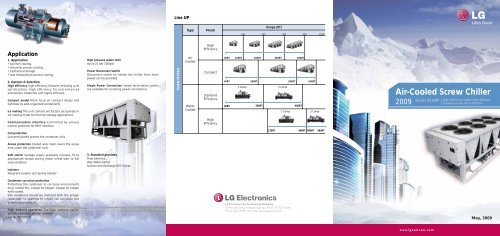

Air-Cooled Screw Chiller

Air-Cooled Screw Chiller

Air-Cooled Screw Chiller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Line UP<br />

Type<br />

Model<br />

100<br />

Range [RT]<br />

200 300 400 1000<br />

Application<br />

1. Application<br />

• Comfort cooling.<br />

• Industrial process cooling.<br />

• Ice/thermal storage.<br />

• Low temperature process cooling.<br />

2. Options & Selection<br />

High efficiency High efficiency features including cycle<br />

optimization, high efficiency fin and enhanced<br />

economizer. Make this unit highly efficient.<br />

Compact model More focus on compact design and<br />

lightness by well-organized components<br />

Ice making The unit controls are factory set operate in<br />

ice making mode for thermal storage applications.<br />

High pressure water shell<br />

Up to 21 bar (300psi)<br />

Power Disconnect Switch<br />

Disconnect switch to isolate the chiller from main<br />

power can be provided.<br />

Single Power Connection Single termination points<br />

are available for incoming power connections.<br />

<strong>Screw</strong> (R134a)<br />

<strong>Air</strong><br />

<strong>Cooled</strong><br />

Water<br />

<strong>Cooled</strong><br />

High<br />

Efficiency<br />

Compact<br />

Standard<br />

Efficiency<br />

50RT 100RT 200RT 300RT 400RT<br />

40RT 180RT 360RT 540RT<br />

1 Comp<br />

2 Comp<br />

40RT<br />

200RT<br />

400RT<br />

1 Comp 2 Comp<br />

<strong>Air</strong>-<strong>Cooled</strong> <strong>Screw</strong> <strong>Chiller</strong><br />

2009 Series RCAW® High Efficiency model 50 to 400Tons<br />

Compact model 40 to 540Tons<br />

Communication interface Controlled by various<br />

control protocols for BMS interface.<br />

High<br />

Efficiency<br />

Coil protection<br />

Louvered panels protect the condenser coils.<br />

220RT<br />

480RT<br />

480RT<br />

960RT<br />

Access protection Coated wire mesh covers the access<br />

area under the condenser coils.<br />

Soft starter Voltage supply gradually increase, fit to<br />

appropriate torque during motor initial start to full<br />

load condition<br />

Isolators<br />

Neoprene isolator and Spring isolator<br />

3. Standard provides<br />

Flow switches<br />

Wye-Delta starter<br />

Suction and discharge SVC Valves<br />

Condenser corrosion protection<br />

Protecting the condenser in corrosive environments<br />

Acryl coated fins, Copper to Copper. Copper to Copper<br />

with coated.<br />

Site conditions should be matched with the proper<br />

condenser fin coatings to inhibit coil corrosion and<br />

extend equipment life.<br />

High ambient operation The high ambient option<br />

permits operation at high ambient<br />

(up to 125°F/52°C).<br />

LG Electronics <strong>Air</strong> Conditioning Marketing<br />

20 Yeouido-dong, Yeongdeungpo-gu, Seoul 150-721, Korea<br />

Phone: 82-2-3777-1114 http://www.lgeaircon.com<br />

May, 2009<br />

www.lgeaircon.com

<strong>Air</strong>-<strong>Cooled</strong> <strong>Screw</strong> <strong>Chiller</strong> 2009<br />

www.lgeaircon.com<br />

Feature & Benefit<br />

1. Excellent Reliability and Powerful Operation<br />

The cutting-edge design of the series RCAW <strong>Air</strong>cooled<br />

screw chiller accomplishes high performance<br />

and reliability for industrial and commercial market.<br />

LG <strong>Air</strong>-cooled screw compressors are precisely<br />

machined from solid compound metal bar using<br />

profound cutting process. Tolerance is maintained<br />

within a few microns just like one-tenth hair thickness.<br />

Robust components with highly skilled assembling<br />

process help the compressor last long time.<br />

LG condenser production technology is already wellknown<br />

to worldwide air conditioning manufacturing<br />

industries because of its leading technologies.<br />

2. World Class High Efficiency (High efficiency<br />

model RCAW****A**)<br />

Top level efficiency in accordance with ARI Standard<br />

550/590. Optimized compressor design including a<br />

rotor and a slide valve is suitable for comfort cooling<br />

applications. The rotor is designed to work efficiently<br />

for different pressure ranges covering air conditioning<br />

and refrigeration application.<br />

The slide valve controls the cooling capacity by<br />

controlling the position of the slide where refrigerant<br />

suction starts using internal pressure difference<br />

between discharge and suction. LG air cooled screw<br />

chiller has 4 steps capacity control (100, 75, 50, 25%)<br />

capability which is optimized for part-load condition.<br />

Precise rotor tip clearance provides excellent energy<br />

efficiency in the screw rotary compressor because this<br />

reduces leakage from high pressure to low pressure<br />

side during compression, achieving top class C.O.P.<br />

The cooler uses internally grooved tubes having<br />

helical angle which enhanced the water side heat<br />

transfer performance. The outside of the tube is of<br />

optimum shape which has highly enhanced<br />

performance for pooling boiling and film-wise<br />

evaporation with R134-a. The V-shape of condenser<br />

allows the largest heat transfer surface area for the<br />

same foot print, resulting in largest heat transfer<br />

performance when the configuration is optimally<br />

designed. The LG V-shape condenser coil was designed<br />

using numerical and experimental analysis, having<br />

optimum air flow path to optimize heat rejection<br />

performance. Also, the enhanced condenser fin<br />

geometry allows the optimum heat transfer<br />

performance at small air side pressure drop, and this<br />

reduce the fan-motor power consumption. The fin is<br />

pre-coated to prevent corrosion at normal conditions,<br />

and acrylic post coated fin condenser, which is<br />

sustainable in harsh conditions, is also available as<br />

option.<br />

Condensor<br />

Ejector<br />

Evaporator<br />

Compressor<br />

Gas<br />

Liquid<br />

Gas-liquid<br />

Separator<br />

EJECTOR<br />

Suction<br />

Diffuser<br />

Nozzle<br />

Chamber<br />

Motive<br />

3. World Class Compact Design (Compact model<br />

RCAW****B**)<br />

The RCAW model <strong>Air</strong>-cooled screw chiller is a compact<br />

model of LG chillers and small compare to those of<br />

other major chiller manufacturers averages 30% in<br />

external dimensional footprint.<br />

This model is also very light because of its<br />

compactness. This model is suitable for the place<br />

where there is restriction in space and for replacement<br />

of old chillers. All physical sizes were reduced without<br />

any sacrifice. This compactness could be achieved by<br />

simplifying compression chamber, modifying coil<br />

configuration, developing new oil separator, and<br />

optimizing oil piping configuration.<br />

'RCAW' was designed to be a prime chiller and was<br />

born to lead air-cooled chiller market. It is LG<br />

technology.<br />

4. Low Noise and Low Vibration<br />

The unit was designed with a compact structure and<br />

robust assembly.<br />

The condenser fan is completed with high-efficiency<br />

wing style axial fan and direct driven motor for low<br />

sound level. The unit configures compressor sound<br />

insulation box (Option), which makes LG chillers silent<br />

and stable.<br />

Anechoic<br />

Noise test simulation<br />

Chamber<br />

5. Advanced Microcomputer Control<br />

Adaptive <strong>Chiller</strong> Control and Higher Level Protection.<br />

The chiller control system is based on recent PLC<br />

(Programmable Logic Controller) technology. Because<br />

the PLC is designed to be compatible with several<br />

electromagnetic interference and also compatible<br />

with severe ambient conditions, the unit has reliable<br />

controllability in any conditions.<br />

The adaptive chiller control is designed to operate the<br />

unit to withstand sever conditions and maintain its<br />

operation. Good examples are condenser fan controls<br />

by cycling according to the temperature of condenser<br />

refrigerant and the limitation of compressor capacity<br />

in the case of high chilled water temperature.<br />

Along with the adaptive control, the control also<br />

provides higher level protection through multiple<br />

protective devices. For example triple protective<br />

devices are used for the detection of abnormal oil<br />

circulation. The control system continues to monitor<br />

the hazardous conditions of the unit, and shutdown<br />

the unit to protect the unit safely when any condition<br />

meets safety limit.<br />

Rich Human Machine Interface<br />

Full dot LCD with four-line display provides rich<br />

human machine interface. The interface shall include<br />

operation conditions of the unit, control outputs, and<br />

alarm encountered. Along with the LCD display, there<br />

are totally nine LEDs are provided to indicated the<br />

important control status of the unit. Through the LCD<br />

and LEDs, operator-friendly interface is achieved for<br />

the easy control of the LGE chiller<br />

Superior power supply monitoring function of the<br />

control system is enabled by protective function of it<br />

against high voltage, low voltage, power loss, phase<br />

reverse, and phase imbalance. The superior function<br />

of safe power supply to the unit is provided by<br />

standard.<br />

Standard Wye-delta Start Type and Optional Soft Start<br />

Type The wye-delta start provides reduced starting<br />

current by 1/3. The LGE chiller is equipped with the<br />

wye-delta start of the compressor. Optionally, soft<br />

start type shall be provided for soft start of the<br />

compressor by linear voltage increase.<br />

6. System Protection Device<br />

All of the LG chiller supplies perfect protective devices<br />

for reliability.<br />

• Proper oil circulation<br />

(triple protection)<br />

- Oil Flow switch<br />

- Oil level switch<br />

- Dual pressure switch<br />

• Anti-freezing switch<br />

- Low chilled water cutout switch (2°C)<br />

• Differential pressure switch<br />

- Between evaporator and condenser<br />

• Compressor overload relay<br />

- Checking comp current<br />

• Compressor internal protector<br />

- Checking comp winding temperature.<br />

• Flow switch<br />

- Checking if there is water flow<br />

7. Installation, Start-up<br />

Small operating footprint fit most retrofit<br />

applications. (Compact model) Factory testing for high<br />

reliability. Factory-installed and tested controls help to<br />

reduce start up time and minimized extra cost. Display<br />

temperatures and pressure for each component spot.<br />

8. Compressor Specification<br />

Semi-hermetic twinrotor<br />

screw compressor.<br />

Direct-drive,low<br />

speed/RPM. Only three<br />

moving parts, resulting<br />

in high reliability.<br />

The slide valve has a<br />

unique profile optimized<br />

for part-load conditions.<br />

Field serviceable and<br />

easy maintenance.<br />

Sauggas<br />

Suction Gas<br />

Gas aspiré<br />

Precise rotor tip clearance A refrigerant dispersing<br />

device is set internal to the compressor for motor<br />

cooling.<br />

1. Factory Testing<br />

Unit Performance Testing<br />

All LG air-cooled screw chillers are given a complete<br />

functional test at the factory. LG computer-based<br />

testing programs completely check the components<br />

including sensors, wiring, electronics and microprocessor<br />

control functions.<br />

LG promotes factory performance tests for air-cooled<br />

chillers and water-cooled chillers to show that we<br />

stand behind the products which are designed and<br />

build up.<br />

The benefits of a performance test include verification<br />

of performance, prevention of operational problems,<br />

and assurance of a smooth start-up. Each compressor<br />

is run and tested to verifying capacity and efficiency.<br />

The result of this testing, <strong>Chiller</strong> arrives at the job site<br />

fully tested and ready for operation. The LG test<br />

facility is able to simulate real circumstance assuring<br />

operation in differing climates.<br />

ECO<br />

Installation for Industrial usage<br />

LG Researching Effort<br />

CR1<br />

CR2<br />

CR3<br />

Druckgas<br />

Discharge gas<br />

Gas de refoulement<br />

CR4<br />

[<strong>Air</strong>-<strong>Cooled</strong> <strong>Chiller</strong> Test Chamber]<br />

2. Structural Strength Analysis<br />

Structural strength evaluation simulation<br />

3. Condenser Numerical Analysis<br />

LG simulate heat circulation for all chiller product to<br />

evaluate air movement to be most appropriate design.<br />

Heat circulation evaluation simulation<br />

4. Assembly V-Module<br />

[Run Test for RCAW 90TON]