KÃB2.3 MB - Viessmann

KÃB2.3 MB - Viessmann

KÃB2.3 MB - Viessmann

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Log boiler<br />

Pyromat ECO<br />

PYROMAT ECO<br />

The Pyromat ECO was developed specifically for the combustion of logs and represents<br />

state of the art combustion technology.<br />

Pyromat ECO log boiler<br />

The Pyromat ECO log boiler has already been<br />

proven in thousands of applications. Charging<br />

from the top offers easy handling; control via<br />

the Lambda probe guarantees low emissions,<br />

and the integral heat management system<br />

ensures maximum convenience.<br />

Clean and efficient combustion<br />

The microprocessor-controlled Ecotronic<br />

captures all details relevant for the operation<br />

and regulates the amount of heat and its<br />

demand. As a result, the boiler system is<br />

monitored constantly in all operating phases,<br />

from heat-up, operation under load, and<br />

from recharging right up to burnout, and it is<br />

held – via its motorised air dampers – within<br />

its optimum operating range. This safeguards<br />

clean and efficient combustion.<br />

Large hopper for combustion lasting<br />

several days<br />

The Pyromat ECO offers the greatest<br />

operating convenience when heating with<br />

logs thanks to its large charging chute. Log<br />

boilers in the output range 40 to 95 kW can<br />

operate with logs of 0.5 m length; in the range<br />

85 to 170 kW the hopper width increases to<br />

1080 mm, ensuring convenient charging, even<br />

with logs of 1 m length.<br />

With oil burner connection<br />

The Pyromat ECO is approved as an oil boiler<br />

compliant with EN standard; the necessary<br />

connections have already been prepared.<br />

Fitting an oil burner may, for example, help to<br />

bridge holiday times when manual charging<br />

with logs is not feasible.<br />

The Pyromat ECO is particularly suitable for<br />

the combustion of logs, wood briquettes and<br />

waste wood, either loose or in pieces.<br />

10<br />

11<br />

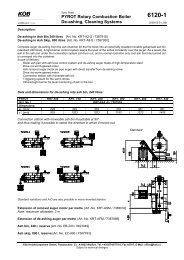

1<br />

Pyromat ECO<br />

2<br />

3<br />

4<br />

5<br />

6<br />

9<br />

7<br />

8<br />

1 Easily accessible charge door for charging<br />

the wood boiler from above<br />

2 Ecotronic control unit<br />

3 Hopper tapering downwards<br />

4 Degasification zone with cast grate and<br />

fireclay bed<br />

5 Large, easily accessible ash box for the<br />

grate ash<br />

6 Combustion chamber made from high<br />

temperature-resistant refractory concrete<br />

7 Ash container below the heat exchanger<br />

8 Induced draught fan with Lambda probe<br />

and temperature sensor<br />

9 Vertical tubular heat exchanger<br />

10 Upper cleaning cover<br />

11 Boiler assembly as part of the standard<br />

delivery (return temperature raising) with<br />

boiler circuit pump, boiler control valve,<br />

flow and return temperature sensor