MBBR ppt for Pulp&Paper, Sabesp, Oct 3, 2008 [Somente leitura]

MBBR ppt for Pulp&Paper, Sabesp, Oct 3, 2008 [Somente leitura]

MBBR ppt for Pulp&Paper, Sabesp, Oct 3, 2008 [Somente leitura]

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

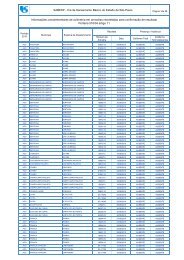

Worldwide Pulp and <strong>Paper</strong> Production<br />

PRODUCTION<br />

182 million ton pulp per year<br />

330 million ton paper per year<br />

WASTEWATER TO TREATMENT<br />

About 30-35 billion m3 wastewater generated per<br />

year<br />

About 25-30 million ton COD generated per year

Overview subindustries<br />

Kraft pulp<br />

Sulphite pulp<br />

Recycled pulp&paper<br />

Integrated pulp&paper<br />

Tissue<br />

Board<br />

Specialty paper<br />

Newsprint<br />

Plywood etc

Pulping and <strong>Paper</strong> Mills<br />

Market pulp mills<br />

Raw material<br />

Pulp Pulp<br />

production<br />

Pulp to free market or<br />

To own paper mills<br />

Integrated mills<br />

Raw material<br />

Pulp Pulp<br />

production<br />

<strong>Paper</strong><br />

production<br />

Non-integrated paper mills<br />

Raw material<br />

Pulp<br />

Deinking<br />

<strong>Paper</strong><br />

production<br />

Pulp

Typical characteristics<br />

Biodegradability<br />

from 50 % to > 95 %<br />

Concentrations of COD<br />

from 100 mg/l to 50 000<br />

mg/l<br />

Concentrations of SS<br />

from 0 mg/l to > 5 000 mg/<br />

Temperature<br />

from 20 °C to 90°C<br />

pH<br />

From 2 to 10<br />

Low concentrations of<br />

nutrients

Bleached Kraft Pulping<br />

Process<br />

COD<br />

kg/t pulp<br />

Debarking 0 - 10<br />

Brownstock area 0 - 7<br />

Bleach plant 25 - 55<br />

Evaporation condensates 3 - 15<br />

Spills 3 - 8<br />

Total 31 - 95

Mechanical Pulping Discharges<br />

Process COD BOD<br />

kg/Adt kg/Adt<br />

SGW 30-40 10-12<br />

PGW 40-50 12-16<br />

TMP 50-80 15-25<br />

CTMP 60-100 20-35<br />

BCTMP (H2O2) 80-140 30-50

Wastewater characteristics<br />

Important parameters<br />

BOD<br />

COD<br />

TOC<br />

TSS<br />

pH<br />

Temperature<br />

Nutrients<br />

Specific compounds (EDTA,<br />

chlorate, resins, etc)<br />

Other (calcium, etc)

<strong>MBBR</strong>

The Natrix TM <strong>MBBR</strong> process

The BAS TM biological process

ADVANTAGES OF BAS PROCESS<br />

Ecellent settling properties 50-80 ml/g<br />

( conventional plants 100 – 250)<br />

No pulking problems, no filament bacteria<br />

Very stable process under big loading<br />

variations<br />

Low biosludge production 0,12 kg/ kg COD<br />

red. ( Conventional 0, 25 kg/ kg COD red)<br />

Small foot print,volume 50% of conventional<br />

Low energy consumption / high basins<br />

Easy to upgrage existing plants

Sedimentation after 180 Seconds<br />

BAS<br />

CONVENTIONAL

The LagoonGuardprocess

Reference projects, selected<br />

Kraft pulp<br />

Södra Cell, Värö mill, Sweden<br />

Zellstoff Stendal, Germany<br />

CMPC Santa Fe, Chile<br />

Suzano Bahia Sul, Brazil<br />

Arkhangelsk Pulp and <strong>Paper</strong>,<br />

Russia<br />

TMP and newsprint<br />

Stora Enso Hylte, Sweden<br />

Stora Enso Kvarnsveden, Sweden<br />

Stora Enso Anjala, Finland<br />

Norske Skog Boyer, Australia

Reference projects<br />

CTMP<br />

Quesnel River Pulp, Canada<br />

Waggeryd Cell, Sweden<br />

Plywood and MDF board<br />

UPM Schauman, Finland<br />

UPM Chudovo, Russia<br />

Norbord, Scotland<br />

Tissue<br />

SCA Edet mill, Sweden<br />

Metsä Tissue Katrine<strong>for</strong>s, Sweden<br />

Metsä Tissue Nyboholm, Sweden

Reference projects<br />

Sulphite pulp and paper<br />

Nordic <strong>Paper</strong>, Sweden<br />

AO Kondopoga, Russia<br />

Fine <strong>Paper</strong><br />

Fraser <strong>Paper</strong>, USA<br />

Arjowiggins Charavines, France<br />

Munkedal, Sweden<br />

Recycled pulp &paper<br />

Asia kraft, Thailand<br />

United <strong>Paper</strong> Board, Malaysia<br />

Greenfield, France

Suzano Papel e Celulose, Mucuri Mill, BA

![MBBR ppt for Pulp&Paper, Sabesp, Oct 3, 2008 [Somente leitura]](https://img.yumpu.com/34976291/1/500x640/mbbr-ppt-for-pulpamppaper-sabesp-oct-3-2008-somente-leitura.jpg)