Workholding - Machinery Canada

Workholding - Machinery Canada

Workholding - Machinery Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

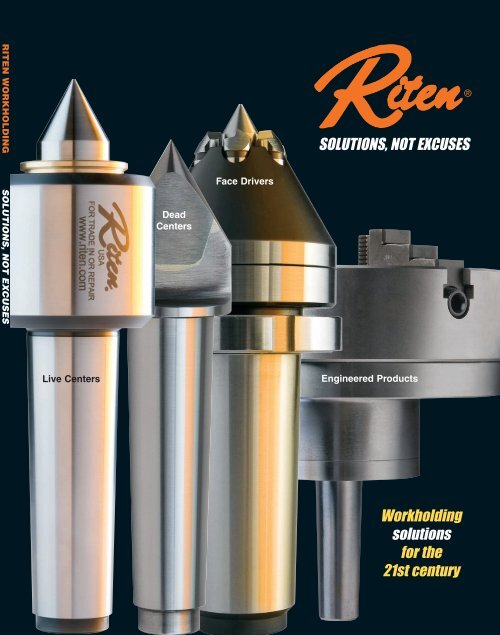

RITEN WORKHOLDING SOLUTIONS, NOT EXCUSES<br />

Dead<br />

Centers<br />

Face Drivers<br />

SOLUTIONS, NOT EXCUSES<br />

®<br />

Live Centers<br />

Engineered Products<br />

<strong>Workholding</strong><br />

solutions<br />

for the<br />

21st century

®<br />

Quality workholding<br />

since 1933<br />

This catalog contains the world’s<br />

largest selection of Live & Dead<br />

Centers and Face Drivers.<br />

<strong>Workholding</strong> is Riten’s only business,<br />

and no other company can match<br />

our experience, craftsmanship, and<br />

engineering skill.<br />

All products are American-made in<br />

Riten’s 35,000 sq. ft. facility in central<br />

Ohio. On-time delivery is assured<br />

through our worldwide network of<br />

stocking distributors and representatives.<br />

Our quality system is certified<br />

annually to meet the demanding<br />

requirements of ISO-9001:2008.<br />

Live & Dead Center Selection Guide<br />

The selection guide below gives you an overview of centers<br />

available by basic application. Check individual models to<br />

determine accuracies, point types, tapers, workpiece weights,<br />

dimensions, and any special features.<br />

CNC Lathe<br />

High RPM live and dead centers for precision<br />

turning applications. Pages 4-9.<br />

Turning and Grinding<br />

Live centers for maximum workpiece weights<br />

ranging from 1,000 to 450,000 lbs. Pages 10-14.<br />

Precision Grinding<br />

High accuracy live centers and a broad<br />

selection of dead centers. Pages 15-20.<br />

If you don’t see the exact center or<br />

driver needed for your unique application,<br />

Riten will make it for you –<br />

special products are a major part of<br />

our business. For specifics, see page<br />

31, visit www.riten.com, or call our<br />

technical service people at<br />

1-800-338-0027.<br />

Large Bore<br />

Live and dead centers for large bore parts,<br />

including pipe, tubing, rolls, hydraulic cylinders,<br />

and similar workpieces. Pages 19-24.<br />

Special Purpose<br />

Live centers designed for unique applications:<br />

spline rolling, medical and lightweight<br />

components, and workpieces requiring linear<br />

compensation in the live center. Pages 25-29.<br />

1<br />

Call 1-800-338-0027

®<br />

Contents<br />

Live and Dead Centers<br />

n Engineered for Accuracy and Durability ...................3<br />

n C4T Live Centers......................................................4<br />

n CNC High RPM Sprint Live Centers, Steel ..............5<br />

n Advantage Carbide Point Live Centers ...................6<br />

n CNC Heavy-Duty Live Centers.................................7<br />

n CNC Dead Centers...................................................8<br />

n Quick Point Sets, Live Centers and Points ...............9<br />

n Advantage Live Centers .........................................10<br />

n Regal Live Centers .................................................11<br />

n Econo-Tri-Bearing Live Centers..............................12<br />

n Heavy-Duty & Extra Heavy-Duty Live Centers .......13<br />

n Super Duty Live Centers ........................................14<br />

n Std. & Med.-Duty Super Accurate Live Centers .....15<br />

n Imperial Large Carbide Point Dead Centers ..........16<br />

n Standard Length & Long Series Dead Centers ..17, 18<br />

n Pipe Nose & Bull Nose Dead Centers....................19<br />

n Fast Trak Special Dead Centers ............................20<br />

n Bull Nose Live Centers ...........................................21<br />

n Precision Bull Nose Live Centers ...........................22<br />

n Std. & Heavy Duty Pipe Nose Live Centers ...........23<br />

n Multi-Use Live Centers ...........................................24<br />

n Concentric Spring Loaded Live Centers ..........25, 26<br />

n Light & Extra-Light Live Centers.............................27<br />

n Self-Adjusting Spring Loaded Live Centers............28<br />

n Spline Rolling Live Centers ....................................29<br />

n Repair/Trade-In & Center Survey Programs...........30<br />

n Specials ............................................................31, 32<br />

Mill Taper standard and special dead centers<br />

available. Visit www.riten.com or see page 32.<br />

Engineered <strong>Workholding</strong> Products<br />

n Live Chuck Mandrels, Linear Comp. Centers ........33<br />

n Replaceable Bell Head Centers .............................34<br />

n Pipe Drivers, Spider Mandrels................................35<br />

n Bull Ring Mandrel, Boring Mill Adapter...................36<br />

n Rebuilding and Repair Services .............................37<br />

n Field Services .........................................................38<br />

Face Drivers<br />

n Introduction to Face Driving....................................39<br />

n Improving quality, increasing productivity ...............40<br />

n Face Driver Selection and Sizing ...........................41<br />

n Installation and Setup .............................................42<br />

n Information Request Form......................................43<br />

n Mechanical, Type 40 ...............................................44<br />

n Mechanical, Type 41 ...............................................45<br />

n Mechanical, Type 42 ...............................................46<br />

n Mechanical, Type 43 ...............................................47<br />

n Mechanical, Type 44 ...............................................48<br />

n Mechanical, Type 45 ...............................................49<br />

n Mechanical, Type 46 ...............................................50<br />

n Mechanical, Type 47 ...............................................51<br />

n Mechanical, Type 48 ...............................................52<br />

n Mechanical, Type 49 ...............................................53<br />

n Mechanical, Type 50 ...............................................54<br />

n Actuated Driver, Quick Change Spindle Adapter ...55<br />

n Hydraulic, Type 62 ..................................................56<br />

n Hydraulic, Types 63 and 64 ....................................57<br />

n Hydraulic, Types 66 and 68 ....................................58<br />

n Face Driver Dimensions ....................................59,60<br />

n Running Off the Driver............................................61<br />

n Calculation of Tailstock Forces ...............................62<br />

n Face Driver Care and Maintenance...................63,64<br />

Collets and Collet Chucks........................................65<br />

Web Site Details ........................................................66<br />

www.riten.com<br />

2

®<br />

Engineered for<br />

accuracy and<br />

durability<br />

Precision Design = Life = Value<br />

Unlike other manufacturers, Riten Industries concentrates solely on the science of rotational<br />

workholding. We are committed to serving our customers with the ultimate in centering technology,<br />

and direct all our energies to being the best there is. That’s why our motto is<br />

“Solutions, not excuses”.<br />

With workpiece capabilities from 4 ounces to more than 400,000 pounds, an industry-leading<br />

.00008 TIR, and the world’s largest selection of standard and custom models, Riten offers<br />

the widest range of workholding options to satisfy today’s global manufacturing requirements.<br />

The Riten threaded seal<br />

adapter/retainer allows easy<br />

bearing access and is lapped<br />

to be parallel to the bearing<br />

face. This guarantees that the<br />

seal adapter makes complete<br />

contact with the face of the<br />

bearing for consistent<br />

accuracy and rigidity.<br />

Perpendicularity is paramount in the<br />

manufacture of a precision live center.<br />

With the latest in CNC grinding technology,<br />

each bearing shoulder is held to<br />

within ± .0001 TIR perpendicular to the<br />

centerline of the taper shank, conforming<br />

to strict international DIN standards.<br />

This precision is crucial for obtaining<br />

maximum rigidity and service life.<br />

Riten’s gageline cross<br />

section, together with our<br />

robust spindle construction,<br />

is designed to produce exceptional<br />

resistance to deflection.<br />

Some manufacturers claim<br />

that their stubbed spindle<br />

design is superior. The truth<br />

is it’s simply less expensive to<br />

manufacture. The Riten full<br />

length spindle design is<br />

supported by multiple bearings<br />

which spread the load<br />

over the full length of the<br />

taper. Riten bearing bores are<br />

ground concentric and coaxial<br />

to the taper in one operation<br />

to ± .0001 TIR. This combination<br />

assures maximum bearing<br />

life and accuracy. Through<br />

precisely calculated fulcrum<br />

positioning, the full length<br />

spindle maintains maximum<br />

rigidity, dampens vibration,<br />

and will flex rather than break<br />

when subject to severe<br />

moment loads. This unique<br />

design is especially important<br />

when supporting heavier<br />

workpieces.<br />

3<br />

Call 1-800-338-0027

®<br />

C4T* Live Centers<br />

Standard, Tracer and Long Point<br />

The first and only live center with<br />

permanent bearing protection<br />

n Accuracy guaranteed to ± .00004<br />

n Ideal for applications which use high-pressure coolant<br />

n Inpro/Seal bronze non-contacting bearing isolator seal<br />

turns freely, runs cooler, and will never wear out<br />

n Point configuration allows for tool clearance<br />

n Riten full service and repair<br />

Contaminants are<br />

captured in the<br />

outer labyrinth path<br />

and expelled<br />

through a port.<br />

Inner section of<br />

labyrinth seals in<br />

bearing lubricant.<br />

* Center for Tomorrow<br />

A<br />

C<br />

STANDARD POINT – MORSE TAPER<br />

Max. W. P.<br />

Model MT A B C D E RPM Weight<br />

53604 4 13/8 113/16 31/16 225/32 3/8 5000 2200<br />

Standard Point<br />

E<br />

D<br />

.25<br />

B<br />

53605 5 13/8 113/16 31/16 225/32 3/8 5000 5000<br />

V2<br />

A<br />

C<br />

TRACER POINT – MORSE TAPER<br />

Max. W. P.<br />

Model MT A B C D E V2 RPM Weight<br />

53904 4 9/16 21/4 31/16 225/32 3/8 40° 5000 1700<br />

Tracer Point<br />

E<br />

D<br />

.25<br />

B<br />

53905 5 9/16 21/4 31/16 225/32 3/8 40° 5000 1700<br />

I<br />

V2<br />

A<br />

C<br />

LONG POINT – MORSE TAPER<br />

Max. W. P.<br />

Model MT A B C D E G V2 I RPM Weight<br />

Long Point<br />

E<br />

D<br />

.25<br />

B<br />

G<br />

53104 4 1/2 25/8 31/16 225/32 3/8 3/4 40° 131/32 5000 1100<br />

53105 5 1/2 25/8 31/16 225/32 3/8 3/4 40° 131/32 5000 1100<br />

4<br />

www.riten.com

®<br />

CNC High RPM Sprint<br />

Live Centers<br />

Standard, Tracer and Long Point<br />

n Accuracy guaranteed to ± .00004<br />

n<br />

n<br />

n<br />

n<br />

n<br />

The largest, toughest bearing set available in<br />

centers of this size<br />

Coolant deflectors for additional protection<br />

from contamination<br />

Points through-hardened to 61-63 Rc<br />

Body heat-treated for additional strength<br />

Riten full service and repair<br />

Redesigned for 21st century machining.<br />

Engineered to allow deeper cuts, better surface finish,<br />

and extended service life!<br />

Standard Point<br />

Coolant Deflector<br />

A<br />

C<br />

STANDARD POINT – MORSE TAPER<br />

Max. W. P.<br />

Model MT A B C D E RPM Weight<br />

14604 4 13/8 113/16 31/16 225/32 3/8 5000 2200<br />

14605 5 19/16 23/8 31/16 225/32 3/8 5000 5000<br />

E<br />

D<br />

B<br />

Coolant Deflector<br />

TRACER POINT – MORSE TAPER<br />

V2<br />

A C<br />

Max. W. P.<br />

Model MT A B C D E V2 RPM Weight<br />

Tracer Point<br />

14904 4 9/16 21/4 31/16 225/32 3/8 40° 5000 1700<br />

14905 5 9/16 21/4 31/16 225/32 3/8 40° 5000 1700<br />

E<br />

D<br />

B<br />

Coolant Deflector<br />

I<br />

LONG POINT – MORSE TAPER<br />

V2<br />

A C<br />

Max. W. P.<br />

Model MT A B C D E G V2 I RPM Weight<br />

14104 4 1/2 25/8 31/16 225/32 3/8 3/4 40° 131/32 5000 1100<br />

Long Point<br />

14105 5 1/2 25/8 31/16 225/32 3/8 3/4 40° 131/32 5000 1100<br />

G<br />

5<br />

E<br />

D<br />

B<br />

Call 1-800-338-0027

A<br />

®<br />

Advantage<br />

Carbide Tipped Live Centers<br />

Standard and Tracer Point<br />

n Accuracy guaranteed to ± .00005<br />

n Four bearing design for superior performance<br />

n Points are through-hardened to 61-63 Rc<br />

n Full-length spindle for extra rigidity<br />

n Less tailstock pressure required<br />

n Body heat-treated for additional strength<br />

n Riten full service and repair<br />

Standard Point<br />

T<br />

STANDARD POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E T* RPM Weight<br />

51692 2 7/8 11/8 13/4 23/8 3/8 1/2 5000 880<br />

51693 3 7/8 11/8 13/4 23/8 3/8 1/2 5000 920<br />

51694 4 11/4 2 27/8 35/16 3/8 7/8 5500 2200<br />

51695 5 11/4 2 27/8 35/16 3/8 7/8 5500 4400<br />

* Carbide tip diameter<br />

TRACER POINT MORSE – MORSE TAPER TAPER<br />

V2<br />

T<br />

C<br />

Max. W. P.<br />

Model MT A B C D E T* V2 RPM Weight<br />

51992 2 1/2 13/4 13/4 23/8 3/8 3/8 30˚ 5000 750<br />

51993 3 1/2 13/4 13/4 23/8 3/8 3/8 30˚ 5000 750<br />

51994 4 5/8 21/16 27/8 35/16 3/8 1/2 30˚ 5500 1700<br />

E<br />

D<br />

B<br />

51995 5 5/8 21/16 27/8 35/16 3/8 1/2 30˚ 5500 1700<br />

Tracer Point<br />

* Carbide tip diameter<br />

6<br />

www.riten.com

A<br />

®<br />

CNC Heavy Duty<br />

Live Centers<br />

Standard and Tracer Point<br />

n Accuracy guaranteed to ± .00005<br />

n May be used in conjunction with Face Drivers<br />

n Large workpieces in CNC applications<br />

n Coolant deflectors for additional protection<br />

from contamination<br />

n Riten full service and repair<br />

These CNC live centers are used to counter the<br />

high thrust in face driving applications. These<br />

centers are also used where workpieces weigh up<br />

to several thousand pounds. Radial pressure, thrust<br />

and rigidity requirements demand centers with a<br />

four-bearing design to handle these loads.<br />

E<br />

Coolant Deflector<br />

D<br />

Standard Point<br />

B<br />

A<br />

C<br />

STANDARD POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E RPM Weight<br />

15103* 3 11/8 11/2 213/16 33/16 1/2 5000 3000<br />

15164* 4 121/32 13/4 33/4 327/32 1/2 4000 4800<br />

15165 5 17/8 21/4 33/4 327/32 1/2 4000 8000<br />

15105 5 2 21/4 45/8 327/32 1/2 4000 14000<br />

15106 6 2 21/4 45/8 327/32 1/2 4000 14000<br />

* Stub spindle design on 3MT and 4MT.<br />

E<br />

Coolant Deflector<br />

D<br />

V2<br />

B<br />

C<br />

TRACER POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E V2 RPM Weight<br />

16103* 3 1/2 21/16 213/16 33/16 1/2 30˚ 5000 1100<br />

16194* 4 5/8 217/32 33/4 327/32 1/2 30˚ 4500 1800<br />

16195 5 5/8 225/32 33/4 327/32 1/2 30˚ 4000 2500<br />

16105 5 15/16 39/32 45/8 327/32 1/2 30˚ 4000 3750<br />

16106 6 15/16 39/32 45/8 327/32 1/2 30˚ 4000 3750<br />

* Stub spindle design on 3MT and 4MT.<br />

Tracer Point<br />

7<br />

Call 1-800-338-0027

®<br />

Type 1<br />

CNC Dead Centers<br />

Steel and Carbide Tipped<br />

Type 2<br />

n Accuracy guaranteed to ± .00005<br />

n Through-hardened to 61-63 Rc<br />

n Works on all CNC machines<br />

n Meets the rigid requirements of CNC turning<br />

n All stock items<br />

n Riten full service and repair<br />

Type 3<br />

Type 4<br />

A<br />

A<br />

Steel, Type 1<br />

N<br />

STEEL, TYPE 1, MORSE TAPER<br />

Model MT A N K Threads Nut<br />

68102 2 3/8 11/4 111/16 7/8 -14 81031<br />

68113 3 3/8 11/4 111/16 7/8 -14 81031<br />

68103 3 1/2 2 27/16 7/8 -14 81031<br />

68123 3 3/4 2 27/16 7/8 -14 81031<br />

68114 4 1/2 2 25/8 11/8 -12 81041<br />

68104 4 5/8 21/4 27/8 11/8 -12 81041<br />

68124 4 1 21/4 27/8 11/8 -12 81041<br />

68184* 4 5/8 21/4 35/16 11/8 -12 81091<br />

68115 5 1/2 2 215/16 15/8 -12 81051<br />

68105 5 7/8 21/2 37/16 15/8 -12 81051<br />

68125 5 11/4 21/2 37/16 15/8 -12 81051<br />

68185* 5 7/8 21/2 45/16 15/8 -12 81051<br />

68106 6 13/4 311/16 55/16 21/2 -12 86061<br />

* Special taper for Mazak machines<br />

Carbide, Type 3<br />

A<br />

T<br />

V2<br />

N<br />

K<br />

CARBIDE TIPPED, TYPE 3, MORSE TAPER<br />

Model MT T A N K V2 Threads Nut<br />

68923 3 3/8 1/2 2 25/8 20˚ 11/8 - 12 81041<br />

68924 4 1/2 5/8 29/32 33/32 20˚ 13/8 - 12 86041<br />

68925 5 1/2 5/8 21/2 37/16 20˚ 15/8 - 12 81051<br />

K<br />

Steel, Type 2<br />

STEEL, TYPE 2, MORSE TAPER<br />

Model MT A N K Threads Nut<br />

68603 3 1 15/8 23/8 11/8 - 12 81041<br />

68604 4 11/4 21/32 215/16 13/8 - 12 86041<br />

68684* 4 11/4 21/16 37/32 13/8 - 12 86041<br />

68605 5 13/4 215/32 35/8 17/8 - 12 86051<br />

68685* 5 13/4 27/16 41/4 17/8 - 12 86051<br />

68606 6 21/4 311/16 55/16 21/2 -12 86061<br />

* Special taper for Mazak machines<br />

Carbide, Type 4<br />

N<br />

K<br />

A<br />

T<br />

N<br />

K<br />

CARBIDE TIPPED, TYPE 4, MORSE TAPER<br />

Model MT T A N K Threads Nut<br />

68913 3 3/4 1 15/8 23/8 11/8 - 12 81041<br />

68914 4 1 11/4 2 229/32 13/8 - 12 86041<br />

68915 5 11/4 13/4 21/2 321/32 17/8 - 12 86051<br />

www.riten.com<br />

8

®<br />

Quick Point Live Centers,<br />

Sets and Replacement Points<br />

n Accuracy guaranteed to ± .00025.<br />

n Interchangeable points reduce the need for several centers.<br />

n Purchase individual replacement points or a complete set.<br />

n Special points are available upon request.<br />

n Mounting taper of points is 1:10.<br />

n Safe storage container provided when you<br />

purchase a complete set.<br />

n Point extractor for easy removal of points is included<br />

in the set or can be purchased separately.<br />

A<br />

A Quick Point Set includes: one live center, one male point,<br />

one female point, one tracer point, one bull nose point, and<br />

one point extractor.<br />

QUICK POINT SETS<br />

Model Taper<br />

49502 2<br />

POINT EXTRACTORS<br />

49503 3 Model Taper<br />

49504 4 49904 2, 3, 4<br />

49505 5 49905 5<br />

B<br />

C<br />

K<br />

M - Male Point<br />

C<br />

B<br />

K<br />

T - Tracer Point<br />

A<br />

A<br />

E<br />

B<br />

B<br />

C<br />

D<br />

C<br />

BN - Bull Nose Point<br />

F<br />

K<br />

F - Female Point<br />

K<br />

B<br />

G<br />

F<br />

C<br />

A<br />

A<br />

LIVE MORSE CENTER* TAPER<br />

Max. W. P.<br />

Model MT A B C D E RPM Weight<br />

49102 2 1 1/4 21/8 2 3/8 5000 100<br />

49103 3 1 1/4 21/8 2 3/8 5000 350<br />

49104 4 11/4 1/4 27/8 35/16 3/8 5500 550<br />

49105 5 19/16 1/4 31/16 225/32 3/8 5500 1400<br />

*Live Center includes male point unless otherwise specified.<br />

QUICK POINTS<br />

Model MT Style A F G K C B<br />

91031 2/3 M 1 – – 13/16 .474 61/64<br />

91032 2/3 F 11/8 1/2 7/8 13/32 .474 61/64<br />

91033 2/3 T 3/8 – – 15/16 .474 61/64<br />

91034 2/3 BN 13/4 7/8 – 13/16 .474 61/64<br />

91041 4 M 11/8 – – 15/16 .591 13/16<br />

91042 4 F 13/8 5/8 11/8 17/32 .591 13/16<br />

91043 4 T 1/2 – – 113/16 .591 13/16<br />

91044 4 BN 21/4 1 – 19/16 .591 13/16<br />

91051 5 M 11/2 – – 111/16 .867 125/64<br />

91052 5 F 11/2 3/4 11/4 11/4 .867 125/64<br />

91053 5 T 1/2 – – 2 .867 125/64<br />

91054 5 BN 23/4 11/2 – 15/8 .867 125/64<br />

9<br />

Call 1-800-338-0027

A<br />

®<br />

Advantage Live Centers<br />

Standard, Tracer and Long Point<br />

n Accuracy guaranteed to ± .00005<br />

n Four bearing design for superior performance<br />

n Points are through-hardened to 61-63 Rc<br />

n Full-length spindle for extra rigidity<br />

n<br />

n<br />

n<br />

Less tailstock pressure required<br />

Body heat-treated for additional strength<br />

Riten full service and repair<br />

STANDARD POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E RPM Weight<br />

51602 2 7/8 11/8 13/4 23/8 3/8 5000 880<br />

51603 3 7/8 11/8 13/4 23/8 3/8 5000 920<br />

51604 4 11/4 2 27/8 35/16 3/8 5500 2200<br />

51605 5 11/4 2 27/8 35/16 3/8 5500 4400<br />

Standard Point<br />

51606 6 17/8 21/4 33/4 327/32 1/2 4000 8000<br />

TRACER POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E V2 RPM Weight<br />

V2<br />

C<br />

51902 2 3/8 13/4 13/4 23/8 3/8 30˚ 5000 750<br />

51903 3 3/8 13/4 13/4 23/8 3/8 30˚ 5000 750<br />

E<br />

D<br />

B<br />

51904 4 9/16 21/16 27/8 35/16 3/8 30˚ 5500 1700<br />

51905 5 9/16 21/16 27/8 35/16 3/8 30˚ 5500 1700<br />

Tracer Point<br />

51906 6 5/8 225/32 33/4 327/32 1/2 30˚ 4000 2200<br />

LONG POINT MORSE - MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E G V2 I RPM Weight<br />

51102 2 3/8 2 13/4 23/8 3/8 3/4 30 111/16 5000 310<br />

51103 3 3/8 2 13/4 23/8 3/8 3/4 30 111/16 5000 310<br />

51104 4 1/2 21/2 27/8 35/16 3/8 15/16 30 23/32 5500 1100<br />

51105 5 1/2 21/2 27/8 35/16 3/8 15/16 30 23/32 5500 1100<br />

Long Point<br />

10<br />

www.riten.com

®<br />

Regal Live Centers<br />

Standard and Long Point<br />

n Accuracy guaranteed to ± .00005<br />

n Points are through-hardened to 61-63 Rc<br />

n Full-length spindle for extra rigidity<br />

n Two angular contact bearings for superior<br />

performance in a compact design<br />

n Body heat-treated for additional strength<br />

n Long point configuration allows for tool clearance<br />

n Riten full service and repair<br />

A<br />

C<br />

E<br />

D<br />

Standard Point<br />

B<br />

STANDARD POINT MORSE – TAPER MORSE TAPER<br />

Max. W. P.<br />

Model MT A B C D E RPM Weight<br />

48602 2 1 11/4 23/8 13/4 1/4 4000 440<br />

48603 3 1 11/4 23/8 13/4 1/4 4000 1100<br />

48604 4 13/8 11/2 3 131/32 3/8 4000 2100<br />

48605 5 13/8 113/16 31/16 23/32 9/32 5000 2800<br />

I<br />

A<br />

V2<br />

C<br />

G<br />

E<br />

D<br />

B<br />

Long Point<br />

LONG POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model MT A B C D E G V2 I RPM Weight<br />

48102 2 3/8 17/8 23/8 13/4 1/4 5/8 40° 11/2 4000 310<br />

48103 3 3/8 17/8 23/8 13/4 1/4 5/8 40° 11/2 4000 310<br />

48104 4 1/2 27/32 3 131/32 3/8 13/16 40° 2 4000 1100<br />

48105 5 1/2 21/2 31/16 23/32 9/32 15/16 40° 25/32 5000 1100<br />

11<br />

Call 1-800-338-0027

®<br />

Econo Tri-Bearing<br />

Live Centers<br />

Standard and Tracer Point<br />

n Accuracy guaranteed to ± .0002<br />

n Three rows of bearings<br />

n Points are through-hardened to 61-63 Rc<br />

n Sealed bearings lubricated for life, protected<br />

against contaminants and coolant<br />

n Non-repairable, trade-in available<br />

E<br />

D<br />

B<br />

A<br />

C<br />

STANDARD POINT MORSE – MORSE TAPER TAPER<br />

Max. W.P.<br />

Model Taper A B C D E RPM Weight<br />

44102 2 9/16 13/16 15/8 15/8 1/4 2500 300<br />

44103 3 13/16 1 2 115/16 1/4 2500 500<br />

44104 4 1 11/4 23/8 21/4 1/4 2500 1100<br />

44105 5 1 11/4 23/8 21/4 1/4 2500 1100<br />

Standard Point<br />

E<br />

D<br />

V2<br />

B<br />

A<br />

C<br />

TRACER POINT MORSE – MORSE TAPER TAPER<br />

Max. W. P.<br />

Model Taper A B C D E V2 RPM Weight<br />

44902 2 3/8 11/4 15/8 15/8 1/4 18° 2500 300<br />

44903 3 3/8 11/2 2 115/16 1/4 30° 2500 300<br />

44904 4 1/2 2 23/8 21/4 1/4 30° 2500 900<br />

44905 5 1/2 2 23/8 21/4 1/4 30° 2500 900<br />

Tracer Point<br />

www.riten.com<br />

12

A<br />

A<br />

®<br />

Heavy Duty and Extra<br />

Heavy Duty Live Centers<br />

Standard Point<br />

n Accuracy guaranteed to ± .0001.<br />

n Four-bearing design for heavier loads such as steel<br />

rolls, paper rolls, printing rolls, castings, forgings and<br />

other large parts.<br />

n For use where the piece part may weigh several<br />

thousand pounds. Radial pressure and thrust<br />

requirements demand centers with bearing structures<br />

that will handle these loads.<br />

n Available in additional metric tapers upon request<br />

n Riten full service and repair.<br />

Jarno,<br />

Brown & Sharpe,<br />

and Straight Shanks<br />

Available<br />

C<br />

C<br />

E<br />

D<br />

B<br />

E<br />

D<br />

B<br />

HEAVY-DUTY – MORSE TAPER<br />

Max W. P.<br />

Model MT A B C D E RPM Weight<br />

34163 3 7/8 11/8 13/4 23/8 3/8 5000 920<br />

34164 4 11/8 2 27/8 33/16 1/2 4200 2200<br />

34105 5 17/8 21/4 33/4 327/32 1/2 3200 8000<br />

34106 6 2 21/4 45/8 327/32 1/2 3000 14000<br />

34107 7 2 21/4 45/8 327/32 1/2 3000 14000<br />

HEAVY-DUTY – JARNO TAPER<br />

34220 20 2 21/4 45/8 327/32 1/2 3000 14000<br />

HEAVY-DUTY – METRIC TAPER (1:20)<br />

34080 80 2 21/4 45/8 327/32 1/2 3000 14000<br />

EXTRA HEAVY-DUTY – MORSE TAPER<br />

Max W. P.<br />

Model MT A B C D E RPM Weight<br />

55103* 3 11/8 11/2 213/16 33/16 1/2 4000 3000<br />

55164* 4 121/32 13/4 33/4 327/32 1/2 4000 4800<br />

55105 5 2 21/4 45/8 327/32 1/2 3000 12000<br />

55106 6 25/8 21/2 69/16 53/32 19/32 3000 22500<br />

55107 7 25/8 21/2 69/16 53/32 3/4 3000 22500<br />

*Stub spindle design on 3MT and 4MT<br />

EXTRA HEAVY-DUTY – METRIC TAPER (1:20)<br />

55080 80 25/8 21/2 69/16 53/32 3/4 3000 22500<br />

55100 100 33/4 31/2 8 63/8 1/2 3000 30000<br />

13<br />

Call 1-800-338-0027

®<br />

Super Duty<br />

Live Centers<br />

Standard and Replaceable Point<br />

n Accuracy guaranteed to ± .0002<br />

n Designed for especially heavy workpieces such as<br />

those found in mill roll manufacturing and rebuilding.<br />

n Unmatched rigidity under load.<br />

n Radial and axial deflection evaluated per application.<br />

n Two-stage/5 point testing of noise level, vibration,<br />

temperature, and accuracy under load.<br />

n Available in metric tapers upon request<br />

Each center is engineered for a specific application. Representative<br />

sizes and capacities are shown below. Contact Riten Technical<br />

Service to discuss your specific needs.<br />

A<br />

STANDARD POINT<br />

E<br />

D<br />

B<br />

F<br />

C<br />

Gage Line Max Bearing<br />

Model Dia. A B C D E F RPM Load Rating<br />

N/A 3.500 33/4 31/4 8 63/8 1/2 1/4 1200 62,000 lbs.<br />

N/A 4.500 41/4 5 93/4 71/4 5/8 3/8 900 69,500 lbs.<br />

N/A 5.000 5 55/8 103/4 73/4 3/4 1/2 800 105,000 lbs.<br />

N/A 6.000 6 53/4 113/8 85/8 7/8 3/4 600 125,000 lbs.<br />

A<br />

F<br />

C<br />

REPLACEABLE POINT<br />

Gage Line Max Bearing<br />

Model Dia. A B C D E F RPM Load Rating<br />

N/A 3.500 33/4 41/4 8 63/8 1/2 1/4 1200 62,000 lbs.<br />

N/A 4.500 41/4 43/4 93/4 71/4 5/8 3/8 900 69,500 lbs.<br />

E<br />

D<br />

B<br />

Applications requiring bearing load ratings from 120,000 to 450,000 lbs. are available. For application<br />

assistance and available product configurations, please contact Riten Technical Support Group<br />

at 1-800-338-0027.<br />

Standard contact angle is 60°. Optional contact angles of 45°, 70°, 80° and 90° are also available.<br />

14<br />

www.riten.com

®<br />

Super Accurate Live Centers<br />

Standard Point<br />

n Accuracy guaranteed to ± .00004<br />

n<br />

n<br />

n<br />

n<br />

n<br />

Ideal for precision grinding<br />

Compact design<br />

Extended points available<br />

Five pounds of thrust to seat bearings<br />

Riten full service and repair<br />

The ultimate live center for precision grinding is provided by Riten's unique design. Medium-duty live centers<br />

are required where the weight of the workpiece is several hundred pounds. These centers are built with<br />

larger bearings to provide the support and strength required to handle heavier workpieces.<br />

A<br />

C<br />

A<br />

C<br />

Standard Duty<br />

E<br />

D<br />

B<br />

Medium Duty<br />

E<br />

D<br />

B<br />

15<br />

MORSE TAPER<br />

W. P.<br />

Model MT A B C D E RPM Weight<br />

12102 2 3/4 13/16 11/4 3/4 3/32 1000 400<br />

12103 3 7/8 11/16 111/16 15/16 3/16 1000 1000<br />

12104 4 1 1 21/8 13/16 1/4 1000 1800<br />

12105 5 11/2 11/2 213/16 113/32 1/4 1000 3800<br />

12106 6 21/8 21/8 43/16 21/2 5/16 1000 6000<br />

Model JT JARNO TAPER<br />

12206 6 3/4 13/16 11/4 3/4 3/32 1000 300<br />

12207 7 7/8 1 111/16 15/16 3/16 1000 800<br />

12209 9 7/8 1 111/16 15/16 3/16 1000 1000<br />

12210 10 1 1 21/8 13/16 3/16 1000 1800<br />

12212 12 1 1 21/8 13/16 1/4 1000 1800<br />

12214 14 11/2 11/2 213/16 113/32 1/4 1000 3800<br />

12216 16 11/2 11/2 213/16 113/32 3/16 1000 3800<br />

12220 20 21/8 21/8 43/16 21/2 5/16 1000 6000<br />

Model BS BROWN & SHARPE TAPER<br />

12407 7 3/4 13/16 11/4 3/4 3/32 1000 400<br />

12409 9 7/8 1 111/16 15/16 3/16 1000 1000<br />

12410 10 1 1 21/8 13/16 9/16 1000 1800<br />

12411 11 1 1 21/8 13/16 1/4 1000 1800<br />

12412 12 11/2 11/2 213/16 113/32 5/16 1000 3800<br />

12413 13 11/2 11/2 213/16 113/32 1/4 1000 3800<br />

Call 1-800-338-0027<br />

MORSE TAPER<br />

W. P.<br />

Model MT A B C D E RPM Weight<br />

34102 2 7/8 1 111/16 11/16 3/32 1000 500<br />

34103 3 1 1 21/8 13/8 3/16 1000 1200<br />

34104 4 11/2 15/8 213/16 121/32 3/16 1000 2200<br />

Model JT JARNO TAPER<br />

34206 6 7/8 1 111/16 11/16 3/32 1000 400<br />

34207 7 1 1 21/8 13/8 3/16 1000 900<br />

34209 9 1 1 21/8 13/8 3/16 1000 1300<br />

34210 10 11/2 11/2 213/16 121/32 5/16 1000 2200<br />

34211 11 11/2 11/2 213/16 121/32 3/16 1000 2200<br />

34212 12 11/2 11/2 213/16 121/32 1/4 1000 2200<br />

34214 14 21/8 21/8 43/16 21/2 1/2 1000 4400<br />

34216 16 21/8 21/8 43/16 21/2 5/16 1000 4400<br />

Model BS BROWN & SHARPE TAPER<br />

34407 7 7/8 1 111/16 11/16 3/32 1000 500<br />

34409 9 1 1 21/8 13/8 3/16 1000 1300<br />

34410 10 11/2 11/2 213/16 121/32 3/16 1000 2200<br />

34411 11 11/2 11/2 213/16 121/32 1/4 1000 2200<br />

34412 12 21/8 21/8 43/16 21/2 5/16 1000 4400<br />

34413 13 21/8 21/8 43/16 21/2 5/16 1000 4400<br />

Both Standard and Medium Duty Centers are also<br />

available in stock in Straight Shank designs.<br />

See Website or call Riten for specifications.

H<br />

®<br />

Imperial Dead Centers<br />

Large Carbide Point<br />

Increased Center Hole Range<br />

n Accuracy guaranteed to ± .00005.<br />

n<br />

n<br />

n<br />

Covers the widest range of center hole sizes.<br />

Eliminates the need for special centers.<br />

Also available in other tapers.<br />

Imperial Carbide Centers cover the requirements for a wide range of workpiece<br />

center holes. They reduce costs by eliminating the need for special dead centers.<br />

Knockout ends are hardened on carbide tipped dead centers. Applying a Moly<br />

EP632 grease on the point will reduce friction and wear.<br />

L<br />

T<br />

A<br />

E<br />

K<br />

Full Dead Centers<br />

E A<br />

K<br />

Half Dead Centers<br />

T<br />

MORSE TAPER<br />

Model Taper T* A K E<br />

69102 2 1 11/4 23/8 3/8<br />

69103 3 1 11/4 23/8 3/8<br />

69104 4 11/4 13/4 211/16 1/2<br />

69105 5 11/4 13/4 35/16 —<br />

MORSE TAPER<br />

Model Taper T* A H L K E<br />

69502 2 1 11/4 1/8 111/16 23/8 3/8<br />

69503 3 1 11/4 1/8 111/16 23/8 3/8<br />

69504 4 11/4 13/4 1/4 21/4 215/16 1/2<br />

69505 5 11/4 13/4 1/4 23/4 35/16 -<br />

JARNO TAPER<br />

Model Taper T* A K E<br />

69206 6 1 11/4 23/8 3/8<br />

69209 9 11/4 13/4 211/16 1/2<br />

69210 10 11/4 13/4 211/16 1/2<br />

69214 14 11/4 13/4 31/2 —<br />

JARNO TAPER<br />

Model Taper T* A H L K E<br />

69606 6 1 11/4 1/8 17/8 23/8 3/8<br />

69609 9 11/4 13/4 1/4 17/8 215/16 1/2<br />

69610 10 11/4 13/4 1/4 2 215/16 1/2<br />

69614 14 11/4 13/4 1/4 3 31/2 -<br />

BROWN & SHARPE TAPER<br />

Model Taper T* A K E<br />

69407 7 1 11/4 23/8 3/8<br />

BROWN & SHARPE TAPER<br />

Model Taper T* A H L K E<br />

69707 7 1 11/4 1/8 17/8 23/8 3/8<br />

69409 9 11/4 13/4 211/16 1/2<br />

69412 12 11/4 151/64 4 —<br />

* Carbide Diameter<br />

69709 9 11/4 13/4 1/4 2 215/16 1/2<br />

69712 12 11/4 151/64 1/4 31/4 4 -<br />

* Carbide Diameter<br />

www.riten.com<br />

16

®<br />

Standard Length<br />

and Long Series<br />

Dead Centers<br />

Std. Length<br />

Style 1, Steel<br />

Std. Length<br />

Style 2, Steel<br />

Std. Length<br />

Style 3, Carbide<br />

Std. Length<br />

Style 4, Carbide<br />

n Accuracy guaranteed to ± .00005<br />

n Through-hardened to 61-63 Rc for extra regrinds<br />

n Carbide tipped dead centers are hardened only<br />

on the knockout ends.<br />

n Riten full service and repair<br />

n Applying a Moly EP632 grease on the point will<br />

reduce friction and wear.<br />

Long Series. Carbide Tipped Points available.<br />

See Fast-Trak Specials, page 20.<br />

STEEL FULL CENTER - STYLE 1<br />

STEEL HALF CENTER - STYLE 2<br />

C<br />

C<br />

D<br />

A<br />

D<br />

A<br />

B<br />

P<br />

C<br />

H L A<br />

B<br />

P<br />

CARBIDE TIPPED FULL CENTER - STYLE 3 CARBIDE TIPPED HALF CENTER - STYLE 4<br />

C<br />

H<br />

L<br />

D<br />

A<br />

D<br />

B<br />

T<br />

B<br />

T<br />

P<br />

P<br />

When ordering, specify 4-digit model # from page 18 and and add style #.<br />

Examples:<br />

Steel full center, 4 Morse Taper = 71041<br />

Carbide tipped half center, 12 Jarno Taper = 72124<br />

17<br />

Call 1-800-338-0027

Standard Length<br />

Dead Centers<br />

Long Series<br />

Dead Centers<br />

MORSE TAPER<br />

Model Taper P B C/A D •T H L<br />

7101 1 35/16 21/8 .475 .369 1/4 1/8 1<br />

7102 2 43/16 29/16 .700 .572 3/8 3/16 13/8<br />

7103 3 51/4 33/16 .938 .778 1/2 1/4 111/16<br />

7104 4 63/4 41/16 1.231 1.020 1/2 1/4 21/4<br />

7105 5 81/2 53/16 1.748 1.475 5/8 3/8 23/4<br />

7106 6 111/2 71/4 2.494 2.116 7/8 1/2 31/2<br />

7107 7 15 10 3.270 2.750 1 3/4 4<br />

JARNO TAPER<br />

Model Taper P B C/A D •T H L<br />

7204 6 41/2 3 .750 .600 3/8 3/16 11/8<br />

7205 6 51/2 3 .750 .600 3/8 3/16 23/16<br />

7206 6 6 3 .750 .600 3/8 3/16 21/2<br />

7207 7 51/4 31/2 .875 .700 3/8 3/16 13/16<br />

7208 8 6 4 1.000 .800 1/2 1/4 15/8<br />

7209 9 63/4 41/2 1.125 .900 1/2 1/4 17/8<br />

7210 10 71/2 5 1.250 1.000 1/2 1/4 2<br />

7211 11 81/4 51/2 1.375 1.100 1/2 1/4 2<br />

7212 12 9 6 1.500 1.200 5/8 5/16 21/4<br />

7213 13 93/4 61/2 1.625 1.300 5/8 5/16 21/2<br />

7214 14 101/2 7 1.750 1.400 5/8 5/16 3<br />

7215 15 111/4 71/2 1.875 1.500 5/8 5/16 3<br />

7216 16 12 8 2.000 1.600 3/4 3/8 3<br />

7218 18 131/2 9 2.250 1.800 7/8 7/16 31/2<br />

7220 20 15 10 2.500 2.000 1 1/2 4<br />

7236 36 27 18 4.500 3.600 21/2 7/8 7<br />

BROWN & SHARPE TAPER<br />

Model Taper P B C/A D •T H L<br />

7405 5 31/8 2 .533 .450 1/4 1/8 15/16<br />

7406 6 35/8 23/8 .599 .500 1/4 1/8 15/16<br />

7407 7 43/8 27/8 .720 .600 3/8 3/16 11/8<br />

7408 8 57/16 39/16 .898 .750 1/2 1/4 13/8<br />

7409 9 61/2 41/4 1.078 .901 1/2 1/4 2<br />

7410 10 77/8 5 1.260 1.045 1/2 1/4 21/4<br />

7400 H10 89/16 511/16 1.289 1.045 1/2 1/4 21/4<br />

7411 11 95/16 515/16 1.498 1.250 5/8 5/16 21/2<br />

7401 H11 101/8 63/4 1.531 1.250 5/8 5/16 21/2<br />

7412 12 111/8 71/8 1.797 1.500 5/8 3/8 31/4<br />

7413 13 113/4 73/4 2.073 1.750 7/8 7/16 31/2<br />

7415 15 131/2 83/4 2.615 2.250 1 1/2 4<br />

7417 17 141/2 93/4 3.156 2.750 11/2 3/4 4<br />

7418 18 15 101/4 3.427 3.000 11/2 3/4 41/2<br />

• Carbide diameter H CINN. Grinder<br />

MORSE TAPER<br />

Model Taper P K C/A<br />

64502 2 53/16 25/8 .700<br />

64602 2 63/4 43/16 .700<br />

64503 3 61/4 31/16 .938<br />

64603 3 63/4 39/16 .938<br />

64504 4 73/4 311/16 1.231<br />

64604 4 81/4 43/16 1.231<br />

64505 5 91/2 45/16 1.748<br />

64605 5 10 413/16 1.748<br />

64506 6 121/2 51/4 2.494<br />

64606 6 13 53/4 2.494<br />

JARNO TAPER<br />

Model Taper P K C/A<br />

64510 10 81/2 31/2 1.250<br />

64610 10 91/4 41/4 1.250<br />

64514 14 111/2 41/2 1.750<br />

64614 14 12 5 1.750<br />

BROWN & SHARPE<br />

Model Taper P K C/A<br />

64407 7 51/4 23/8 .720<br />

64412 12 121/4 51/8 1.797<br />

Metric Rate of<br />

Model Size Taper P K C/A<br />

70080 80 1:20 121/2 43/4 3.150<br />

70100 100 1:20 141/2 53/8 3.937<br />

70081 80 1:10 123/8 43/4 3.150<br />

70101 100 1:10 141/2 43/8 3.937<br />

C<br />

METRIC TAPER<br />

Drawing shows Long Series and Metric<br />

Taper dimensions only.<br />

P<br />

K<br />

A<br />

www.riten.com<br />

18

A<br />

A<br />

®<br />

Pipe and Bull Nose<br />

Dead Centers<br />

n Accuracy guaranteed to ± .00005.<br />

n Through-hardened to 61-63 Rc.<br />

n Riten full service and repair.<br />

n Special “F” dimension available on bull nose.<br />

n Quick delivery available on these items.<br />

F<br />

E<br />

N<br />

K<br />

Pipe Nose Dead Center<br />

MORSE TAPER<br />

Model Taper A N E K<br />

66102 2 21/8 1.831 1/2 2.84<br />

66103 3 23/4 2.370 1/2 3.38<br />

66104 4 23/4 2.370 1/2 3.38<br />

66105 5 31/2 3.017 1/2 4.03<br />

JARNO TAPER<br />

Model Taper A N E K<br />

66214 14 31/2 3.017 1/2 4.03<br />

E<br />

N<br />

K<br />

Bull Nose Dead Center<br />

Special F dimensions available. Quick delivery on these items.<br />

MORSE TAPER<br />

Model Taper A F N E K<br />

66502 2 21/8 1/2 1.400 1/2 213/32<br />

66602 2 21/8 1 .969 1/2 131/32<br />

66503 3 23/4 1/2 1.939 1/2 261/64<br />

66603 3 23/4 1 1.508 1/2 233/64<br />

66703 3 23/4 11/2 1.077 1/2 25/64<br />

66504 4 23/4 1/2 1.939 1/2 215/16<br />

66604 4 23/4 1 1.508 1/2 233/64<br />

66704 4 23/4 11/2 1.077 1/2 25/64<br />

66505 5 31/2 1 2.155 1/2 311/64<br />

66605 5 31/2 2 1.293 1/2 219/64<br />

JARNO TAPERS<br />

Model Taper A F N E K<br />

66514 14 31/2 1 2.155 1/2 311/64<br />

66614 14 31/2 2 1.293 1/2 219/64<br />

19<br />

www.riten.com<br />

Models available with carbide tipped points.<br />

See Fast-Trak Specials on page 20.

T<br />

®<br />

Fast-Trak Specials<br />

Order a Fast-Trak Special when you need a special center and<br />

time is of the essence. Additional tapers are available from our<br />

semi-finished inventories. Call Riten at 800-338-0027 with<br />

your special requirements. If you would rather fax your<br />

requirements, see pages 31 and 32.<br />

n Accuracy guaranteed to ± .00005<br />

n Popular sizes in stock for fast delivery<br />

n Other tapers available<br />

n Hardened knockout ends<br />

n Riten full service and repair<br />

Special Carbide Full & Half Dead Centers<br />

When ordering, specify 4-digit model # and add style #.<br />

Example: Full center, 3 Morse Taper = 79053<br />

Special Carbide Bull<br />

Nose Dead Centers<br />

STYLE 3 - FULL CENTER<br />

C<br />

STYLE 4 - HALF CENTER<br />

C<br />

H<br />

L<br />

F<br />

D<br />

A<br />

D<br />

A<br />

B<br />

T<br />

B<br />

T<br />

P<br />

P<br />

MORSE TAPER<br />

Model Taper P B C/A D •T H L<br />

7905 3MT 51/4 33/16 0.938 0.778 3/4 1/8 111/16<br />

7906 3MT 61/4 33/16 0.938 0.778 3/4 1/8 25/8<br />

7907 3MT 63/4 33/16 0.938 0.778 3/4 1/8 31/8<br />

7908 4MT 63/4 41/16 1.231 1.020 3/4 1/8 21/4<br />

7909 4MT 63/4 41/16 1.231 1.020 1 1/8 21/4<br />

7910 4MT 73/4 41/16 1.231 1.020 3/4 1/8 23/4<br />

7911 4MT 73/4 41/16 1.231 1.020 1 1/8 23/4<br />

7912 4MT 81/4 41/16 1.231 1.020 3/4 1/8 31/4<br />

7913 4MT 81/4 41/16 1.231 1.020 1 1/8 31/4<br />

7914 5MT 81/2 53/16 1.748 1.475 1 1/8 23/4<br />

7915 5MT 91/2 53/16 1.748 1.475 1 1/8 33/4<br />

7916 5MT 10 53/16 1.748 1.475 1 1/8 41/4<br />

JARNO TAPER<br />

7926 10J 71/2 5 1.25 1.000 1 1/8 2<br />

7927 10J 81/2 5 1.25 1.000 1 1/8 3<br />

7928 10J 91/4 5 1.25 1.000 1 1/8 33/4<br />

7929 14J 101/2 7 1.75 1.400 1 1/8 3<br />

7930 14J 111/2 7 1.75 1.400 1 1/8 4<br />

7931 14J 12 7 1.75 1.400 1 1/8 41/2<br />

E<br />

N<br />

K<br />

MORSE TAPER<br />

Model MT •T F N E K<br />

66901 3 13/4 3/4 0.87 1/2 1.86<br />

66902 3 2 3/4 1.08 1/2 2.08<br />

66903 3 21/2 1 1.30 1/2 2.30<br />

66904 3 23/4 1 1.52 1/2 2.51<br />

66905 4 13/4 3/4 0.87 1/2 1.86<br />

66906 4 2 3/4 1.08 1/2 2.08<br />

66907 4 21/2 1 1.30 1/2 2.30<br />

66908 4 23/4 1 1.52 1/2 2.51<br />

66909 5 13/4 3/4 0.87 1/2 2.64<br />

66910 5 2 3/4 1.08 1/2 2.08<br />

66911 5 21/2 1 1.30 1/2 2.30<br />

66912 5 23/4 1 1.52 1/2 2.51<br />

• Carbide diameter<br />

20<br />

Call 1-800-338-0027

®<br />

Bull Nose<br />

Live Centers<br />

n<br />

n<br />

n<br />

Large workpiece center holes.<br />

Large piece parts.<br />

Riten full service and repair.<br />

Riten Bull Nose Centers are designed for large bore, heavy work pieces such as<br />

hydraulic cylinders, thick wall pipe and heavy rolls. They utilize both ball and tapered<br />

roller bearings. For best results, choose a bull nose center that will place the workpiece<br />

in the middle or toward the larger end of the 60˚ angle. This will balance the<br />

weight of the part on the center and help carry the load evenly over the bearings.<br />

E<br />

K<br />

Accuracy guaranteed to ± .00015<br />

F<br />

A<br />

MORSE TAPER<br />

W. P.<br />

Model MT A F E K Weight<br />

56412 2 4 1 3/8 4 9/32 2000<br />

56413 3 4 1 3/8 4 9/32 3800<br />

56414 4 4 1 3/8 4 9/32 4800<br />

56415 5 4 1 3/8 4 9/32 4800<br />

56523 3 5 2 3/8 3 13/16 3800<br />

56524 4 5 2 3/8 3 13/16 4800<br />

56525 5 5 2 3/8 3 13/16 4800<br />

56633 3 6 1/2 3 3/8 3 29/32 3800<br />

56634 4 6 1/2 3 3/8 3 29/32 4800<br />

56635 5 6 1/2 3 3/8 3 29/32 4800<br />

56636 6 6 1/2 3 25/32 4 5/16 4800<br />

MORSE TAPER<br />

21<br />

Jarno,<br />

Brown & Sharpe,<br />

and Straight Shanks<br />

Available<br />

E<br />

K<br />

F<br />

Accuracy guaranteed to ± .0002<br />

A<br />

W. P.<br />

Model MT A F E K Weight<br />

56945 5 9 4 15/32 6 5/8 7000<br />

56946 6 9 4 15/32 6 5/8 12000<br />

56105 5 10 1/2 5 7/16 7 7/16 7000<br />

56106 6 10 1/2 5 7/16 7 7/16 15000<br />

56107 7 10 1/2 5 7/16 7 7/16 15000<br />

56126 6 12 6 7/16 7 7/16 15000<br />

56127 7 12 6 7/16 7 7/16 15000<br />

Call 1-800-338-0027

®<br />

Precision Bull Nose<br />

Live Centers<br />

n Accuracy guaranteed to ± .0001.<br />

n For heavy, large center hole workpieces.<br />

n High RPM capacity.<br />

n Riten full service and repair<br />

Riten Precision Bull Nose Centers are engineered for precision grinding, threading and turning of heavy, large<br />

center hole work pieces. They provide greater accuracy and higher speeds than standard Bull Nose Centers.<br />

The rigidity of the center prevents vibration and chatter. For the best support and chatter-free parts, choose a<br />

center where the part will seat as close to the large diameter as possible.<br />

Engineered for precision grinding, threading<br />

and turning of heavy, large center<br />

hole work pieces. For the best support<br />

and chatter-free parts, choose a center<br />

where the part will seat as close to the<br />

large diameter as possible.<br />

Jarno,<br />

Brown & Sharpe,<br />

and Straight Shanks<br />

Available<br />

E<br />

Accuracy guaranteed to ± .0001<br />

K<br />

F<br />

A<br />

MORSE TAPER<br />

Max W. P.<br />

Model MT A F E K RPM Weight<br />

56202 2 21/2 9/16 1/4 31/4 8500 1350<br />

56203 3 21/2 9/16 1/4 31/4 8500 1350<br />

56303 3 31/2 1 1/4 33/4 7000 2700<br />

56304 4 31/2 1 1/4 33/4 7000 2700<br />

56404 4 41/2 1 5/8 53/8 6000 4000<br />

56405 5 41/2 1 5/8 53/8 6000 4000<br />

56505 5 51/2 11/2 5/8 59/16 4500 7000<br />

56506 6 51/2 11/2 5/8 59/16 4500 7000<br />

56605 5 61/2 11/2 5/8 613/16 4000 10,000<br />

56606 6 61/2 11/2 5/8 613/16 4000 10,000<br />

56705 5 71/2 2 5/8 71/4 3000 15,000<br />

56706 6 71/2 2 5/8 71/4 3000 15,000<br />

56707 7 71/2 2 5/8 71/4 3000 15,000<br />

56855 5 81/2 3 5/8 71/4 3000 15,000<br />

56856 6 81/2 3 5/8 71/4 3000 15,000<br />

56857 7 81/2 3 5/8 71/4 3000 15,000<br />

56805 5 10 4 5/8 71/8 2800 19,000<br />

56806 6 10 4 5/8 71/8 2800 19,000<br />

56807 7 10 4 5/8 71/8 2800 19,000<br />

56905 5 12 6 5/8 71/8 2800 19,000<br />

56906 6 12 6 5/8 71/8 2800 19,000<br />

56907 7 12 6 5/8 71/8 2800 19,000<br />

56915 5 14 8 5/8 71/8 2800 19,000<br />

56916 6 14 8 5/8 71/8 2800 19,000<br />

56917 7 14 8 5/8 71/8 2800 19,000<br />

22<br />

www.riten.com

®<br />

Standard & Heavy Duty<br />

Pipe Nose Live Centers<br />

Standard<br />

n<br />

For use with pipe, tubing and thin walled piece parts.<br />

Designed for use in machining pipe, tubing and other<br />

thin wall workpieces. One center fits a wide range of<br />

sizes. For the best support and chatter-free parts,<br />

choose a center where the part will seat as close to the<br />

large diameter as possible.<br />

Heavy Duty<br />

STANDARD - MORSE TAPER<br />

W. P.<br />

Model Taper A E K Weight<br />

65252 2 21/2 5/16 33/4 260<br />

Jarno,<br />

Brown & Sharpe,<br />

and Straight Shanks<br />

Available<br />

E<br />

K<br />

Accuracy guaranteed to ± .00025<br />

A<br />

65253 3 21/2 5/16 33/4 260<br />

65254 4 21/2 5/16 33/4 260<br />

65353 3 31/2 7/16 429/32 1500<br />

65354 4 31/2 7/16 429/32 1500<br />

65355 5 31/2 7/16 429/32 1500<br />

65453 3 41/2 7/16 47/8 1500<br />

65454 4 41/2 7/16 47/8 1500<br />

65455 5 41/2 7/16 47/8 1500<br />

65555 5 51/2 3/8 65/16 4500<br />

65556 6 51/2 3/8 65/16 4500<br />

HEAVY DUTY - MORSE TAPER<br />

Max W. P. Pipe Point<br />

Model MT A F E K K1 RPM Weight Part No.<br />

65202* 2 21/2 – 1/4 31/4 33/4 8500 1350 –<br />

65203* 3 21/2 – 1/4 31/4 33/4 8500 1350 –<br />

23<br />

E<br />

K<br />

K1<br />

Accuracy guaranteed to ± .0001<br />

Call 1-800-338-0027<br />

60°<br />

F A<br />

65303 3 31/2 1 1/4 33/4 45/8 7800 2700 96501<br />

65304 4 31/2 1 1/4 33/4 45/8 7800 2700 96501<br />

65404 4 41/2 1 5/8 53/8 61/4 6000 4000 96501<br />

65405 5 41/2 1 5/8 53/8 61/4 6000 4000 96501<br />

65505 5 51/2 11/2 5/8 59/16 67/8 4000 7000 96515<br />

65506 6 51/2 11/2 5/8 59/16 67/8 4000 7000 96515<br />

65605 5 61/2 11/2 5/8 613/16 81/8 2600 10,000 96515<br />

65606 6 61/2 11/2 5/8 613/16 81/8 2600 10,000 96515<br />

65705 5 71/2 2 5/8 71/4 95/8 1900 15,000 96502<br />

65706 6 71/2 2 5/8 71/4 95/8 1900 15,000 96502<br />

65707 7 71/2 2 5/8 71/4 95/8 1900 15,000 96502<br />

* Solid point in pipe nose design.

®<br />

Multi-Use Live Center<br />

n Accurate to ± .0001.<br />

n Great for manual lathe applications.<br />

n Riten full service and repair.<br />

The Multi-Use live center is ideal for general<br />

machine shop use. It can be used when<br />

machining thin-walled workpieces or general<br />

shaft work applications. The versatility of this<br />

center makes it a “must have” tool when your<br />

center needs change frequently.<br />

A2<br />

C<br />

V2<br />

A<br />

V<br />

E<br />

G<br />

K<br />

MULTI-USE LIVE CENTER - MORSE TAPER<br />

Max W. P.<br />

Model MT A A2 C E G K V V2 RPM Weight<br />

60222 2 1/2 21/4 .700 1/4 3/4 33/16 60° 60° 5000 330<br />

60223 3 1/2 21/4 .938 1/4 3/4 33/16 60° 60° 5000 330<br />

60263 3 5/8 25/8 .938 1/4 15/16 33/16 60° 60° 4000 685<br />

60264 4 5/8 25/8 1.231 3/8 15/16 37/8 60° 60° 4000 685<br />

60354 4 3/4 31/2 1.231 3/8 11/8 37/8 60° 60° 3500 1165<br />

60355 5 3/4 31/2 1.748 3/8 11/8 45/8 60° 60° 3500 1165<br />

24<br />

www.riten.com

®<br />

Standard Spring Loaded<br />

and Interchangeable<br />

Bell Head Live Centers<br />

n Accuracy to ± .0001.<br />

n Spring loaded spindle compensates for thermal expansion.<br />

n Low profile - less overhang, added load capacity, and increased rigidity<br />

Sixty years ago, Concentric pioneered and patented the first spring loaded<br />

live center. Today, this streamlined high precision center still features handcrafted<br />

quality with all bearings physically matched and honed to size when<br />

necessary.<br />

Standard Spring Loaded Live Center<br />

Bell Head Spring Loaded Live Center<br />

A<br />

B<br />

K<br />

P<br />

STANDARD SPRING LOADED LIVE CENTER<br />

Max Thrust Max Spring Max W.P.<br />

Type A B K* P Load Travel Weight Max RPM<br />

II .378 .880 1.380 3.95 173 3/32 274 3000<br />

III .558 1.160 1.690 4.95 235 1/8 400 3000<br />

IV .686 1.380 2.380 6.29 780 5/32 960 2000<br />

V 1.075 2.000 2.880 8.02 1088 3/16 1450 1500<br />

VI 1.509 2.812 3.630 11.00 2183 3/16 2500 1500<br />

* K: Gage line to point typical for Morse Tapers.<br />

25<br />

Call 1-800-338-0027

Standard Spring Loaded Live Centers<br />

TYPE II<br />

TYPE III<br />

TYPE IV<br />

TYPE V<br />

TYPE VI<br />

Taper Part No.<br />

2 MT 17102<br />

7 B&S 17407<br />

8 B&S 17408<br />

6 Jarno 17206<br />

7 Jarno 17207<br />

5/8 SS 17301<br />

3/4 SS 17302<br />

Taper Part No.<br />

3 MT 17103<br />

9 B&S 17409<br />

8 Jarno 17208<br />

9 Jarno 17209<br />

1 SS 17303<br />

1 1 /16 SS 17304<br />

1 1 /4 SS 17305<br />

Taper Part No.<br />

4 MT 17104<br />

10 B&S 17410<br />

11 B&S 17411<br />

10 Jarno 17210<br />

11 Jarno 17211<br />

12 Jarno 17212<br />

1 1 /2 SS 17306<br />

Taper Part No.<br />

5 MT 17105<br />

12 B&S 17412<br />

13 B&S 17413<br />

14 B&S 17414<br />

14 Jarno 17214<br />

16 Jarno 17216<br />

1 3 /4 SS 17307<br />

2 SS 17308<br />

Taper Part No.<br />

6 MT 17106<br />

15 B&S 17415<br />

16 B&S 17416<br />

20 Jarno 17220<br />

22 Jarno 17222<br />

2 1 /4 SS 17309<br />

2 1 /2 SS 17310<br />

3 SS 17311<br />

Bell Head Spring Loaded Live Centers<br />

TYPE II<br />

TYPE III<br />

TYPE IV<br />

TYPE V<br />

TYPE VI<br />

Taper Part No.<br />

2 MT 17122<br />

7 B&S 17427<br />

8 B&S 17428<br />

6 Jarno 17226<br />

7 Jarno 17227<br />

5/8 SS 17321<br />

3/4 SS 17322<br />

Taper Part No.<br />

3 MT 17123<br />

9 B&S 17429<br />

8 Jarno 17228<br />

9 Jarno 17229<br />

1 SS 17323<br />

1 1 /16 SS 17324<br />

1 1 /4 SS 17325<br />

Taper Part No.<br />

4 MT 17124<br />

10 B&S 17430<br />

11 B&S 17431<br />

10 Jarno 17230<br />

11 Jarno 17231<br />

12 Jarno 17232<br />

1 1 /2 SS 17326<br />

Taper Part No.<br />

5 MT 17125<br />

12 B&S 17432<br />

13 B&S 17433<br />

14 B&S 17434<br />

14 Jarno 17234<br />

16 Jarno 17236<br />

1 3 /4 SS 17327<br />

2 SS 17328<br />

Taper Part No.<br />

6 MT 17126<br />

15 B&S 17435<br />

16 B&S 17436<br />

20 Jarno 17240<br />

22 Jarno 17242<br />

2 1 /4 SS 17329<br />

2 1 /2 SS 17330<br />

3 SS 17331<br />

Interchangeable Bell Head Adapters<br />

Style 1 Style 2<br />

Style 3 Style 4<br />

Style 5 Female Head<br />

STYLE 1 STYLE 2 STYLE 3 STYLE 4 STYLE 5<br />

Center<br />

Type Part No. A B Part No. A B Part No. A B Part No. A B Part No. A B<br />

II 00231 0.25 1.31 00232 1.24 1.82 00233 1.75 2.33 00234 2.26 2.84 00235 0.13 0.76<br />

III 00331 0.35 1.83 00332 1.72 2.58 00333 2.46 3.32 00334 3.20 4.06 00335 0.19 1.12<br />

IV 00431 0.36 2.27 00432 2.17 3.25 00433 3.14 4.22 00434 4.11 5.19 00435 0.23 1.37<br />

V 00531 0.51 3.33 00532 3.21 4.80 00533 4.60 6.19 00534 6.06 7.65 00535 0.38 2.00<br />

VI 00631 0.68 5.12 (Contact factory for availability).<br />

26<br />

www.riten.com

®<br />

Light and Extra-Light<br />

Live Centers<br />

n Accuracy guaranteed to ± .00005.<br />

n Light live center designed for 2 to 10 lb. workpiece loads.<br />

n X-Light live center designed for extremely light<br />

workpiece loads – 2 oz. to 2 lb.<br />

n Excellent for very small workpieces. Used in medical,<br />

orthopedic, aerospace and similar applications.<br />

n Free turning.<br />

n Maximum 8,000 RPM.<br />

Extra-Light Live Center and<br />

quarter shown actual size<br />

E D B<br />

Maximum axial load: 500 lbs.<br />

A<br />

c<br />

LIGHT LIVE CENTER - MORSE TAPER<br />

Max W. P.<br />

Model Taper A B C D E RPM Weight<br />

40552 2 3/8 7/8 11/2 21/16 3/16 8000 10<br />

40553 3 3/8 7/8 11/2 21/16 3/16 8000 10<br />

40554 4 3/8 7/8 11/2 21/16 3/16 8000 10<br />

40555 5 3/8 7/8 11/2 21/16 3/16 8000 10<br />

N<br />

E D B<br />

Maximum axial load: 100 lbs.<br />

A<br />

C<br />

EXTRA-LIGHT LIVE CENTER - MORSE TAPER<br />

Max W. P.<br />

Model Taper A B C D E N RPM Weight<br />

40101 1 9/32 7/8 11/4 13/4 3/16 3/4 8000 2<br />

40102 2 9/32 7/8 11/4 13/4 3/16 3/4 8000 2<br />

40103 3 9/32 7/8 11/4 13/4 3/16 3/4 8000 2<br />

40104 4 9/32 7/8 11/4 13/4 3/16 3/4 8000 2<br />

27<br />

Call 1-800-338-0027

Self-Adjusting Live Centers<br />

Standard and Tracer Point<br />

n Accuracy guaranteed to ± .0001.<br />

n Bellville washers for automatic compensation for<br />

thermal expansion<br />

n Selectable axial clamping pressure range:<br />

light, medium or heavy.<br />

n<br />

n<br />

n<br />

n<br />

Four-point support for high axial and radial loads.<br />

Double labyrinth seal protects bearings from<br />

coolants and contaminants.<br />

Imported from Switzerland. Serviced and<br />

repaired in the U.S. by Riten.<br />

Replaces Sandvik, Madison and SFJ live centers<br />

Pressure Indicator<br />

Color coded rings visually indicate one of three ranges of axial clamping pressure: light, medium or<br />

heavy. Push the point back into the housing to select the corresponding color band, as follows:<br />

Low pressure for light workpieces<br />

and/or low stock removal<br />

Medium pressure for medium workpieces<br />

and/or medium stock removal<br />

High pressure for heavy workpieces<br />

and/or heavy stock removal<br />

A<br />

A<br />

C<br />

C<br />

D<br />

B<br />

D<br />

B<br />

STANDARD POINT - MORSE TAPER<br />

Max.<br />

Axial Max W. P.<br />

Model Taper A B C D Load RPM Weight<br />

17503 3 31/32 17/32 21/4 129/32 1150 4000 1600<br />

17504 4 13/8 121/32 23/4 213/32 2150 3000 2600<br />

17505 5 131/32 29/32 325/32 33/16 3000 2000 4300<br />

17506 6 23/4 31/8 51/32 43/32 5600 1000 7600<br />

TRACER POINT - MORSE TAPER<br />

Max.<br />

Axial Max W. P.<br />

Model Taper A B C D Load RPM Weight<br />

17513 3 15/32 121/32 21/4 129/32 1150 4000 1300<br />

17514 4 9/16 23/8 23/4 213/32 2150 3000 2100<br />

17515 5 19/32 315/32 325/32 33/16 3000 2000 3100<br />

17516 6 7/8 415/16 51/32 43/32 5600 1000 5300<br />

www.riten.com<br />

28

®<br />

Spline Rolling<br />

Live Centers<br />

n Accuracy guaranteed to ± .00025<br />

n Tapered and ball bearings.<br />

n Points are through-hardened to 61-63 Rc<br />

n Riten full service and repair<br />

• Ideal for tight-tolerance applications<br />

• Prompt deliveries on special points<br />

• Also available in heavy-duty design<br />

A C<br />

MORSE MORSE TAPER TAPER<br />

W. P.<br />

Model Taper A B C D E Weight<br />

46103 3 7/8 13/8 163/64 23/8 5/16 250<br />

46104 4 7/8 13/8 163/64 23/8 5/16 250<br />

E<br />

D<br />

B<br />

CENTER EXTRACTOR<br />

46993 3 MT<br />

46994 4 MT<br />

Spline Rolling Centers are special application centers. Their design includes<br />

heavy-duty taper roller and ball bearings. The heat-treated points extend the life of<br />

the center. Lubrication is sealed in and no additional lubricant is required. Prompt<br />

deliveries on special points including female, cupped, long point, or radius end<br />

from semi-finished inventories. The Spline Rolling Center is available in heavyduty<br />

design to meet difficult applications.<br />

29<br />

Call 1-800-338-0027

®<br />

Center Service Programs<br />

Riten Repair/Trade-In Program<br />

Upon receipt, Riten standard Live Centers will be<br />

rebuilt to “like new” condition at 40% of the cost<br />

of a new center. This is a total reconditioning,<br />

which includes new spindle, new front and rear<br />

bearings, new seal, and new lubricant. All rebuilt<br />

centers are restored to original accuracy and<br />

receive the same factory warranty as a new<br />

center. The average turnaround time is a speedy<br />

two weeks.<br />

If for any reason a Riten standard Live Center is<br />

determined to be beyond practical repair, a preferred<br />

customer trade-in allowance of 35% will<br />

be allowed toward the purchase of an equivalent<br />

new center.<br />

Riten repairs 97% of all centers received, ours<br />

and competitors’, and remanufactures them to<br />

manufacturers’ specifications. Unrepairable centers<br />

will earn a trade-in allowance of up to 35%<br />

on a new Riten center.<br />

Replace<br />

Grease Seal<br />

New Lubricant<br />

Replace Spindle<br />

Restore to Original Accuracy<br />

Replace Rear<br />

Bearing<br />

Replace Front Bearings<br />

Center Survey Program<br />

In response to a number<br />

of customer requests,<br />

Riten has developed an<br />

in-plant survey program<br />

that helps you gain control<br />

of live and dead center<br />

availability and cost.<br />

An authorized Riten representative,<br />

together with<br />

the distributor of your<br />

choice, conducts a complete<br />

inventory of all centers at your plant. The<br />

result is a written report listing all centers found at<br />

your location, their condition, standardization suggestions,<br />

identification of duplicates, and trade-in<br />

opportunities. This information is extremely valuable<br />

in making sure the right centers are on hand,<br />

streamlining your inventory, and cutting costs.<br />

This program is free to qualified customers. To<br />

request a center survey, call Riten Customer Service<br />

at 1-800-338-0027, or log on to www.riten.com.<br />

Samples of previous customer surveys can be provided<br />

on request.<br />

30<br />

www.riten.com

®<br />

Specials<br />

To order, fill in the dimensions you require and Fax to<br />

800-338-0717 or E-mail a copy to quotes@riten.com. You can<br />

also go to www.riten.com and “Design Your Own” center.<br />

Any dimension not supplied will be Riten factory standard.<br />

# TAPER<br />

Live Center Key<br />

A<br />

V<br />

C<br />

A - Point Diameter<br />

G - Point to Angle (Sprint)<br />

B - Point Length<br />

K - Gage Line to Point<br />

C - Head Diameter<br />

P - Overall Length<br />

D - Head Length<br />

V - Point Angle<br />

E - Gage Line to Back of Head<br />

F - Minimum Diameter (Bull Nose and Female)<br />

E<br />

P<br />

D<br />

K<br />

B<br />

# ______ TAPER A _______ B _______ C _______<br />

E ______ F _______ G _______ V _______<br />

RPM ______ Workpiece Weight ______ Thrust ________<br />

Dead Center Key<br />

A - Point Diameter F - Minimum Diameter K - Gage Line to Point V - Point Angle<br />

B - Taper Length (Bull Nose and Female) L - Length of Cut Out V2 - Secondary Angle<br />

C - Gage Line Diameter G - Female Major Diameter N - Point Length W - Flange Outside Diameter<br />

E - Gage Line to Back of Head H - Height Above Center Line P - Overall Length<br />

J - Flat Length<br />

T - Carbide Tip Diameter<br />

CNC TAILSTOCK DEAD CENTER<br />

# TAPER C<br />

A<br />

# TAPER<br />

FULL DEAD CENTER<br />

C<br />

A<br />

V<br />

V<br />

B<br />

N<br />

B<br />

K<br />

P<br />

P<br />

# ______ TAPER A _______ B _______ C ______<br />

N ______ P _______ V _______ T _______<br />

# ______ TAPER A _______ B _______ C ______<br />

K ______ P _______ V _______ T _______<br />

HALF DEAD CENTER<br />

FEMALE DEAD CENTER<br />

# TAPER<br />

C<br />

# TAPER<br />

C<br />

F<br />

G<br />

H L V<br />

A<br />

V<br />

B<br />

P<br />

B<br />

P<br />

K<br />

31<br />

# ______ TAPER B _______ C _______ H ______<br />

L ______ P _______ V _______ T _______<br />

Call 1-800-338-0027<br />

# ______ TAPER A _______ B _______ C ______<br />

F ______ G _______ K _______ P _______ V ______

V<br />

A<br />

V<br />

A<br />

®<br />

Specials (cont.)<br />

BULL NOSE DEAD CENTER<br />

J<br />

# TAPER<br />

C<br />

F<br />

PIPE NOSE DEAD CENTER<br />

J<br />

A<br />

C<br />

# TAPER<br />

V<br />

B<br />

E N<br />

P<br />

T ______<br />

# ______ TAPER A _______ B _______ C ______<br />

E _____ F ______ J______ N ______ P _____ V _____<br />

MILL TAPER DEAD CENTER<br />

# MILL TAPER<br />

A<br />

E<br />

B<br />

K<br />

P<br />

T ______<br />

# ______ TAPER A _______ B _______ C ______<br />

E ______ J _______ K _______ P _______ V ______<br />

MILL TAPER DEAD CENTER<br />

# MILL TAPER<br />

A<br />

V2<br />

V<br />

V2<br />

V<br />

# ______ TAPER<br />

J<br />

N<br />

# ______ TAPER<br />

J<br />

N<br />

A ______ J _______ N _______ V _______ V2 _____<br />

A ______ J _______ N _______ V _______ V2 _____<br />

V2<br />

B<br />

J<br />

P<br />

FLANGE CENTER<br />

___DIA. DRILL THRU<br />

___C.B.x___DEEP<br />

___B.C.___PLACES<br />

___THREAD<br />

___B.C.___PLACES<br />

INTERCHANGEABLE POINT DEAD CENTER & SPECIAL POINT<br />

# TAPER # TAPER<br />

C<br />

C<br />

G<br />

A<br />

V<br />

B K<br />

B<br />

P<br />

P<br />

W C<br />

F<br />

DEAD CENTER # _______ TAPER A _____<br />

B ______ C _______ G _______ K _______ P ______<br />

SPECIAL POINT # _______ TAPER<br />

A ______ B _______ C _______ F _______ J ______<br />

B ______ C _______ P _______ V _______<br />

P ______ V _______ V2 ______ W ______<br />

________<br />

DIAMETER DRILL THROUGH<br />

SLEEVE WITH TANG<br />

# O.D.TAPER<br />

SLEEVE<br />

# O.D.TAPER<br />

________ C. B. X _______ DEEP<br />

________ B. C. ________ PLACES<br />

________ THREAD ________ B. C. ________ PLACES<br />

# I.D.TAPER # I.D.TAPER<br />

FILL IN NUMBERS ON DIAGRAM<br />

www.riten.com<br />

32

®<br />

Engineered Products<br />

Live Chuck Mandrel<br />

For rolls with damaged center holes, a Riten Live Chuck Mandrel can be<br />

used to chuck the bearing journals of the part. A variety of custom mandrels<br />

can be manufactured to fit any application. A new or<br />

existing chuck can be mounted on the taper of your choice.<br />

• High precision: accuracy guaranteed to ± .0001<br />

• Designed for maximum rigidity<br />

• Compatible with all flat back chucks, 6” to 48”<br />

• Load capabilities to 100,000 lbs.<br />

• Long bearing life<br />

• Chuck selection by Riten or the customer<br />

Order<br />

Code<br />

Morse<br />

Taper<br />

Morse<br />

Taper<br />

Chuck Size<br />

Chuck Type<br />

23104 4<br />

23105 5<br />

23106 6<br />

23107 7<br />

4 6” 8” 10”<br />

5 8” 10” 12”<br />

6 10” 12” 16”<br />

7 12” 16” 18”<br />

3JS<br />

4JS<br />

6JS<br />

4JI<br />

3-Jaw Scroll<br />

4-Jaw Scroll<br />

6-Jaw Scroll<br />

4-Jaw Independent<br />

Example: a 5 Morse Taper Live Chuck Mandrel with a 10” 4-Jaw Independent<br />

chuck is part number 23105-10-4JI. Other chuck sizes and taper shanks<br />

available on request.<br />

Linear Compensating Live Center<br />

• Four interchangeable springs provide light, medium, heavy duty and<br />

extra heavy duty axial deflection pressures to compensate for thermal<br />

expansion and varying workpiece dimensions.<br />

• Reduced center inventory and significant reductions in set-up time.<br />

• Available in tapered and straight shanks, as well as a self-contained<br />

model (shown) that can be chucked for sub-spiindle applications.<br />

• Lockable spindle quickly transforms the unit into a carbide tipped<br />

dead center.<br />

• Handles workpieces from tens to thousands of pounds.<br />

33<br />

Call 1-800-338-0027

®<br />

Engineered Products (cont.)<br />

Replaceable Bell Head Live and Dead Centers<br />

Dead Center Mandrels<br />

• Heat treated for additional strength<br />

• Series 1 mandrels fit Series 1 bell heads<br />

• Series 2 mandrels fit Series 2 bell heads<br />

• Accuracy guaranteed to ± .0001 assembled<br />

Live Centers<br />

• Body and spindle heat treated for additional strength<br />

• Full length spindle for extra rigidity<br />

• Accuracy guaranteed to ± .0001 assembled<br />

• Riten full service and repair<br />

E<br />

BELL HEAD<br />

MANDREL<br />

BELL HEAD<br />

LIVE CENTER<br />

F<br />

A<br />

F<br />

A<br />

K<br />

N<br />

N<br />

DEAD CENTER MANDRELS - MORSE TAPER<br />

Model MT Threads E K Bell Head<br />

01104 4 – 0.50 2.19 Series 1<br />

01114 4 M35 x 1.5 0.75 2.44 Series 1<br />

01124* 4 M35 x 1.5 1.25 2.94 Series 1<br />

01105 5 – 0.50 2.19 Series 1<br />

01115 5 M45 x 1.5 0.75 2.44 Series 1<br />

01125* 5 M45 x 1.5 1.25 2.94 Series 1<br />

01106 6 – 0.50 2.63 Series 2<br />

01116 6 M55 x 2.0 0.75 2.88 Series 2<br />

LIVE CENTERS - MORSE TAPER<br />

Max. W. P.<br />

Model MT Weight Bell Head<br />

51404 4 1760 Series 1<br />

51405 5 3520 Series 1<br />

34405 5 6400 Series 2<br />

34406 6 11,200 Series 2<br />

Threaded mandrels include the extraction nut.<br />

* Special taper for Mazak machines<br />

BELL HEADS (Fit both live centers and mandrels)<br />

Model A F N Bell Head<br />

01375 3.75 2.12 1.69 Series 1<br />

01525 5.25 3.62 1.69 Series 1<br />

01675 6.75 5.12 1.69 Series 1<br />

01825 8.25 6.62 1.69 Series 1<br />

01975 9.75 8.12 1.69 Series 1<br />

BELL HEADS (Fit both live centers and mandrels)<br />

Model A F N Bell Head<br />

02055 5.50 3.33 2.13 Series 2<br />

02075 7.50 5.33 2.13 Series 2<br />

02095 9.50 7.33 2.13 Series 2<br />

02115 11.50 9.33 2.13 Series 2<br />

02135 13.50 11.33 2.13 Series 2<br />

All Bell Heads are heat treated for additional strength.<br />

34<br />

www.riten.com

®<br />

Engineered Products (cont.)<br />

Pipe Driver (Bore Driver)<br />

• Full turning or grinding without unchucking<br />

• Blades index in the event or scoring, doubling blade life<br />

• Replacement blades are interchangeable within .005”<br />

• Blades can be replaced or indexed without removing from machine<br />

• Retainer lugs and slot depth provide excellent stiffness and rigidity<br />

under extreme feeds and speeds<br />

• Torque limit on straight shanks prevents driver from slipping at<br />

breakaway/startup<br />

• Crowned angles and flats designed to minimize impressions in<br />

bevels<br />

• Material selection and heat treating are carefully monitored to<br />

maximize performance under demanding production conditions<br />

F<br />

A<br />

SQUARE<br />

CROWNED<br />

PIPE DRIVER<br />

No. of<br />

Model A F Blades<br />

PD045 4.50 1.50 3<br />

PD075 7.50 4.50 5<br />

PD105 10.50 7.50 7<br />

PD135 13.50 10.50 9<br />

Pipe Driver comes with two sets<br />

of square blades.<br />

Model<br />

BS100<br />

BC100<br />

BLADES<br />

Blade Style<br />

Square<br />

Crowned<br />

35<br />

Spider Mandrels (Live or Dead)<br />

• Precision incremental adjustments<br />

in thin wall bores<br />

• Rotational accuracy of mandrels<br />

is .0002”<br />

• Available with 3, 4, and 6<br />

adjustment lugs<br />

• Design of mandrel provides easy<br />

access to adjustment lugs<br />

• Optional materials available for<br />

special design lugs<br />

• Bull rings with extended lugs available<br />

to accommodate larger bores<br />

without changing the mandrel<br />

• Can be configured as a bull ring<br />

mandrel for qualified I.D.s<br />

Call 1-800-338-0027

® Engineered Products (cont.)<br />

Bull Ring Mandrel<br />

This versatile mandrel is one live center<br />

with interchangeable rings that can<br />

accommodate a wide variety of largediameter<br />

parts. Custom mandrels and<br />

rings can be manufactured to fit almost<br />

any application.<br />

• Ring accuracy assembled<br />

guaranteed to ± .0002<br />

• Rings from 10” to 60” in diameter<br />

• Available in all tapers<br />

• See page 34 for smaller units.<br />

Boring Mill Adapter<br />

With boring mill tooling transitioning from<br />

morse taper to more popular and readily<br />

available shank styles, Riten offers an<br />

engineered adapter assembly that provides<br />

faster and easier tool changeout<br />

than the conventional boring mill drawbar.<br />

• Designed for excellent stiffness and<br />

rigidity<br />

• Proven in demanding applications such<br />

as energy, mining and marine<br />

SPINDLE*<br />