Master Blacksmith Jack O'Neill - Leitrim Guardian

Master Blacksmith Jack O'Neill - Leitrim Guardian

Master Blacksmith Jack O'Neill - Leitrim Guardian

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

M A S T E R B L A C K S M I T H<br />

Jim Williamson<br />

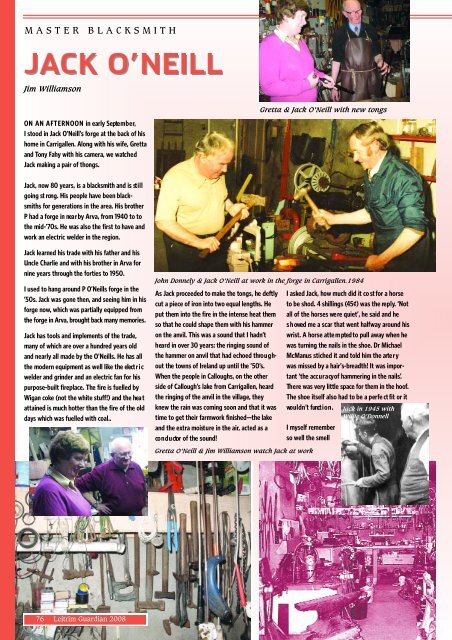

Gretta & <strong>Jack</strong> O’Neill with new tongs<br />

ON AN AFTERNOON in early Septe m b e r,<br />

I stood in <strong>Jack</strong> O’Neill’s fo rge at the back of his<br />

home in Carrigallen. Along with his wife, Gret t a<br />

and Tony Fahy with his camera, we watc h e d<br />

<strong>Jack</strong> making a pair of thongs.<br />

<strong>Jack</strong>, now 80 years, is a blacksmith and is st i l l<br />

going st rong. His people have been blacksmiths<br />

for generations in the area. His brot h e r<br />

P had a fo rge in nea r by Arva, from 1940 to to<br />

the mid-’70s. He was also the first to have and<br />

work an electric welder in the re g i o n .<br />

<strong>Jack</strong> learned his trade with his father and his<br />

Uncle Charlie and with his brother in Arva fo r<br />

nine years through the forties to 1950.<br />

I used to hang around P O’Neills fo rge in the<br />

’50s. <strong>Jack</strong> was gone then, and seeing him in his<br />

fo rge now, which was partially equipped fro m<br />

the fo rge in Arva, brought back many memories.<br />

<strong>Jack</strong> has tools and implements of the trade,<br />

many of which are over a hundred years old<br />

and nearly all made by the O’Neills. He has all<br />

the modern equipment as well like the elect r i c<br />

welder and grinder and an electric fan for his<br />

purpose-built fire p l a ce. The fire is fuelled by<br />

Wigan co ke (not the white stuff!) and the hea t<br />

attained is much hot ter than the fire of the old<br />

d a ys which was fuelled with co a l ..<br />

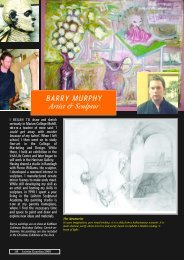

John Donnely & <strong>Jack</strong> O’Neill at work in the forge in Carrigallen.1984<br />

As <strong>Jack</strong> pro ceeded to make the tongs, he deftly<br />

cut a piece of iron into two equal lengths. He<br />

put them into the fire in the intense heat them<br />

so that he could shape them with his hammer<br />

on the anvil. This was a sound that I hadn’t<br />

h ea rd in over 30 years: the ringing sound of<br />

the hammer on anvil that had echoed thro u g h-<br />

out the towns of Ireland up until the ’50’s .<br />

When the people in Calloughs, on the ot h e r<br />

side of Callough’s lake from Carrigallen, hea rd<br />

the ringing of the anvil in the village, they<br />

knew the rain was coming soon and that it was<br />

time to get their farmwork finished—the lake<br />

and the extra moist u re in the air, acted as a<br />

co n d u ctor of the sound!<br />

I asked <strong>Jack</strong>, how much did it co st for a horse<br />

to be shod. 4 shillings (45¢) was the re p l y. ‘Not<br />

all of the horses we re quiet’, he said and he<br />

s h owed me a scar that went halfway around his<br />

w r i st. A horse atte m pted to pull away when he<br />

was turning the nails in the shoe. Dr Michael<br />

McManus stiched it and told him the arte r y<br />

was missed by a hair’s - b readth! It was important<br />

‘the acc u r a cy of hammering in the nails’.<br />

Th e re was very little space for them in the hoof.<br />

The shoe itself also had to be a perfe ct fit or it<br />

wo u l d n ’t funct i o n .<br />

I myself re m e m b e r<br />

so well the smell<br />

<strong>Jack</strong> in 1945 with<br />

Willie O’Donnell<br />

Gretta O’Neill & Jim Williamson watch <strong>Jack</strong> at work<br />

76 <strong>Leitrim</strong> <strong>Guardian</strong> 2008

Hugh O’Neill, <strong>Jack</strong> O’Neill at<br />

12 years old and his Uncle<br />

Charlie. This picture taken at<br />

the original forge in<br />

Carrigallen where McCanns<br />

supermarket now stands.<br />

of the hooves as the hot shoes we re mea s u re d<br />

a g a i n st them to e n s u re that they we re level and<br />

the smell of the horsehair burning and the oil that<br />

the blacksmith used to paint the hooves to give<br />

them a nice finish. Many of these blacksmiths had<br />

a great rapport with the horses, but they got lots<br />

of abuse to o, both from the horses and their ow n e r s .<br />

<strong>Jack</strong> remembers John Duffy ’s Circus in the ’40s<br />

and all the wagons we re pulled by horses. Fo rg e s<br />

we re full of circus horses all day. ‘John Duffy<br />

made up the area’, acco rding to <strong>Jack</strong>. He bought<br />

p l e n ty of hay, oats and grain, food for the big<br />

ca ts, hard w a re items and supplies for the st af f.<br />

The big four wheel circus wagons we re pulled by<br />

P H O T O S I N J A C K O ’ N E I L L S F O R G E 2 0 0 4 & 2 0 0 7 (Sept) : T O N Y F A H Y<br />

USING THE FO RGE IN CARRIGA L L E N<br />

This account by Declan Tierney, was published in<br />

The <strong>Leitrim</strong> Observer in Sept 1984<br />

T R A D I T I O N S in a place are not easily broken and no<br />

place is this more evident than in Carrigallen where<br />

<strong>Jack</strong> O’Neill contents himself in pursuing that age old<br />

occupation of a blacksmith.<br />

Even in these days of electric welders and the like,<br />

there is something distinctly appealing about the<br />

furnace and the bellows that heat the metal until it is<br />

nearly liquefied.<br />

<strong>Jack</strong> O’Neill is by no means new to the business as<br />

his great, great grandfather, John O’Neill was also a<br />

blacksmith and the tradition has been handed down<br />

through generations.<br />

<strong>Jack</strong> still does business in repairs for a few people<br />

around the area and mostly concentrates on repairing<br />

machinery or other metal items. He built the furnace<br />

himself along with the water trough beside it to cool<br />

down the metal. But instead of using the time co n s u m-<br />

i n g puffing bellows which were responsible for a lot<br />

of arm muscles in its time, <strong>Jack</strong> uses a double blast<br />

electric fan to increase the strength of the fire.<br />

The process he told me for joining two pieces of<br />

iron together is to first prepare them by cleaning off<br />

any dust or dirt to ensure a perfect joint. Then you<br />

scarf the two pieces, which means that you cut a slice<br />

off each one in order to, basically, graft them together.<br />

When the two pieces of iron are ready to drip with hea t<br />

in the furnace, they are joined by putting one gently<br />

on top of the other. They are then hammered together<br />

and smoothed with a rounding iron. The perfect joint<br />

is achieved when the graft cannot be noticed.<br />

The making of loy-iron and horse shoes were the<br />

big business with a blacksmith. The loy was originally<br />

used for ploughing and often farmers had to face into<br />

a few acres of land with just a simple loy in their possession<br />

with which to plough with.<br />

The implements used in making a horseshoe were a<br />

fuller, which made the tracks on the shoes, the stamp,<br />

which was used to bore holes for the nails while<br />

pritchel was used to finish off around the nail holes.<br />

<strong>Jack</strong> O’Neill is a qualified blacksmith as he served<br />

his time with his brother for nine years in Arva. At the<br />

moment he turns his hand to doing a few welding jobs<br />

whenever he is approached, but he is otherwise occupied<br />

with his thriving electrical shop in the town.<br />

<strong>Jack</strong> believes that, even though technology has<br />

taken over with the electric welder, there is still quite<br />

a lot of business to be done with the old furnace if he<br />

had the time and farmers especially seem to have<br />

more confidence in the blacksmith where they could<br />

come and watch a job being done and they can identify<br />

with it better than an electric machine.<br />

There were five blacksmiths in Carrigallen at one<br />

stage and there were loads of work for all of them.<br />

Indeed, if one were to seriously concentrate on doing<br />

work with the furnace even now, there would be<br />

plenty for him to do, <strong>Jack</strong> told me.<br />

“The reason I have rebuilt this forge is to show my<br />

kids how it was all done when I was a young lad,” he<br />

explained.<br />

M etal frames for cart wheels we re also a popular ite m<br />

that needed repairing and <strong>Jack</strong> showed me some sa m p l e s<br />

of joints that he did and how to make a frame. He said<br />

that there is another blacksmith in Carrigallen also<br />

who is still working the forge and he is Pakie Maguire.<br />

“People who have worked on an old forge are well<br />

co m p etent to work an electric we l d e r,” concluded <strong>Jack</strong>.<br />

2008 <strong>Leitrim</strong> <strong>Guardian</strong> 77

78 <strong>Leitrim</strong> <strong>Guardian</strong> 2008

Left: Inside the forge<br />

in Carrigallen<br />

Above: Working on the<br />

tongs.<br />

Right: The O’Neill,<br />

Hardware & Electrical<br />

shop in Carrigallen.<br />

Dec 2000.<br />

Far Right: <strong>Jack</strong> with<br />

two long spades that<br />

he has just made.<br />

P HOT OS: TO NY FA H Y<br />

horses and some of these included Lion and<br />

Tigers, who seemed to watch eve r yone inte n t l y<br />

as they passed.<br />

Many blacksmiths at that time made the rims<br />

for the ca r twheels and also the blades for the<br />

ploughs that the draught horses pulled. To d a y,<br />

<strong>Jack</strong> still makes fine spades, tongs, hand-loys ,<br />

slans and other items for the home such as<br />

w a ter keys, co o ke r-lid lifters, ash box lifte r s<br />

and solid fuel stove openers.<br />

In 1950, <strong>Jack</strong> went to England and wo r ked for a<br />

year in a copper mill in Cove n t r y. Af ter he<br />

returned, he went to Smiths garage in Cavan<br />

(their cousin), with his Uncle Charlie and<br />

bought a new Fe rguson 20 tracto r, tvo fuelled,<br />

for £444 including plough and tailor-made<br />

canvas cove r.<br />

<strong>Jack</strong> wo r ked up the country in <strong>Leitrim</strong> for five<br />

years and soon got a mowe r, a threshing mill<br />

and later a diesel Fe rguson. He mostly wo r ke d<br />

in the Ballinamore and Carrigallen areas and<br />

of ten wo r ked through the night by the lights<br />

that he had fixed up on the tracto r. And yet<br />

when the tractors came in, it signalled the<br />

demise of the blacks m i t h .<br />

In 1956, <strong>Jack</strong>’s Uncle Charlie died suddenly and<br />

his Aunt wanted him to take over in Carrigallen.<br />

He opened a hard w a re sto re in 1957 and also<br />

sold implements from the fo rge as his uncle<br />

had done. <strong>Jack</strong> married Gretta Dolan from<br />

B a l l i n a m o re in 1970. They rea red two sons,<br />

Hugh O’Neill, a solicitor and fluent Spanish<br />

s p ea ke r, living on the Iberian peninsula and<br />

Pete r, an accountant working and living in<br />

Dublin. In 1977, <strong>Jack</strong>’s brother P who was<br />

s even years older than him, died af ter an<br />

illness.<br />

<strong>Jack</strong> continued working at his trade and<br />

running the business until 2004 when he<br />

closed the hard w a re shop and ret i red fro m<br />

business. As well as his fo rge wo r ks h i p,<br />

<strong>Jack</strong> does plenty of gardening and re m a i n s<br />

a ct i ve. May he have many years of good<br />

fortune ahead of him.<br />

2008 <strong>Leitrim</strong> <strong>Guardian</strong> 79