Custom Calendering - Hoosier Racing Tire

Custom Calendering - Hoosier Racing Tire

Custom Calendering - Hoosier Racing Tire

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

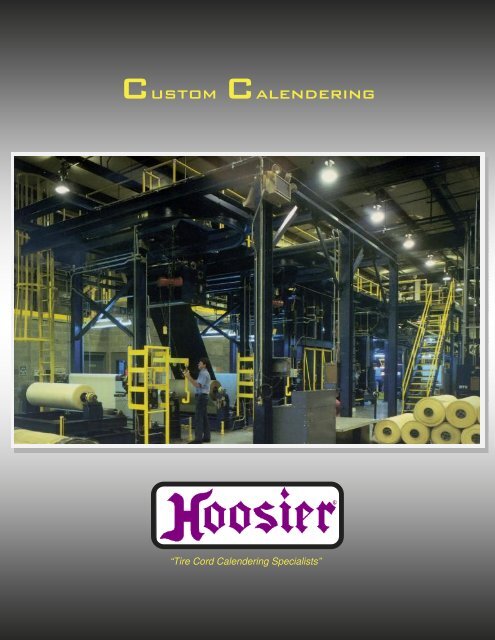

<strong>Custom</strong> <strong>Calendering</strong><br />

“<strong>Tire</strong> Cord <strong>Calendering</strong> Specialists”

Responsive Service<br />

● Performance. Finished materials<br />

produced to consistently meet<br />

the customer’s strict quality<br />

standards.<br />

● Commitment. Timely deliveries of<br />

finished goods through efficient<br />

scheduling and productive work<br />

habits.<br />

● Problem solving. When things<br />

don’t always go as planned, you<br />

can count on our specialized<br />

skills.<br />

● Flexibility. At <strong>Hoosier</strong>, we pride<br />

ourselves on our ability to “turn<br />

on a dime.” We welcome your<br />

most challenging stocks.<br />

● Experience. Let our background<br />

as a supplier of high performance<br />

materials benefit your customers.<br />

We offer the latest in calendaring<br />

and mixing technology.<br />

● Confidentiality. We understand<br />

the importance of keeping a competitive<br />

edge.

State-of-the-Art<br />

Technology<br />

● All new textile calendering system.<br />

● 4-roll inclined “Z” calender system<br />

∗ Individual calender roll drives offer infinite<br />

frictioning ratios.<br />

∗ Cross-Axis control systems (rolls #1 and<br />

#4).<br />

∗ Automatic individual roll temperature control<br />

units.<br />

● Automatic mass measuring and gauge control<br />

system (nuclear).<br />

∗ Complete analytical and production documentation<br />

capabilities.<br />

● Fully equipped operator control panel with<br />

automatic and manual capabilities.<br />

● Let-off and windup accumulators permit uninterrupted<br />

production during raw roll and finished<br />

roll changes.<br />

● Cooling drum tower provides stable control of<br />

material tack automatically.<br />

● Pin-barrel extruder<br />

∗ Capable of running the toughest of stocks.<br />

● Automatic web centering and width control<br />

units.<br />

● Pre-tension and post-tension control units.<br />

● Heavy-duty hydraulic splice press.<br />

● Fully integrated PLC drive systems.<br />

● Dual raw material let-off stations.<br />

● Dual finished material windup and liner let-off<br />

stations.<br />

● Perforation capability.<br />

● Clean environment.

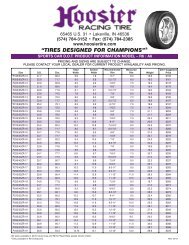

Capabilities<br />

● Maximum calendered fabric width: 59.0 inches<br />

● Minimum calendered fabric width: 30.0 inches<br />

● Maximum calendered fabric gauge: .080 inches<br />

● Minimum calendered fabric gauge: .020 inches<br />

● Maximum gum thickness (each side): .035 inches<br />

● Minimum gum thickness (each side): .008 inches<br />

● Maximum finished roll weight: 2,000 pounds<br />

● Maximum raw roll weight: 4,000 pounds<br />

● Product tolerances: per customer’s requirements<br />

State-of-the-Art R&D<br />

● Technical design of textiles, compounds, and calendered<br />

materials to customer specifications.<br />

● Post-process analysis and certification available<br />

for most applications.<br />

● Complete SPC documentation.<br />

Raw Materials<br />

● Modern intensive rubber mixing capabilities.<br />

● Modern textile weaving and treating capabilities.<br />

● Short-term warehousing available.<br />

<strong>Hoosier</strong> <strong>Tire</strong> & Rubber<br />

P.O. Box 538 ~ Lakeville, IN 46536<br />

574.784.3409<br />

“<strong>Tire</strong> Cord <strong>Calendering</strong> Specialists”