Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

----..'/<br />

--------------------"'--...---------------<br />

·-..,··~-. ..~·.·.l~~r<br />

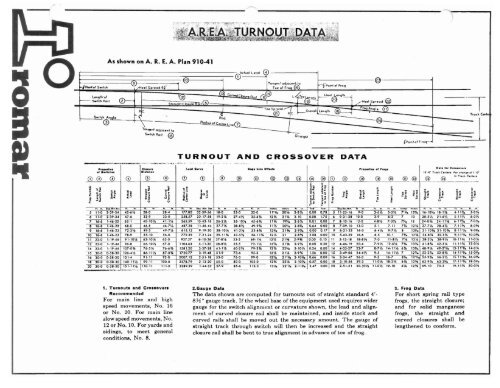

As shown on A. R. E. A. Plan 910-41<br />

I'<br />

~<br />

~~~~~~~~~~~~~~~~~~~~~~~~======i==c®C'.uO' Lead<br />

(Pol'" 0' Swlteh<br />

u"qlh'ol<br />

l----- S.,ieh Roll<br />

TCs)<br />

~ j Str~iahtCIOlurt F«;II (5).<br />

~., R~d<br />

1-1--==0 I \-<br />

S- >-<br />

, 11·0 2·39·3( '2.6V, 28·0 28·' 177.80 32·39·'6 18·0 2'·0 --32·0 11'1Ii ~2cf~ -0.00 0.78~.16 9·0 3·6VJ ,·,V, 7'1

(<br />

TURNOUTS<br />

Turnouts are the means by<br />

which rolling stock is<br />

diverted from one track to<br />

another. This is done by<br />

making use of a frog,<br />

switch, stock <strong>and</strong> closure<br />

rails. <strong>Romar</strong> maintains a<br />

working stock of turnout<br />

accessories in order to<br />

provide a complete turnout<br />

or to assist you in turnout<br />

or maintenance needs.<br />

.........rolllar_43<br />

-----1

DIAGRAMS giving names of the main formations in trackwork<br />

RIGHT HAND TURNOUT<br />

EQUILATERAL TURNOUT<br />

LEFT HAND TURNOUT<br />

THREE-WAY TURNOUT<br />

CROSSING<br />

FROG-TYPE CROSSING(<br />

RIGHT HAND CROSSOVER LEFT HAND CROSSOVER DOUBLE CROSSOVER<br />

o<br />

.....-rollla~_44 1

<strong>Rail</strong>road Frogs<br />

FROG CONSTRUCTION<br />

BOLTED RIGID FROGS - Constructed of carbon ste&! rails with<br />

rolled cast fillers, securely bolted together. While this type of<br />

construction may vary from heavy to extremely light duty, the<br />

rolled steel rails receive the full impact <strong>and</strong> wear.<br />

SPRING RAIL FROGS· Generally used on main lines where the<br />

turnout run is infrequently u~ed. Elim inating the open flangeway in<br />

the turnout run reduces impact <strong>and</strong> wear at the point, <strong>and</strong> provides<br />

smoother operation in the main line.<br />

RAIL BOUND MANGANESE STEEL FROGS· Designed for maximum<br />

severity of service, they incorporate acast managanese steel<br />

center, designed to receive the full impact <strong>and</strong> wear through the<br />

intersection. Rolled carbon steel rails support the manganese steel<br />

center, with arms extending to a point where conventional splices<br />

may !:'e able to the connecting rails. All components. lnell-ding<br />

fillers, are securely bolted with heat-treated bolts.<br />

SOLID MANGANESE STEEL FROGS· Completely integrated<br />

frogs. cast in one piece from manganese steel. Such a frog is<br />

designed to receive the connecting rails, so necessary straps <strong>and</strong><br />

special length bolts are furnished with the frog. The st<strong>and</strong>ard joint<br />

bars are usually supplied by the User.<br />

SOLID MANGANESE STEEL SELF-GUARDED FROGS - Similar<br />

to solid manganese steel frogs, with the addition of raised guards,<br />

cast integrally with the frog body. These are designed to guide the<br />

wheel flanges past the frog point. The design eliminates need for<br />

separate guard rails in the track opposite the frog <strong>and</strong> is used in<br />

yards <strong>and</strong> other locations where speeds are moderate to slow.<br />

FROG NUMBERS AND ANGLES ARE AS FOLLOWS<br />

No. 4 Frog - Angle 14°15'00"<br />

No. 5 Frog - Angle 11°25'16"<br />

No. 6 Frog - Angle 9°31'38"<br />

No. 7 Frog - Angle 8°10'16"<br />

No. 8 Frog - Angle 7°09'10"<br />

No. 9 Frog - Angle 6°21'35"<br />

No. 10 Frog - Angle 5°43'29"<br />

No. 11 Frog - Angle 5°12'18"<br />

No. 12 Frog - Angle 4°46'19"<br />

No. 14 Frog - Angle 4°05'27"<br />

No. 16 Frog - Angle 3°34'47"<br />

No. 18 Frog - Angle 3°10'56"<br />

No. 20 Frog - Angle 2°51'51"<br />

The simple turnout frog is a device to enable the wheels<br />

running on one track to cross the rail of a diverging track. It<br />

provides continuous channels for the wheel flanges, <strong>and</strong><br />

supports the wheels over the intersection of the flangeways.<br />

Turnout frogs are divided into two principal classes: RIGID<br />

FROGS, which are without movable parts; <strong>and</strong> SPRING RAIL<br />

FROGS, in which one wing is movable.<br />

Information required when ordering frogs<br />

Refer to type of frog required.<br />

<strong>Rail</strong> <strong>Section</strong>: weight, arid section number.<br />

Drilling for joints: distance from end of rail to center of first hole.<br />

DistanCe center to center, first <strong>and</strong> second holes, <strong>and</strong> second <strong>and</strong><br />

third holes. Diameter of holes. Distance from bottom of rail to center of hole.<br />

Frog angle or number.<br />

Length over all. Also distance from theoretical point to heel as<br />

indicated in diagram on following page.<br />

45<br />

rOIDar<br />

----I

FROG. DETAILS<br />

(<br />

Preferred names of parts<br />

When a frog is needed to meet certain existing conditions or a st<strong>and</strong>ard<br />

size cannot be used. it is necessary that certain dimensions be furnished<br />

before construction can take place.<br />

Send rough sketch showing LENGTH. TOE LENGTH. HEEL LENGTH.<br />

TOE SPREAD AND HEEL SPREAD. GIVE DIMENSIONS TO GAUGE.<br />

LINES AND FROM ACTUAL POINT OF FROG<br />

IMPORTANT: The above applies toSTRAIGHT FROGS ONLY. If ONE or<br />

BOTH tracks are curved. we will furnish special instructions.<br />

(<br />

HOW TO ORDER FROGS<br />

Give the following information:<br />

1. Type of Frog - refer to catalog figure number when same applies.<br />

2. Frog number or angle--found by dividing the length overall (L)<br />

by the sum of the gage line spreads at the heel <strong>and</strong> toe (HS & TS).<br />

3. Detail of <strong>Rail</strong>-weight <strong>and</strong> section number in rail manufacturer's<br />

catalog (See Page 112).<br />

Diagram to show how Frog Number is obtained<br />

for Curved Frog<br />

For curv~d (rog submit dio~ram showina: direction of curvature <strong>and</strong> radiu<br />

or sun;cien~ d:ata to c1etumine the curvature <strong>and</strong> radius. (Le.) the heet Iprca<br />

(HSl. toe spread (TS). h«1 offset (HOI <strong>and</strong> toe offset (TOl.<br />

GAGE<br />

LINE<br />

The Frog Number is the ratio of the SPREAQ 10 Its<br />

DISTANCE from the theoretical pOint The spread<br />

must be at right angles to the centerline. as shown In<br />

the diagram.<br />

For example: spread in the diagram IS 1" in 4". a ratio<br />

of 14. designating a Number 4 Frog If the spread to<br />

distance is 2" in 8". or 3" in 12" etc. the 14 ratio still<br />

holds. designating a Number 4 frog<br />

If spread to distance is '" in 7". or 2" in '4". the Frog<br />

Number is 7. Similarly. spread to distance of 3" in {<br />

15" designates a Number 5 frog 2" In 12". a Number<br />

6 frog: 2" in goo. a Number 4 1 /;>" frog. etc<br />

rolDar_46-------'

__- '"0G~lM6Tll HEEL. LEMGTH<br />

C<br />

L27 L27 L23<br />

SECTION A-A<br />

SECTION c-e<br />

SECTION B-B<br />

ELEVATION OF POINT<br />

BOLTED RIGID FR OG<br />

'/<br />

Recommended for yard And other medium speed<br />

turnouts where heavy duty design!; are not reqwred.<br />

St<strong>and</strong>ard lengths~Hnd the quantity

__..rOlllar_49-- ---1<br />

<strong>Rail</strong>bound Manganese<br />

STEEL FROGS A.R.E.A. Plans 622-625<br />

<strong>Rail</strong> bound manganese steel frogs for heavy traffic<br />

ELEVATION OF WING WHEEL RISER<br />

FROG AREA FROG FROG AREA FROG<br />

NO. PLAN LENGTH NO, PLAN LENGTH<br />

6 622 11'Or 12 624 20'4"<br />

7 622 12'0" 14 624 237"<br />

8 622 13'0" 15 624 24'4%"<br />

9 623 16'0" 16 625 26'0"<br />

10 623 16'6" 18 625 29'3"<br />

11 623 18'8'/2" 20 625 3O'10\fz"

~ook Twin Tie Plates<br />

,<br />

Required For <strong>Rail</strong>bound Manganese<br />

Steel Frogs<br />

Hook tWin lie plates as listed below will be furnished with frogs are classified by width - Type 1, Type 2, Type 3 - as indicatec<br />

unless. otherwIse specified. Quantities shown are based on in table. Any type, style or arrangement of plates can b<br />

19 1 //' lie spacing, with center of one tie 4" back of 112" point. <strong>Rail</strong>s furnished when specified.<br />

Hook twin tie plates required for A.R.E.A. frogs -<br />

Plans 611 to 615 inclusive.<br />

Type 1 <strong>Rail</strong>s - <strong>Rail</strong>s having Type 2 Ralls - <strong>Rail</strong>s having Type 3 <strong>Rail</strong>s - <strong>Rail</strong>s having<br />

base up 10 SJ/ 1fi " <strong>and</strong> head 2 9 / 16 " inc!. base up 10 5%" <strong>and</strong> head 2 3 / 4 " incl. base up 10 6" <strong>and</strong> head 3" incl.<br />

Frog Mark No. Mark No. Mark No.<br />

No. l23 l27 LR23 lR27 lR3l L23 L27 LR23 LR27 LR3l L23 L27 LR23 LR27 LR31<br />

4 4 4 2 0 0 2 6 2 2 0 2 6 2 2 0<br />

5 6 4 4 0 0 4 6 4 2 0 4 6 4 2 0<br />

--<br />

6 10 2 2 2 0 4 8 2 2 2 4 10 2 2 2<br />

7 12 4 2 2 0 8 8 2 2 2 10 6 2 2 2<br />

8 12 4 2 2 0 8 10 2 4 2 8 10 2 4 2<br />

9 16 4 2 2 0 10 .10 2 4 2 10 10 2 4 2<br />

10 16 4 4 2 0 12 8 4 4 2 12 10 4 4 2<br />

11 18 6 4 2 0 14 10 4 2 2 12 14 4 2 4<br />

12 18 8 4 4 0 14 12 4 4 2 12 14 4 4 4<br />

,14 22 8 4 4 0 16 14 4 6 2 14 16 4 6 4<br />

15 24 8 4 4 0 16 18 4 6 2 16 18 4 6 4<br />

16 26 8 6 2 0 16 18 6 6 2 16 20 6 6 4<br />

18 26 12 6 4 0 18 22 6 8 2 18 22 6 8 4<br />

20 32 10 6 6 0 20 24 6 8 4 16 28 6 8 6<br />

Hook twin tie plates required for A.R.E.A. frogs -<br />

Plans 622 to 625 inclusive.<br />

Type 2 <strong>Rail</strong>s - <strong>Rail</strong>s having base up 10 Type 3 <strong>Rail</strong>s - Ralls having base up 10<br />

5%" <strong>and</strong> head 2W' inct 6" <strong>and</strong> head 3" Inc!.<br />

Frog No. Mark No. Mark No.<br />

.<br />

L23 . l27 L3l LR23 LR27 LR31 L23 L27 L3l LR23 LR27 LR3l<br />

6 4 8 2 2 2 2 4 8 2 2 2 2<br />

7 4 10 2 2 2 2 4 10 2 2 2 2<br />

8 6 10 2 2 4 2 6 10 2 2 4 2<br />

9 e 10 2 ~ 4 ~ tl lU ~ 2 4 2<br />

10 10 10 2 2 4 2 10 12 2 2 4 2<br />

11 10 12 2 4 2 2 10 14 2 4 2 4<br />

12 10 14 2 4 4 2 10 14 2 4 4 4<br />

14 10 18 2 4 6 2 10 18 2 4 6 4<br />

15 12 18 4 4 6 2 12 18 4 4 6 4<br />

16 12 20 2 6 6 2 12 22 2 6 6 4<br />

18 16 22 2 6 8 2 16 22 2 6 8 4<br />

20 16 28 2 4 8 4 16 28 2 4 8 6<br />

J•<br />

.lQ<br />

- ...... ==- rolfta~ 51

Solid Manganese<br />

Steel Self-guarded Frogs<br />

Solid manganese steel self-guarded frogs can be used to<br />

eliminate cost of guard rail installation <strong>and</strong> maintenance<br />

in yard tracks <strong>and</strong> at terminals where speeds are<br />

moderate, <strong>and</strong> traffic is heavy.<br />

Frog is designed to guide the wheel flanges past the frog<br />

point by means of raised guards which form easy contact<br />

with the outside rim of the wheels, deflecting them into<br />

proper alignment without shock.<br />

A.R.E.A. has adopted st<strong>and</strong>ard plans for solid manganese<br />

steel self-guarded frogs of Nos. 4 to 10, inclusive.<br />

Solid manganese steel self-guarded frog. heavy duty type,<br />

desgined to provide years of dependable service under the most<br />

rugged conditions.<br />

Hook twin tie plates as listed below will be furnished with frogs<br />

unless otherwise specified. Quantities shown are based on<br />

19%" tie spacing, with center of onetie 4" back of l/2" point. <strong>Rail</strong>s<br />

are classified by width - Type 1, Type 2, Type 3 - as indicated<br />

in fable.<br />

QUANTITY OF HOOK TWIN TIE-PLATES REQUIRED<br />

Type 1 <strong>Rail</strong>s - <strong>Rail</strong>s having base up to Type 2 <strong>Rail</strong>s - <strong>Rail</strong>s having base up to Type 3 <strong>Rail</strong>. - <strong>Rail</strong>a having b.ae up 10<br />

53/,." <strong>and</strong> head 2'/11" incl. 5%" <strong>and</strong> head 23j.' incl. 6" <strong>and</strong> head 3" Incl.<br />

Mark No. Mark No. Mark No.<br />

Frog L L H H H H LR LR LR Frog L L H H H H LR LR LR Frog L L H H H H LA LR LA<br />

No. 23 27 23 27 31 35 23 27 31 No. 23 27 23 27 31 35 23 27 31 No. 23 27 23 27 31 35 23 27 31<br />

4 2 4 4 2 0 0 0 0 0 4 2 4 4 2 0 0 0 0 0 4 2 2 4 2 0 2 0 0 0<br />

5 4 2 4 2 0 2 0 2 0 5 4 2 4 2 0 2 0 2 0 5 4 2 4 2 0 2 0 2 0<br />

6 4 2 4 2 0 2 0 2 0 6 4 2 4 2 0 2 0 2 2 6 4 2 4 2 2 2 0 2 2<br />

7 4 4 2 4 0 2 2 2 0 7 4 4 2 4 0 2 2 2 2 7 4 2 4 4 2 2 0 2 2<br />

8 6 2 2 4 2 0 2 4 0 8 6 4 4 4 2 0 0 4 2 8 4 4 4 4 2 2 0 4 2<br />

9 8 2 2 4 2 0 2 4 0 9 6 4 4 6 0 0 2 4 2 9 4 4 6 6 2 0 0 4 2<br />

10 8 2 4 6 0 0 4 4 0 10 6 4 6 6 2 0 2 4 2 10 6 4 6 6 2 0 2 4 2<br />

I<br />

(<br />

rolftarS2<br />

I

L..---·----TOTAL LENGTH -----+,<br />

7 -IJZ* fOR ·9 FROG<br />

." fOR ·10 FROG<br />

fn I<br />

~j.,,~!<br />

TYPICAL PLAN VIEW<br />

FROG LENGTHS<br />

WHEElIISfl<br />

GROUP A RAilS GROUP B RAILS GROUP C RAilS GROUP D RAILS RAilS 112 lBS OR HEAVIER<br />

FIIOG DIIE/ISIONS FROG<br />

/10. NO.<br />

R' I' I' I' TotJl Toe Heel V.r. TotJl Toe H"I V'I, 10111 Toe H"I V.r. lot.l Toe lltel V.r. TotJl Toe Heel V.r.<br />

lel\lfh laneth l'ncth Radius l'ncth l·ncth l.nJlh ladius l.nelh lenJlh lenJlh Radius l.ncth lenclh ltnctlt Radius l'nclh lenclh l.nelh Radius<br />

4 11" 0" 2" 4" 5'1" 15" 3'10" 23" 5'1" IS" 3'10" 23" 5'1" IS" 3'10" 23" 5'1" IS" 3'10" n" 5'11" 2'1" 3'10" 23" 4<br />

I<br />

5 13'/, 0" 2V," 5" 5;6" 18" 4'0" 3'2" 5'5" 17" 4'0" 3'2" 5'5" 17" 4'0" 3'2" 5'5" ]7" 4'0" 3'2" 6'5" 2'1' 4'4" 3'3" 5<br />

6 16'h 0" 3" 6" 6'0" 22" 4'2" 4'10" 5'11" 21" 4'2" 4'10" 5'10" 20" 4'2" 4'9" 5'10" 20" 4'2" 4'9" 7'4" 2'11" 4'5" 5'0' 6<br />

7 18" n; 3Y," 7" 6'10" 2'1" 4'g" 6'9" 6'7" 2'0" 4'7" 6'8" 6'3" 23" 4'4" 6'8" 6'2" 22" 4'4" 6'6" 8'1'," 2'11" 5'2:," 7'1)" )<br />

8 18" 4" 4" 8" no" 2'5" 5'5" S'll" 1'7" 2'4" 5'3" S'IO" 7'3" 2'3" 5'0" S'g" 6'11" 2'l" 4'10" 8'7" 8'11" 2'11" 60" S-->" 8<br />

9 20'/. 4'h" 4Y," 9" 8'10" 2'9" 6'1" 11'5" 8'5" 2'7" 5'10" 11'3" 8'1" 2'6" 5'7" 11'2" 7'g" 2'4" 5'5" 11'0" g'g" 2'11" 6'10" 11'6" 9<br />

10 22V, 5" 5" 10" 9'9" 3'0" 6'9" 14'2" 9'4" 2'10" 6'6" 14'0" 8'11" 2'9" 6'2" 13'11" 8'7" 2'7" 6'0" 13'S" 11'4'," 3'9" 7'7'';' 14'S" 10<br />

-....-.....Olllar_ 3<br />

----..I

Hook Twin Tie Plates<br />

Hook Twin Tie Plates are easily installed<br />

rolled steel tie plates that fit any tie position under any frog<br />

regardless of length. angle or-rail weight. They may be used<br />

under frogs, crossing, guard rails, switch lead rails <strong>and</strong> other<br />

special track work.<br />

'~__L-~<br />

•:':P;lBe.;.,<br />

. ". "".~<br />

A pair of hook twin tie plates provides greater bearing surface<br />

than a single ordinary plate. Warping is minimized, while their<br />

greater holding power, both against thrust <strong>and</strong> lifting, helps<br />

maintain alignment.<br />

L<br />

1---- d<br />

'UIICH '" oJ.: IOLATU OIlLY<br />

L<br />

I I:<br />

Lit<br />

r ~<br />

fu o<br />

'"UTES<br />

, :<br />

iU<br />

~~--------::~--+-h'--!=;J.<br />

J."<br />

4 SO.<br />

I fso.'"I<br />

_ I"j if- l-·~,<br />

!::~::"5:1 \'<br />

I : : , : , ; : I<br />

"L" plates are used with rolled rail sections.<br />

"H" plates are used with manganese steel castings.<br />

PLATE MARK 1<br />

LENGTH<br />

THICKNESS<br />

I PLATE MARK I LENGTH ITHICKNESS<br />

]<br />

L23 23" 9/,6"<br />

L27 'l.7" ~16<br />

L31 31 16<br />

H23 23 16<br />

H27 27 16<br />

H31 31 16<br />

H~:> 35 16<br />

Hook Twin Tie Plates are manufactured according to<br />

A.R.E.A. st<strong>and</strong>ards on automatic equipment. <strong>and</strong> guaranteed against<br />

bending or breaking when properly installed,<br />

o<br />

rolfta r_4<br />

I

TWIN TIE PLATES<br />

FLAT PLATES: A.R.E.A. 241-41<br />

____2'.0 1 /," --;1<br />

31 ,,--:l-<br />

14 I<br />

i 3/0"<br />

01-<br />

Flat twin tie plates <strong>and</strong> hook twin tie plates provide<br />

more bearing area <strong>and</strong> better support for frogs <strong>and</strong><br />

switches. They prolong tie life <strong>and</strong> reduce maintenance<br />

<strong>and</strong> inventory costs; eliminate the need for storing many<br />

special-use plates that require specific punchings to<br />

adapt them for different rail sections <strong>and</strong> tie spacings.<br />

Twin tie plates are used "as is" for turnout plates, frog<br />

plates, switch plates <strong>and</strong> guard rail plates with all rail<br />

sections on any tie spacing. Two plates fit side by side<br />

on each tie, <strong>and</strong> easily adapt to any position.<br />

; i<br />

TYPE 2<br />

+-_-+-+__2_'.6'_'-_-_-_-_-_~~I-~--iaL>;."<br />

_ '2"! ! _ I<br />

3/0' I/."<br />

I 'rO T 4 .. ,<br />

~** >;." I~<br />

TYPE 3<br />

,<br />

3/. "<br />

~ I<br />

I<br />

LlJ<br />

,.<br />

t<br />

MAIN<br />

GUARD RAIL CLAMP<br />

This design for securing guard rails meets A.R.E.A.<br />

specifications <strong>and</strong> will withst<strong>and</strong> heaviest traffic. Yoke<br />

<strong>and</strong> wedge are made of heat treated forged steel. Yoke<br />

can be installed without removing guard rail, <strong>and</strong> ad·<br />

justments are quickly <strong>and</strong> easily made. Available for rail<br />

from 60 lb•. to 140 lbs. inclusive.<br />

o<br />

o<br />

o<br />

o<br />

1GU,"" .:" m "An<br />

GUARD RAil FLARE<br />

IS DOUBLE·PLANED<br />

A.R.E.A. 504-55<br />

Fixed flangewny type guard rail ends are double-planed.<br />

flared <strong>and</strong> beveled. St<strong>and</strong>ard ('quipment includes two<br />

heavy-duty end blocks <strong>and</strong> single separator block for<br />

8'-3" length. Two separator blocks are supplied with<br />

11' <strong>and</strong> 13' lengths. Shoulder tie plates are supplied 7"<br />

wide (or rail under 1121b <strong>and</strong> 8" wide (or rail over 1121b.<br />

F~=_}_~~-_=:-:~-::--=-.·:.--:.~.=.~:":=~'nd~·"·''':U'':-''~:~C';''''-G:':'~:':u-::'::::~:~S~~- --- ~;~~=~r<br />

This guard rail hos bent flores<br />

<strong>and</strong> Includes the feature of the aree guard roil.<br />

............OIft8r_ 55 ----1

"Otr41It.1l.tK,-:<br />

IWITCII DETAILS<br />

Diagrams, with names applying to various switch parts.<br />

No particular type or design is represented.<br />

!<br />

d:1<br />

~t<br />

~<br />

-:!/rOC"<br />

A'"<br />

-.!'WI (.M<br />

I(,'D RAIL MAtl<br />

)01.'0 &A~ ~1I0{ PI. An<br />

"f L<br />

rOOl.I(,IO ..... 8llACl<br />

PLAN VIEW (FOR ILLUSTRATION ONLY) INDICATING VARIOUS PARTS OF SWITCH LAYOUTS.<br />

DRAWN FOR LEFT HAND TURNOUT.<br />

1---------·---IlEKOAC... &A.~<br />

~---'e-CUT----- ._ p""" .Nl ••U<br />

ELEVATION OF SWITCH POINT WITH UNIFORM RISERS<br />

------·---·.. -··f'l(...,OIlC_a~- ~<br />

-----·-rCll'tuT--· _0 ... =.~L.~... I<br />

ELEVATION OF SWITCH POINT WITH GRADUATED RISERS<br />

NOMENCLATURE FOR ORDERING SWITCH<br />

A "Switch Complete" consists of the two switch points with<br />

necessary clips, bolls, rods. plates <strong>and</strong> braces. Reinforcing bars,<br />

stops, heel block assemblies, etc., are also included if the type of<br />

switch requires them.<br />

"Switch Points" mean~ the rails only, except for specified<br />

reinforcing bars, clips, stops <strong>and</strong> foot guards if required.<br />

NOTE: A "Switch" is not a "Turnout" ... only part of a "Turnout"<br />

To branch from a track requires a ''Turnout'', composed in the<br />

main of a "Frog" <strong>and</strong> a "Switch Complete" plus guard rails if<br />

required.<br />

rolllar_56<br />

_

-o<br />

I<br />

I<br />

I<br />

I<br />

I<br />

• .. .. .. 0 N N .. N N ..<br />

if<br />

.... .... .... .... .:Ii .:Ii<br />

"N .... e" ew e" .. ;;; .. ;;;<br />

.. ."."<br />

"N<br />

."." ."." ."." ."." ... ." ." ... ...." ."...<br />

...<br />

"..<br />

"<br />

St<strong>and</strong>ard Bill of Material<br />

For Industrial Switch<br />

-ii--<br />

Switch Switch<br />

Length<br />

How to Order Straight Switch<br />

1. Specify area plan number or Industrial switch If possible<br />

2. Roll NT. section <strong>and</strong> drilling<br />

3. Switch Length<br />

Rods<br />

11 '·0" I 2<br />

--<br />

15'·0" 2<br />

16'·6" 2<br />

Guage<br />

Plate<br />

1 Ea.<br />

1 Ea.<br />

1 Ea.<br />

Comb. Slid.<br />

Plate.<br />

&Braces<br />

Plain<br />

Slide<br />

Plat••<br />

10 2<br />

12 2<br />

14 2<br />

.,<br />

Heel<br />

Hee' Turnout<br />

Block Plates Plates<br />

... -<br />

1 Pr. 4 B<br />

-,,' ..' =<br />

1 Pr. 4 12<br />

4. Non-Insulated or Insulated<br />

5. Non reinforced. single or double reinforced<br />

6. Track guage<br />

7. Right or left h<strong>and</strong> switch If turnout Is curved<br />

_._. ---<br />

1 Pr. 4 12<br />

SWITCH HEEL BLOCK ASSEMBLY<br />

A<br />

'\._4 :"110..____ ---- .,<br />

Heel blocks are installed at heel of switch point to<br />

maintain the stock rail <strong>and</strong> heel of switch point in<br />

perfect alignment horizontally <strong>and</strong> vertically under<br />

heavy traffic conditions. Can be furnished in cast steel<br />

or in cast iron.<br />

When ortl~ring heel blocks or assemblies separately, it<br />

is necessary to specify if switch points are level with<br />

stock rail at heel ofswitch, <strong>and</strong> ifused with graduated<br />

or uniform risers. Also advise heel spread, length of<br />

point <strong>and</strong> switch desi~ number, rail weight <strong>and</strong> section,<br />

diameter, elevation <strong>and</strong> spacing of holes (G-H-G)<br />

injointbar. Ifnot ordered in palrs, specify iffor rightor<br />

left h<strong>and</strong> point. Can be furnished as bolted type (illustrated)<br />

or floating type.<br />

~ ti-L::,~,r,~<br />

H +<br />

CROSS<br />

SECTION A·A<br />

SECTION 8·8<br />

JOINT eAR HOLE SPACING<br />

~"olDar_57<br />

___

Transit Clip<br />

"'-l.....J......L--..., ,<br />

.!'===--a.-:::-=:C:::: : ........r-.;~_..:<br />

_<br />

_<br />

Switch clips connect the switch rod to the switch point.<br />

Switch clips are of single piece, rugged, cast steel design.<br />

••<br />

•<br />

Adjustable Side Jaw Clip<br />

Single Side Jaw Clip<br />

OCTAJlMQ<br />

JIOt .2012 3012<br />

.u. (l'''.<br />

OLTAll HQ<br />

AOJ SfDt 2112 3112<br />

"•• I;L.'<br />

.MM"''''''<br />

Ill• 1'11('<br />

B 2'/>.+ 3"<br />

Hie ttl 'f .....<br />

0;- 10\'1"· IY.f,°<br />

0 I'V~<br />

....<br />

RAIL$ 110 ""•<br />

CLW·.Ol.T f'3); 1~4f<br />

OOO-..T 1;"1" If·II.'<br />

'.- I,. ....<br />

O':-----IiJ~r-----------~<br />

[....0____ 01 ~1.-.- o.;;.J1<br />

SPRING HEAD ROD, as illustrated, may be thrown as<br />

a rigid rod yet will allow the rolling stock to trail through<br />

the switch. When trailing through the switch should the<br />

l:b...o... ~ switch be set incorrectly, the wheel flanges force over<br />

C=========;;=;;~~==============;;:Z~~=====::ithe switch points by compressing the spring. After being<br />

For Transit Clips<br />

forced over, the points return to their original position.<br />

~IO,-- -.;;.o ..:o:...- .=.ol This rod can be used only where the track gauge is<br />

36" or more because of the space required for the<br />

spring <strong>and</strong> fittings. Made to suit any size rail. Rod may<br />

be used with transit clips as shown in photograph 0<br />

For Side Jaw Lllps<br />

with Side jaw clips.<br />

fJI..<br />

SPRING HEAD ROD<br />

Orders for switch rods should specify the style, the siz<br />

I :;~6~~~~.:..:~~n~'~~~'"":lI~d~!!.;;iI;;;;;;;;;;;;;;~' of rail with wh ich the rods are to be used, the gauge 0<br />

I~ --n_- I<br />

the track, the length of the switch <strong>and</strong> the throw of th<br />

switch.<br />

Illustrations show only the head rod as extended fo<br />

connection to the switch st<strong>and</strong>. The second, or ordina<br />

rod, is of the same construction but the ends are I'\~.<br />

extended. The application of these different rods·<br />

shown on the various illustrations of complete swite,'\

,-ditch plates. or slide plates. maintain the desired<br />

elevation of the switch rails. <strong>and</strong> provide a smooth sliding<br />

GAGE PLATES<br />

surface over which the rails move to right or left. Theyare<br />

of two types: plain. <strong>and</strong> with risers.<br />

Insulated<br />

gage plate<br />

..<br />

Gage plates are used directly ahead of or under the switch point as a means of holding the track to<br />

gage at the switch. gage plates are available either insulated or non-insulated,<br />

for use with adjustable or non-adjustable rail braces.<br />

Non-insulated<br />

gage plate<br />

COMBINATION SOUD RISER SUDE PLATE<br />

AND RIGID BRACE<br />

This plate is machined from solid steel <strong>and</strong> is specified<br />

with heavy-duty switches used with heavier rail sections.<br />

A shoulder provides a solid seat for the stock rail.<br />

TOP VIEW OF PLATE SHOWING<br />

NOTCHED AND RECESSED HOLES<br />

FOR INSERTION OF BOLT HEADS<br />

Plain<br />

"'9 . shape.<br />

O<br />

square<br />

ADJUSTABLE<br />

RAIL BRACE<br />

This improved Security Brace has been redesigned to<br />

provide for the insertion of the bolts from the top of the<br />

plate which facilitates easy installation. Both bolts <strong>and</strong><br />

8RACE APPLIED TO FORGED brace are readily removable which simplifies replacement<br />

SHOULDER PLATE of stock rails.<br />

Simplicity of design reduces installation <strong>and</strong> maintenance<br />

costs.<br />

Can be easily adjusted by loosening nuts, driving wedge<br />

to proper position <strong>and</strong> retightening nuts. No special tools<br />

required. The brace is designed without exterior ribs to<br />

permit the free wrenching of bolts using st<strong>and</strong>ard track<br />

wrench.<br />

....•<br />

A.R.E.A.<br />

{.C>.;; "x%.\ ...., ..~ .'Jf':"'~:.,~~.;.'~"J"' -'".<br />

of--------------·--1<br />

These plain switch plates are<br />

steel rolled <strong>and</strong> pressed to exact Shoulder slide plate-without riser.<br />

The switch point slides on<br />

the wide smooth riser surface<br />

while the stock rail abuts the<br />

riser shoulder. They are<br />

made with risers of various heights.<br />

If riser height is not speCified,<br />

•<br />

"'''~r:"<br />

i .:<br />

•<br />

'Iiii rom~~_:_~_g_h_t_w_il_l_b_e_fu_r_- S_h_O_u_ld_e_r_s_1_id_e_p_'_a_te-_-_W_._lt_h_r_is_e_f_._...I

SWITCH POINT<br />

WITH<br />

MANGANESE TIP<br />

(<br />

Switch points with manpneae tipe are dcaicned for<br />

uae on IWitchea which are wbjec:t to heavy tra5c<br />

conditions. The manpnae tip sreatly reduCeI the<br />

wear of the pointe <strong>and</strong> may be UIed OIl either or bOth<br />

.witch points.<br />

SWITCH POINT PROTECTOR: DESIGN 303<br />

Manganese steel, reversible switch point protectors<br />

are made for all sizes of rail from 60 lb. up. They are<br />

placed directly ahead of the switch point, completely<br />

absorb the impact of passing wheels <strong>and</strong> increase the<br />

service life of the switch point. It takes a "gang" to<br />

replace a costly switch point, but one man can replace<br />

this protector or reverse it--an added economy.<br />

Protectors are usually placed 2" ahead of the switch<br />

point, but this distance may be varied depending<br />

upon traffic conditions. When ordering, state size of<br />

rail with which protector will be used.<br />

o<br />

ttEAT-TREATED<br />

POINT GUARD RAIL<br />

SWITCH<br />

Design 755.B<br />

Bet hlehem's HeM-Trealed Switch-Point (;ual'd I{ail, Design 755-B.<br />

is it 4-ft-9-in.length of rail that performs guard duty at the swilt'h.<br />

It is lIsed with st<strong>and</strong>ard gage yarrl tr;ll'ks. This guard rail !

This point guard is unique in the Industry.<br />

The manganese bar Is not only replaceable,<br />

but adjustable also.<br />

Maintainability<br />

1. As wear occurs. adjustment cams can be reversed.<br />

effecting a total wear capacity of approxlmate.ly<br />

5/8", or nearly twice the normal service life.<br />

2. When the wear reaches maximum. the superstructure<br />

of the switch point guard remains In-track. Only<br />

the deflector assembly is replaced, resulting<br />

2. In substantial'materlal <strong>and</strong> labor cost reducttons.<br />

MODEL FM MANGANESE<br />

SWITCH POINT GUARD<br />

,',<br />

ItCTIOI'I ••<br />

~{~C~<br />

"'.. ......<br />

~~Ee· ~~IJ!f3=<br />

IlU\i6TIOII<br />

U-'aI<br />

]j" ~..<br />

'." .<br />

. -..e. "'." '.<br />

J _....- •..<br />

. ~"):.,<br />

Il,f~ ••<br />

JYUi.ll<br />

~~~ ".. ·~,rn···i<br />

, ,.', t<br />

I<br />

I<br />

,CCtlDlll ••<br />

RACOR MANGANESE STEEL<br />

SWITCH POINT GUARDS<br />

Racor Manganese Flange Switch Guards, illustrated on<br />

this page, are recommended for busy yard switches to<br />

protect the turnout point against weal' <strong>and</strong> thus to greatly<br />

increase its life in track. Fig. 3091 is designed for application<br />

on st<strong>and</strong>ard slide plates by omitting the rigid braces.<br />

Two bolts for attaching guard to stock rail And the short<br />

plate ahead of switch are furnished with this type. Fig.<br />

3092 is an adjustable type which is bolted to the stock rail<br />

<strong>and</strong> is securely held in place by wedges, cover plates <strong>and</strong><br />

bolts. It is designed for application on switch plates made<br />

to fit Racor Security Adjustable <strong>Rail</strong> Braces, Page 41.<br />

Three sets of wedges, cover plates <strong>and</strong> bolts <strong>and</strong> the plate<br />

ahead of switch point, as illustrated, are furnished with<br />

these guards. Additional switch plates will be furnished<br />

when desired. The guarding face can be reset when WOnt<br />

by slight grinding of the projections fitting the rail web<br />

<strong>and</strong> driving in the adjusting wedges.<br />

......._rolftar_61---------'

PARALLEL-THR<br />

FOR MEAYY RAILS<br />

New Century Model 51-A (Adjustable)<br />

COMPONENT PARTS FOR MODEL 51-A SWITCH STAND<br />

New Century Model 51-A is recommended for use with heavy<br />

rails, 70 lb per yd <strong>and</strong> over, at all points of heavy traffic on main<br />

lines. branch lines. or in the yards. It is furnished in two st.yles:<br />

with plug lamp tip, for 1I~ with switch lamp having day Larget.<br />

discs: <strong>and</strong> with socket lamp tip for use with a low t.arget.<br />

Construction. Model 51-A is a covered, low parallel-t.hrow<br />

switl'h st<strong>and</strong> of unusually heavy construction. It is of gear-type<br />

construction, as dist.inguished from the sliding-block design of<br />

other types of Bethlehem switch st.<strong>and</strong>s. It C:lIl he made posit.ive<br />

by the use of two Model 46:> latches.<br />

SPINDLE~<br />

No. 63 ~<br />

••<br />

. - Q .<br />

·.W! .<br />

~•••• f,<br />

COVER<br />

No. 39<br />

THROWING L.EVER REST<br />

No. 463<br />

ADJUSTABLE<br />

GEAR SEGMENT<br />

No. 49<br />

DOUBLE CRANK<br />

MALLEABLE<br />

No. 69<br />

DOUBLE CRANK<br />

FORGED STEEL<br />

No. 1216<br />

SINGLE CRANK<br />

FORGED STEEL No. 67<br />

RING<br />

No. 1611<br />

CROSS PIN<br />

No. 2228<br />

ADJUSTMENT BOLT<br />

No. 54<br />

(<br />

ADJUSTMENT SHi.. ··<br />

No. 1824<br />

••••••1rolDar_6 2<br />

_<br />

P_' .._os_e_o_,cI_er_o_"_p_or_ts_b_Y_"_Om_e_o_"_cl_"U_m_b_"'_'<br />

..J

No.<br />

Reqd.<br />

1<br />

1<br />

1<br />

1<br />

Parts<br />

Part<br />

No.<br />

2200<br />

220106.<br />

2202<br />

2203<br />

DESCRIPTION<br />

Spring<br />

Spindle<br />

Crank Eye<br />

Connecting Rod Forging Per Detail<br />

Hex Jam Nut for Connecting Rod<br />

Bolt for Switch Connection with Hex Nut <strong>and</strong> Cotter<br />

Bolt for Switch St<strong>and</strong> Connection wilh Hex Nut <strong>and</strong> Cotte<br />

Clevis<br />

Lamp Tip<br />

Bolts for Lamp Tip with Lock Nuts <strong>and</strong> Washers<br />

H<strong>and</strong> Lever Bolts, Square Nuts <strong>and</strong> Lock Washers<br />

Thrust Ball<br />

Base<br />

Cover<br />

4<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

3<br />

3<br />

1<br />

2<br />

5<br />

2213<br />

22148<br />

2215B<br />

221606.<br />

2217B<br />

2218A<br />

2220A<br />

2221<br />

2222<br />

2223/\<br />

2224<br />

2226<br />

2228B<br />

223006.<br />

2231<br />

VIEW OF<br />

WORKING PARTS<br />

WITH TOP COVER<br />

REMOVED<br />

Racor Heavy Duty Automatic<br />

safety Adjustable switch st<strong>and</strong><br />

An extra heavy duty Switch St<strong>and</strong>. with adj11.~table throw lamp rotates, so that the position of the points is indicated<br />

for yard, ladder <strong>and</strong> busy switrh turnouls, When run nd the. h<strong>and</strong> lever remains stationary. Lever n~sts are ca.st<br />

through, the switch points are partly opened hy the wheel mtegrally with base ca!':ting.<br />

flanges <strong>and</strong> throw to opposite position is automatically com- Separate Padlock Pedestals will be furnished whe'l spedpleted<br />

by st<strong>and</strong>. During automatic operation the target fied, for application over the integral lever rests, if pad·<br />

locking of h<strong>and</strong> lever is necessary.<br />

(<br />

~ 1 2204<br />

1 2205<br />

1 2206<br />

1 220806.<br />

2<br />

2 2209B<br />

1 2210<br />

1 2211A<br />

1 22126<br />

Housing Bolts, Hex Nut <strong>and</strong> lock<br />

Spring Base<br />

Washers<br />

H<strong>and</strong> Lever<br />

Thrust Bushing<br />

Spring Cap<br />

Spring Adjuster<br />

Rear Link<br />

Intermediate Unk<br />

Pivot Link<br />

Slide Block<br />

Link Pins<br />

Holding Pins<br />

Bolt for Linkage<br />

Padlock Pedestals<br />

Oil Cups<br />

..... .... .... ....<br />

220lA<br />

., ,<br />

\<br />

2217B<br />

...<br />

... 2211A<br />

rGlftar 63 _______________--J

TRACKWORK ACCESSORIES<br />

OIL SWITCH LAMP: DESIGN 12T<br />

<strong>Rail</strong>road st<strong>and</strong>ard with day targets feature nonsweating,<br />

balanced draft ventilation. Wind-proof<br />

lamp body is permanently sealed against drafts.<br />

Hinged <strong>and</strong> hasp fastened at the top to easily open<br />

heavy steel body <strong>and</strong> square vent cone for servicing<br />

burner <strong>and</strong> oil fount. All parts<br />

are heavy terne metal coated<br />

after assembly to protect against<br />

rust <strong>and</strong> to seal joints <strong>and</strong><br />

seams.<br />

Normally equipped with 31<br />

ounce oil fount. Lenses are available<br />

in 4", 4%", 4 1 h", 5" <strong>and</strong><br />

5:lfM" diameters, can also be supplieci<br />

without day tar~ds.<br />

ELECTRIC SWITCH LAMP: DESIGN 13W<br />

Spherical lamp body is drawn from heavy stainless<br />

steel to assure strength <strong>and</strong> to resist damage <strong>and</strong> corrosion.<br />

Compact lamp is just 10"-high, has weathertight,<br />

hinged cap for ensy access to check orreplace<br />

electric bulb. Base is fabricated<br />

from ductile iron <strong>and</strong> springmounted<br />

to absorb shock <strong>and</strong><br />

protect bulb filaments. Available<br />

to operate on commercial current<br />

or batteries.<br />

REFlECTORIZED SWITCH TARGETS<br />

Type 14- CH<br />

Reflectorized Switch Targets-Modulnr design, choice<br />

of colors. High intensity reflector made of highstrength<br />

Lexan. A unique mounting arrangement discourages<br />

theft. The reflectors are impregnated with a<br />

release agent which makes them self cleaning. Low<br />

cost-no maintenance. Fits A.R.E.A. St<strong>and</strong>ard Lamp<br />

Staff. When ordering, specify color <strong>and</strong> whether<br />

single, double or triple unit is desired.<br />

These targets can also be electrified.<br />

"Olfta~_65<br />

_

SWITCH TIES<br />

Switch ties or turnout ties conforming to A.R.E.A. specifications<br />

can be furnished in the various lengths as shown in the adjoining<br />

chart for the specific frog number or angles, where heavy<br />

duty track is needed. These switch ties are pressure creosoted<br />

with ends usually S-ironed <strong>and</strong> in either 6" x 8" or 7" x 9"<br />

section. Ties are also available in sets with slightly wider spacing<br />

between ties which is usually sufficient for secondary <strong>and</strong><br />

industrial trackage,<br />

n n<br />

lli<br />

[I 11 1'1\<br />

Typical Switch Timber Schedule for Turnouts-Industrial Application<br />

Bill OF SWITCH TIES FOR TURNOUTS WITH STRAIGHT SWITCHES<br />

I<br />

U<br />

n n nr:;1'1n~n n<br />

n l-<br />

I<br />

'-<br />

II1I<br />

!l IT<br />

Uuu U'<br />

5 I 11 '0" 3'6Y," 42'6Y,"<br />

6 i 11'0" 3'9" 47'6"<br />

7 16'6" 4'8Y," 62'1"<br />

8 16'6" 5'1" 68'0"<br />

9 16'6" 6'41'1" 72'3\'/"<br />

10 16'6" 6'5" 78'9"<br />

11 22'0" 7'0" I 91'10V'"<br />

12 22'0" 7'9"",,1 96'8"<br />

14 22'0" 8'7Y," 107'0¥0 "<br />

15 30'0" 9'5" 126'4"""<br />

16 30'0" 9'5" 131'4"<br />

18 30'0" 11'0\'/" 1

STEEL MINE TIES<br />

from <strong>Romar</strong><br />

Setting new st<strong>and</strong>ards<br />

in mine rail haulage<br />

reliability <strong>and</strong><br />

durability<br />

STEEL MINE TIES<br />

• Feature special riveted rail clips for No.4 <strong>and</strong> No.5<br />

mine ties.<br />

• Lightweight. Easy to h<strong>and</strong>le.<br />

• Easy installation. Easy to relocate.<br />

• Assure constant track gauge.<br />

• For 30-lb to 85-lb rails.<br />

• Made to fit any track gauge.<br />

• Now offers the upset end TUF-TIE for use in tunneling.<br />

IRONCLAD TIES<br />

• Retain the stability <strong>and</strong> rigidity of spiked wooden ties.<br />

• Install as fast as steel ties.<br />

• Establish perfect gauge.<br />

• Pick up <strong>and</strong> relay qUickly.<br />

• Lend themselves to the most punishing main line<br />

haulage needs.<br />

• Have outst<strong>and</strong>ing longevity when used with pressuretreated<br />

oak ties.<br />

• Do not require constant inspection <strong>and</strong> maintenance.<br />

• Require no spikes to work loose <strong>and</strong> cause gauge<br />

spread.<br />

• Available in 3" x 5" X 54", 3" x 8" X 60", <strong>and</strong><br />

3" x 8" x 72" grooved <strong>and</strong> treated or untreated base.<br />

........rGlllar_67 ---------'