<br />

• Cheaper products/services may not be<br />

produced under a quality system<br />

– Questionable quality

<strong>ISO</strong> <strong>15189</strong>: Element 4.7<br />

Advis<strong>or</strong>y Services<br />

• Meet regularly with medical staff<br />

– Services provided<br />

– Knowledge base required

<strong>ISO</strong> <strong>15189</strong>: Element 4.8<br />

Resolution of Complaints<br />

• Primary opp<strong>or</strong>tunity <strong>to</strong> identify<br />

weaknesses in the quality system<br />

– Opp<strong>or</strong>tunities f<strong>or</strong> improvement<br />

• Maintain rec<strong>or</strong>d of the complaint<br />

– Nature, date of occurrence, individuals<br />

involved, any investigations undertaken,<br />

resolution<br />

• A c<strong>or</strong>e requirement

<strong>ISO</strong> <strong>15189</strong>: Element 4.9<br />

Identification and Control of Non-conf<strong>or</strong>mities<br />

• An occurrence that conflicts with a stated<br />

policy, process <strong>or</strong> procedure<br />

• Must be:<br />

– Rec<strong>or</strong>ded, investigated<br />

• Identify and document root cause and<br />

c<strong>or</strong>rective action<br />

• Halt testing<br />

– Depends on nature of non-conf<strong>or</strong>mance and<br />

criticality<br />

– Results rep<strong>or</strong>ted may need <strong>to</strong> be recalled<br />

• A c<strong>or</strong>e element

<strong>ISO</strong> <strong>15189</strong>: Element 4.9<br />

Identification and Control of<br />

Non-conf<strong>or</strong>mities<br />

• Examples of non-conf<strong>or</strong>mities:<br />

– Testing a plasma sample when a serum sample is<br />

required<br />

– Using expired reagents<br />

– Modifying the test procedure without appropriate<br />

approvals<br />

– Increasing incubation temperature <strong>to</strong> decrease<br />

incubation time<br />

– Improper preservation of samples<br />

– Using tap water instead of distilled <strong>or</strong> reagent<br />

grade water

<strong>ISO</strong> <strong>15189</strong>: Element 4.10<br />

C<strong>or</strong>rective Action<br />

• Document and rec<strong>or</strong>d<br />

• Moni<strong>to</strong>r and document effectiveness<br />

• Maintain rec<strong>or</strong>ds<br />

– Use <strong>to</strong> design process improvements<br />

• A c<strong>or</strong>e element

<strong>ISO</strong> <strong>15189</strong>: Element 4.11<br />

Preventative Action<br />

• Actions taken <strong>to</strong> prevent non-conf<strong>or</strong>mances<br />

(occurrences)<br />

– Policy and procedure<br />

• Examples of possible preventative actions<br />

– Regular review of QC data<br />

• Trends, shifts , other anomalies<br />

– Participation in an external quality assessment<br />

scheme (EQA/EQAS)<br />

• Proficiency testing in the US

<strong>ISO</strong> <strong>15189</strong>: Element 4.12<br />

Continual Improvement<br />

• Review all operational procedures regularly<br />

– Minimum is annual<br />

• Review the quality system annually<br />

– Rec<strong>or</strong>ds of complaints <strong>or</strong> non-conf<strong>or</strong>mances<br />

– Redundant/obsolete policies/procedures<br />

• Implement quality indica<strong>to</strong>rs <strong>to</strong> moni<strong>to</strong>r lab<br />

contribution <strong>to</strong> overall patient care<br />

• A c<strong>or</strong>e element

<strong>ISO</strong> <strong>15189</strong>: Element 4.13<br />

Quality and Technical Rec<strong>or</strong>ds<br />

• Definition:<br />

– “a document (inf<strong>or</strong>mation and supp<strong>or</strong>ting medium)<br />

stating results achieved <strong>or</strong> providing evidence of<br />

activities perf<strong>or</strong>med” (<strong>ISO</strong> 9000-2000)<br />

– “a document that furnishes objective evidence of<br />

inf<strong>or</strong>mation obtained, activities perf<strong>or</strong>med <strong>or</strong><br />

results achieved” (NCCLS NRSCL8)<br />

– General rule:<br />

• “something that is written upon”

<strong>ISO</strong> <strong>15189</strong>: Element 4.13<br />

Quality and Technical Rec<strong>or</strong>ds<br />

• Can be paper <strong>or</strong> electronic<br />

• Must be kept and maintained by the<br />

lab<strong>or</strong>a<strong>to</strong>ry<br />

– Specified period of time<br />

• Must be readily accessible<br />

• A c<strong>or</strong>e element

<strong>ISO</strong> <strong>15189</strong>: Element 4.13<br />

Quality and Technical Rec<strong>or</strong>ds<br />

• Some examples:<br />

–QC rec<strong>or</strong>ds<br />

– Instrument prin<strong>to</strong>uts<br />

– Patient test requisitions and rep<strong>or</strong>ts<br />

– Rec<strong>or</strong>ds of specimen referrals<br />

– Non-conf<strong>or</strong>mances<br />

– Complaint rec<strong>or</strong>ds<br />

– Specimen acquisition rec<strong>or</strong>ds<br />

– Calibration and maintenance logs<br />

– Logs of contact with outside clients

<strong>ISO</strong> <strong>15189</strong>: Element 4.14<br />

Internal audits<br />

• Internal audits<br />

– Regular interval<br />

• Minimum is annual<br />

– Perf<strong>or</strong>med by trained lab<strong>or</strong>a<strong>to</strong>ry staff<br />

• Avoid auditing own department<br />

– Document findings<br />

– Respond <strong>to</strong> findings<br />

• A c<strong>or</strong>e element

<strong>ISO</strong> <strong>15189</strong>: Element 4.15<br />

Management Review<br />

• Review the quality system annually<br />

– M<strong>or</strong>e frequently f<strong>or</strong> a new quality system<br />

– Assess level of commitment <strong>to</strong> the quality system<br />

– Review occurrences and activities since last review<br />

• Non-conf<strong>or</strong>mances, c<strong>or</strong>rective actions, preventative measures,<br />

feedback and complaints from clients, results from internal and<br />

external QC programs<br />

– Make <strong>or</strong> recommend changes <strong>or</strong> adjustments as necessary<br />

• Document review<br />

• A c<strong>or</strong>e element

<strong>ISO</strong> <strong>15189</strong>: Element 5.1<br />

Personnel<br />

• Job descriptions must include qualifications<br />

– Use certified <strong>or</strong> licensed personnel<br />

• Lab direc<strong>to</strong>r must have knowledge and experience <strong>to</strong><br />

direct lab<br />

• Management must provide staff adequate training<br />

• Staff must have access <strong>to</strong> continuing education<br />

• Must make eff<strong>or</strong>t <strong>to</strong> protect patient inf<strong>or</strong>mation<br />

• Comprehensive listing of direc<strong>to</strong>r responsibilities

<strong>ISO</strong> <strong>15189</strong>: Element 5.2<br />

Accommodation and Environmental Conditions<br />

• Adequate space, safe environment, clean w<strong>or</strong>kspace<br />

– Lighting, ventilation, water, waste and refuse disposal, dust,<br />

electromagnetic interference, ambient temperature and<br />

humidity, electrical supply, sound and vibration levels<br />

• Maintain rec<strong>or</strong>ds of environmental conditions<br />

– Temperature and humidity<br />

• Prevent cross contamination<br />

– Mycobacteriology, nucleotide amplification<br />

• Accommodate patient disabilities and privacy

<strong>ISO</strong> <strong>15189</strong>: Element 5.3<br />

<strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> Equipment<br />

• Instruments, reference materials,<br />

consumables, reagents, and analytical<br />

systems<br />

– Adequate <strong>to</strong> meet lab<strong>or</strong>a<strong>to</strong>ry quality policy<br />

– Verify perf<strong>or</strong>mance specifications<br />

• Accuracy and precision<br />

– Regularly moni<strong>to</strong>r instrument calibration and<br />

preventative maintenance<br />

• Date, time, results, adjustments, acceptance criteria, due<br />

date f<strong>or</strong> next calibration<br />

– Cofac<strong>to</strong>rs: insure current cofac<strong>to</strong>rs in use

<strong>ISO</strong> <strong>15189</strong>: Element 5.3<br />

<strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> Equipment<br />

• Validate computer software bef<strong>or</strong>e putting<br />

in<strong>to</strong> use.<br />

• Protect privacy of patient inf<strong>or</strong>mation and test<br />

results<br />

– Control access <strong>to</strong> computer files<br />

• Prevent alteration <strong>or</strong> destruction<br />

– Annex B: Recommendations f<strong>or</strong> protection of<br />

lab<strong>or</strong>a<strong>to</strong>ry inf<strong>or</strong>mation systems (LIS) (inf<strong>or</strong>mative)<br />

– Annex C: Ethics in lab<strong>or</strong>a<strong>to</strong>ry medicine<br />

(inf<strong>or</strong>mative)

<strong>ISO</strong> <strong>15189</strong>: Element 5.4<br />

Pre-examination Procedures (pre-analytical)<br />

• Requisition<br />

– Patient identification, name of <strong>or</strong>dering physician,<br />

clinician’s address, type of primary sample,<br />

ana<strong>to</strong>mic site (where appropriate), the test<br />

requested, patient gender, date of birth, pertinent<br />

clinical inf<strong>or</strong>mation as may be required f<strong>or</strong> test<br />

interpretation<br />

• Verbal requests<br />

– Have a procedure

<strong>ISO</strong> <strong>15189</strong>: Element 5.4<br />

Pre-examination Procedures (pre-analytical)<br />

• Procedures f<strong>or</strong> proper patient preparation and<br />

specimen collection<br />

– Type of sample, initials of person collecting sample,<br />

anticoagulant required, acceptable sample volume<br />

– Date and time of specimen collection noted on test request<br />

– Date and time of receipt by the lab<strong>or</strong>a<strong>to</strong>ry noted on test<br />

request<br />

• Moni<strong>to</strong>r elapsed time f<strong>or</strong> time critical tests<br />

• Specimen rejection criteria<br />

– No <strong>or</strong> inadequate patient identification<br />

– Insufficient sample<br />

– Improper sample (hemolysis)<br />

• Specimen s<strong>to</strong>rage requirements

<strong>ISO</strong> <strong>15189</strong>: Element 5.5<br />

Examination Procedures (analytical)<br />

• Validated written <strong>or</strong> electronic procedure f<strong>or</strong><br />

perf<strong>or</strong>ming the test<br />

– Common language<br />

– May be product insert, textbook procedure, journal<br />

article.<br />

– In house methods must be fully validated bef<strong>or</strong>e<br />

use.<br />

• Review reference intervals at regular intervals<br />

• A c<strong>or</strong>e requirement

<strong>ISO</strong> <strong>15189</strong>: Element 5.6<br />

Assuring Quality of Examination (Analytical)<br />

Procedures<br />

• Lab shall have an internal quality control<br />

program <strong>to</strong> verify the quality of patient<br />

test results<br />

– Regular testing of quality control materials<br />

• Stability of method, frequency of testing,<br />

average number of samples tested<br />

– Regular review of QC rec<strong>or</strong>ds<br />

– Program should detect err<strong>or</strong> when it occurs

<strong>ISO</strong> <strong>15189</strong>: Element 5.6<br />

Assuring Quality of Examination (Analytical)<br />

Procedures<br />

• Determine the uncertainty of measurement<br />

f<strong>or</strong> each test and rep<strong>or</strong>t as appropriate<br />

• Insure calibration materials are traceable <strong>to</strong><br />

SI units<br />

• Participate in EQA programs<br />

– Small private non-commercial<br />

– Large non-commercial (College of American<br />

Pathologists, CWQAL, and Lab Quality)<br />

– Commercial (Bio-Rad, Randox)

Calibration Traceability Chain<br />

Modified from <strong>ISO</strong> 17511:2003 (E) In vitro diagnostic<br />

medical devices-Measurement of quantities in biological<br />

samples-Metrological traceability of values assigned <strong>to</strong><br />

calibra<strong>to</strong>rs and control materials

<strong>ISO</strong> <strong>15189</strong>: Element 5.7<br />

Post-examination Procedures (post analytical)<br />

• Routinely review all results bef<strong>or</strong>e<br />

rep<strong>or</strong>ting by auth<strong>or</strong>ized staff<br />

• Dispose of used samples in a safe and<br />

environmentally sensitive manner

<strong>ISO</strong> <strong>15189</strong>: Element 5.8<br />

Rep<strong>or</strong>ting of Results<br />

• Rep<strong>or</strong>t on f<strong>or</strong>ms approved by Management and part<br />

of the quality system<br />

• Date and time of specimen collection, the test<br />

perf<strong>or</strong>med, reference <strong>or</strong> n<strong>or</strong>mal range, the<br />

interpretation where appropriate, name <strong>or</strong> initial of<br />

person who perf<strong>or</strong>med the test, auth<strong>or</strong>ized signature<br />

of person releasing results<br />

• Indicate if specimen was acceptable <strong>or</strong> unacceptable<br />

• Retain test rep<strong>or</strong>ts f<strong>or</strong> specified period of time

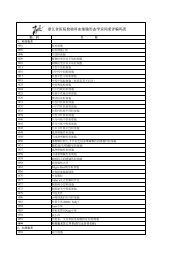

<strong>ISO</strong>/IEC 17025:1999 <strong>ISO</strong> <strong>15189</strong>:2002<br />

1.0 Scope 1.0 Scope<br />

2.0 N<strong>or</strong>mative References 2.0 N<strong>or</strong>mative References<br />

3.0 Terms and Definitions 3.0 Terms and Definitions<br />

4.0 Management Requirements 4.0 Management Requirements<br />

4.1 Organization 4.1 Organization<br />

4.2 Quality System 4.2 Quality Management System<br />

4.3 Document Control 4.3 Document Control<br />

4.4 Review of requests, tenders and contracts 4.4 Review of contracts<br />

4.5 Subcontracting of tests and calibrations 4.5 Examination by referral lab<strong>or</strong>a<strong>to</strong>ries<br />

4.6 Purchasing services and supplies 4.6 External services and supplies<br />

4.7 Service <strong>to</strong> the client 4.7 Advis<strong>or</strong>y services<br />

4.8 Complaints 4.8 Complaints<br />

4.9 Control of nonconf<strong>or</strong>ming testing and/<strong>or</strong> calibration w<strong>or</strong>k 4.9 Identification and control of nonconf<strong>or</strong>mities<br />

4.10 C<strong>or</strong>rective action 4.10 C<strong>or</strong>rective action<br />

4.11 Preventative action 4.11 Preventative action<br />

4.12 Continual improvement<br />

4.12 Control of rec<strong>or</strong>ds 4.13 Quality and technical rec<strong>or</strong>ds<br />

4.13 Internal audits 4.14 Internal audits<br />

4.14 Management reviews 4.15 Management review<br />

5.0 Technical Requirements 5.0 Technical requirements<br />

5.1 General<br />

5.2 Personnel 5.1 Personnel<br />

5.3 Accommodation and environmental conditions 5.2 Accommodation and environmental conditions<br />

5.4 Test and method validation 5.5 Examination procedures<br />

5.5 Equipment 5.3 <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> equipment<br />

5.6 Measurement traceability 5.6 Assuring the quality of examination procedures<br />

5.7 Sampling 5.4 Pre-examination procedures<br />

5.8 Handling of test and calibration items<br />

5.9 Assuring the quality of test and calibration results 5.6 Assuring the quality of examination procedures<br />

5.10 Rep<strong>or</strong>ting the results 5.8 Rep<strong>or</strong>ting of results

Summation<br />

• <strong>ISO</strong> <strong>15189</strong> sets minimum standards<br />

– It is not static – constantly evolving<br />

• Available <strong>to</strong> lab<strong>or</strong>a<strong>to</strong>ries who wish <strong>to</strong><br />

certify <strong>to</strong> an international standard<br />

verifying lab<strong>or</strong>a<strong>to</strong>ry commitment <strong>to</strong><br />

quality<br />

• Available <strong>to</strong> lab<strong>or</strong>a<strong>to</strong>ries who wish <strong>to</strong><br />

accredit under this standard.

Lab<strong>or</strong>a<strong>to</strong>ries wishing <strong>to</strong> obtain<br />

a copy of <strong>ISO</strong> <strong>15189</strong><br />

International Organization f<strong>or</strong> Standardization<br />

Web www.iso.<strong>or</strong>g<br />

Phone +41 22 749 01 11<br />

Fax +41 22 749 09 47<br />

E-mail sales@iso.<strong>or</strong>g<br />

Post <strong>ISO</strong>, 1, rue de Varembé, CH-1211 Geneva 20, Switzerland<br />

NCCLS<br />

Web www.nccls.<strong>or</strong>g<br />

Phone +1 610 688 0100<br />

Fax +1 610 688 0700<br />

Post 940 West Valley Road, Suite 1400, Wayne PA 19087 USA<br />

Lab<strong>or</strong>a<strong>to</strong>ries interested in the GP 26 standard Application of a Quality System Model f<strong>or</strong> <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> Services should<br />

contact NCCLS.

Lab<strong>or</strong>a<strong>to</strong>ries wishing m<strong>or</strong>e inf<strong>or</strong>mation<br />

regarding certification <strong>or</strong> accreditation<br />

Asia Pacific <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> <strong>Accredit</strong>ation Cooperation (APLAC)<br />

Web www.ianz.govt.nz/aplac (provides listing of member accrediting<br />

<strong>or</strong>ganizations by country)<br />

COLA (f<strong>or</strong>merly Commission on Office <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> <strong>Accredit</strong>ation)<br />

Web www.cola-international.<strong>or</strong>g<br />

Phone +1 410 381 6581<br />

Fax +1 410 381 8611<br />

Post 9881 Broken Land Parkway, Suite 200, Columbia MD 21046 USA<br />

College of American Pathologists (CAP)<br />

Web www.cap.<strong>or</strong>g<br />

Phone +1 847 832 7000<br />

Fax +1 847 832 8000<br />

Post 325 Waukegan Road N<strong>or</strong>thfield, IL 60093-2750 USA<br />

International <strong>Lab<strong>or</strong>a<strong>to</strong>ry</strong> <strong>Accredit</strong>ation Organization (ILAC)<br />

Web www.ilac.<strong>or</strong>g (provides listing of member accrediting<br />

<strong>or</strong>ganizations by country)