Highlights 2004 - Central Pollution Control Board

Highlights 2004 - Central Pollution Control Board

Highlights 2004 - Central Pollution Control Board

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Highlights</strong> <strong>2004</strong><br />

PREFACE<br />

Since its inception in 1974, the <strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> is committed to pollution control. We<br />

started with monitoring of ambient air and surface water. Over the years, the monitoring network has<br />

been strengthened. The <strong>Board</strong> initiated R & D efforts, standards formulations and after established itself<br />

as a technical advisory body in adition to being a regulatory agency. Over the years, we have<br />

contributed a lot towards Preventive, Promotional and Mitigative (PPM) measures for pollution control.<br />

The protection of environment calls for a multi-disciplinary approach investing various areas of science,<br />

engineering and technology. Based on monitoring in different parts of the country, we are continuously<br />

gathering and disseminating scientific and technical information as well as status and trends in<br />

environmental quality. For capacity building of State <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong>s, training programmes are<br />

regularly organised and support is provided for strengthening laboratories and infrastructural facilities.<br />

To catalyse partnerships among the stakeholders, we are continuously interacting with the student<br />

communities, NGOs, industry and civic authorities.<br />

We have made an attempt to highlight some of our activities during the year <strong>2004</strong> in this special issue of<br />

Parivesh. We seek your support in our endeavour for a better and pollution-free environment. I am<br />

thankful to Dr. B. Sengupta, Member Secretary and Dr. C.S. Sharma, Sr. Scientist of CPCB who have<br />

put in a lot of efforts to bring out the <strong>Highlights</strong>.<br />

(V. RAJAGOPALAN)<br />

Chairman, CPCB<br />

March, 2005

AIR QUALITY ASSESSMENT<br />

NATIONAL AIR QUALITY MONITORING PROGRAMME (NAMP)<br />

<strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> initiated National Ambient Air Quality Monitoring (NAAQM) programme<br />

in the year 1984 with 7 stations at Agra and Anpara. Subsequently the programme was renamed as<br />

National Air Monitoring Programme (N.A.M.P.). The number of monitoring stations under N.A.M.P. has<br />

increased, steadily, to 313 by <strong>2004</strong>-05 covering 113 cities/towns in 28 States and 4 Union Territories of<br />

the country.<br />

Under N.A.M.P., four air pollutants viz ., Sulphur Dioxide (SO 2 ), Oxides of Nitrogen as NO 2 and<br />

Suspended Particulate Matter (SPM) and Respirable Suspended Particulate Matter (RSPM/PM 10 ),<br />

have been identified for regular monitoring at all the locations. Besides this, additional parameters such<br />

as Respirable Lead and other toxic trace metals, Hydrogen Sulphide (H 2 S), Ammonia (NH 3 ) and<br />

Polycyclic Aromatic Hydrocarbons (PAHs) are also being monitored at selected locations. The<br />

monitoring of meteorological parameters such as wind speed and direction, relative humidity and<br />

temperature was also integrated with the monitoring of air quality. . The monitoring of pollutants is<br />

carried out for 24 hours (4-hourly sampling for gaseous pollutants and 8-hourly sampling for particulate<br />

matter) with a frequency of twice a week, to have 104 observations in a year. The monitoring is being<br />

carried out with the help of <strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong>: ; State <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong>s :<strong>Pollution</strong><br />

<strong>Control</strong> Committees:National Environmental Engineering Research Institute (NEERI), Nagpur: and other<br />

research institutions/universities etc. CPCB co-ordinates with these agencies to ensure the uniformity<br />

and consistency of air quality data and provides technical and financial support to them for operating the<br />

monitoring stations.<br />

Air Quality Status and Trends<br />

Sulphur dioxide (SO 2 )<br />

• Annual average concentration of SO 2 levels are within the prescribed National Ambient Air<br />

Quality Standards (NAAQS) at almost all the locations. A decreasing trend has been observed<br />

in sulphur dioxide levels in many cities<br />

• There has been a change in domestic fuel use from coal to LPG. Also various measures have<br />

been taken such as reduction of sulphur in diesel that may have contributed to low levels of SO<br />

2 .<br />

Nitrogen dioxide (NO 2 )<br />

• Annual average concentration of NO 2 was also within NAAQS at most of the locations. Trend<br />

in annual average concentration of NO 2 is fluctuating in many cities<br />

• The monitoring locations near traffic intersection show high levels of NO 2 . Vehicles are one of<br />

the major sources of NO 2 in the country.<br />

Particulate Matter<br />

• Annual average concentrations of RSPM and SPM exceeded the NAAQS in most of the cities.<br />

The trend in annual average concentration of RSPM is fluctuating in most of the cities.<br />

• One of the major source of high RSPM levels is vehicles. The vehicle population is increasing<br />

exponentially in many cities. This is the single major factor responsible for high RSPM levels.<br />

• The sources of SPM include, vehicles, natural dust, industries such as thermal power plants,<br />

sugar, cement etc., resuspension of dust, refuse burning etc.<br />

• The reason for high particulate matter levels may be vehicles, engine gensets, small scale<br />

industries, biomass incineration, boilers and emission from power plants, resuspension of<br />

traffic dust, commercial and domestic use of fuels, etc.<br />

• Lower levels of RSPM and SPM were observed during monsoon months possibly due to wet<br />

deposition. Higher levels of RSPM and SPM were observed during winter months possibly due<br />

to lower mixing heights and more calm conditions.<br />

• One of the reason for low levels of pollution in coastal cities like Chennai is that it has excellent<br />

ventilation effects due to sea and land breezes which reduces pollution levels.<br />

Non-attainment Cities

CPCB has identified list of polluted cities in which the prescribed National Ambient Air Quality Standards<br />

(NAAQS) are violated. These cities have been identified based on ambient air quality data obtained<br />

under National Air Quality Monitoring Programme (NAMP) for the period 1995 to 2003. The list of nonattainment<br />

cities state-wise is enclosed. Action plans are being formulated and implemented to control<br />

air pollution in non-attainment cities by respective states.<br />

Strengthening of National Air Quality Monitoring Programme (NAMP)<br />

Monitoring stations were sanctioned in cities like Khajuraho, Gwalior, Tirupati, Vijayawada, Asansol,<br />

Ranchi etc. State <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong>s were asked to monitor additional pollutants like carbon<br />

monoxide etc. near traffic intersections. Non-operational stations were made operational. Monitoring<br />

through automatic continuous analysers is also being initiated in many cities.<br />

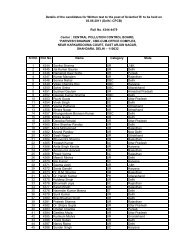

List of Non Attainment Cities in India<br />

S. No. State/Union<br />

Territory<br />

City<br />

Major Sources of<br />

<strong>Pollution</strong><br />

Air Pollutants of<br />

Concern<br />

1 Andhra Pradesh Hyderabad Vehicles RSPM, SPM<br />

Visakhapatnam Vehicles, Industries RSPM, SPM<br />

2 Assam Guwahati Vehicles, Industries RSPM, SPM<br />

3 Bihar Patna Vehicles, Natural Dust RSPM, SPM<br />

4 Chandigarh Chandigarh Vehicles, Industries RSPM, SPM<br />

5 Chattisgarh Bhilai Industries RSPM, SPM<br />

Korba Industries RSPM, SPM<br />

Raipur Vehicles RSPM, SPM<br />

6 Delhi Delhi Vehicles NO 2 , RSPM, SPM<br />

7 Goa Panaji Industries, Vehicles SPM<br />

8 Gujarat Ahemadabad Vehicle, Industries RSPM, SPM<br />

Ankleshwar Industries RSPM, SPM<br />

Jamnagar Industries, Vehicles RSPM, SPM<br />

Rajkot Vehicles, Natural Dust RSPM, SPM<br />

Surat Industries, Vehicles RSPM, SPM<br />

Vadodara Vehicles, Industries RSPM, SPM<br />

Vapi Industries RSPM, SPM<br />

9 Haryana Faridabad Vehicles, Industries SPM<br />

Yamuna Nagar Industries, Vehicles SPM<br />

10 Himachal Pradesh Damtal Natural Dust SPM<br />

Paonta Sahib Natural Dust SPM<br />

Parwanoo Industries, Natural Dust RSPM, SPM<br />

Shimla Natural Dust SPM<br />

11 Jharkhand Dhanbad Industries NO 2 , SPM<br />

Jamshedpur Industries NO 2 , SPM<br />

Jharia<br />

Industries, Natural Dust SPM<br />

Sindri<br />

Industries, Natural Dust SPM<br />

12 Karnataka Bangalore Vehicle RSPM, SPM<br />

Mysore Vehicles RSPM<br />

13 Kerala Kottayam Vehicles RSPM<br />

Kochi Vehicles, Industries RSPM, SPM<br />

Thiruvananthapuram<br />

Vehicles<br />

RSPM<br />

Kozhikode Natural Dust RSPM<br />

14 Madhya Pradesh Bhopal Vehicle RSPM, SPM

Indore Vehicles RSPM, SPM<br />

Jabalpur Vehicles RSPM, SPM<br />

Nagda Industries SO 2 , RSPM, SPM<br />

Satna Industries RSPM, SPM<br />

15 Maharashtra Chandrapur Industries RSPM, SPM<br />

Mumbai Vehicles, Industries RSPM, SPM<br />

Pune Vehicles, NO 2 , RSPM, SPM<br />

Nagpur Vehicles RSPM, SPM<br />

Nashik Vehicles RSPM, SPM<br />

Solapur Vehicles, Natural Dust RSPM, SPM<br />

16 Meghalaya Shillong Vehicles RSPM<br />

17 Orissa Angul Vehicles, Industries,<br />

Natural Dust<br />

RSPM, SPM<br />

Rayagada Industries RSPM<br />

Rourkela Industries RSPM, SPM<br />

Talcher Industries RSPM<br />

18 Punjab Gobindgarh Industries RSPM, SPM<br />

Ludhiana Vehicles, Industries RSPM, SPM<br />

Jalandhar Vehicles, Industries RSPM, SPM<br />

19 Rajasthan Alwar Vehicles, Natural Dust NO 2 , RSPM, SPM<br />

Jaipur Vehicles RSPM, SPM<br />

Jodhpur Natural Dust RSPM, SPM<br />

Kota Vehicles Industries NO 2 , RSPM, SPM<br />

Udaipur Vehicles, Natural Dust NO 2 , RSPM, SPM<br />

20 Tamil Nadu Chennai Vehicle, Industries RSPM, SPM<br />

Madurai Vehicles, RSPM, SPM<br />

Coimbatore Vehicles RSPM, SPM<br />

Tuticorin Vehicles RSPM<br />

21 Uttar Pradesh Agra Vehicle, Industries RSPM, SPM<br />

Anpara Industries RSPM, SPM<br />

Kanpur Vehicles, Industries RSPM, SPM<br />

Lucknow Vehicles, RSPM, SPM<br />

Gajraula Industries RSPM, SPM<br />

Noida<br />

Vehicles, Natural Dust,<br />

Industries<br />

RSPM, SPM<br />

Varanasi Vehicles, Natural Dust RSPM, SPM<br />

22 Uttaranchal Dehradun Vehicles, Natural Dust RSPM, SPM<br />

23 West Bengal Kolkata Vehicles, Industries RSPM, SPM, NO 2<br />

Howrah Vehicles, Industries NO 2, RSPM, SPM<br />

Haldia Industries, Vehicles RSPM<br />

AMBIENT AIR QUALITY IN DELHI DURING <strong>2004</strong><br />

The <strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> has been monitoring ambient air quality at seven locations in Delhi<br />

for the past several years. The locations have been categorized on land use, i.e., residential, industrial<br />

and traffic intersection.<br />

With the reduction of sulphur content in diesel, the sulphur dioxide concentrations have shown a<br />

declining trend at most of the locations in Delhi. Sulphur dioxide in residential areas during <strong>2004</strong> has<br />

shown no change with respect to 2003 (10 µg/m 3 ), the change observed at BSZ Marg traffic<br />

intersection was also found to be insignificant.

Nitrogen dioxide is the only parameter which shows an upward trend since 2001. During <strong>2004</strong>, it<br />

increased in residential area (40 µg/m 3 ) and industrial area (42 µg/m 3 ) by 5 and 17 percent<br />

respectively, while in traffic intersection (89 µg/m 3 ) it decreased by 5 percent in comparison to 2003.<br />

Annual average SPM concentration during <strong>2004</strong> registered a decrease of approximately 4 and 2 percent<br />

respectively in industrial areas (339 µg/m 3 ) and traffic intersection (500 µg/m 3 ). SPM concentration at<br />

residential areas (330 µg/m 3 ) registered an increase of 5 percent.<br />

RSPM recorded 135 µg/m 3 in industrial areas and 228 µg/m 3 in traffic intersection during <strong>2004</strong>. These<br />

are 4 and 7 percent respectively lower than the values recorded in 2003. RSPM at residential areas<br />

(131 µg/m 3 ) registered an increasing trend of only 3 percent.<br />

CO levels measured at BSZ traffic intersection during <strong>2004</strong> was found to be 2581 µg/m 3 as against<br />

2831 µg/m 3 recorded in 2003, thus indicating a decline of 9 percent.<br />

Sulphur Dioxide levels in Ambient Air of Delhi<br />

Suspended Particulate Matter levels in Ambient Air of Delhi

Respirable Suspended Particulate Matter levels in Ambient Air of Delhi<br />

Oxides of Nitrogen levels in Ambient Air of Delhi<br />

Carbon Monoxide levels in Ambient Air of Delhi

Vehicle Registration in Millions<br />

Ambient Air Quality Trends in Delhi<br />

Parameter Percent increase/decrease in <strong>2004</strong> with respect to 2003<br />

Area<br />

Sulphur dioxide (SO 2 ) Residential 0%<br />

Industrial (+) 11%<br />

Traffic Intersection (-) 11%<br />

Nitrogen dioxide (NO 2 ) Residential (+) 5%<br />

Industrial (+) 17<br />

Traffic Intersection (-) 5%<br />

Suspended Particulate Matter (SPM) Residential (+) 5%<br />

Industrial (-) 4%<br />

Traffic Intersection (-) 2%<br />

Respirable Suspended Particulate<br />

Matter (RSPM) Residential (+) 3%<br />

Industrial (-) 4%<br />

Traffic Intersection (-) 7%<br />

Carbon monoxide (CO) Traffic Intersection (-) 9%<br />

Increase/Decrease<br />

Ambient air quality monitoring in Delhi by Mobile van<br />

The ambient air quality monitoring have been conducted at 10 (Ten) sites i.e. Red Fort, Pusa Road,<br />

Lawrence Road, Badli, Jhilmil, Windsor Place, Connaught Place S.P. Marg, Mathura Road and<br />

Safdarjung using ambient air quality monitoring van during May to July <strong>2004</strong>. Results obtained from the<br />

monitoring are depicted below:<br />

LOCATION DATE NO 2 SO 2 CO O 3 RSPM<br />

(µg/m 3 )<br />

(µg/m 3 ) (µg/m 3 ) 06-14 14-22 22-06 (µg/m 3 ) (µg/m 3 )<br />

REDFORT 06/05/04 74 21 802 4630 3100 60 289

PUSA ROAD 12/05/04 46 04 1745 2970 846 15 353<br />

LAWRENCE<br />

RD.<br />

17/05/04 69 10 1425 1315 692 36 365<br />

BADLI 19/05/04 28 08 300 767 455 30 -<br />

JHILMIL 24/05/04 62 11 797 1475 615 33 370<br />

WINDSOR<br />

PLACE<br />

26/05/04 89 03 1375 2440 1495 18 267<br />

CONN. PLACE 01/06/04 151 14 4865 4760 2355 14 395<br />

S.P. MARG 03/06/04 111 07 1185 3035 719 30 359<br />

MATHURA RD. 07/06/04 72 02 7950 5875 1581 13 231<br />

SAFDARJUNG 06/07/04 46 - 1110 1060 734 22 67

Ambient Air Quality during Deepawali, <strong>2004</strong><br />

Ambient air quality is being measured during Deepawali days for the past several years. During<br />

Deepawali days, the air quality deteriorates alarmingly due to the bursting of crackers. In order of<br />

assess the air pollution caused due to bursting of crackers, ambient air quality was measured at<br />

selected locations in Delhi during <strong>2004</strong> also. The observations are as follows:<br />

• Except for sulphur dioxide, the levels of all other pollutants at almost all the locations exceeded<br />

the air quality standards.<br />

• RSPM and SPM levels during <strong>2004</strong> at all locations were found to be higher than that recorded<br />

during 2003.<br />

• Gaseous pollutants namely Nitrogen dioxide and Sulphur dioxide recorded mixed trend in <strong>2004</strong><br />

as compared to 2003. Four locations out of eight monitored in <strong>2004</strong> recorded higher<br />

concentration as compared to 2003.<br />

Ambient Air Quality during Deepawali 2003 & <strong>2004</strong><br />

(All Values are in microgram per cubic metre)<br />

Parameter SO 2 NO 2 SPM RSPM<br />

Year 2003 <strong>2004</strong> 2003 <strong>2004</strong> 2003 <strong>2004</strong> 2003 <strong>2004</strong><br />

B.S.Z Marg 15 13 99 107 676 1107 553 896<br />

Ashok Vihar 8 9 63 43 1136 1826 877 1222<br />

Janakpuri 28 8 92 42 1209 1435 468 607<br />

Nizamuddin 4 10 71 100 787 1654 520 1161<br />

Patel Nagar 7 8 115 124 - - 788 1146<br />

Sirifort 4 13 40 51 989 - 469 936<br />

Shahazada 43 22 89 93 1177 1934 819 827<br />

Bagh<br />

Shahdara 38 17 83 80 1516 2247 920 1797<br />

Ambient Noise Level in Delhi during Deepawali, <strong>2004</strong>

Ambient noise level monitoring was carried out at various locations in Delhi, i.e. All India Institute of<br />

Medical Sciences (AIIMS), Lajpat Nagar, New Friends Colony, East Arjun Nagar, Connaught Place,<br />

India Gate, Mayur Vihar Phase – II, Raja Garden, Pitam Pura, Model Town, Patel Nagar, Kamla Nagar,<br />

Dilshad Garden and ITO on the occasion of Deepawali festival. At Kamla Nagar, Patel Nagar and<br />

Dilshad Garden noise monitoring were conducted from 18.00 hrs. to 23.00 hrs. (long duration) while at<br />

other locations short duration (half hourly noise level monitoring were conducted between 18.00 hrs. &<br />

23.00 hrs. This year, three new locations, i.e. Raja Garden , Model Town and Pitam Pura were selected<br />

for short duration monitoring. Normal day noise monitoring was conducted on November 5, <strong>2004</strong>. The<br />

findings are as follows:<br />

• Noise level on Deepawali day, <strong>2004</strong> decreased at six locations whereas it slightly increased at<br />

four locations and remained same at one location as compared to the Deepawali day, 2003<br />

(Three locations, being new could not be compared.<br />

• The Ambient noise level has increased on Deepawali day as compared to the normal day, i.e.<br />

November 5, <strong>2004</strong> at all the locations.<br />

• The average ambient noise levels on normal day were ranging from 52 to 78 Leq dB(A) and 64<br />

to 88 Leq dB(A) on Deepawali day.<br />

• Average noise values on Deepawali were ranging from 64 to 88 Leq dB(A) against last year's<br />

average values of 69 to 90 Leq dB(A).<br />

• Highest average value for noise level was observed at Model Town .<br />

Impact of fire crackers on Ambient Air Quality during Deepawali at Kanpur<br />

In order to assess the pollution generated by fire crackers, monitoring of Particulate Matter (PM 10 ), SO<br />

2 and NO 2 was conducted during Deepawali week (Deepawali on 12 th ) in year <strong>2004</strong> at Vikas Nagar,<br />

a typical residential colony of Kanpur . This study reflects the clear impact on air quality.

Rise in RSPM and NO 2 concentrations was observed during Deepawali . RSPM was increased two<br />

times to that of normal 8hours average values.<br />

Impact of Fire Crackers on Ambient Air and Noise During Deepawali at Lucknow<br />

Noise Impact in Lucknow<br />

Noise Monitoring was conducted at Gomti Nagar (R), Indira Nagar (R), Aliganj (C), Vikas Nagar (R).<br />

Noise levels are depicted below:<br />

Noise Impact in Lucknow<br />

Observations<br />

• At all the places day time, & night time Noise levels are exceeding the prescribed standards.<br />

• The maximum increase from the prescribed standards was observed at Indira Nagar in the<br />

night time of +31.2 dB(A) due to firing of crackers.<br />

• The Day time maximum deviation +25.8 dB(A) observed at Vikas Nagar.<br />

• Out of all areas monitored, maximum noise pollution was observed at Indira Nagar area. The<br />

Peak value was observed at Vikas Nagar on the day of Deepawali. Aliganj commercial area is<br />

having values higher in the evening hours during commercial activities period.<br />

Levels of Benzene Soluble Organic Fraction (BSOF) in PM 10<br />

BSOF is being sporadically measured in RSPM at BSZ Marg Traffic Intersection Delhi since 2001.<br />

Benzene Soluble Organic Fraction (BSOF) mainly comprises of hundreds of particulate bound organic<br />

compounds present in ambient air. Some of the important BSOF compounds include Polycyclic<br />

Aromatic Hydrocarbons (PAHs), Dioxins and Furans, Oxidized Hydrocarbons (aldehydes, ketones,<br />

oxyacids etc.). Measurement of BSOF gives an idea about the anthropogenic emissions originating from<br />

the combustion of fossil fuels. The concentration of BSOF in PM 10 ranged between 16 – 70 µg/m 3 .<br />

Preliminary results indicate that BSOF during the winter months were higher ranging from 34 – 70 µg/m<br />

3 , while the lowest values (16 µg/m 3 ) were observed in monsoon period. The percent BSOF in PM 10<br />

ranged between 4 and 25. The highest percentage was observed in July 2003 when average RSPM<br />

was found to be only 67 µg/m 3 (perhaps due to wash out factor) but the BSOF even at such low levels<br />

of RSPM was found to be highest (25%) in comparison to other months.<br />

BSOF Levels in RSPM at B.S.Z Marg, Delhi

Period<br />

BSOF<br />

RSPM<br />

Percent BSOF in RSPM<br />

µg/m 3<br />

µg/m 3<br />

December-2001 34 327 11%<br />

January-2002 70 387 20%<br />

December-2002 67 361 17%<br />

January-2003 44 285 12%<br />

May-2003 34 834 4%<br />

June-2003 30 944 3%<br />

July-2003 16 67 25%<br />

November-<strong>2004</strong> 52 266 20%<br />

December-<strong>2004</strong> 33 353 9%<br />

Seasonal Variation of Benzene Levels in Ambient Air of Delhi during 2003 - <strong>2004</strong><br />

<strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> is monitoring benzene in Delhi using diffusive samplers (passive<br />

sampling method) at seven locations namely Ashok Vihar, I.T.O, J.N.U., Moti Nagar, East Arjun Nagar,<br />

Siri Fort, and Town Hall. Benzene is one of the volatile organic compounds (VOC). Benzene comes<br />

under aromatic category of volatile organic compounds. Benzene is a harmful pollutant causing<br />

exposure-related health affects in human beings. It is mainly released from anthropogenic activities such<br />

as transportation (from vehicle exhaust, filling and evaporative losses), industrial processes, combustion<br />

etc.<br />

The maximum concentration of benzene was observed in winter season at all the location in comparison<br />

to summer and monsoon and ranged between 8 µg/m 3 (J.N.U) to 18 µg/m 3 (I.T.O). The benzene<br />

levels in summer season ranged between 5 µg/m 3 (J.N.U) to 11 µg/m 3 (I.T.O). Minimum concentration<br />

of benzene was observed during monsoon season at all the location and ranged between 4 µg/m 3<br />

(J.N.U) to 10 µg/m 3 (I.T.O).<br />

Active BTX Sampling Followed By ATD-GC Analysis<br />

Samples were collected at selected locations near ITO Bride for shorter period (two-three hours) using<br />

low flow pump at different time intervals including peak and lean traffic periods. The exercise was

epeated thrice during March & June <strong>2004</strong>. BTX samples collected were analysed using Automated<br />

Thermal Desorption - Gas Chromatography (ATD-GC). The observations are as follows:<br />

Benzene concentration during Peak & Lean hours along roadside near ITO Bridge<br />

Traffic intersection (ITO) recorded short-term highest Benzene level (18.5 to 59.0 µg/m 3 ) during peak<br />

hours i.e. morning & evening due to high-traffic density as compared to lean period on the same day<br />

(9.0 to 19.0 µg/m 3 ).<br />

Benzene Monitoring at CNG filling Stations<br />

Benzene levels ( 7.0- 10.0 µg/m 3 ) monitored at two CNG filling stations at CBD Complex , East Arjun<br />

Nagar, Shahdra and Inder Prastha, Ring Road were recorded low as compared to traffic intersection<br />

and petrol pumps.<br />

Benzene Monitoring at CNG Filling Stations in Delhi<br />

On-line Volatile Organic Compounds (VOCs) Monitoring in Ambient Air of Delhi (<strong>2004</strong>)<br />

<strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> is regularly monitoring volatile organic compounds (VOC's) in the<br />

ambient air at Sirifort using continuous Analyzer. The surrounding area of the monitoring station is flat<br />

plateau with dense residential localities, commercial establishments and a famous sports complex.<br />

There is no major immediate source of air pollution in the vicinity of Sirifort monitoring station. However,<br />

there may be some impact of vehicles plying on a busy road at a distance of approximate 100 meters<br />

from the station.<br />

The monthly mean concentration observed was found to be in the range of 3.9 µg/m 3 to 18.4 µg/m 3<br />

and 7.7 ug/m 3 to 47.3 ug/m 3 of Benzene and Toluene respectively. The maximum mean concentration<br />

of Benzene (18.4 µg/m 3 ) and Toluene (47.3 µg/m 3 ) observed in the month of November and the<br />

minimum value 3.9 µg/m 3 and 7.7 ug/m 3 in month of March. High levels in November may be<br />

attributed to the low inversion conditions in winter month.

Poly aromatic Hydrocarbons (PAHs) Monitoring in Ambient Air in Delhi<br />

Poly Aromatic Hydrocarbons are one of the EPAs seven specific categories of air toxics. These<br />

pollutants pose serious health hazards in urban areas because of multiple sources especially vehicular<br />

traffic, thermal power plants, and industrial & domestic fuel burning. <strong>Central</strong> <strong>Pollution</strong> control <strong>Board</strong> has<br />

started particulate PAH measurement. The samples are collected at six NAAQM (TSPM laden PAH)<br />

locations and one integrated monitoring station at ITO (TSPM and RSPM laden PAH). 15 important PAH<br />

compound such as major PAH Napthalene, Phenanthrene, Anthracene, Fluoranthene, Pyrene,<br />

Chrysene, Benzo (a) anthracene, Benzo (b) fluoranthene, Benzo (k) fluoranthene, Benzo (a) pyrene,<br />

Benzo (ghi) perylene, Dibenzo(ah) anthracene, Indeno (cd) pyrene, Coronene are analysed after<br />

extraction in toluene and using GC-FID . The results of total PAHs levels measured at selected NAMP<br />

stations & at ITO are shown in following figures.<br />

Total Ambient Particulate PAH in Delhi

Total PAH in Total & Respirable Ambient Particulate in Delhi<br />

Ambient air quality monitoring in Delhi by Mobile van<br />

The ambient Noise monitoring have been conducted at 10 (Ten) sites i.e. Redfort, Pusa Road,<br />

Lawrence Road, Badli, Jhilmil, Windsor Place, Connaught Place S.P. Marg, Mathura Road, Safdarjung<br />

using ambient air quality monitoring van during May to July <strong>2004</strong>. Results obtained from the monitoring<br />

are depicted in the table below:<br />

Locations Date Morning Afternoon Evening Night<br />

REDFORT<br />

PUSA ROAD<br />

LAWRENCE<br />

ROAD<br />

BADLI<br />

JHILMIL<br />

WINDSOR<br />

PLACE<br />

CONNAUGHT<br />

PLACE<br />

S. P. MARG<br />

MATHURA<br />

ROAD<br />

07-05-<br />

04<br />

13-05-<br />

04<br />

18-05-<br />

04<br />

20-05-<br />

04<br />

25-05-<br />

04<br />

26-05-<br />

04<br />

02-06-<br />

04<br />

03-06-<br />

04<br />

07-06-<br />

04<br />

(09-10<br />

Hrs.)<br />

dB(A)<br />

(13-14<br />

Hrs.)<br />

(18-19<br />

Hrs.)<br />

59.6 59.8 64.7 57.4<br />

79.2 76.5 77.7 71.1<br />

68.8 72.1 68.9 66.9<br />

59.0 62.1 54.2 57.1<br />

74.0 75.1 70.8 74.1<br />

71.5 74.2 74.6 69.7<br />

69.1 72.2 78.9 70.9<br />

74.8 68.7 66.9 65.8<br />

80.0 75.4 75.6 70.7<br />

STANDARD 65 65 65 55<br />

(00-01 Hrs.)<br />

BTX Profile in Fugitive Emissions & Ambient Air at Mathura Refinery<br />

The BTX profile of fugitive emissions and ambient air at Mathura Refinery using ATD-GC-FID<br />

techniques is presented in following table.

BTX Profile in Fugitive Emissions & Ambient Air at Mathura Refinery<br />

(Monitored during September, <strong>2004</strong>)<br />

Fugitive Emissions Conc(mg/m 3 )<br />

Benzene Toluene Xylene<br />

Naphtha Splitter1 6.88 14.27 0.24<br />

CCRU 6.88 28.94 4.47<br />

ETP Inlet 46.60 24.21 6.00<br />

Crude oil tank 0.69 3.44 0.04<br />

Truck loading area 13.34 639.10 69.00<br />

Truck top loading 27.06 69.92 14.17<br />

MS Tank 0.59 2.14 0.05<br />

Ambient Air Conc (ug/m 3 )<br />

Benzene Toluene Xylene<br />

Farah 55.10 80.71 -<br />

Keetham 211.53 382.03 -<br />

• The Benzene was found higher near ETP inlet followed by truck top loading & truck loading<br />

area, which range between 13.34 µg/m 3 & 46.6 mg/m 3 at these locations. The second<br />

highest categories of fugitive emissions were Naphtha Splitter & CCRU sections (7.0µg/m 3 ).<br />

The Benzene concentrations monitored in crude oil & MS tanks near seals were found below<br />

1.0 µg/m 3 .<br />

• The Benzene levels monitored at two ambient air quality stations fixed by Mathura refinery for<br />

routine ambient air quality monitoring namely at Farah and Keetham were found as 55.10 &<br />

211.53 µg/m 3 respectively .<br />

Continuous Monitoring of BTX in Kanpur<br />

Monitoring for Benzene, Toluene, Ethyl Benzene, m+p Xylene and O-Xylene was done using online<br />

BTX analyzer at Sharda Nagar, Kanpur to find daily variation and long term trends.<br />

The daily average values for these parameters are arranged in the table below.<br />

Date Values are expressed in µg/m 3<br />

Benzene Toluene Ethylbenzene m+p Xylene O-Xylene<br />

06.Feb.<strong>2004</strong> 32.0 115.6 70.8 10.6 13.8<br />

09. Feb.<strong>2004</strong> 42.6 161.9 87.0 18.3 7.4<br />

12. Feb.<strong>2004</strong> 26.8 93.6 26.2 41.1 29.7<br />

16. Feb.<strong>2004</strong> 14.9 152.0 23.3 51.9 27.1<br />

25. Feb.<strong>2004</strong> 40.4 77.4 25.9 31.5 15.4<br />

15.Apr.<strong>2004</strong> 17.9 49.1 15.1 19.8 13.5<br />

20.Apr.<strong>2004</strong> 15.7 32.3 12.4 14.5 8.8<br />

25.Apr.<strong>2004</strong> 18.1 33.4 10.3 13.2 11.9<br />

Hourly distribution for a day, in February-<strong>2004</strong> is depicted below:

Observations :<br />

• The concentration of Ethylebenzene also increases with the increase in the concentration of<br />

Toluene. This is a relatively stable compound.<br />

• Benzene is a stable compound and stays in the environment for several days.<br />

• Daily variation of the pollutants shows that the concentration of Toluene increases during<br />

evening hours and remains consistent till 3-4 am.<br />

• O-Xylene is a stable compound and follows the trend of Toluene.<br />

Sodar System<br />

A Sodar System is continuously working at Parivesh Bhawan. As observed by the system in the<br />

beginning of the year the period of free convection in the atmosphere was mainly from 11.00 a.m. to<br />

04.00 p.m..In summer months period of free convection was mainly from 08.00 a.m. or 09.00 a.m. to<br />

06.00 p.m. or 07.00 p.m.. In monsoon season period of free convection was mainly from 07.00 a.m. or<br />

08.00 a.m. to 06.00 p.m. or 07.00 p.m.. In post monsoon season the period of free convection was<br />

mainly from 09.00 a.m. to 06.00 p.m.. In winter period the period of free convection was mainly from<br />

11.00 a. m. to 05.00 p. m.<br />

Ambient Air Monitoring in Kanpur<br />

Regular monitoring of SO 2 , NO x and RSPM is being conducted round the clock on all working days in<br />

Kanpur at Vikas Nagar. The data is being disseminated on web site of CPCB. Monthly average of<br />

RSPM and NO x for year <strong>2004</strong> are given below:

Studies carried out at Kanpur indicates that<br />

• Values of RSPM range from 72 µg/m 3 to 344 µg/m 3 on monthly basis.<br />

• RSPM concentration was observed high during summer months. During monsoon<br />

comparatively lower values were observed. This may be due to wash out of pollutants during<br />

rain<br />

• RSPM concentration was observed very high as compared to prescribed standards ie.100<br />

µg/m 3 (24 hr average) throughout the year except during monsoon months.<br />

• NO 2 concentration ranges from 12 µg/m 3 to 34 µg/m 3 , which is much lower than standards<br />

i.e. 80 µg/m 3 (24 hr basis)<br />

• SO 2 was observed very low, all over the year and has not at all any concern.<br />

• It is observed that the values of RSPM show an increasing trend over the years barring winter<br />

of 2001, when RSPM had gone higher due to exceptionally prolonged and acute winter. All the<br />

values are higher than the prescribed standard.<br />

• Reason for higher RSPM in Kanpur may be attributed to Vehicular pollution, bad road<br />

conditions, burning of garbage and suspension of natural dust due to dry weather and high<br />

wind velocity. Apart from these, during power cuts indiscriminate use of generators also<br />

contribute a lot to air pollution in local areas.<br />

Characterization of Respirable Suspended Particulate Matter (RSPM) in Ambient Air at Vikas<br />

Nagar, Kanpur<br />

In all major North Indian cities, RSPM concentrations are very high. The source apportionment study is<br />

needed to plan for effective mitigation strategy. Taking first step in this direction, CPCB Zonal office,<br />

North took up Characterization of RSPM to identify the constitution of dust contributing to it. Accordingly<br />

characterization of RSPM. - Benzene Soluble Organic Fractions, Polyaromatic Hydrocarbons and Anion<br />

parameters, were taken up. Analyses of Benzene Soluble Organic Fractions and Anions have started<br />

while PAH analysis is under process.<br />

Benzene Soluble Organic Fraction<br />

The Filter Papers obtained during the monitoring at Vikas Nagar, Kanpur are used for the analysis of<br />

Benzene Soluble Organic Fractions in RSPM. Organic part of the total RSPM is analyzed from March<br />

2003 to December 2003 with the help of IIT, Kanpur and thereafter developing expertise, analysis was<br />

done at CPCB, Zonal Lab, Lucknow from January to March'<strong>2004</strong>.<br />

Benzene has been widely used as the solvent and aerosol organics concentrations, expressed as<br />

Benzene Soluble Organic Fraction (BSOF). BSOF levels were high in summer and winter – highest<br />

being in summer (61 µg/m 3 ),which was against the expectation of its being higher in winter, as

temperature is low and volatile organic compounds will be mostly in particulate form. It appears that<br />

there would have been some local source of VOC in the vicinity of sampling site. Percentage of BSOF<br />

typically stayed around 8-9 percent. As expected, during monsoon time both PM 10 and BSOF levels<br />

came down considerably due to wash out of pollutants.<br />

It is found that PM 10 and BSOF correlate very well (R 2 = 0.97) shown in figure below. Typical range of<br />

organic content in PM 2.5 is 30-60 percent (USEPA, 1995) and correspondingly this can be 15-30<br />

percent in PM 10 . Since BSOF will not represent all organic compounds, therefore a value of 10<br />

percent BSOF in PM 10 appears reasonable.<br />

Observations<br />

• Results suggest that PM 10 and BSOF correlate very well. High level of PM 10 is suggesting a<br />

possibility of high level of PM 2.5 in the air of Kanpur.<br />

• The contribution of organic substances of RSPM ranges from 3% to 22% during winter month.<br />

This is contributed by various anthropogenic activities like combustion.<br />

• Inorganic component dominates the RSPM indicating that natural sources are also area for<br />

concern.<br />

• The fraction of organic component is obtained from the burning of fuel.<br />

Anions analysis<br />

GF/A Filter Papers obtained during the monitoring at Gol Chouraha, Ghantaghar, Civil Lines and<br />

Ramadevi, Kanpur (sampling period April'2001-March'2002) were used for the analysis of anions.<br />

Anions have been analyzed using Ion Chromatograph, at IIT, Kanpur. Mainly Chloride, Nitrate, Fluoride<br />

and Sulphate ions were found at all the four locations.

Among all four anions, sulphate and chloride anion were found higher at all four locations. The important<br />

reaction of SO 2 in the atmosphere is its oxidation to SO 3 , which with water gives sulfuric acid. The<br />

acid or sulphates occur as aerosols. At Civil Lines Sulphate concentration ranges from 4-35 µg/m 3 , at<br />

Ghantaghar ranges from 4-43 µg/m 3 , at Gol chouraha ranges from 3-33 µg/m 3 and at Ramadevi it<br />

ranges from 4-31 µg/m 3 . At some points NO 3 concentration was found little higher. Fluoride ion<br />

concentration was found very less at all the locations.<br />

Air Quality Monitoring in Lucknow<br />

Ambient air quality monitoring for 24 hours was conducted at Vikas Nagar a typical residential area of<br />

Lucknow for two consecutive days during Deepawali and one day background study (on 3 rd December)<br />

for PM 10 , SO 2 and NO 2 . Results of monitoring are shown as below:

Observations:<br />

• Increased RSPM and NO 2 level were observed during Deepawali.

• The increase in RSPM values is obvious in this duration because of heavy vehicular<br />

movement. This statement is reconfirmed with the increased NO 2 values simultaneously.<br />

Noise Monitoring in Hardwar (Uttaranchal)<br />

Objective of the Study were<br />

• To map the city in respect of Noise Levels.<br />

• To find the extent of violation of Ambient Noise Standards.<br />

• To identify the significant contributors to Ambient Noise Level.<br />

The results of the Noise levels (Leq values expressed in dB (A) ) at 12 locations are presented in tables<br />

below:<br />

Locations <br />

Prem Nagar<br />

( R )<br />

Ranipur<br />

More<br />

Swarn<br />

Jayanti Park<br />

BHEL ( R )<br />

BHEL Main<br />

Gate<br />

ChainRai<br />

Distt. W.<br />

Hospital<br />

Railway<br />

Station<br />

Slots ↓<br />

( R )<br />

( R )<br />

( C )<br />

( S )<br />

Morning 58 73 52 65 74 79<br />

Day 62 73 62 63 - 78<br />

Evening 62 81 56 60 - 69<br />

Night 47 71 55 50 - 75<br />

Locations Shiv Har Ki Gurukul<br />

Shanti Jwalapur<br />

Chowk Paudi<br />

Kunj<br />

Daksh<br />

Prajapati<br />

Mandir<br />

Slots ↓<br />

( S )<br />

( I )<br />

( C ) ( S )<br />

( S )<br />

( S )<br />

Morning 77 81 - 70 61 -<br />

Day 76 78 - 64 - -<br />

Evening 79 72 61 64 - 76<br />

Night 75 69 - 63 - -<br />

Observations:<br />

• Har Ki Pauri was observed as the most noisy place of Haridwar.<br />

• At all the locations noise level were found above the prescribed standards.<br />

• Loudspeakers, Generators, Traffic noise were identified as major contributor of noise.<br />

Recommendations<br />

1. Chain Rai District Women Hospital situated in the heart of the city should be shifted to<br />

some suitable location.<br />

2. Use of loud speakers at Har Ki Paudi should be minimized.<br />

3. Systematization of commercial activities can be done. For example loading and<br />

unloading of goods may be avoided during night hours near Har Ki Paudi and Shiv<br />

Chowk.<br />

4. Low noise small commercial vehicles should be allowed to ply.<br />

Noise Monitoring At Tajmahal, Agra<br />

Noise measurement study was conducted on 24 th , 25 th ,and 27 th November'<strong>2004</strong> at Red Stone<br />

area, Four Minars of Taj and on the main monument to assess the increment in the noise level due to<br />

Taj Night Viewing opening on its 350 th Anniversary. Monitoring results are depicted below :

Observations:<br />

• The Day time average Leq level is found quite high.<br />

• The night time values are also high on a normal working day where main contributors are birds,<br />

bells of the temple near by this monument.

MANAGEMENT OF MUNICIPAL SOLID WASTES<br />

Health Studies on Conservancy Staff & Ragpickers<br />

A study was initiated by CPCB on assessment of health status of conservancy staff and other<br />

community associated with handling of solid waste management. The study was taken-up at Kolkata<br />

through Chittaranjan Cancer Research Institute and at Chennai with the association with Sri<br />

Ramchandra Medical College. The objective of the study is to assess health status of each target group<br />

involved in handling of municipal solid waste (MSW).<br />

Studies at Kolkata<br />

Health assessment studies at Kolkata included clinical examination of 732 individuals of which, 376<br />

were conservancy workers, 151 regpickers and 205 controls. After detailed examination, the findings of<br />

the study are summarized below :<br />

Parameter Con RP MSW Implication<br />

Upper respiratory symptoms 43 82 93 Infection in nose, throat<br />

Lower respiratory symptoms 32 80 89 Infection in lung<br />

Impaired lung function 43 84 71 Breathing problem<br />

Sputum neutrophilia 13 53 64 Infection, Inflammation<br />

Sputum eosinophilia 11 28 36 Allergy, asthma<br />

Elevated AM number 12 65 85 High PM 10 exposure<br />

Larger and multinucleated AM 8 23 32 Sustained high pollution load<br />

Multinucleated giant cell 2 5 10 Bacterial infection<br />

Curschman's spiral 2 4 5 Obstruction in airways<br />

Goblet cell hyperplasia 2 16 25 Elevated mucus production<br />

Elevated siderophage count 6 34 44 Covert lung hemorrhage<br />

Elevated micronucleus count 8 68 82 Chromosome break<br />

Low hemoglobin, RBC in blood 17 32 45 Anemia<br />

Leukocytosis 7 26 34 Infection<br />

Elevated platelet count 12 62 75 Cardiovascular risk<br />

High platelet P-selectin 9 55 87 Cardiovascular risk<br />

Low CD4+,high CD8+cells 11 42 78 Altered immunity<br />

Low CD20+,high CD56+cells 12 54 89 Altered immunity<br />

Con = <strong>Control</strong>, RP = Ragpickers, MSW = Conservancy staff of Kolkata Municipal Corporation<br />

Methane Emissions from Landfill sites<br />

Improper disposal of waste through landfilling may cause several environmental problems. The emission<br />

of gaseous decomposition products as well as organic compounds may also affect the health of<br />

surrounding population. It is becoming essential to monitor landfill gaseous emissions (LFG) for<br />

establishing appropriate analytical methodology and to evolve strategy for their control. Monitoring of<br />

LFG has significance from the point of view of environmental impact, energy capture, etc. CPCB, in<br />

association with National Environmental Engineering Research Institute (NEERI), Nagpur and Indian<br />

Agricultural Research Institute (IARI), Delhi took-up a study on assessing levels of methane generation<br />

from landfill sites located at Delhi and Nagpur. Among the different methods available in the literature,<br />

flux box method was found suitable for monitoring from practical point of view and is simple to operate.<br />

From the results of monitoring data, it was concluded that flux box method is appropriate for estimation<br />

of landfill gas emission. Application of flux box method for monitoring landfill gas emission reveals that<br />

the rate of LFG emission for Bhandewadi disposal site is in the range of 27.3 to 165.9 mg/m 2 /sec.<br />

Validation of established methodology at disposal site at Amravati reveals that rate of LFG emission is in<br />

the range of 2.1 to 877.8 mg/m 2 /sec. Detailed investigations are required to observe net LFG emission<br />

i.e. LFG production potential, surface production of methane and its dispersion.

No relevance is observed between estimated biogas production potential and biogas emission. Though<br />

the degradation in the samples collected from bottom layer is more, complete stabilization takes years<br />

together. Further, the results of surface analysis does not differentiate between the zone of LFG<br />

emission and the stabilization zone.<br />

Status of Municipal Solid Waste Management<br />

Periodic/regular updating of inventorization including assessment of status of solid waste management<br />

(SWM) is an important activity. Such assessment are becoming essential particularly with reference to<br />

ascertaining compliance by the urban local bodies (ULBs) to Municipal Solid Wastes (Management and<br />

Handling) Rules, 2000. With this background, CPCB in association with NEERI, Nagpur has initiated a<br />

comprehensive survey for assessing status of solid waste management in the country. The survey<br />

includes following objectives;<br />

• Assessment of quantity of wastes<br />

• Assessment of characteristics of wastes<br />

• Assessment of existing status of collection, storage, transportation, treatment and disposal<br />

activities.<br />

• Studies on financial and institutional aspects<br />

• Review of the situation in the perspective of existing legislation<br />

So far, out of 59 cities/towns targeted during the first phase, 28 cities have already been intensively<br />

surveyed. After completion of survey and detailed analysis of system followed by ULBs for management<br />

of MSW, attempts will be made to suggest an indicative action plan for the benefit of municipalities.<br />

Demonstration Projects<br />

To demonstrate implementation of all the provisions of MSW rules, CPCB undertook pilot projects at<br />

North Dum-Dum and New Barrackpore municipalities in West Bengal and at Chandigarh. The purpose<br />

of this project is to undertake collection, segregation, storage, transportation, processing and disposal of<br />

waste in accordance with MSW rules. The demo-projects are on cost sharing basis where the respective<br />

local bodies have agreed to share 50% of the total cost of the project.<br />

North Dum-Dum and New Barrackpore (West Bengal)<br />

• The North Dum-Dum Municipality submitted formal NOC application to the Airport Authority<br />

Kolkata. The NOC Committee of the Kolkata Airport Authority reviewed the application and had<br />

already sent it to the Delhi Airport Authority with their recommendations for the clearance.<br />

• The New Barrackpore Municipality has received all the equipments for collection storage and<br />

transportation of solid wastes and North Dum-Dum Municipality has received 75% of the same.<br />

• West Bengal <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> has received the modified project report of NPC for landfill<br />

site from the KMDA. However, the project report of KCDC for the Compost Plant is under<br />

finalisation.<br />

• Both the municipalities have done the awareness campaign several times in their areas<br />

involving the school students, NGOs, Ward Committees, Bazar Committees. They have also<br />

prepared the documentary film, showing the awareness programme, door-to-door collection,<br />

transportation and storage of the municipal solid wastes using the new equipments procured<br />

under the project.<br />

Chandigarh<br />

• Entire supply of 100 No. Garbage container of 6.5 Cubic M. Capacity has been received.<br />

• Out of 200 Large/small cycle carts each, a total no. of 30 (large) and 67 (small) cycle carts<br />

have been received<br />

• One number of mechanical Road sweeper has been procured and performance is being<br />

assessed.<br />

• The work regarding preparation of Detailed Design, Cost estimates etc. for the remediation of<br />

existing landfill site was allotted to M/S.Eco Designs, the Consultant appointed by the Municipal<br />

Corporation. Report has been prepared for implementation.<br />

• The work order in respect of 30 numbers of SSKs has been placed and out of this 12 SSKs are<br />

completed.

Inspection Report on Collection, Transportation and Disposal of Municipal Solid Wastes in Delhi<br />

Pursuant to the directions of Hon'ble Supreme Court, dated 1 st March 1996, the <strong>Central</strong> <strong>Pollution</strong><br />

<strong>Board</strong> (CPCB) had been regularly carrying out bi-monthly inspections on municipal solid waste (MSW)<br />

management in Delhi. CPCB submitted eleven reports to the Hon'ble Court until January 1998.<br />

Subsequent to an Order of the Hon'ble Supreme Court dated 23.01.1998, CPCB submitted thirteen<br />

inspection reports to the Hon'ble High Court of Delhi. CPCB submitted the first inspection report on<br />

collection, transportation and disposal of municipal solid wastes in Delhi to the Hon'ble High Court of<br />

Delhi, vide its affidavit dated 15.04.1998, which contained summary and findings of the eleven previous<br />

reports submitted before the Supreme Court, and also a time-bound Action Plan for management of<br />

municipal solid wastes and it was prayed before the Hon'ble court that this action plan may be<br />

considered for implementation in a time bound manner by the Municipal Corporation of Delhi (MCD) and<br />

the New Delhi Municipal Council (NDMC). The Hon'ble High Court of Delhi, vide an order dated<br />

28.4.1999, directed CPCB to carry out further inspections every four month and submit the reports. In<br />

compliance with the Order, CPCB is carrying out inspections once every four months since April 1999<br />

and has submitted 24 report s so far.

PLASTIC WASTES<br />

Recycling of Plastics through Environmentally Sound Process:<br />

Jadavpur University, Kolkata in collaboration with CPCB, Delhi has reengineered a process for plastics<br />

recycling. The existing extrusion process is not considered to be environmentally sound as it causes<br />

noise and fugitive emissions. The machine developed and tested by the Department of Mechanical<br />

Engineering, Jadavpur University, Kolkata is equipped with pollution monitoring and control device and<br />

has been tested for fugitive emissions, which were found far less than traditional machines. The main<br />

components of the machine are as follows:<br />

Phase-I: Segregation, Cutting, Cleaning & pulping: Raw materials collected from the supplier is stored at<br />

the proper place. The segregated High and low density polyethylene (HDPE & LDPE) are cut and<br />

cleaned (wherever required) with the help of detergent. The cleaned plastic wastes are taken to a<br />

machine called agglomerator with low temperature heating arrangement to convert plastic wastes in the<br />

form of pulp like shape which act as raw material for extrusion process. In some cases the cleaned and<br />

cut plastic wastes directly fed to the extrusion machine.<br />

Phase – II, Extrusion & Palletization : It is done by a barrel and screw type extrusion machine with band<br />

electric heater. Power is supplied from a motor and the screw barrel is fed through a gearbox. Electric<br />

band heater is heated through electrical power source. Crushed raw material is fed through the hopper.<br />

Output from the extrusion machine is the wire shape plastics, which is palletized to get plastic granules.<br />

Re-engineering the Extrusion Process<br />

The Extrusion and Pelletisation process have been redesigned to minimise the pollution from the<br />

process and to enhance the efficiency of the process.<br />

Observations :<br />

It is anticipated that the reengineered machine can replace the existing to minimize pollution problems.<br />

Interactions are made with the manufactures to commercialize the developed machine<br />

The concentration of sulphur dioxide ( SO 2 ), gaseous Hydrochloric Acid (HCl), Formaldehyde (HCHO) ,<br />

Carbon monoxide & Dioxides ( CO & CO 2 ), NO X and Particulate matters were measured. It has been<br />

found that in most of the cases the measured value of Carbon Monoxide & Di oxides ( CO & CO 2 ) and<br />

Nitrous Oxides (NO x ) were found below the detectable limit. However, the presence of sulphur dioxide,<br />

gaseous hydrochloric acid and formaldehyde were predominant.<br />

The Pilot Plant: The Re-engineered Developed Pilot Plant (Extruder, <strong>Control</strong> Panel Hood & part of<br />

<strong>Pollution</strong> Monitoring System

Screw & its different zones of the Newly Developed Pilot Plant at the Center for Quality<br />

Management System, Jadavpur University<br />

National Symposium on "Plastics Waste Management:<br />

A National Symposium was organised on December 15, <strong>2004</strong> by Jadavpur University, Kolkata in<br />

collaboration with CPCB, Delhi at Kolkata. The recommendations of the symposium are below:<br />

• The environmental impact assessment due to the recycling process at the unit is to be carried<br />

once in a year;<br />

• The existing machines are to be restructured with pollution monitoring & treatment device;<br />

• The operators must be trained on effective extrusion process, pollution control and monitoring<br />

process. Staff working at the unit must be given awareness on the impact of potential pollutants<br />

generating from recycling process;<br />

• The screw-barrel has to covered to avoid heating the ambient atmosphere;<br />

• <strong>Control</strong>ling process temperature to help save energy vis-à-vis cost;

• Involvement of NGOs/institutions for collection of post-consumer plastics and transportation of<br />

recycling units/waste collection centers;<br />

• Establishing plastics recycling park in metropolitan cities;<br />

• Developing a corpus fund by the major producers of polymers in the country<br />

• National level Mass Awareness programmes/campaigns shall be conducted involving media<br />

and school children.<br />

Utilisation of Plastics in Road Construction:<br />

Experimental Studies<br />

Since Plastics show binding properly on softening (heating around 140 0 C) this property can be used to<br />

modify Bitumen, a binder for road construction. Studies are being carried out at Department of<br />

Chemistry on this line and it has been observed that polymer coated aggregate with Bitumen is a better<br />

materials for road construction in terms of strength and resistance to wands rain water. In addition, by<br />

this process, the plastic waste find a very useful disposal technique and a new technology can come<br />

into existence. Polymer blended Bitumen shows higher Softening point, lower penetration point, and<br />

better ductility. Polymer coated aggregate blended with Bitumen shows higher Marshall value and better<br />

stripping value showing that the mix is more suited for road laying.<br />

Process of road laying using polymer- aggregate – Bitumen mix<br />

The dry cleaned or diried plastics waste is shredded into small pieces (passing through 4.35mm sieve)<br />

The aggregate (granite) is heated to 170 o C in the Mini Hot Mix Plant and then shredded plastics waste<br />

is added, It gets softened and coated over the aggregate. Immediately the hot Bitumen (160 o C) is<br />

added and mixed well. As the polymer and the bitumen are in the molten state (liquid state) they get<br />

mixed and the blend is formed at surface of the aggregate. The mixture is transferred to the road and<br />

the road is laid. This technique is extended to <strong>Central</strong> Mixing Plant too.<br />

Salient features of the polymer-waste-bitumen mix Road<br />

• Road strength is twice stronger than normal roads;<br />

• Resistance towards water stagnation i.e. no potholes are formed;<br />

• Less bleeding during summer;<br />

• Burning of plastics waste could be avoided<br />

• It doesn't involve any extra machinery;<br />

• It doesn't increase cost of road construction; and<br />

• It helps to reduce the consumption of bituminous mix vis-à-vis reduce cost<br />

It has been observed that addition of plastics waste upto 10-15% by weight of bitumen resulted into<br />

higher values of softening point and lower values of penetration, which are appreciable improvements in<br />

the properties of the binder. This has resulted and withstood higher traffic load and high temperature<br />

variation. Several experimental stretches have been laid in the State of Tamilnadu, Maharashtra,<br />

Karnataka and Pondicherry using both Mini hot-mix and <strong>Central</strong> mixing plants.<br />

Plastics Waste Management in the States/Union Territories<br />

Government of India has notified "Recycled Plastics Manufacturer and usage Rules, 1999 as amended<br />

2003, which is applicable in all the States/Union Territories. Out of 34 States and Union territories, 15<br />

States and Union territories have brought out separate Non-biodegradable Garbage Act. These States<br />

and Union Territories are also conducting mass-awareness programmes to make the public aware<br />

about the ill-effectsof littering of plastics. As per the provisions of the "Recycled Plastics Manufacturer<br />

and Usage Rules, 1999 as amended 2003", all the plastics manufacturing/recycling units are to be<br />

registered with concerned State <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong>s/<strong>Pollution</strong> <strong>Control</strong> Committees. In this context,<br />

17 States <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong>s/<strong>Pollution</strong> <strong>Control</strong> Committees have completed inventorisation<br />

process and started granting registration.

INDUSTRIAL POLLUTION<br />

Minimum National Standards (MINAS) for Sugar Industry<br />

The sugar industry is one of the major agro-based industries and also the backbone of rural economy of<br />

India. <strong>Central</strong> <strong>Pollution</strong> <strong>Control</strong> <strong>Board</strong> is in the process of revising the Minimal National Standards for<br />

sugar industry. The detailed study of some of the sugar industries reveal that it is not difficult to meet the<br />

standards. It is, therefore, suggested to continue the existing MINAS for sugar industry for discharge on<br />

land for irrigation as BOD

* Hydrogen 0.0064 0.339 0.006<br />

* Others (Chlorine) 0.001<br />

* Spent H 2 SO 2 , if sold 0.0057 0.0266 ---<br />

Sub – total 0.06511 5.9618 0.037<br />

B. Solid Wastes<br />

* Brine mud 2.200 1.8124 3.640<br />

* Salt Saturator mud --- --- ---<br />

* Sludge from ETP --- 0.030 0.012<br />

* Residue from Hg Distillation Unit 0.100 0.0892 0.018<br />

Sub – total 2.300 1.9316 3.670<br />

C. Waste Water<br />

* Mercury in treated cell house liquid --- --- 0.012<br />

effluent<br />

Sub – total Nil Nil 0.012<br />

D. Air<br />

*Cell room ventilation 1.800 4.1874 2.067<br />

*Hg emission from brine clarifier --- 0.5469 ---<br />

*Hg emission from brine saturator 0.197 0.0254 ---<br />

Sub – total 1.997 4.7723 2.067<br />

E. Estimated losses<br />

a) Handling loss (spillage)-@ 2% of 0.922 1.049 0.945<br />

consumption<br />

b) Hg carry over with spent brine during 14.530 8.581 7.500<br />

power failure<br />

c) Hg carry over with spent brine during 22.730 27.804 5.647<br />

cell cut-outs<br />

d) Others 3.205<br />

Sub – total 22.730 39.532 14.092<br />

Mercury consumption 46.10 52.45 47.27<br />

Total Mercury loss (A+B+C+D+E) 45.749 52.1977 19.878<br />

Unaccounted loss (consumption – 0.351 0.2523 27.392<br />

loss)<br />

Year<br />

Mercury consumed in gm per tonne of caustic soda produced<br />

M/s. Grasim industries M/s.Hukum Chand<br />

Ltd.<br />

Jute Mills.<br />

2002 60.00 94.00 160.00<br />

2003 52.58 82.31 58.3<br />

<strong>2004</strong> 47.27 52.45 46.1<br />

M/s.Sriram chemicals and<br />

fertilizers<br />

Studies of Ground Water Quality Around Common Secured Land Fill Sites in Gujarat &<br />

Maharashtra<br />

Gujarat<br />

Gujarat has developed secured land fill sites at Ankleshwar, Vapi, Nandesari, Vatva, Odhav, Surat etc.<br />

Presently 8 common & 13 private common secured land fill sites are in operation across the state & 2<br />

more sites are in developing stage. Almost all the sites were developed before the Guidelines for this<br />

were issued by CPCB. However, all the new cells are being developed in accordance with CPCB<br />

Guidelines. The total hazardous waste generation in the Gujarat state is around 1.2 MMT per annum,

against the total capacity for storage of hazardous waste is around 2.77 MMT. CPCB has carried out<br />

ground water quality monitoring regarding at 2 TSDFs located at Nandesari and Ankleshwar.<br />

Ground water quality near CSLS in Gujarat<br />

• Nandesari<br />

Location<br />

Parameter<br />

pH SS TDS BOD COD TH T. Alk Cl-<br />

Bore well U/S of 6.8 17 4464 BDL 85 1045 480 1160<br />

CSLS<br />

Bore well D/S of 6.8 17 5014 BDL 245 1061 530 1480<br />

CSLS<br />

Leachate (New site) 7.4 70 11889 129 1798 -- -- 4799<br />

Bore well, Damanpura 6.6 15 3727 BDL 153 954 470 1080<br />

• Ankleshwar<br />

Location<br />

Leachate well-5<br />

(Cell under Oper.)<br />

Leachate<br />

(Covered cell)<br />

Parameter<br />

pH SS TDS BOD COD TH T.<br />

Alk<br />

Chloride<br />

7.4 264 42318 600 5387 -- -- 15137<br />

well-3 7.4 662 159340 6000 23395 -- -- 64009<br />

Bore well EB-1 7.1 -- 1716 -- 6.7 395 461 283<br />

(E-Down stream)<br />

Depth: 29m.<br />

Bore well HB-1 7.1 -- 1289 -- 1.2 328 434 366<br />

(SW-Ref. well)<br />

Depth: 29m.<br />

Bore well HB-2 7.0 -- 2090 3.2 546 548 419<br />

(NE-D/S)<br />

Depth: 29m.<br />

• Maharashtra<br />

In Maharashtra state presently 2 common secured land fill sites are operational, the sites are located at<br />

Taloja, Capacity of 0.15 MMT and at TTC industrial area, Navi Mumbai, capacity of 0.010 MMT.<br />

Ground water near CSLS in Maharashtra<br />

Taloja<br />

Location Parameter<br />

pH SS TDS BOD COD TH T. Cl-<br />

Alk<br />

Borewell-4 7.9 -- 352 -- BDL 94 187 41<br />

Borewell-5 7.8 -- 664 -- 0.4 330 223 170<br />

Studies on Municipal Solid Waste in Vadodara<br />

The Vadodara city is located in National Highway No.8 in between Ahmedabad and Bombay at latitude<br />

of 22 o -17'-59, longitude of 73 o -15'-18 having a population of 13.23 lakhs approximately. The quantity<br />

of solid waste generated in Vadodara city is around 500 MT/day and per capita waste is around 0.378<br />

kg/day.

The disposal of solid waste is carried out at nine landfill sites. The site at Vadsar is in operation on the<br />

bank of river Vishwamitri, the mixed garbage is being dumped in this site without any segregation.<br />

Further, the solid waste is being burnt in the site, which contaminates the ambient air near the dumping<br />

site. During the monsoon season the dumped garbage is being washed out into the river Vishwamitri<br />

and contaminating the river. A Physical Characteristics of Municipal Solid Waste in Vadodara is as<br />

below.<br />

Type of Waste Percent of Weight<br />

Bio degradable waste 50<br />

Recyclable waste 10<br />

Inert waste 08<br />

Moisture Content 20<br />

Unclassified Debris 12<br />

An attempt has been made to study the seasonal impact of dumping of municipal solid waste by way of<br />

monitoring the Vishwamitri river, Ambient air etc.<br />

Some of the observations based on study of the management of Municipal Solid Waste Management<br />

are as below.<br />

• There was no segregation of garbage at source.<br />

• The haphazard dumping of waste on roadside at various unauthorized places have been<br />

noticed. This results in logging of rainwater in most areas of the city.<br />

• Drainage system of the major part of the city was poor.<br />

• Rag pickers are exposed to toxic fumes because of practice of the burning garbage.<br />

• There was no scheduled time fixed by VMC for collection of domestic waste from dustbins.<br />

• At Vadsar dumping site, mixed garbage is burnt on the bank of the river Vishwamitri which<br />

disturb the flora and fauna of the Ecosystem and also deteriorates the river water quality and<br />

ambient air<br />

• The bio-hazardous waste generated from various health care facility collected by private<br />

agency is also being dumped along with Municipal waste at Vadsar dumping site.<br />

Status of Environment of Coastal Town Daman<br />

CPCB has taken up a project on Status of Environment of Coastal Town Daman during the financial<br />

year <strong>2004</strong>-2005. Accordingly, two rounds of monitoring have been carried out at the following locations<br />

in Daman for the study of environment.

• Municipal Market - Commercial, Residential Area<br />

• Somnath Circle - Industrial, Commercial areas<br />

• Kachigaon Circle – Industrial area.<br />

The study has conducted for ambient air quality, noise pollution, ground water, surface water (River<br />

Daman Ganga) and sea water quality (at Beaches) monitoring. The results of the air quality monitoring<br />

reveals, the fast deterioration of air quality in Daman due to industrialization and urbanization. The water<br />

analysis results show that, the coastal water is being contaminated due to discharge of industrial as well<br />

as domestic waste water into the sea.<br />

Air Quality in Daman<br />

Performance Studies of CETPs and CBMWTFs in Western Region<br />

CETPs in Gujarat and Maharastra<br />

There are 19 CETPs in Gujarat and 12 CETPs in Maharashtra, located in different industrial areas. The<br />

results of the performance evaluation monitoring are as follows:<br />

CETPs in Gujarat<br />

S.No Name of the CETP<br />

1. Enviro Technology Ltd.,<br />

Ankleshwar<br />

(Designed Cap.<br />

1000m3/day)<br />

Parameters<br />

pH S.S BOD COD O&G N-NH 3<br />

Inlet 1.0 1076 1020 4297 12 552<br />

Outlet 7.9 17 5.3 157 7.6 56<br />

% Red. 98 99 96 37 90<br />

2. Panoli Enviro<br />

Inlet 7.1 563 1215 3614 47.1 1114<br />

Technology Ltd., Panoli,<br />

Dist. Bharuch<br />

(Designed Cap.<br />

1000m3/day)<br />

Outlet 7.5 160 51 779 11.3 414<br />

% Red. 72 96 78 76 50<br />

3. The Green Environment Inlet 8.2 855 700 3604 12 140<br />

ServicesCo-operative<br />

Society Ltd.,Vatva,<br />

Ahmedabad<br />

(Designed Cap.<br />

16000m3/day)<br />

Outlet 6.1 214 71 860 11 39<br />

% Red. 75 90 76 10 72<br />

4. Odhav Enviro Projects Inlet 7.0 362 142 1147 -- 123<br />

Limited,Odhav,<br />

Ahmedabad<br />

(Designed Cap.<br />

1200m3/day)<br />

Outlet 7.0 52 35 550 3.3 54<br />

% Red. -- 86 75 52 -- 56<br />

5. Enviro Infrastructure Inlet 7.2 454 474 1255 7.7 11.2<br />

Co. Ltd.,<br />

Umaraya, Tal. Padra,<br />

(Designed Cap.<br />

2250m3/day)<br />

Outlet 7.7 84 3 364 1.7 6.7<br />

% Red. -- 81 99 71 78 40

6. Nandesari Industries Inlet 7.8 145 139 1124 32.5 378<br />

Association, Nandesari.<br />

(Designed Cap.<br />

5500m3/day)<br />

Outlet 7.8 33 27 295 11.1 70<br />

% Red. -- 77 81 74 66 81<br />

7. Naroda Enviro Project Inlet 7.3 1694 1540 5299 -- 72<br />

Ltd.,<br />

Naroda, Ahmedabad.<br />

(Designed Cap.<br />

3000m3/day)<br />

Outlet 7.8 265 375 2988 11.1 98<br />

% Red. 84 76 44 -- -Ve<br />

8. G.V.M.S.A.V.Limited Inlet 6.9 335 283 1028 -- 105<br />

Odhav, Ahmedabad<br />

(Designed Cap.<br />

1000m3/day)<br />

Outlet 7.7 56 100 614 0.4 121<br />

% Red. 83 65 40 -- --<br />

The monitoring results show that, in Gujarat most of the CETPs are not meeting the prescribed<br />

standards stipulated by the GPCB.<br />

CETPs in Maharashtra<br />

Sr.No Name of the CETP<br />

1. Tarapur CETP,<br />

Maharashtra.<br />

(Designed Cap. 1000m3/day)<br />

2. Taloja CETP,<br />

Maharashtra .<br />

(Designed Cap. 1250m3/day)<br />

Parameters<br />

pH S.S BOD COD O&G N-<br />

NH<br />

3<br />

Inlet 8.3 1056 2480 11194 13 1736<br />

Outlet 6.7 224 27 652 17 225<br />

% Red. 79 99 94 - 87<br />

Inlet 7.1 172 92 417 3 63<br />

Outlet 7.1 78 08 201 2 63<br />

% Red. 55 91 52 28 --<br />

In Maharashtra only two CETPs have been monitored for the performance evolution.<br />

Coastal Aquaculture<br />

The Aquaculture can be described in simple terms as the controlled raising of aquatic animals and<br />

plants. The principle behind it is to control the environment, nutrition, breeding and life cycle, so as to<br />

improve the quality and productivity of their crops, thereby commercializing the activity. India is placed<br />

fifth in the major aquaculture shrimp producers in the world, after Thailand, China, Equador and<br />

Indonesia, contributing about 8.59% of the total world production (1999). At present China leads among<br />

all shrimp producing countries, which is contributing 60% of the world production. In India almost 59% of<br />

the shrimp export is contributed from the aquaculture.<br />

In the process of coastal aquaculture large quantity of brackish water/coastal water is drawn and utilized<br />

for culture and finally discharged as wastewater to the same system, which is significant as far as<br />

coastal water quality is concerned. The aquaculture practiced in India can be categorized into four types<br />

such as Traditional, Extensive culture, Modified extensive culture, Semi intensive culture. In India the<br />

aquaculture practice was limited to the coastal states like West Bengal, Kerala, Karnataka, Goa, Andhra<br />

Pradesh, Tamilnadu, Gujarat and Maharashtra.

The state of Gujarat has a coastline of 1,663 km endowed with coastal features suitable for developing<br />

the aquaculture. Even though the state has 3,76,000 hectares of potential brackish water area, so far it<br />

has developed only 540 hectares of land for aquaculture. Mainly the aqua farms are scattered in the<br />

coastal districts like Valsad, Bilimora, Navasari, Surat, Bahvnagar etc. In Union territory of Daman and<br />

Diu 55 hectares of salt pans have been converted into aquaforms recently. In Maharashtra state. The<br />

Maharashtra state is having the coast line of 720 km and 80,000 hectares of brackish water area, out of<br />

which only 300 hectares have been utilized for the aquaculture in the area like Tarapur, Alibag,<br />

Ratnagiri.<br />

This office has monitored 15 aquaculture ponds located near Surat. The results of the samples reveal<br />

that the coastal water is being contaminated due to the discharge of waste water during the harvesting,<br />

which carries the nutritional load into the sea in the form of nitrates, sulphates and phosphates etc.<br />

Results of the Aqua Farm samples collected near Surat<br />

Location<br />

Neelkamal<br />

Aqua farm<br />

Apeksha<br />

Aqua farm<br />

Ratilal<br />

Safari Aqua<br />

farm<br />

Location<br />

Dhanprasad<br />

Aqua farm<br />

Westcoast<br />

Aqua farm<br />

Parameter<br />

pH SS TDS BOD COD DO Alk . NH 3 -N O-PO 4 SO 4<br />

Pond -1 8.0 206 39137 47 992 5.8 157 0.8 0.16 4000<br />

Pond -1 7.7 125 31151 27 534 9.5 164 2.5 0.08 2760<br />

Pond -2 7.9 138 29880 12 687 7.9 150 0.6 0.09 2780<br />

Pond -3 8.1 125 29494 11 649 11.6 206 1.9 0.15 6010<br />

Pond -4 7.6 163 31260 25 763 6.0 208 1.9 0.09 1100<br />

Pond -3 8.1 109 17297 14 840 8.9 202 1.4 0.04 1090<br />

Pond -6 8.0 294 16673 13 482 7.4 182 1.1 0.12 1900<br />

Pond -7 7.7 304 15564 03 321 5.5 187 2.7 0.17 1310<br />

Parameter<br />

pH SS TDS BOD COD DO Alk . NH 3 -N O-PO 4 SO 4<br />

Pond -1 8.0 207 21647 28 522 7.9 196 1.4 0.13 1180<br />

Pond -2 8.3 373 15159 31 402 8.2 174 1.4 0.24 3773<br />

Pond –B1 8.1 271 38372 38 683 6.2 160 1.1 0.06 3743<br />

Pond –B2 8.1 187 39696 39 643 - 166 1.4 - 3923<br />

Defco Aqua Pond –A1 8.0 304 25238 11 683 7.2 172 0.8 0.14 2026<br />

farm<br />

Pond –A2 7.6 363 29727 10 562 - 172 3.0 - 2436<br />

Pond –A3 7.9 374 29070 24 402 - 192 1.9 - 1667<br />

Note : Except pH and conductivity, all other results are in mg/L. Conductivity is in micromhos/cm<br />

Environmental Status of Problem Area Singrauli<br />

CPCB sponsored this project to Banwasi Sewa Asram, an active NGO in Singrauli area . In order to<br />

ensure regular surveillance the project continued for the second successive year in 2003-04. Focused<br />

on generating trends in air and water quality data in the area and also to suggest area specific<br />

measures of pollution control, the salient findings of the study in year 2003-04 are as under:<br />

Ambient air / Water quality monitoring of Singrauli area<br />

Ambient air quality was monitored at six different locations for RSPM, SPM, SO2 NOx, Fluoride and<br />

mercury at each locations. It was observed that except for two locations at Kubari and Ghaghri, RSPM

and SPM values were significantly high. The highest being at Dalla Bari, which is mainly due to stone<br />

crushers.<br />

The other parameters observed in higher concentration were mercury and fluoride. Both of them have<br />

been reported at all the six locations, their area wise concentration vary in wide range. It was observed<br />

that apart from high mercury and fluoride concentrations and sporadic cases of high COD, TDS and<br />

conductivity the rest of the physico-chemical parameters are close to prescribed norms.<br />

Water quality monitoring in river, reservoir and village ponds in Singraulli Area :<br />

Monitoring of surface water was undertaken at River Rihand, Rihand reservoir and six major drains. The<br />

highest concentration of mercury was reported in Dongia and Balia drains respectively. The state of the<br />

reservoir and ponds was relatively better. The distribution of fluoride concentration are depicted in<br />

following figures.

Enforcement of pollution control measures in Singrauli area<br />

CPCB organized a workshop on Problem Area Singrauli, wherin the Action plan for Singrauli area was<br />

reviewed and revised in accordance to CREP recommendations. The salient points of the Revised<br />

Action Plan are.<br />