Surge-Trap SPD Type 1 XT Installation Instructions - Mersen

Surge-Trap SPD Type 1 XT Installation Instructions - Mersen

Surge-Trap SPD Type 1 XT Installation Instructions - Mersen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSTALLATION INSTRUCTIONS<br />

<strong>Surge</strong>-<strong>Trap</strong> ® <strong>Type</strong> 1 <strong>XT</strong> Series <strong>SPD</strong><br />

The ST<strong>XT</strong> Series is a high quality, high energy surge<br />

suppressor designed to protect equipment from<br />

damaging transient overvoltages. The ST<strong>XT</strong> Series<br />

is parallel connected device intended for service<br />

entrance, panelboard or equipment specific protection.<br />

Proper installation is important for maximize product<br />

performance. These installation instructions do not<br />

replace national or local electrical codes requirements.<br />

WARNING – Risk of Electric Shock<br />

• Qualified licensed electricians should install or service<br />

all <strong>SPD</strong>s<br />

• <strong>SPD</strong>s should never be installed or serviced when<br />

energized or during electrical storms<br />

• Use appropriate safety precautions including Personal<br />

Protection Equipment<br />

• Failure to follow instructions can result in death, serious<br />

injury, and/or equipment damage<br />

• For outdoor applications, customer must seal conduit<br />

nipple using watertight fittings to ensure watertight<br />

connection<br />

• Read this manual in its entirety prior to installing<br />

Compliance:<br />

UL 1449 Third Edition and 2008/2011 NEC ® Article 285<br />

generated changes regarding <strong>SPD</strong>s installation. The STXP<br />

Series <strong>SPD</strong> fully complies with latest regulatory changes.<br />

There is new emphasis on installation location and are<br />

identified as <strong>Type</strong>s 1, 2, 3 or 4 locations, outlined below.<br />

<strong>Type</strong> 1:<br />

<strong>Type</strong> 2:<br />

<strong>Installation</strong> on the line side or load side of the<br />

service disconnect overcurrent device, and<br />

may be used in <strong>Type</strong> 2 or <strong>Type</strong> 4 installations.<br />

Examples: <strong>Surge</strong> arresters, lightning arrestors,<br />

meter hubs, metering cabinets, ran out of breaker<br />

positions, etc.<br />

Downstream of service disconnect; probably will<br />

connect via breaker. Examples: Switchboards,<br />

power panels, panelboards, equipment, motors,<br />

pumps, etc.<br />

The ST<strong>XT</strong> Series is a <strong>Type</strong> 1 <strong>SPD</strong> and suitable for use in<br />

all locations. <strong>Type</strong> 1 <strong>SPD</strong>s are evaluated more rigorously<br />

by UL for 2008/2011 NEC Article 285 compliance. <strong>Type</strong><br />

1 <strong>SPD</strong>s have been evaluated for line side applications<br />

without need for supplemental overcurrent protection. <strong>Type</strong><br />

1 <strong>SPD</strong>s include internal overcurrent protection. There are<br />

practical maintenance reasons for installing on load side<br />

of the main overcurrent device (i.e. <strong>Type</strong> 2 installation).<br />

When connected on load side of main disconnect, its<br />

recommend connecting a 50A - 30A circuit breaker to<br />

protect the recommended 8 AWG conductors. The circuit<br />

breaker serves as a disconnect switch and provides NEC<br />

imposed short circuit protection to the conductors in <strong>Type</strong> 2<br />

or 4 applications.<br />

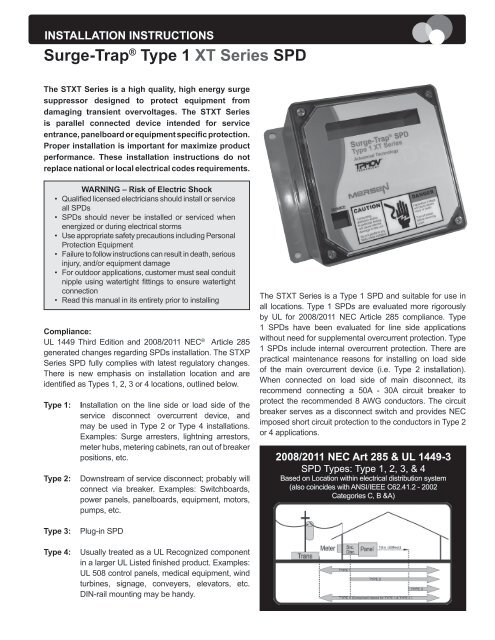

2008/2011 NEC Art 285 & UL 1449-3<br />

<strong>SPD</strong> <strong>Type</strong>s: <strong>Type</strong> 1, 2, 3, & 4<br />

Based on Location within electrical distribution system<br />

(also coincides with ANSI/IEEE C62.41.2 - 2002<br />

Categories C, B &A)<br />

<strong>Type</strong> 3:<br />

<strong>Type</strong> 4:<br />

Plug-in <strong>SPD</strong><br />

Usually treated as a UL Recognized component<br />

in a larger UL Listed finished product. Examples:<br />

UL 508 control panels, medical equipment, wind<br />

turbines, signage, conveyers, elevators, etc.<br />

DIN-rail mounting may be handy.

Specifications<br />

Temperature Operating<br />

Temperature Storage<br />

Wire Size & <strong>Installation</strong><br />

Torque<br />

Appropriate Circuit<br />

Breaker based on<br />

conductor size<br />

NEMA 250 Enclosure<br />

Rating<br />

-40 o C (-40 o F) to 60 o C<br />

(+140 o F)<br />

-55 o C (-67 o F) to 65 o C<br />

(+149 o F)<br />

8 AWG; 18 inch-pounds<br />

30A (<strong>SPD</strong> includes internal<br />

OCP)<br />

<strong>Type</strong> 4X with appropriate<br />

sealing<br />

Device Operation:<br />

<strong>SPD</strong>s sense overvoltage conditions and create a momentary<br />

short circuit to redirect harmful surge energy to earth ground,<br />

resetting automatically waiting for the next surge. Operation<br />

is similar to a pressure relief valve on a water heater: pressure<br />

builds, valve opens to relieve pressure, resets when pressure<br />

drops. <strong>SPD</strong>s are capable of repeating this function thousands<br />

of times before needing replacement.<br />

Voltage Rating & Application:<br />

Before installing your STXP, verify by nameplate voltage or<br />

model number that it has the same voltage rating as the<br />

power distribution system. DO NOT INSTALL ANY LOWER<br />

VOLTAGE RATED PRODUCT. See attached Data Sheet or<br />

call <strong>Mersen</strong> Technical Services at (978) 465-4853 for help.<br />

The system configuration is defined by the secondary<br />

windings of the transformer supplying the service entrance<br />

main or load. This includes whether or not the transformer<br />

windings are referenced to earth via a grounding conductor.<br />

The system configuration is not based on any specific load<br />

or equipment connection. <strong>SPD</strong>s should be installed per<br />

the distribution system, not per a load or motor’s wiring<br />

connection. For example: A 480V three phase motor<br />

appears to be connected in 480V Delta. In reality, the<br />

distribution system is configured as a 480Y/277V grounded<br />

Wye, with or without a neutral pulled to the motor or MCC.<br />

The system is a 480Y/277V Wye, even though the load<br />

is connected as a Delta. A grounded Wye has a defined<br />

reference to ground (i.e., neutral is bonded to ground). In<br />

contrast, some Delta systems are ungrounded, which have<br />

no reference to ground.<br />

WARNING <strong>SPD</strong>s on Ungrounded Systems:<br />

Caution – Ungrounded systems are inherently unstable<br />

and can produce excessively high line-to-ground voltages<br />

during certain fault conditions. During these fault conditions,<br />

any electrical equipment including <strong>SPD</strong>s, may be subjected<br />

to voltages which exceed their designed ratings. This<br />

information is being provided to the user so that an informed<br />

decision can be made before installing any electrical<br />

equipment on an ungrounded power system.<br />

ST<strong>XT</strong> Series <strong>SPD</strong>s have high a SCCR (short circuit<br />

current ratings) capacity including the lead conductors.<br />

Supplemental overcurrent protection is not required to<br />

protect your ST<strong>XT</strong> <strong>SPD</strong>. However, NEC ® convention<br />

requires that connecting conductors have overcurrent<br />

protection in <strong>Type</strong> 2 or 4 applications. Follow applicable<br />

codes. Your ST<strong>XT</strong> device features internal overcurrent and<br />

over-temperature protection that will disconnect effected<br />

surge suppression components at end of life. Power to the<br />

load is maintained but unprotected and the ST<strong>XT</strong> should<br />

be replaced as soon as possible. The ST<strong>XT</strong> <strong>SPD</strong> is factory<br />

sealed and contains no serviceable parts.<br />

Service Clearance:<br />

Service clearance is needed at the front of the <strong>XT</strong> Series<br />

unit only, 36 inches minimum is the required distance for<br />

clearance pursuant to the NEC.<br />

Cascade <strong>Surge</strong> Protection:<br />

For optimum surge protection, cascade or staged surge<br />

suppression should be implemented at the service entrance<br />

and downstream locations as appropriate. Known or<br />

expected surge sources, as well as sensitive loads, should<br />

also have localized surge suppression. For interconnected<br />

electronic loads (data cabling), <strong>SPD</strong>s should also be utilized<br />

to protect the devices on either end of the interconnecting<br />

data cables.<br />

System Grounding:<br />

Equipment grounding conductor must be used on all electrical<br />

circuits connected to the <strong>SPD</strong>. For best performance,<br />

use single point ground system where service entrance<br />

grounding electrode system is connected and bonded to all<br />

other available electrodes, building steel, metal water pipes,<br />

driven rods, etc. For sensitive electronics and computer<br />

systems, we recommend that the ground impedance<br />

measurement be as low as possible. When metallic raceway<br />

is used as an additional grounding conductor, an insulated<br />

grounding conductor should be run inside the raceway and<br />

sized per the NEC. Adequate electrical continuity must be<br />

maintained at all raceway connections. Do not use isolating<br />

bushings to interrupt a metallic raceway run.<br />

A separate isolated ground for the <strong>SPD</strong> is NOT<br />

recommended. Proper equipment connections to grounding<br />

system and ground grid continuity should be verified via<br />

inspections and testing on a regular basis as part of a<br />

comprehensive electrical maintenance program. On 4-Wire<br />

Power Systems, neutral to ground bonding (Main Bonding<br />

Jumper) must be installed per the NEC. Failure to do so<br />

WILL damage <strong>SPD</strong>s.<br />

2

INSTALLATION:<br />

Plan your installation and accomplish the following:<br />

• Meet all National and Local codes (NEC ® Article 285<br />

and UL 1449 address <strong>SPD</strong>s).<br />

• Confirm System voltage to <strong>SPD</strong> voltage (120V <strong>SPD</strong> will<br />

fail instantly on 240V, 277V, etc.).<br />

• Mount STXP as close to panel or equipment as possible,<br />

keeping leads as short as possible.<br />

• Ensure leads are as short and straight as possible,<br />

including neutral and ground. If using a breaker, use a<br />

breaker position closest to <strong>SPD</strong> and panel’s neutral &<br />

ground.<br />

• If using a breaker, recommended breaker size is 50A -<br />

30A due to recommended 8 AWG conductors.<br />

• Make sure system is grounded per NEC and clear of<br />

faults before energizing <strong>SPD</strong>.<br />

• Never Hi-Pot test any <strong>SPD</strong>. Product will fail prematurely.<br />

1. Use voltmeter to check voltages and ensure correct<br />

<strong>SPD</strong>. See Data Sheet for specs & wire-outs.<br />

2. Determine mounting method (See Figure 2) – weather<br />

resistant equipment may be required.<br />

3. If <strong>SPD</strong> has optional Dry Contact, pre-plan its installation.<br />

4. Remove power from panel/source. Confirm panel and<br />

all sources are de-energized.<br />

5. Identify breaker location and <strong>SPD</strong> location. Position<br />

<strong>SPD</strong> such that front panel is visible.<br />

6. Mount <strong>SPD</strong> – weather resistant applications require<br />

additional sealing, o-rings, etc. (not included).<br />

• Remove an appropriately sized knockout from panel.<br />

• Connect conductors as appropriate – short and<br />

straight as possible (Hi-Legs are Phase B).<br />

7. Label or mark conductors as appropriate (neutral:<br />

white, ground: green, energized: black, hi-leg: orange).<br />

8. Make sure system is bonded per NEC and is clear of<br />

hazards or faults before energizing (N-G bonding not<br />

per NEC will fail <strong>SPD</strong>s: #1 cause of <strong>SPD</strong> failures).<br />

9. Energize and confirm proper operation of green<br />

indicators and/or options.<br />

Connecting Optional Form C Dry Contact & Audible Alarm:<br />

Three (3) 3’ (~1m) 18 AWG wires are included through the<br />

nipple with this option. (These are smaller than the 10 AWG<br />

<strong>SPD</strong> conductors.) Gray is Common, Blue is Normally Open<br />

and Blue is Normally Closed. (We generally recommend<br />

the Normally Closed configuration because it detects<br />

disconnected or failed wiring whereas normally open does<br />

not.) If the dry contacts are not utilized, insulate lead ends,<br />

coil and secure. Audible alarm will still function correctly.<br />

The contact is rated 250V, 5A. Higher energy applications<br />

require supplemental relaying. This option monitors<br />

suppression element condition and is not intended for use<br />

as phase loss or phase detection monitoring.<br />

NORMAL OPERATION:<br />

Phase indicator LEDs (Green)<br />

Each ST<strong>XT</strong> phase is equipped with Green LED. Should loss<br />

of surge protection occur on each phase, the Green LED<br />

will extinguish and the Red Service LED will flash. Every<br />

suppression component is monitored. Note -Green LED’s<br />

will go out due to loss of power or severe under voltage.<br />

Service LED (Red) Flashes due to problem. Red Service<br />

LED is slaved to Green LEDs and will illuminate when any<br />

Green LED extinguishes.<br />

Audible Alarm Option<br />

If equipped with optional Dry Contact and Audible Alarm,<br />

these options are slaved via logic to the Green LEDs. In<br />

the event of a problem, the dry contacts will change state<br />

and the audible alarm will sound. The audible alarm may be<br />

silenced by de-energizing the <strong>SPD</strong>.<br />

Dry Contact Option<br />

One set of Form C dry contacts are included with the<br />

Dry Contact option. Dry Contacts change state during<br />

inoperative conditions, including loss of power. Any status<br />

change can be monitored elsewhere via Dry Contacts.<br />

Note – Dry contacts are rated at max 5A at 240V AC or DC.<br />

Figure 3<br />

Dry Contacts<br />

Figure 2<br />

Mounting & Dimensions<br />

3<br />

Remote Monitor Accessory Option<br />

Remote Monitor is available for remote annunciation.<br />

It requires a standalone 120V power source (wall plug<br />

transformer) and uses one set of Form C dry contacts.<br />

The Remote Monitor can be configured to monitor several<br />

<strong>Mersen</strong> <strong>SPD</strong>s simultaneously. <strong>Installation</strong> is detailed in a<br />

separate document. Contact factory as appropriate.

Figure 4<br />

Flush Mount “/FM”<br />

(Preferred <strong>Installation</strong>)<br />

Maintenance:<br />

<strong>SPD</strong>s require minimal maintenance. Periodic inspection of<br />

diagnostic indicator is suggested to ensure proper operation.<br />

Supplemental <strong>Instructions</strong> for<br />

Deep Wall Mounting (Walls over 4” thick)<br />

Using the Enclosed Mounting Feet<br />

Troubleshooting & Service:<br />

Please contact <strong>Mersen</strong> Technical Services for any service<br />

related issues.<br />

Figure 5<br />

Conduit <strong>Installation</strong><br />

CORRECT INSTALLATION<br />

Threaded 6 Full Turns<br />

INCORRECT INSTALLATIONS<br />

Step 1<br />

Prepare Wall and <strong>SPD</strong><br />

Step 2<br />

Insert into Wall<br />

POOR ENGAGEMENT<br />

Conduit needs to be<br />

threaded in farther<br />

OVERTIGHTENED<br />

Stresses box, ONLY<br />

6 full turns required<br />

Figure 6<br />

Typical Panel <strong>Installation</strong><br />

To Protected Loads<br />

Step 3<br />

Mount the <strong>SPD</strong><br />

Step 4<br />

Mount the Lid<br />

• Use closest breaker to<br />

<strong>SPD</strong><br />

• Locate <strong>SPD</strong> close<br />

to intended breaker<br />

• Keep Leads Short as<br />

Possible<br />

• Avoid Sharp Bends<br />

Wall Cutout<br />

Front View<br />

6 3/4”<br />

Tall<br />

• Rotate <strong>XT</strong><br />

such that LED<br />

indicator is<br />

most visible<br />

6 1/16”<br />

Wide<br />

• Outdoor installation<br />

requires appropriate<br />

weather sealing at<br />

nipple (o-ring, sealing<br />

condulet, etc.)<br />

4

Figure 7<br />

Electrical Drawings for Customer Connections<br />

SPLIT<br />

2 Hots, 1 Neu, 1 Grnd<br />

WYE<br />

3 Hots, 1 Neu, 1 Grnd<br />

Figure 5<br />

HI-LEG DELTA (B High)<br />

3 Hots, (B HIGH),<br />

1 Neu, 1 Grnd<br />

DELTA & HRG WYE<br />

3 Hots, 1 Grnd<br />

SINGLE POLE<br />

1 Hot, 1 Neu, 1 Grnd<br />

CORNER GROUND<br />

DELTA (B grounded)<br />

2 Hots, 1 Grnd<br />

5

European Authorized Representative:<br />

Obelis S.A.<br />

Boulevard Général Wahis, 53<br />

B-1030 Brussels<br />

Belgium<br />

Tel.: +32.2.732.59.54 · Fax: +32.2.732.60.02<br />

Email: mail@obelis.net<br />

© 2010 <strong>Mersen</strong> USA Newburyport-MA, L LC. All rights reserved.<br />

USA T 978 462 6662 F 978 462 0181 info.nby@mersen.com<br />

CANADA T 416 252 9371 F 416 252 6572 sales.tor@mersen.com<br />

www.us-ferrazshawmut.mersen.com<br />

#8294