Tech Data - AMT Composites

Tech Data - AMT Composites

Tech Data - AMT Composites

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

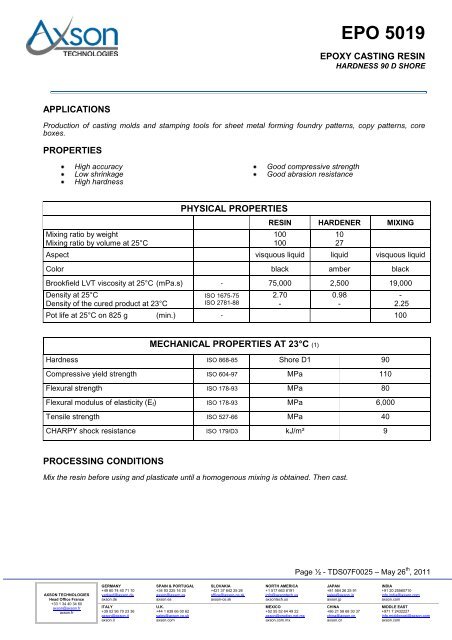

EPO 5019<br />

EPOXY CASTING RESIN<br />

HARDNESS 90 D SHORE<br />

APPLICATIONS<br />

Production of casting molds and stamping tools for sheet metal forming foundry patterns, copy patterns, core<br />

boxes.<br />

PROPERTIES<br />

High accuracy<br />

Low shrinkage<br />

High hardness<br />

Good compressive strength<br />

Good abrasion resistance<br />

Mixing ratio by weight<br />

Mixing ratio by volume at 25°C<br />

PHYSICAL PROPERTIES<br />

RESIN HARDENER MIXING<br />

Aspect visquous liquid liquid visquous liquid<br />

Color black amber black<br />

Brookfield LVT viscosity at 25°C (mPa.s) - 75,000 2,500 19,000<br />

Density at 25°C<br />

Density of the cured product at 23°C<br />

ISO 1675-75<br />

ISO 2781-88<br />

Pot life at 25°C on 825 g (min.) - 100<br />

100<br />

100<br />

2.70<br />

-<br />

10<br />

27<br />

0.98<br />

-<br />

-<br />

2.25<br />

MECHANICAL PROPERTIES AT 23°C (1)<br />

Hardness ISO 868-85 Shore D1 90<br />

Compressive yield strength ISO 604-97 MPa 110<br />

Flexural strength ISO 178-93 MPa 80<br />

Flexural modulus of elasticity (E f ) ISO 178-93 MPa 6,000<br />

Tensile strength ISO 527-66 MPa 40<br />

CHARPY shock resistance ISO 179/D3 kJ/m² 9<br />

PROCESSING CONDITIONS<br />

Mix the resin before using and plasticate until a homogenous mixing is obtained. Then cast.<br />

Page ½ - TDS07F0025 – May 26 th , 2011<br />

AXSON TECHNOLOGIES<br />

Head Office France<br />

+33 1 34 40 34 60<br />

axson@axson.fr<br />

axson.fr<br />

GERMANY<br />

+49 60 74 40 71 10<br />

verkauf@axson.de<br />

axson.de<br />

ITALY<br />

+39 02 96 70 23 36<br />

axson@axson.it<br />

axson.it<br />

SPAIN & PORTUGAL<br />

+34 93 225 16 20<br />

axson@axson.es<br />

axson.es<br />

U.K.<br />

+44 1 638 66 00 62<br />

sales@axson.co.uk<br />

axson.com<br />

SLOVAKIA<br />

+421 37 642 25 26<br />

office@axson-ce.sk<br />

axson-ce.sk<br />

NORTH AMERICA<br />

+1 517 663 8191<br />

info@axsontech.us<br />

axsontech.us<br />

MEXICO<br />

+52 55 52 64 49 22<br />

axson@prodigy.net.mx<br />

axson.com.mx<br />

JAPAN<br />

+81 564 26 25 91<br />

sales@axson.jp<br />

axson.jp<br />

CHINA<br />

+86 21 58 68 30 37<br />

china@axson.cn<br />

axson.cn<br />

INDIA<br />

+91 20 25560710<br />

info.india@axson.com<br />

axson.com<br />

MIDDLE EAST<br />

+971 7 2432227<br />

info.middleeast@axson.com<br />

axson.com

EPO 5019<br />

EPOXY CASTING RESIN<br />

HARDNESS 90 D SHORE<br />

THERMAL (1) AND SPECIFIC PROPERTIES<br />

Temperature of glass transition T.M.A.-Mettler °C 74<br />

Coefficient of linear expansion (C L TE)<br />

[+10, +60]°C<br />

T.M.A.-Mettler 10 -6 K -1 50<br />

Maximal casting thickness mm 40<br />

Linear shrinkage (250x60x40) - °/ 00 1.7<br />

Demolding time of the maximal thickness - hr 24<br />

Complete hardening time - d 4<br />

(1) : Average values obtained on standard specimens after a 16 hours at 50°C curing.<br />

STORAGE<br />

Use the resin and hardener before 18 months according to the manufacturing date.<br />

Expiration date indicated on the packaging.<br />

Any open can must be tightly closed under dry inert gas (dry air, nitrogen, etc.).<br />

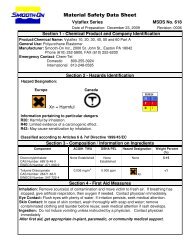

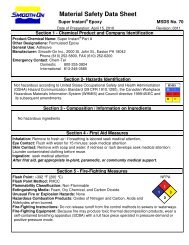

SAFETY PRECAUTIONS<br />

Normal health and safety precautions should be observed when handling these products:<br />

ensure good ventilation,<br />

wear gloves and safety glasses.<br />

For further information, please consult the product safety data sheet.<br />

PACKAGING<br />

RESIN<br />

HARDENER<br />

6 x 1.500 kg 6 x 0.15 kg<br />

1 x 15,000 kg 1 x 1.50 kg<br />

GUARANTEE<br />

The information contained in this technical data sheet result from research and tests conducted in our Laboratories under precise conditions.<br />

It is the responsibility of the user to determine the suitability of AXSON products, under their own conditions before commencing with the<br />

proposed application. AXSON guarantee the conformity of their products with their specifications but cannot guarantee the compatibility of a<br />

product with any particular application. AXSON disclaim all responsibility for damage from any incident which results from the use of these<br />

products. The responsibility of AXSON is strictly limited to reimbursement or replacement of products which do not comply with the published<br />

specifications.<br />

Page ½ - TDS07F0025 – May 26 th , 2011<br />

AXSON TECHNOLOGIES<br />

Head Office France<br />

+33 1 34 40 34 60<br />

axson@axson.fr<br />

axson.fr<br />

GERMANY<br />

+49 60 74 40 71 10<br />

verkauf@axson.de<br />

axson.de<br />

ITALY<br />

+39 02 96 70 23 36<br />

axson@axson.it<br />

axson.it<br />

SPAIN & PORTUGAL<br />

+34 93 225 16 20<br />

axson@axson.es<br />

axson.es<br />

U.K.<br />

+44 1 638 66 00 62<br />

sales@axson.co.uk<br />

axson.com<br />

SLOVAKIA<br />

+421 37 642 25 26<br />

office@axson-ce.sk<br />

axson-ce.sk<br />

NORTH AMERICA<br />

+1 517 663 8191<br />

info@axsontech.us<br />

axsontech.us<br />

MEXICO<br />

+52 55 52 64 49 22<br />

axson@prodigy.net.mx<br />

axson.com.mx<br />

JAPAN<br />

+81 564 26 25 91<br />

sales@axson.jp<br />

axson.jp<br />

CHINA<br />

+86 21 58 68 30 37<br />

china@axson.cn<br />

axson.cn<br />

INDIA<br />

+91 20 25560710<br />

info.india@axson.com<br />

axson.com<br />

MIDDLE EAST<br />

+971 7 2432227<br />

info.middleeast@axson.com<br />

axson.com