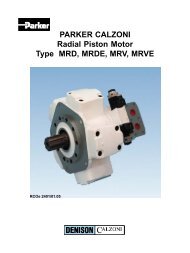

PARKER CALZONI Radial Piston Motor Type MR, MRE

PARKER CALZONI Radial Piston Motor Type MR, MRE

PARKER CALZONI Radial Piston Motor Type MR, MRE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RCOe 1806/03.05<br />

<strong>PARKER</strong> <strong>CALZONI</strong><br />

<strong>Radial</strong> <strong>Piston</strong> <strong>Motor</strong><br />

<strong>Type</strong> <strong>MR</strong>, <strong>MR</strong>E

TABLE OF CONTENTS - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

CONTENTS<br />

PAG.<br />

TABLE OF CONTENTS 2<br />

GENERAL CHARACTERISTICS 3<br />

FUNCTIONAL DESCRIPTION 4<br />

TECHNICAL DATA 5<br />

FLUID SELECTION 6<br />

FLUSHING PROCEDURE 7<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 33 <strong>MR</strong> 57 <strong>MR</strong> 73 8<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 93 <strong>MR</strong> 110 <strong>MR</strong> 125 9<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 160 <strong>MR</strong> 190 <strong>MR</strong> 200 10<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 250 <strong>MR</strong> 300 <strong>MR</strong>E 330 11<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 350 <strong>MR</strong> 450 <strong>MR</strong>E 500 12<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 600 <strong>MR</strong> 700 <strong>MR</strong>E 800 13<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 1100 <strong>MR</strong>E 1400 <strong>MR</strong> 1600 14<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 1800 <strong>MR</strong>E 2100 <strong>MR</strong> 2400 15<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 2800 <strong>MR</strong>E 3100 <strong>MR</strong> 3600 16<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 4500 <strong>MR</strong>E 5400 <strong>MR</strong> 6500 17<br />

OPERATING DIAGRAM MOTOR TYPE <strong>MR</strong> 7000 <strong>MR</strong>E 8200 18<br />

OPERATING DIAGRAM (RUNNING PRESSURE DIFFERENCE AT NO LOAD) 19-20<br />

OPERATING DIAGRAM (MOTOR/PUMP: BOOST PRESSURE) 20-21<br />

RADIAL LOAD 22<br />

BEARING LIFE 23<br />

MOTOR DIMENSIONS 24-25<br />

SHAFT END DIMENSIONS 26-27<br />

COMPONENTS FOR SPEED CONTROL 28-29<br />

PIPE CONNECTION FLANGES 30<br />

COUPLINGS - KEY ADAPTERS 31<br />

HOLDING BRAKE - UNIT DIMENSIONS - TECHNICAL DATA 32-33<br />

INSTALLATION NOTES 34<br />

ORDERING CODE 35<br />

SALES AND SERVICE LOCATIONS WORLDWIDE 36<br />

2<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

GENERAL CHARACTERISTICS - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

GENERAL CHARACTERISTICS<br />

A<br />

B<br />

CONSTRUCTION<br />

TYPE<br />

MOUNTING<br />

CONNECTION<br />

MOUNTING POSITION<br />

Fixed displacement radial piston motor<br />

<strong>MR</strong> ; <strong>MR</strong>E<br />

Front flange mounting<br />

Connection flange<br />

Any (please note the installation notes on page 34)<br />

BEARING LIFE, RADIAL LOAD<br />

See page 22 and 23<br />

DIRECTION OF ROTATION<br />

Clockwise, anti-clockwise - reversible<br />

FLUID<br />

HLP mineral oils to DIN 51 524 part 2; Fluid type HFB, HFC and Bio-fluids on<br />

enquiry. FPM seals are required with phosphorous acid-Ester (HFD)<br />

FLUID TEMPERATURE RANGE<br />

t °C – 30° to + 80°<br />

VISCOSITY RANGE 1)<br />

ν mm 2 /s 18 to 1000: Recommended operating range 30 to 50 (see fluid selection<br />

on page 6)<br />

FLUID CLEANLINESS<br />

Maximum permissible degree of contamination of fluid NAS 1638 Class 9. We<br />

therefore recommend a filter with a minimum retention rate of ß 10<br />

> 75.<br />

To ensure a long life we recommend class 8 to NAS 1638.<br />

This can be achieved with a filter, with a minimum retention rate of ß 5<br />

>100.<br />

1) For different valves of viscosity please contact <strong>PARKER</strong> Calzoni<br />

3<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

FUNCTIONAL DESCRIPTION - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

2<br />

a<br />

1<br />

3<br />

A<br />

B<br />

8 6 5 7<br />

4<br />

FUNCTIONAL DESCRIPTION<br />

The outstanding performance of this motor is the result of an original and patented design.<br />

The principle is to transmit the effort from the stator to the rotating shaft (2) by means of<br />

a pressurized column of oil (a) instead of the more common connecting rods, pistons, pads<br />

and pins.<br />

This oil column is contained by a telescopic cylinder (1) with a mechanical connection<br />

at the lips at each end which seal against the spherical surfaces of the cylinder-heads (3)<br />

and the spherical surface of the rotating shaft (4).<br />

These lips retain their circular cross section when stressed by the pressure so there is no<br />

alteration in the sealing geometry. The particular selection of materials and optimisation<br />

of design has minimized both the friction and the leakage.<br />

Another advantage of this design stems from the elimination of any connecting rods, the<br />

cylinder can only expand and retract linearly so there are no transverse components of<br />

the thrust. This means no oval wear on the moving parts and no side forces on the cylinder<br />

joints.<br />

A consequence of this novel design is a significant reduction in weight and overall size<br />

compared with other motors of the same capacity.<br />

TIMING SYSTEM<br />

EFFICIENCY<br />

The timing system is realized by means of a rotary valve (5) driven by the rotary valve<br />

driving shaft (8) that it is connected to the rotating shaft.<br />

The rotary valve rotates between the rotary valve plate (6) and the reaction ring (7)<br />

which are fixed with the motor's housing. This timing system is also of a patented design<br />

being pressure balanced and self compensating for thermal expansion.<br />

The advantages of this type of valve coupled with a revolutionary cylinder arrangement<br />

produce a motor with extremly high values of mechanical and volumetric efficiency.<br />

The torque output is smooth even at very low speed and the motor gives a high performance<br />

starting under load.<br />

4<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

TECHINICAL DATA - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

Siz<br />

ize<br />

<strong>Motor</strong><br />

version<br />

Displace<br />

isplace-<br />

ment<br />

Momen<br />

oment<br />

inertia of<br />

rotating<br />

parts<br />

Theore<br />

heore-<br />

tical<br />

specific<br />

torque<br />

Min<br />

in.<br />

start.<br />

torque<br />

/<br />

Theoretical<br />

torque<br />

M<br />

aximum Pressure<br />

e<br />

input<br />

c ont. int.<br />

p eak<br />

A+B<br />

*<br />

Drain<br />

S<br />

peed rang<br />

e<br />

without<br />

flushing<br />

with<br />

Maximu<br />

m<br />

output<br />

power<br />

flushing<br />

without<br />

with<br />

Weigh<br />

eight<br />

V J % p p p p p n n P P m<br />

cm<br />

3 2<br />

kg<br />

cm<br />

Nm/bar<br />

bar<br />

bar<br />

bar<br />

bar<br />

bar<br />

rpm<br />

rpm<br />

kW<br />

kW<br />

kg<br />

M<br />

R<br />

33<br />

3 32,<br />

1 4,32<br />

0,50<br />

90<br />

250<br />

300<br />

420<br />

400<br />

5 1-1400<br />

1-1400<br />

6,<br />

6 10<br />

30<br />

57<br />

56,<br />

4 4,76<br />

0,90<br />

90<br />

(15<br />

bar 1-1300<br />

1-1300<br />

11<br />

17<br />

30<br />

with<br />

73<br />

72,<br />

6 14,03<br />

1,20<br />

90<br />

"F1"<br />

shaft<br />

1-1200<br />

1-1200<br />

15<br />

20<br />

38<br />

93<br />

92,<br />

6 15,11<br />

1,50<br />

90<br />

seal) 1-1150<br />

1-1150<br />

17<br />

25<br />

38<br />

10<br />

1<br />

109,<br />

0 16,19<br />

1,70<br />

90<br />

1-1100<br />

1-1100<br />

18<br />

28<br />

38<br />

1 25<br />

124,<br />

7 56,88<br />

2,00<br />

90<br />

1-900<br />

1-900<br />

17<br />

25<br />

46<br />

1 60<br />

159,<br />

7 57,50<br />

2,54<br />

90<br />

1-900<br />

1-900<br />

20<br />

30<br />

46<br />

1 90<br />

191,<br />

6 58,20<br />

3,05<br />

90<br />

1-850<br />

1-850<br />

24<br />

36<br />

46<br />

2 00<br />

0 199,<br />

2 57,15<br />

3,20<br />

90<br />

1-800<br />

1-800<br />

25<br />

38<br />

50<br />

2 50<br />

250,<br />

9 60,80<br />

4,00<br />

90<br />

1-800<br />

1-800<br />

32<br />

48<br />

50<br />

3 00<br />

0 304,<br />

1 65,43<br />

4,80<br />

90<br />

1-750<br />

1-750<br />

35<br />

53<br />

50<br />

3 50<br />

349,<br />

5 225,90<br />

5,57<br />

90<br />

1-640<br />

1-640<br />

41<br />

62<br />

77<br />

4 50<br />

451,<br />

6 229,80<br />

7,20<br />

90<br />

1-600<br />

1-600<br />

46<br />

75<br />

77<br />

6 00<br />

0 607,<br />

9 265,07<br />

9,70<br />

90<br />

1-520<br />

1-520<br />

56<br />

84<br />

97<br />

7 00<br />

0 706,<br />

9 358,40<br />

11,30<br />

90<br />

1-500<br />

1-500<br />

65<br />

97<br />

97<br />

1 100<br />

0 1125,<br />

8 451,50<br />

17,90<br />

90<br />

0,5-330<br />

0,5-330<br />

77<br />

119<br />

140<br />

1 600<br />

0 1598,<br />

4 666,43<br />

25,40<br />

90<br />

0,5-260<br />

0,5-260<br />

96<br />

144<br />

209<br />

1 800<br />

0 1809,<br />

6 854,10<br />

28,80<br />

90<br />

0,5-250<br />

0,5-250<br />

103<br />

153<br />

209<br />

2 400<br />

0 2393,<br />

0 2835,40<br />

38,10<br />

90<br />

0,5-220<br />

0,5-220<br />

120<br />

183<br />

322<br />

2 800<br />

0 2792,<br />

0 2975,70<br />

44,50<br />

90<br />

0,5-215<br />

0,5-215<br />

127<br />

194<br />

322<br />

3 600<br />

0 3636,<br />

8 4851,40<br />

57,90<br />

90<br />

0,5-150<br />

0,5-180<br />

123<br />

185<br />

505<br />

4 500<br />

0 4502,<br />

7 5015,10<br />

71,70<br />

91<br />

0,5-130<br />

0,5-170<br />

140<br />

210<br />

505<br />

6 500<br />

0 6460,<br />

5 11376,<br />

6 103,57<br />

91<br />

0,5-110<br />

0,5-130<br />

165<br />

240<br />

797<br />

7 000<br />

0 6967,<br />

2 11376,<br />

6 111,39<br />

91<br />

0,5-100<br />

0,5-130<br />

170<br />

250<br />

797<br />

M<br />

R<br />

E<br />

3 30<br />

332,<br />

4 65,50<br />

5,30<br />

90<br />

210<br />

250<br />

350<br />

400<br />

5 1-750<br />

1-750<br />

32<br />

49<br />

50<br />

5 00<br />

0 497,<br />

9 229,80<br />

7,93<br />

90<br />

(15<br />

bar 1-600<br />

1-600<br />

46<br />

70<br />

77<br />

with<br />

8 00<br />

0 804,<br />

2 358,40<br />

12,81<br />

90<br />

"F1"<br />

shaft<br />

1-450<br />

1-450<br />

65<br />

93<br />

97<br />

1 400<br />

0 1369,<br />

5 451,50<br />

21,80<br />

92<br />

seal) 0,5-280<br />

0,5-280<br />

77<br />

102<br />

145<br />

2 100<br />

0 2091,<br />

2 854,10<br />

33,30<br />

91<br />

0,5-250<br />

0,5-250<br />

100<br />

148<br />

221<br />

3 100<br />

0 3103,<br />

7 2975,70<br />

49,40<br />

91<br />

0,5-215<br />

0,5-215<br />

125<br />

190<br />

326<br />

5 400<br />

0 5401,<br />

2 5015,10<br />

86,01<br />

92<br />

0,5-120<br />

0,5-160<br />

140<br />

210<br />

509<br />

8 200<br />

0 8226,<br />

4 11376,<br />

6 130,90<br />

92<br />

0,5-90<br />

0,5-120<br />

170<br />

250<br />

807<br />

L<br />

ARGER DISPLACEMENTS ARE AVAILABLE IN THE<br />

M<br />

RT<br />

-<br />

<strong>MR</strong>TE -<br />

<strong>MR</strong>T<br />

F<br />

MOTOR SERIE<br />

S<br />

(*) Please consult <strong>PARKER</strong> Calzoni<br />

5<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

FLUID SELECTION - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

EXAMPLE: At a certain ambient<br />

temperature, the operating temperature in the<br />

circuit is 50°C. In the optimum operating<br />

viscosity range (v rec<br />

; shaded section), this<br />

corresponds to viscosity grades VG 46 or VG<br />

68; VG 68 should be selected.<br />

IMPORTANT: The drain oil temperature<br />

is influenced by pressure and speed and is<br />

usually higher than the circuit temperature or<br />

the tank temperature. At no point in the<br />

system, however, may the temperature be<br />

higher than 80°C.<br />

If the optimum conditions cannot be met due<br />

to the extreme operating parameters or high<br />

ambient temperature, we always recommend<br />

flushing the motor case in order to operate<br />

within the viscosity limits.<br />

Should it be absolutely necessary to use a<br />

viscosity beyond the recommended range,<br />

you should first contact <strong>PARKER</strong> Calzoni<br />

for confirmation.<br />

viscosity ν (mm 2 /s)<br />

Temperature t in °C<br />

Oil temperature range<br />

ν REC<br />

GENERAL NOTES<br />

OPERATING VISCOSITY RANGE<br />

LIMITS OF VISCOSITY RANGE<br />

CHOOSING THE TYPE OF FLUID<br />

ACCORDING TO THE OPERATING<br />

TEMPERATURE<br />

FILTRATION<br />

CASE DRAIN PRESSURE<br />

"FPM" SEALS<br />

More detailed information regarding the choice of the fluid can be requested to <strong>PARKER</strong> Calzoni.<br />

Further notes on installation and commissioning can be found on page 34 of this data sheet. When<br />

operating with HF pressure fluids or bio-degradable pressure fluids possible limitations of the<br />

technical data must be taken into consideration, please see information sheet TCS 85, or consult<br />

<strong>PARKER</strong> Calzoni.<br />

The viscosity, quality and cleanliness of operating fluids are decisive factors in determining the<br />

reliability, performance and life-time of an hydraulic component. The maximum life-time and performance<br />

are achieved within the recommended viscosity range. For applications that go beyond this<br />

range, we recommend to contact <strong>PARKER</strong> Calzoni.<br />

ν rec.<br />

= recommended operating viscosity 30...50 mm 2 /s<br />

This viscosity refers to the temperature of the fluid entering the motor, and at the same time to the<br />

temperature inside the motor housing (case temperature). We recommend to select the viscosity of<br />

the fluid based on the maximum operating temperature, to remain within the recommended viscosity<br />

range. To reach the value of maximum continuous power the operating viscosity should be within the<br />

recommended viscosity range of 30 - 50 cSt.<br />

For limit conditions the following is valid:<br />

ν min.abs.<br />

= 10 mm 2 /s in emergency, short term<br />

ν min.<br />

= 18 mm 2 /s for continuous operation at reduced performances<br />

= 1000 mm 2 /s short term upon cold start<br />

ν max.<br />

The operating temperature of the motor is defined as the greater temperature between that of the<br />

incoming fluid and that of the fluid inside the motor housing (case temperature).We<br />

recommend that you choose the viscosity of the fluid based on the maximum operating temperature,<br />

to remain within the recommended viscosity range (see diagram). We recommend that the higher<br />

viscosity grade must be selected in each case.<br />

The motor life also depends on the fluid filtration. At least it must correspond to one of the<br />

following cleanliness. class 9 according to NAS 1638<br />

class 6 according to SAE, ASTM, AIA<br />

class 18/15 according to ISO/DIS 4406<br />

In order to assure a longer life a cleanliness class 8 to NAS 1638 is recommended, achieved<br />

with a filter of β 5<br />

=100. In case the above mentioned classes can not be achieved, please consult us.<br />

The lower the speed and the case drain pressure, the longer the life of the shaft seal. The maximum<br />

permissible housing pressure is<br />

p max<br />

= 5 bar<br />

If the case drain pressure is higher than 5 bar it is possible to use a special 15 bar shaft seal<br />

(see page 35, Seals, Code"F1").<br />

In case of operating conditions with high oil temperature or high ambient temperature, we<br />

recommend to use "FPM" seals (see page 35, Seals, Code "V1"). These "FPM" seals should be used<br />

with HFD fluids.<br />

6<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

FLUSHING PROCEDURE - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

Restrictor<br />

Restrictor<br />

1<br />

)“VFC” Flushing valve.<br />

1<br />

) Please consult us.<br />

FLUSHING CIRCUIT<br />

(MONO-DIRECTIONAL ROTATION)<br />

FLUSHING CIRCUIT<br />

(BI-DIRECTIONAL ROTATION)<br />

FLUSHING<br />

NOTE1:<br />

NOTE2:<br />

The motor case must be flushed when the continuous operating performances of the<br />

motor are inside the "Continuous operating area with flushing" (see Operating Diagram<br />

from page 8 to page 18), in order to assure the minimum oil viscosity inside the motor case<br />

of 30 mm 2 /s (see page 6 - Fluid Selection). The flushing can be necessary also when the<br />

operating performances are outside the "Continuous operating area with flushing", but the<br />

system is not able to assure the minimum viscosity conditions requested by the motor as<br />

specified at page 6.<br />

The oil temperature inside the motor case is obtainable by adding 3°C to the motor surface<br />

temperature (t A<br />

, see figures).<br />

With the standard shaft seal the maximum drain case pressure is 5 bar. For the selection<br />

of the restrictor, please consult us.<br />

FLOW<br />

TYPE<br />

MOTOR VERSION<br />

FLUSHING<br />

FLOW<br />

<strong>MR</strong><br />

33,<br />

57, 73, 93, 110<br />

Q = 5 l/min<br />

<strong>MR</strong> - <strong>MR</strong>E 125,<br />

160, 190, 200, 250, 300, 330<br />

Q = 6 l/min<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

350,<br />

450, 500<br />

Q = 8 l/min<br />

<strong>MR</strong> - <strong>MR</strong>E 600,<br />

700, 800, 1100, 1400<br />

Q = 10 l/min<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

1600,1800,<br />

2100<br />

Q = 15 l/min<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

2400, 2800, 3100, 3600, 4500, 5400,<br />

6500, 7000, 8200<br />

Q = 20 l/min<br />

7<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 33<br />

120<br />

105<br />

90<br />

94%<br />

3Kw<br />

4Kw<br />

5Kw<br />

6.6Kw<br />

300 bar<br />

250 bar<br />

7Kw<br />

8Kw<br />

9Kw<br />

10Kw<br />

1<br />

2<br />

Torque in Nm<br />

75<br />

60<br />

45<br />

30<br />

h<br />

96%<br />

97%<br />

v=98%<br />

t=83%<br />

h<br />

200 bar<br />

150 bar<br />

100 bar<br />

80%<br />

3<br />

4<br />

5<br />

15<br />

1 l/min 4 l/min 9 l/min 13 l/min 18 l/min 22 l/min 27 l/min 31 l/min 36 l/min 40 l/min 45 l/min<br />

77%<br />

75%<br />

140 280 420 560 700 840 980 1120 1260 1400<br />

Speed in rpm<br />

<strong>MR</strong> 57<br />

210<br />

3 Kw<br />

5 Kw<br />

7 Kw<br />

9 Kw<br />

11 Kw<br />

13 Kw<br />

15 Kw<br />

17 Kw<br />

1<br />

180<br />

96%<br />

300 bar<br />

250 bar<br />

2<br />

Torque in Nm<br />

150<br />

120<br />

90<br />

60<br />

30<br />

97%<br />

h<br />

v=98%<br />

h t=83%<br />

81%<br />

200 bar<br />

150 bar<br />

100 bar<br />

79%<br />

76%<br />

73%<br />

70%<br />

3<br />

4<br />

5<br />

8 l/min 16 l/min 24 l/min 32 l/min 39 l/min 47 l/min 55 l/min 63 l/min 71 l/min<br />

200 400 600 800 1000 1200 1300<br />

Speed in rpm<br />

<strong>MR</strong> 73<br />

400<br />

6 Kw<br />

8 Kw<br />

10 Kw<br />

13 Kw<br />

15 Kw<br />

17 Kw<br />

18 Kw<br />

20 Kw<br />

1<br />

320<br />

300 bar<br />

2<br />

Torque in Nm<br />

240<br />

160<br />

96%<br />

97%<br />

250 bar<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

80<br />

hv=98%<br />

h t=83%<br />

81%<br />

100 bar<br />

79%<br />

3 l/min 9 l/min 18 l/min 27 l/min 37 l/min 46 l/min 55 l/min 64 l/min 73 l/min 82 l/min<br />

77%<br />

75%<br />

5<br />

200 400<br />

600<br />

Speed in rpm<br />

800 1000 1150<br />

8<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 93<br />

450<br />

400<br />

6 Kw<br />

9 Kw<br />

12 Kw<br />

15 Kw<br />

17 Kw<br />

19 Kw<br />

20 Kw<br />

22 Kw<br />

25 Kw<br />

1<br />

300 bar<br />

2<br />

300<br />

250 bar<br />

Torque in Nm<br />

200<br />

96%<br />

97%<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

100<br />

hv=98%<br />

h t=83%<br />

81%<br />

100 bar<br />

79%<br />

77%<br />

75%<br />

5<br />

4 l/min 11 l/min 22 l/min 33 l/min 44 l/min 56 l/min 67 l/min 78 l/min 89 l/min 100 l/min<br />

200<br />

400 600 800 1000 1100<br />

Speed in rpm<br />

<strong>MR</strong> 110<br />

500<br />

8 Kw<br />

11 Kw<br />

15 Kw<br />

19 Kw<br />

21 Kw<br />

24 Kw<br />

26 Kw<br />

28 Kw<br />

1<br />

400<br />

300 bar<br />

2<br />

250 bar<br />

Torque in Nm<br />

300<br />

200<br />

hv=98%<br />

96%<br />

97%<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

100<br />

ht=83%<br />

h<br />

t=81%<br />

79%<br />

100 bar<br />

77%<br />

75%<br />

5<br />

4 l/min<br />

13 l/min<br />

26 l/min<br />

39 l/min<br />

52 l/min<br />

65 l/min<br />

78 l/min 92 l/min<br />

105 l/min<br />

200<br />

400<br />

600<br />

Speed in rpm<br />

800<br />

1050<br />

<strong>MR</strong> 125<br />

600<br />

4 Kw<br />

7 Kw<br />

9 Kw<br />

11 Kw<br />

14 Kw<br />

17 Kw<br />

20 Kw<br />

23 Kw<br />

25 Kw<br />

300 bar<br />

1<br />

500<br />

250 bar<br />

2<br />

400<br />

93%<br />

Torque in Nm<br />

300<br />

200<br />

100<br />

h<br />

95%<br />

96%<br />

97%<br />

v=98%<br />

h<br />

t=89%<br />

200 bar<br />

150 bar<br />

100 bar<br />

88%<br />

87%<br />

85%<br />

83%<br />

81%<br />

3<br />

4<br />

5<br />

12 l/min 30 l/min 50 l/min 68 l/min<br />

85 l/min<br />

105 l/min<br />

100 200 300 400 500<br />

Speed in rpm<br />

600 700 800 900<br />

9<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 160<br />

800<br />

700<br />

600<br />

4 Kw<br />

9 Kw<br />

13 Kw<br />

17 Kw<br />

20 Kw<br />

23 Kw<br />

27 Kw<br />

30 Kw<br />

300 bar<br />

250 bar<br />

1<br />

2<br />

500<br />

200 bar<br />

3<br />

Torque in Nm<br />

400<br />

300<br />

200<br />

150 bar<br />

100 bar<br />

4<br />

5<br />

100<br />

50 bar<br />

5 l/min 15 l/min 30 l/min 45 l/min 60 l/min 75 l/min 90 l/min 105 l/min 120 l/min<br />

<strong>MR</strong> 190<br />

900<br />

5 Kw<br />

100 200 300 400 500 600 700 800<br />

Speed in rpm<br />

10 Kw<br />

15 Kw<br />

20 Kw<br />

24 Kw<br />

28 Kw<br />

32 Kw<br />

36 Kw<br />

300 bar<br />

900<br />

1<br />

800<br />

700<br />

250 bar<br />

2<br />

Torque in Nm<br />

600<br />

500<br />

400<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

300<br />

100 bar<br />

5<br />

200<br />

100<br />

50 bar<br />

5 l/min 15 l/min 30 l/min 45 l/min 60 l/min 75 l/min 90 l/min 105 l/min 120 l/min 135 l/min 150 l/min<br />

100 200 300 400 500 600 700 800<br />

Speed in rpm<br />

850<br />

<strong>MR</strong> 200<br />

1000<br />

900<br />

5 Kw<br />

10 Kw<br />

15 Kw<br />

20 Kw<br />

25 Kw<br />

28 Kw<br />

32 Kw<br />

38 Kw<br />

300 bar<br />

1<br />

800<br />

700<br />

250 bar<br />

2<br />

Torque in Nm<br />

600<br />

500<br />

400<br />

300<br />

200<br />

h<br />

97.5%<br />

98.5%<br />

v=99%<br />

ht=91.5%<br />

91%<br />

90%<br />

87%<br />

89%<br />

85%<br />

200 bar<br />

150 bar<br />

100 bar<br />

83%<br />

77%<br />

73%<br />

3<br />

4<br />

5<br />

100<br />

15 l/min 30 l/min 45 l/min 60 l/min 75 l/min 90 l/min 105 l/min 120 l/min 135 l/min 150 l/min 165 l/min<br />

100 200<br />

300 400 500 600 700 800<br />

Speed in rpm<br />

10<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 250<br />

1200<br />

5 Kw<br />

9 Kw<br />

14 Kw<br />

18 Kw<br />

23 Kw<br />

27 Kw<br />

32 Kw<br />

37 Kw<br />

43 Kw<br />

48 Kw<br />

1<br />

1000<br />

300 bar<br />

2<br />

250 bar<br />

Torque in Nm<br />

800<br />

600<br />

400<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

200<br />

50 bar<br />

5 l/min 20 l/min 40 l/min 60 l/min 80 l/min 100 l/min<br />

120 l/min 140 l/min 160 l/min 180 l/min<br />

<strong>MR</strong> 300<br />

1400<br />

5 Kw<br />

10 Kw<br />

100 200 300 400 500 600 700<br />

Speed in rpm<br />

15 Kw<br />

20 Kw<br />

25 Kw<br />

30 Kw<br />

35 Kw<br />

41 Kw<br />

47 Kw<br />

53 Kw<br />

300 bar<br />

800<br />

1<br />

1200<br />

250 bar<br />

2<br />

Torque in Nm<br />

1000<br />

800<br />

600<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

400<br />

100 bar<br />

5<br />

200<br />

50 bar<br />

20 l/min 40 l/min 60 l/min 80 l/min 100 l/min 120 l/min 140 l/min 160 l/min 180 l/min 200 l/min 220 l/min<br />

100 200 300 400 500 600 700 750<br />

Speed in rpm<br />

<strong>MR</strong>E 330<br />

1400<br />

12 Kw<br />

18 Kw<br />

24 Kw<br />

31 Kw<br />

36 Kw<br />

42 Kw<br />

49 Kw<br />

1<br />

1200<br />

250 bar<br />

2<br />

1000<br />

97.5%<br />

h<br />

t=92%<br />

210 bar<br />

Torque in Nm<br />

800<br />

600<br />

400<br />

200<br />

98.5%<br />

hv=99%<br />

92%<br />

91%<br />

89%<br />

150 bar<br />

100 bar<br />

86%<br />

50 bar<br />

78%<br />

3<br />

4<br />

5<br />

30 l/min 60 l/min 100 l/min 130 l/min 160 l/min 190 l/min 220 l/min<br />

100 200 300 400 500 600 700<br />

Speed in rpm<br />

11<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM (average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar 1<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 350<br />

1800<br />

1600<br />

1400<br />

5 Kw<br />

10 Kw<br />

15 Kw<br />

21 Kw<br />

26 Kw<br />

31 Kw<br />

36 Kw<br />

42 Kw<br />

48 Kw<br />

54 Kw<br />

300 bar<br />

1<br />

2<br />

250 bar<br />

Torque in Nm<br />

1200<br />

1000<br />

800<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

600<br />

400<br />

100 bar<br />

5<br />

200<br />

50 bar<br />

10 l/min 25 l/min 50 l/min 75 l/min 100 l/min 125 l/min 150 l/min 175 l/min 200 l/min<br />

<strong>MR</strong> 450<br />

2200<br />

13 Kw<br />

100 200 300 400 500 600 640<br />

Speed in rpm<br />

20 Kw<br />

26 Kw<br />

46 Kw<br />

56 Kw<br />

65 Kw<br />

75 Kw<br />

1<br />

33 Kw<br />

39 Kw<br />

2000<br />

1800<br />

300 bar<br />

2<br />

Torque in Nm<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

250 bar<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

400<br />

50 bar<br />

200<br />

10 l/min 30 l/min 60 l/min 90 l/min 120 l/min 150 l/min 180 l/min 210 l/min 240 l/min<br />

<strong>MR</strong>E 500<br />

2000<br />

7 Kw<br />

100 200 300 400 500 600<br />

Speed in rpm<br />

39 Kw<br />

46 Kw<br />

54 Kw<br />

62 Kw<br />

70 Kw<br />

13 Kw<br />

20 Kw<br />

26 Kw<br />

33 Kw<br />

Torque in Nm<br />

250 bar<br />

1800<br />

1600<br />

210 bar<br />

1400<br />

1200<br />

150 bar<br />

1000<br />

800<br />

100 bar<br />

600<br />

400<br />

50 bar<br />

200<br />

10 l/min 30 l/min 60 l/min 90 l/min 120 l/min 150 l/min 180 l/min 210 l/min 240 l/min 270 l/min<br />

100 200 300 400 500 600<br />

Speed in rpm<br />

2<br />

3<br />

4<br />

5<br />

12<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM (average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar 1<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 600<br />

3000<br />

16 Kw<br />

32 Kw<br />

40 Kw<br />

48 Kw<br />

56 Kw<br />

65 Kw<br />

75 Kw<br />

84 Kw<br />

1<br />

24 Kw<br />

2700<br />

2400<br />

300 bar<br />

2<br />

Torque in Nm<br />

2100<br />

1800<br />

1500<br />

1200<br />

250 bar<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

900<br />

100 bar<br />

5<br />

600<br />

300<br />

50 bar<br />

10 l/min 40 l/min 70 l/min<br />

100 l/min 130 l/min 160 l/min 190 l/min 220 l/min 250 l/min 280 l/min<br />

50 100 150 200 250 300 350 400 450<br />

Speed in rpm<br />

520<br />

<strong>MR</strong> 700<br />

3300<br />

9 Kw<br />

18 Kw<br />

28 Kw<br />

37 Kw<br />

46 Kw<br />

56 Kw<br />

65 Kw<br />

76 Kw<br />

86 Kw<br />

97 Kw<br />

1<br />

3000<br />

2700<br />

300 bar<br />

2<br />

Torque in Nm<br />

2400<br />

2100<br />

1800<br />

1500<br />

1200<br />

900<br />

250 bar<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

600<br />

300<br />

15 l/min 40 l/min 80 l/min<br />

50 bar<br />

120 l/min 160 l/min 200 l/min 240 l/min 280 l/min 320 l/min<br />

50 100 150 200 250 300 350 400 450 500<br />

Speed in rpm<br />

<strong>MR</strong>E 800<br />

Torque in Nm<br />

3300<br />

3000<br />

2700<br />

2400<br />

2100<br />

1800<br />

1500<br />

1200<br />

900<br />

11 Kw<br />

22 Kw<br />

33 Kw<br />

43 Kw<br />

54 Kw<br />

65 Kw<br />

74 Kw<br />

84 Kw<br />

93 Kw<br />

250 bar<br />

210 bar<br />

150 bar<br />

100 bar<br />

2<br />

3<br />

4<br />

5<br />

600<br />

300<br />

50 bar<br />

20 l/min 60 l/min 100 l/min 140 l/min 180 l/min 200 l/min 260 l/min 300 l/min 340 l/min<br />

50 100 150 200 250 300 350 400 450<br />

Speed in rpm<br />

13<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 1100<br />

5500<br />

5000<br />

4500<br />

22 Kw<br />

33 Kw<br />

44 Kw<br />

55 Kw<br />

66 Kw<br />

77 Kw<br />

91 Kw<br />

105 Kw<br />

119 Kw<br />

300 bar<br />

1<br />

2<br />

4000<br />

250 bar<br />

Torque in Nm<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

1000<br />

500<br />

15 l/min<br />

50 l/min<br />

50 bar<br />

100 l/min 150 l/min 200 l/min 250 l/min 300 l/min 350 l/min<br />

50 100 150 200 250 300 330<br />

Speed in rpm<br />

<strong>MR</strong>E 1400<br />

5500<br />

5000<br />

4500<br />

22Kw<br />

33 Kw<br />

44 Kw<br />

55 Kw<br />

66 Kw<br />

77 Kw<br />

85 Kw<br />

94 Kw<br />

102 Kw<br />

250 bar<br />

1<br />

2<br />

Torque in Nm<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

210 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

1000<br />

500<br />

50 bar<br />

15 l/min 50 l/min 100 l/min 150 l/min 200 l/min 250 l/min 300 l/min 350 l/min<br />

40 80 120 160 200 240 280<br />

Speed in rpm<br />

<strong>MR</strong> 1600<br />

8000<br />

29 Kw<br />

44 Kw<br />

59 Kw<br />

74 Kw<br />

88 Kw<br />

98 Kw<br />

108 Kw<br />

126 Kw<br />

144 Kw<br />

1<br />

7000<br />

300 bar<br />

2<br />

Torque in Nm<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

97.5%<br />

98.5%<br />

hv=99%<br />

h<br />

t=93%<br />

92.5%<br />

92%<br />

91%<br />

90%<br />

89%<br />

88%<br />

86%<br />

250 bar<br />

200 bar<br />

150 bar<br />

100 bar<br />

84%<br />

78%<br />

3<br />

4<br />

5<br />

30 l/min 60 l/min 120 l/min 180 l/min<br />

240 l/min<br />

300 l/min 360 l/min<br />

25 50 75 100 125 150 175 200 225 250<br />

Speed in rpm<br />

14<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 1800<br />

9000<br />

8000<br />

29 Kw<br />

44 Kw<br />

59 Kw<br />

74 Kw<br />

88 Kw<br />

103 Kw<br />

121 Kw<br />

139 Kw<br />

157 Kw<br />

300 bar<br />

1<br />

7000<br />

250 bar<br />

2<br />

Torque in Nm<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

<strong>MR</strong>E 2100<br />

1000<br />

8000<br />

7000<br />

20 l/min 60 l/min 120 l/min 180 l/min<br />

240 l/min 300 l/min 360 l/min 420 l/min<br />

25 50 75 100 125 150 175 200 225 250<br />

Speed in rpm<br />

20 Kw<br />

40 Kw<br />

60 Kw<br />

80 Kw<br />

100 Kw<br />

116 Kw<br />

132 Kw<br />

148 Kw<br />

250 bar<br />

50 bar<br />

1<br />

2<br />

Torque in Nm<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

210 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

1000<br />

50 bar<br />

20 l/min 60 l/min 120 l/min 180 l/min 240 l/min 300 l/min 360 l/min 420 l/min 480 l/min<br />

25 50 75 100 125 150 175 200 225 250<br />

Speed in rpm<br />

<strong>MR</strong> 2400<br />

11000<br />

20 Kw<br />

40 Kw<br />

60 Kw<br />

80 Kw<br />

100 Kw<br />

120 Kw<br />

141 Kw<br />

162 Kw<br />

183 Kw<br />

1<br />

Torque in Nm<br />

10000<br />

9000<br />

8000<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

300 bar<br />

250 bar<br />

200 bar<br />

150 bar<br />

100 bar<br />

2<br />

3<br />

4<br />

5<br />

2000<br />

1000<br />

25 l/min 75 l/min<br />

50 bar<br />

140 l/min 210 l/min 280 l/min 350 l/min 420 l/min 490 l/min<br />

20 40 60 80 100 120 140 160 180 200 220<br />

Speed in rpm<br />

15<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM (average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar 1<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 2800<br />

<strong>MR</strong>E 3100<br />

Torque in Nm<br />

Torque in Nm<br />

13000<br />

12000<br />

11000<br />

10000<br />

9000<br />

8000<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

13000<br />

12000<br />

11000<br />

10000<br />

9000<br />

8000<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

20 Kw<br />

40 Kw<br />

1000<br />

25 l/min 80 l/min<br />

20 Kw<br />

40 Kw<br />

60 Kw<br />

60 Kw<br />

80 Kw<br />

80 Kw<br />

100 Kw<br />

100 Kw<br />

127 Kw<br />

125 Kw<br />

149 Kw<br />

20 40 60 80 100 120 140 160 180 200 215<br />

Speed in rpm<br />

145 Kw<br />

172 Kw<br />

165 Kw<br />

194 Kw<br />

190 Kw<br />

300 bar<br />

250 bar<br />

200 bar<br />

150 bar<br />

100 bar<br />

50 bar<br />

25 l/min 80 l/min 160 l/min 240 l/min 320 l/min 400 l/min 480 l/min 530 l/min<br />

250 bar<br />

210 bar<br />

150 bar<br />

100 bar<br />

50 bar<br />

160 l/min 240 l/min 320 l/min 400 l/min 480 l/min 550 l/min<br />

1<br />

2<br />

3<br />

4<br />

5<br />

1<br />

2<br />

3<br />

4<br />

5<br />

<strong>MR</strong> 3600<br />

18000<br />

20 40 60 80 100 120 140 160 180 200 215<br />

Speed in rpm<br />

104 Kw<br />

130 Kw<br />

153 Kw<br />

175 Kw<br />

185 Kw<br />

26 Kw<br />

52 Kw<br />

78 Kw<br />

16000<br />

14000<br />

300 bar<br />

250 bar<br />

2<br />

Torque in Nm<br />

12000<br />

10000<br />

8000<br />

200 bar<br />

150 bar<br />

3<br />

4<br />

6000<br />

4000<br />

100 bar<br />

5<br />

2000<br />

50 bar<br />

35 l/min 100 l/min 200 l/min<br />

300 l/min 400 l/min 500 l/min 600 l/min<br />

15 30 45 60 75 90 105 120 135 150 165 180<br />

Speed in rpm<br />

16<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 4500<br />

22000<br />

20000<br />

40 Kw<br />

60 Kw<br />

80 Kw<br />

100 Kw<br />

120 Kw<br />

140 Kw<br />

163 Kw<br />

187 Kw<br />

210 Kw<br />

300 bar<br />

1<br />

18000<br />

2<br />

16000<br />

250 bar<br />

Torque in Nm<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

<strong>MR</strong>E 5400<br />

Torque in Nm<br />

4000<br />

2000<br />

22000<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

35 l/min 100 l/min<br />

40 Kw<br />

60 Kw<br />

80 Kw<br />

100 Kw<br />

120 Kw<br />

140 Kw<br />

163 Kw<br />

50 bar<br />

2000<br />

35 l/min 100 l/min 200 l/min 300 l/min 400 l/min 500 l/min 600 l/min 700 l/min 800 l/min<br />

187 Kw<br />

20 40 60 80 100 120 140 160<br />

Speed in rpm<br />

210 Kw<br />

50 bar<br />

200 l/min 300 l/min 400 l/min 500 l/min 600 l/min 700 l/min<br />

10 30 50 70 90 110 130 150 170<br />

Speed in rpm<br />

250 bar<br />

210 bar<br />

150 bar<br />

100 bar<br />

1<br />

2<br />

3<br />

4<br />

5<br />

<strong>MR</strong> 6500<br />

33000<br />

30000<br />

27000<br />

47 Kw<br />

71 Kw<br />

94 Kw<br />

118 Kw<br />

141 Kw<br />

165 Kw<br />

193 Kw<br />

222 Kw<br />

240 Kw<br />

300 bar<br />

1<br />

2<br />

24000<br />

250 bar<br />

Torque in Nm<br />

21000<br />

18000<br />

15000<br />

12000<br />

9000<br />

200 bar<br />

150 bar<br />

100 bar<br />

3<br />

4<br />

5<br />

6000<br />

3000<br />

35 l/min 100 l/min<br />

50 bar<br />

200 l/min 300 l/min 400 l/min 500 l/min 600 l/min 700 l/min 780 l/min<br />

10 20 30 40 50 60 70 80 90 100 110 120 130<br />

Speed in rpm<br />

17<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

1 Output power 2 Intermittent operating area 3 Continuous operating area with flushing<br />

4 Continuous operating area 5 Inlet pressure ηt Total efficiency ηv Volumeter efficiency<br />

<strong>MR</strong> 7000<br />

33000<br />

49 Kw<br />

73 Kw<br />

97 Kw<br />

121 Kw<br />

146 Kw<br />

170 Kw<br />

200 Kw<br />

230 Kw<br />

250 Kw<br />

1<br />

Torque in Nm<br />

30000<br />

27000<br />

24000<br />

21000<br />

18000<br />

15000<br />

300 bar<br />

250 bar<br />

200 bar<br />

150 bar<br />

2<br />

3<br />

4<br />

12000<br />

9000<br />

100 bar<br />

5<br />

6000<br />

3000<br />

50 bar<br />

35 l/min 100 l/min 200 l/min 300 l/min 400 l/min 500 l/min 600 l/min 700 l/min<br />

800 l/min<br />

10 20 30 40 50 60 70 80 90 100 110 120 130<br />

Speed in rpm<br />

<strong>MR</strong>E 8200<br />

33000<br />

49 Kw<br />

73 Kw<br />

97 Kw<br />

121 Kw<br />

146 Kw<br />

170 Kw<br />

200 Kw<br />

230 Kw<br />

250 Kw<br />

1<br />

30000<br />

27000<br />

250 bar<br />

2<br />

Torque in Nm<br />

24000<br />

21000<br />

18000<br />

15000<br />

210 bar<br />

150 bar<br />

3<br />

4<br />

12000<br />

9000<br />

100 bar<br />

5<br />

6000<br />

50 bar<br />

3000<br />

35 l/min 100 l/min 200 l/min 300 l/min 400 l/min 500 l/min 600 l/min 700 l/min 800 l/min 900 l/min<br />

10 20 30 40 50 60 70 80 90 100 110 120<br />

Speed in rpm<br />

18<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

Min. required pressure difference ∆p with idling speed (shaft unloaded)<br />

<strong>MR</strong><br />

33 - 110<br />

pressure drop in bar<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong> 110<br />

<strong>MR</strong> 93<br />

<strong>MR</strong> 73<br />

<strong>MR</strong> 57<br />

<strong>MR</strong> 33<br />

4<br />

200 400 600 800 1000 1200 1400<br />

Speed in rpm<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

125 - 330<br />

pressure drop in bar<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 330<br />

<strong>MR</strong> 300<br />

<strong>MR</strong> 250<br />

<strong>MR</strong> 200<br />

<strong>MR</strong> 190<br />

<strong>MR</strong>160<br />

<strong>MR</strong>125<br />

4<br />

100 200 300 400 500 600 700 800 900<br />

Speed in rpm<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

350 - 800<br />

pressure drop in bar<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 800<br />

<strong>MR</strong> 700<br />

<strong>MR</strong> 600<br />

<strong>MR</strong>E 500<br />

<strong>MR</strong> 450<br />

<strong>MR</strong> 350<br />

4<br />

50 100 150 200 250 300 350 400 450 500 550 600 640<br />

Speed in rpm<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

1100 - 2100<br />

pressure drop in bar<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 2100<br />

<strong>MR</strong> 1800<br />

<strong>MR</strong> 1600<br />

<strong>MR</strong>E 1400<br />

<strong>MR</strong> 1100<br />

4<br />

30 60 90 120 150 180 210 240 270 300 330<br />

Speed in rpm<br />

19<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

Min. required pressure difference ∆p with idling speed (shaft unloaded)<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

2400 - 8200<br />

pressure drop in bar<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 8200<br />

<strong>MR</strong> 7000<br />

<strong>MR</strong> 6500<br />

<strong>MR</strong>E 5400<br />

<strong>MR</strong> 4500<br />

<strong>MR</strong>E 3100<br />

<strong>MR</strong> 2800<br />

<strong>MR</strong> 3600<br />

<strong>MR</strong> 2400<br />

4<br />

20 40 60 80 100 120 140 160 180 200 220<br />

Speed in rpm<br />

Minimum boost pressure during pump operation<br />

<strong>MR</strong><br />

33 - 110<br />

Min. boost pressure in bar<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong> 110<br />

<strong>MR</strong> 93<br />

<strong>MR</strong> 73<br />

<strong>MR</strong> 57<br />

<strong>MR</strong> 33<br />

4<br />

200 400 600 800 1000 1200 1400<br />

Speed in rpm<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

125 - 330<br />

Min. boost pressure in bar<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 330<br />

<strong>MR</strong> 300<br />

<strong>MR</strong> 250<br />

<strong>MR</strong> 200<br />

<strong>MR</strong> 190<br />

<strong>MR</strong> 160<br />

<strong>MR</strong> 125<br />

4<br />

100 200 300 400 500 600 700 800 900 950<br />

Speed in rpm<br />

20<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

OPERATING DIAGRAM - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

OPERATING DIAGRAM<br />

Minimum boost pressure during pump operation<br />

(average values) measured at ν = 36 mm 2 /s; t = 45° C; p<br />

outlet = 0 bar<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

350 - 800<br />

Min. boost pressure in bar<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 800<br />

<strong>MR</strong> 700<br />

<strong>MR</strong> 600<br />

<strong>MR</strong>E 500<br />

<strong>MR</strong> 450<br />

<strong>MR</strong> 350<br />

4<br />

50<br />

100 150 200 250 300 350 400 450 500 550 600<br />

Speed in rpm<br />

640<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

1100 - 2100<br />

Min. boost pressure in bar<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 2100<br />

<strong>MR</strong> 1800<br />

<strong>MR</strong> 1600<br />

<strong>MR</strong>E 1400<br />

<strong>MR</strong> 1100<br />

4<br />

30 60 90 120 150 180 210 240 270 300 330<br />

Speed in rpm<br />

<strong>MR</strong> - <strong>MR</strong>E<br />

2400 - 8200<br />

Min. boost pressure in bar<br />

40<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

<strong>MR</strong>E 8200<br />

<strong>MR</strong> 7000<br />

<strong>MR</strong> 6500<br />

<strong>MR</strong>E 5400<br />

<strong>MR</strong> 4500<br />

<strong>MR</strong> 3600<br />

<strong>MR</strong>E 3100<br />

<strong>MR</strong> 2800<br />

<strong>MR</strong> 2400<br />

4<br />

20 40 60 80 100 120 140 160 180 200 220<br />

Speed in rpm<br />

21<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

RADIAL LOAD - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

RADIAL LOAD<br />

MOTO<br />

OTOR<br />

TYPE<br />

RADIA<br />

ADIAL<br />

MAX.<br />

PERMITTED RADIAL FORCE IN SHAFT CENTRE<br />

E<br />

FORCE<br />

M<br />

A<br />

X<br />

BRIEFLY<br />

BASED ON L<br />

H0<br />

5000<br />

HOUR<br />

S<br />

1<br />

PERMITTED WITH<br />

INPUT PRESSURE<br />

E I<br />

INPUT PRESSURE<br />

E I<br />

INPUT PRESSURE<br />

E<br />

DYNAMIC LOAD<br />

F in kN 1<br />

)<br />

200 bar<br />

F in kN<br />

150 bar<br />

F in kN<br />

100 bar<br />

F in kN<br />

speed in<br />

rpm<br />

M R 33<br />

3<br />

19,<br />

0<br />

9,<br />

5<br />

10,<br />

2<br />

10,<br />

6<br />

400<br />

M R 57<br />

19,<br />

0<br />

9,<br />

5<br />

10,<br />

2<br />

10,<br />

6<br />

400<br />

M R 73<br />

22,<br />

5<br />

9,<br />

0<br />

11,<br />

6<br />

13,<br />

5<br />

350<br />

M R 93<br />

22,<br />

5<br />

9,<br />

0<br />

11,<br />

6<br />

13,<br />

5<br />

350<br />

M R 110<br />

22,<br />

5<br />

9,<br />

0<br />

11,<br />

6<br />

13,<br />

5<br />

350<br />

M R 125<br />

22,<br />

5<br />

5,<br />

0<br />

9,<br />

9<br />

12,<br />

9<br />

275<br />

M R 160<br />

22,<br />

5<br />

5,<br />

0<br />

9,<br />

9<br />

12,<br />

9<br />

275<br />

M R 190<br />

22,<br />

5<br />

5,<br />

0<br />

9,<br />

9<br />

12,<br />

9<br />

275<br />

M R 200<br />

*<br />

- - - - -<br />

M R 250<br />

28,<br />

0<br />

5,<br />

6<br />

9,<br />

9<br />

12,<br />

6<br />

250<br />

M R 300<br />

0<br />

28,<br />

0<br />

5,<br />

6<br />

9,<br />

9<br />

12,<br />

6<br />

250<br />

M R 350<br />

35,<br />

0<br />

14,<br />

5<br />

18,<br />

4<br />

21,<br />

2<br />

225<br />

M R 450<br />

35,<br />

0<br />

14,<br />

5<br />

18,<br />

4<br />

21,<br />

2<br />

225<br />

M R 600<br />

0<br />

43,<br />

0<br />

15,<br />

0<br />

22,<br />

5<br />

27,<br />

3<br />

200<br />

M R 700<br />

0<br />

43,<br />

0<br />

15,<br />

0<br />

22,<br />

5<br />

27,<br />

3<br />

200<br />

M R 1100<br />

0<br />

54,<br />

0<br />

18,<br />

5<br />

28,<br />

5<br />

35,<br />

2<br />

150<br />

M R 1600<br />

0<br />

68,<br />

0<br />

26,<br />

2<br />

40,<br />

6<br />

50,<br />

0<br />

125<br />

M R 1800<br />

0<br />

68,<br />

0<br />

26,<br />

2<br />

40,<br />

6<br />

50,<br />

0<br />

125<br />

M R 2400<br />

0<br />

85,<br />

0<br />

50,<br />

1<br />

66,<br />

0<br />

76,<br />

8<br />

110<br />

M R 2800<br />

0<br />

85,<br />

0<br />

54,<br />

0<br />

69,<br />

0<br />

79,<br />

4<br />

100<br />

M R 3600<br />

0<br />

108,<br />

0<br />

55,<br />

0<br />

90,<br />

0<br />

103,<br />

0<br />

100<br />

M R 4500<br />

0<br />

108,<br />

0<br />

78,<br />

0<br />

97,<br />

0<br />

109,<br />

0<br />

85<br />

M R 6500<br />

0<br />

134,<br />

0<br />

74,<br />

0<br />

123,<br />

0<br />

141,<br />

0<br />

50<br />

M R 7000<br />

0<br />

134,<br />

0<br />

74,<br />

0<br />

123,<br />

0<br />

141,<br />

0<br />

50<br />

M RE 330<br />

28,<br />

0<br />

4,<br />

5<br />

8,<br />

5<br />

11,<br />

9<br />

250<br />

M RE 500<br />

0<br />

35,<br />

0<br />

12,<br />

4<br />

17,<br />

3<br />

20,<br />

8<br />

225<br />

M RE 800<br />

0<br />

43,<br />

0<br />

8,<br />

5<br />

19,<br />

8<br />

26,<br />

3<br />

200<br />

M RE 1400<br />

0<br />

54,<br />

0<br />

8,<br />

6<br />

24,<br />

0<br />

33,<br />

6<br />

140<br />

M RE 2100<br />

0<br />

68,<br />

0<br />

12,<br />

5<br />

35,<br />

6<br />

48,<br />

3<br />

120<br />

M RE 3100<br />

0<br />

85,<br />

0<br />

45,<br />

0<br />

64,<br />

5<br />

77,<br />

6<br />

100<br />

M RE 5400<br />

0<br />

108,<br />

0<br />

63,<br />

0<br />

90,<br />

2<br />

107,<br />

3<br />

80<br />

M RE 8200<br />

0<br />

134,<br />

0<br />

68,<br />

0<br />

110,<br />

0<br />

128,<br />

0<br />

50<br />

) in accordance with the<br />

dynamic<br />

condition,<br />

higher values<br />

can be<br />

accepted -<br />

<strong>MR</strong> 200*<br />

only<br />

code<br />

"F1<br />

"<br />

1 )<br />

in accordance<br />

with the<br />

dynamic<br />

condition,<br />

higher<br />

values<br />

can be<br />

accepted -<br />

<strong>MR</strong> 200*<br />

only<br />

code<br />

"F1<br />

"<br />

22<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

BEARING LIFE - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

BEARING LIFE<br />

L 50h<br />

L 10h<br />

<strong>Motor</strong> speed [rpm]<br />

Load coefficent<br />

C p = Load coefficent<br />

K = Sevice life coefficent for standard bearing<br />

p = operating pressure in bar<br />

L 10h<br />

is the theoretically service life value normally reached or exceeded by the 90% of the bearings.<br />

50 % of the bearings reach the value L 50h<br />

= 5 times L<br />

10h.<br />

M OTOR TYPE<br />

K M OTOR TYP<br />

E<br />

K M<br />

OTOR TYP<br />

E<br />

K<br />

M R 33<br />

3<br />

2600<br />

M RE 33<br />

0<br />

1000<br />

M RE 210<br />

0<br />

800<br />

M R 57<br />

2600<br />

M R 35<br />

0<br />

1340<br />

M R 240<br />

0<br />

1020<br />

M R 73<br />

1540<br />

M R 45<br />

0<br />

1340<br />

M R 280<br />

0<br />

1020<br />

M R 93<br />

1540<br />

M RE 50<br />

0<br />

1215<br />

M RE 310<br />

0<br />

920<br />

M R 110<br />

1540<br />

M R 60<br />

0<br />

1080<br />

M R 360<br />

0<br />

880<br />

M R 125<br />

1120<br />

M R 70<br />

0<br />

1080<br />

M R 450<br />

0<br />

880<br />

M R 160<br />

1120<br />

M RE 80<br />

0<br />

950<br />

M RE 540<br />

0<br />

730<br />

M R 190<br />

1120<br />

M R 110<br />

0<br />

1020<br />

M R 650<br />

0<br />

880<br />

M R 200<br />

0<br />

1120<br />

M RE 140<br />

0<br />

840<br />

M R 700<br />

0<br />

880<br />

M R 250<br />

1120<br />

M R 160<br />

0<br />

920<br />

M RE 820<br />

0<br />

680<br />

M R 300<br />

0<br />

1120<br />

M R 180<br />

0<br />

920<br />

23<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

MOTOR DIMENSIONS - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

D7/T1- SAE<br />

5<br />

4<br />

L8<br />

L9 - SAE<br />

B<br />

A<br />

Ø D11 - SAE<br />

1<br />

3<br />

2<br />

1 Splined shaft with flank contact (for dimension see page 26)<br />

Ordering code "N1"<br />

(for further shaft ends see page 26 - 27)<br />

2 Case drain port BSP threads to ISO 228/1<br />

3 On request the port flange can be rotated by 72°<br />

(For <strong>MR</strong> 33, <strong>MR</strong> 57, <strong>MR</strong> 73, <strong>MR</strong> 93, <strong>MR</strong> 110, <strong>MR</strong> 125, <strong>MR</strong> 160,<br />

<strong>MR</strong> 190, <strong>MR</strong> 200, <strong>MR</strong> 250, <strong>MR</strong> 300, <strong>MR</strong>E 330, <strong>MR</strong> 350, <strong>MR</strong> 450,<br />

<strong>MR</strong>E 500, <strong>MR</strong> 600,<strong>MR</strong> 700, <strong>MR</strong>E 800 can be rotated by 36°)<br />

For standard position see ange a.<br />

4 Port 1/4“ BSP threads to ISO 228/1 for pressure reading.<br />

5 Rotary valve housing with BSP threads (from <strong>MR</strong> 2400 to <strong>MR</strong>E<br />

8200) available on request, please contact Parker Calzoni.<br />

Dir.<br />

of<br />

Rotation<br />

(Viewed on<br />

shaft end)<br />

clockwise<br />

anti-clockwise<br />

clockwise<br />

anti-clockwise<br />

Port<br />

A<br />

B<br />

B<br />

A<br />

inlet<br />

2<br />

ordering code<br />

(see page35)<br />

"N"<br />

"S"<br />

B2 - SAE<br />

B3 - SAE<br />

24<br />

RCOe 1806/03.05<br />

The specified data are for product description purposes only and must not be interpreted as warranted characteristic in a<br />

legal sense. All rights reserved. Subject to revision.

MOTOR DIMENSIONS - MOTOR TYPE <strong>MR</strong> - <strong>MR</strong>E<br />

MOTO<br />

OTOR<br />

TYPE<br />

<strong>MR</strong> 33<br />

3<br />

<strong>MR</strong> 57<br />

<strong>MR</strong> 73<br />

<strong>MR</strong> 93<br />

<strong>MR</strong> 110<br />

<strong>MR</strong> 125<br />

<strong>MR</strong> 160<br />

<strong>MR</strong> 190<br />

<strong>MR</strong> 200<br />

0<br />

<strong>MR</strong> 250<br />

<strong>MR</strong> 300<br />

<strong>MR</strong>E 330<br />

<strong>MR</strong> 350<br />

<strong>MR</strong> 450<br />

<strong>MR</strong>E 500<br />

<strong>MR</strong> 600<br />

0<br />

<strong>MR</strong> 700<br />

<strong>MR</strong>E 800<br />

<strong>MR</strong> 1100<br />

0<br />

<strong>MR</strong>E 1400<br />

<strong>MR</strong> 1600<br />

0<br />

<strong>MR</strong> 1800<br />

<strong>MR</strong>E 2100<br />

<strong>MR</strong> 2400<br />

0<br />

<strong>MR</strong> 2800<br />

<strong>MR</strong>E 3100<br />

<strong>MR</strong> 3600<br />

0<br />

<strong>MR</strong> 4500<br />

<strong>MR</strong>E 5400<br />

<strong>MR</strong> 6500<br />

0<br />

<strong>MR</strong> 7000<br />

<strong>MR</strong>E 8200<br />

L1<br />

L2<br />

L3<br />

L4<br />

L5<br />

L6<br />

L7<br />

L8<br />

L9<br />

*<br />

low<br />

pressure<br />

L9<br />

-<br />

SAE<br />

*<br />

high<br />

h<br />

pressure<br />

L 10<br />

L1<br />

1<br />

L 1<br />

2<br />

L 1<br />

3 a b<br />

253,5<br />

19<br />

6 14<br />

8 10<br />

7 57,<br />

2 14<br />

19<br />

70<br />

--<br />

52,<br />

4 110,<br />

2 78,<br />

5 70<br />

19,<br />

7 108<br />

° 36 °<br />

297<br />

228,<br />

5 190,<br />

5 131,<br />

5 68,<br />

5 17<br />

20<br />

54<br />

34<br />

--<br />

119,<br />

8 94<br />

72<br />

- 90<br />

° 36 °<br />

309<br />

24<br />

2 20<br />

4 14<br />

5 67<br />

14<br />

16<br />

54<br />

34<br />

--<br />

147,<br />

5 10<br />

3 72<br />

6 , 5 90<br />

° 36 °<br />

323<br />

24<br />

2 20<br />

4 14<br />

5 81<br />

15<br />

16<br />

54<br />

34<br />

--<br />

153,<br />

5 11<br />

9 72<br />

7 , 5 90<br />

° 36 °<br />

376<br />

27<br />

9 23<br />

5 16<br />

7 97<br />

15<br />

18<br />

70,<br />

4 40<br />

--<br />

174,<br />

5 13<br />

0 84<br />

9 , 5 90<br />

° 36 °<br />

400<br />

29<br />

9 25<br />

5 18<br />

7 10<br />

1 15<br />

20<br />

70,<br />

4 40<br />

--<br />

19<br />

2 14<br />

3 84<br />

8 90<br />

° 36 °<br />

458<br />

34<br />

1 29<br />

3 20<br />

3 11<br />

7 20<br />

22<br />

82<br />

50<br />

--<br />

--<br />

22<br />

3 16<br />

5 10<br />

5 9 104<br />

° 36 °<br />

506<br />

37<br />

4 32<br />

6 23<br />

6 13<br />

2 21<br />

24<br />

82<br />

50<br />

--<br />

--<br />

26<br />

4 19<br />

7 10<br />

5 11<br />

90<br />

° 36 °<br />

619<br />

46<br />

6 39<br />

2 28<br />

5 15<br />

3 24<br />

26<br />

13<br />

5 62<br />

69,8<br />

5 79,<br />

4 30<br />

3 22<br />

1 12<br />

3 15<br />

90<br />

° 36 °<br />

699,5<br />

489,<br />

5 418,<br />

5 307,<br />

5 21<br />

0 34<br />

28<br />

13<br />

5 68<br />

77,7<br />

7 96,8<br />

2 359,<br />

5 24<br />

7 12<br />

3 19<br />

108<br />

° 36 °<br />

796<br />

56<br />

6 49<br />

5 38<br />

4 23<br />

0 37<br />

30<br />

13<br />

5 68<br />

77,7<br />

7 96,8<br />

2 407,<br />

3 24<br />

7 12<br />

3 21<br />

108<br />

° 36 °<br />