Formwork, Shoring and Scaffolding Issue 1 - PERI Formwork ...

Formwork, Shoring and Scaffolding Issue 1 - PERI Formwork ...

Formwork, Shoring and Scaffolding Issue 1 - PERI Formwork ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

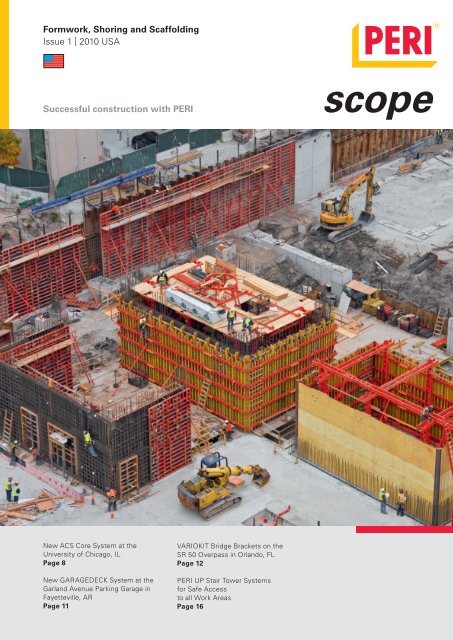

<strong>Formwork</strong>, <strong>Shoring</strong> <strong>and</strong> <strong>Scaffolding</strong><br />

<strong>Issue</strong> 1 | 2010 USA<br />

Successful construction with <strong>PERI</strong> scope<br />

New ACS Core System at the<br />

University of Chicago, IL<br />

Page 8<br />

New GARAGEDECK System at the<br />

Garl<strong>and</strong> Avenue Parking Garage in<br />

Fayetteville, AR<br />

Page 11<br />

VARIOKIT Bridge Brackets on the<br />

SR 50 Overpass in Orl<strong>and</strong>o, FL<br />

Page 12<br />

<strong>PERI</strong> UP Stair Tower Systems<br />

for Safe Access<br />

to all Work Areas<br />

Page 16

2<br />

To Our Valued Clients <strong>and</strong><br />

Prospective Clients<br />

In today’s difficult market our clients<br />

are faced with increased competition<br />

<strong>and</strong> price pressure which require<br />

the most cost effective formwork<br />

<strong>and</strong> shoring solutions to satisfy their<br />

needs. <strong>PERI</strong> continues to invest in<br />

new system technologies to improve<br />

the efficiency of concrete construction.<br />

In this edition of <strong>PERI</strong> scope we<br />

profile thirteen current projects<br />

that illustrate <strong>PERI</strong>’s wide range of<br />

form work, shoring <strong>and</strong> scaffolding<br />

systems including the new<br />

ACS Core, GARAGEDECK <strong>and</strong><br />

VARIOKIT systems.<br />

ACS Core is latest addition to <strong>PERI</strong>’s<br />

proven Automatic Climbing System<br />

that is the world’s most widely used<br />

selfclimbing system for high <br />

rise buildings <strong>and</strong> bridge pylons.<br />

ACS Core consists of 100% rentable<br />

components <strong>and</strong> has the capability<br />

to selfclimb a placing boom without<br />

the need for an additional wall<br />

bracket.<br />

GARAGEDECK is an extension to<br />

<strong>PERI</strong>’s existing MULTIFLEX shoring<br />

system for the construction of<br />

beam <strong>and</strong> slab posttensioned<br />

parking garages. GARAGEDECK’s<br />

100% rentable components are<br />

preassembled at a <strong>PERI</strong> warehouse<br />

<strong>and</strong> delivered to the jobsite ready<br />

to be used.<br />

VARIOKIT employs st<strong>and</strong>ard rentable<br />

components to economically<br />

construct a wide range of load<br />

bearing structures for bridge, tunnel<br />

<strong>and</strong> other civil construction thus<br />

eliminating the expense of custom<br />

falsework.<br />

At <strong>PERI</strong> we constantly strive to offer<br />

the best technical solutions, logistics<br />

service <strong>and</strong> jobsite support. We truly<br />

value your business <strong>and</strong> look forward<br />

to working with you in 2010.<br />

Thomas Ameel, P.E.<br />

Chief Executive Officer<br />

<strong>PERI</strong> USA<br />

<strong>PERI</strong> VARIO for the Construction of<br />

Complex Walls<br />

Linville L<strong>and</strong> Harbor Dam, Pineola, North Carolina<br />

VARIO formwork panels with adjustable braces erected for<br />

the tight corner of the labyrinth wall.<br />

VARIO formwork <strong>and</strong> CB platforms were<br />

selected to form the labyrinth battered walls at<br />

the Linville L<strong>and</strong> Harbor Dam in Pineola, NC.<br />

The walls are 19’ in height <strong>and</strong> taper from 3’1”<br />

wide at the base to 1’6” at the top. With the<br />

specifics of <strong>PERI</strong>’s design the contractor saves<br />

cost by maximizing the number of pours using<br />

the same VARIO panel.<br />

For the labyrinth battered walls<br />

custom VARIO formwork panels with<br />

CB platforms were designed for<br />

efficiency <strong>and</strong> safety.<br />

Contractor<br />

Wayne Brothers, Kannapolis, NC<br />

Field Service<br />

<strong>PERI</strong> Orl<strong>and</strong>o, FL<br />

Isaiah Wayne,<br />

Project Manager (left)<br />

<strong>and</strong> Cecilio Gonzalez,<br />

Superintendent:<br />

“The design of the adjustable<br />

VARIO wall formwork system<br />

minimizes custom equipment<br />

<strong>and</strong> therefore reduces our<br />

overall construction cost. We<br />

like the safety of the CB platforms<br />

for our workers.”

Innovative RCS <strong>and</strong> ACS Systems<br />

Significantly Increase Safety <strong>and</strong> Productivity<br />

Fifteen Twenty-One 2 nd Avenue, Seattle, Washington<br />

Overlooking the waterfront <strong>and</strong> Pike<br />

Place Market, Fifteen Twenty-One<br />

2nd enclosed with RCS climbing protection<br />

panels, providing shelter from the<br />

Avenue is the tallest residential weather as well as unsurpassed fall<br />

high-rise building in downtown Seattle. protection. The VARIO core wall form-<br />

With a height of 400’ it will consist work is self-climbed using a combina-<br />

of 38 floors, including one retail <strong>and</strong> tion of ACS <strong>and</strong> RCS to free up crane<br />

nine parking levels, with 143 luxury time <strong>and</strong> to facilitate the installation of<br />

condominiums. The full perimeter of the reinforcing steel to achieve the one<br />

the uppermost floors is completely week typical floor schedule.<br />

Chris McCorkle,<br />

Project Manager:<br />

“With safety in mind, we decided<br />

to use these systems for the first<br />

The VARIO formwork for the core wall is sup- time. The panels keep our workers<br />

ported <strong>and</strong> raised by an ACS P internal platform<br />

<strong>and</strong> RCS climbing strongbacks offering unobstructed<br />

over wall access for rebar installation.<br />

safe <strong>and</strong> keep any building material<br />

from flying off the building. With<br />

the extreme winds we get in Seattle<br />

coming right off the lake, this system<br />

Contractor<br />

is amazing <strong>and</strong> we are very pleased<br />

SAK Construction, LLC,<br />

Puyallup, WA<br />

Field Service<br />

<strong>PERI</strong> Woodl<strong>and</strong>, WA <strong>and</strong><br />

<strong>PERI</strong> Weissenhorn, Germany<br />

with the higher productivity <strong>and</strong> cost<br />

savings.”<br />

10’-6’’<br />

RCS climbing protection panels enclose<br />

the top three floors providing a work<br />

environment with unparalleled safety which<br />

results in increased productivity.<br />

Outrigger platforms were added to the RCS<br />

protection panels allowing the contractor<br />

to easily move material from floor to floor.<br />

CB crane-climbing platforms in use to support<br />

the VARIO formwork for the core walls from the<br />

foundation through the parking levels.<br />

3

4<br />

BEAMDECK <strong>and</strong> UNIPORTAL Tables<br />

Quickly <strong>and</strong> Safely Form Flat Slabs<br />

University of Arizona, Tucson, Arizona<br />

For the construction of eight new six<br />

story dormitories at the University of<br />

Arizona, <strong>PERI</strong> provided a combination<br />

of BEAMDECK <strong>and</strong> UNIPORTAL<br />

shoring systems for the bowtie<br />

shaped 8’ flat slab structures.<br />

To achieve a three-day cycle for each<br />

6,000 ft² pour, the perimeter of the<br />

11’ high decks are formed using the<br />

Contractor<br />

Concrete Structures Inc., Peoria, AZ<br />

Field Service<br />

<strong>PERI</strong> Casa Gr<strong>and</strong>e, AZ<br />

UNIPORTAL tables while the interior<br />

of the slabs are formed with the<br />

BEAMDECK grid beam system.<br />

This combination of shoring systems<br />

provides Concrete Structures with high<br />

productivity <strong>and</strong> excellent perimeter<br />

safety <strong>and</strong> eliminates almost all<br />

filler areas. Both systems allow the<br />

contractor to use their choice of<br />

A 1/8” chamfer board under the barn-wood<br />

look form liner was used to line TRIO panels to<br />

achieve the architectural finish of the walls.<br />

BEAMDECK’s lightweight components<br />

<strong>and</strong> systematic assembly make it very easy <strong>and</strong><br />

efficient to erect.<br />

A three-day pour cycle is achieved using the<br />

combination of UNIPORTAL perimeter tables<br />

<strong>and</strong> BEAMDECK shoring.<br />

Mark Murphy,<br />

Senior Project Manager (left)<br />

<strong>and</strong> Adam Arenivas, Superintendent:<br />

“The flexibility of the <strong>PERI</strong> BEAM-<br />

DECK system allows us to efficiently<br />

accommodate the intricate floor plate<br />

<strong>and</strong> the UNIPORTAL tables provide<br />

excellent perimeter safety.”<br />

plywood to achieve a nice finish of the<br />

exposed ceilings.<br />

St<strong>and</strong>ard TRIO wall formwork was<br />

lined with a 1/8” chamfer board under<br />

the form liner to achieve the unique<br />

architectural barn-wood finish of the<br />

walls. KGF 240 climbing scaffolds<br />

provide a safe working platform for the<br />

multi-lift walls.<br />

For the lower levels of the exposed walls of<br />

the dormitories, a barn-wood look was achieved<br />

using st<strong>and</strong>ard TRIO panels with a form liner.

RUNDFLEX Offers Optimal Solution<br />

for Circular Structures<br />

Spokane Regional WWTP, Spokane, Washington<br />

The new Spokane Regional WWTP<br />

started construction in September<br />

2009 <strong>and</strong> consists of nine buildings to<br />

be completed in only six months.<br />

Garco Construction selected an array<br />

Versatile TRIO for Quick <strong>and</strong> Efficient<br />

Adjustment to Any Wall Configuration<br />

Calumet Water Reclamation Plant, Calumet Park, Illinois<br />

The Calumet Water Reclamation Plant<br />

is an expansion to the existing facility<br />

south of Chicago with new primary<br />

tanks, tunnels, chambers, conduits <strong>and</strong><br />

other structures.<br />

Over 35,000 ft² of TRIO wall formwork<br />

was supplied to this project in which<br />

the structural walls vary in height,<br />

thickness <strong>and</strong> plan view configuration.<br />

TRIO was the logical choice to provide<br />

the contractor the versatility <strong>and</strong> adjustability<br />

to meet their wall formwork<br />

requirements. For the construction of<br />

the cantilevered slabs, MULTIFLEX<br />

was selected <strong>and</strong> supplied with<br />

aluminum MULTIPROP shores to<br />

accommodate the variety of shoring<br />

heights.<br />

Contractor<br />

F.H. Paschen, SN Neilsen & Associates, LLC,<br />

Chicago, IL<br />

Field Service<br />

<strong>PERI</strong> Chicago, IL<br />

of <strong>PERI</strong> systems to meet this dem<strong>and</strong>ing<br />

schedule. For the anaerobic digester<br />

tanks which have a 38‘ diameter,<br />

RUNDFLEX is used to form the 66‘-6“<br />

tall walls in two lifts.<br />

Gary Darrah,<br />

Concrete Superintendent:<br />

“We are very satisfied with the TRIO<br />

<strong>and</strong> MULTIFLEX systems because of<br />

the highly interchangeable components<br />

on this very complicated project.”<br />

Karl Hoyt, Superintendent:<br />

“We are very pleased with the<br />

flawless performance of the formwork<br />

<strong>and</strong> <strong>PERI</strong> systems are the best we have<br />

ever used. We look forward to working<br />

with <strong>PERI</strong> in the future.”<br />

The anaerobic digester tanks with 38‘diameter, 66’-6”<br />

tall walls formed with RUNDFLEX.<br />

Contractor<br />

Garco Construction, Spokane, WA<br />

Field Service<br />

<strong>PERI</strong> Woodl<strong>and</strong>, WA<br />

5

6<br />

Cost-Effective Solution with Unique<br />

Configuration of SKYTABLEs<br />

Centene Plaza, Clayton, Missouri<br />

A slab table is pulled out of the building balanced<br />

by a lifting mechanism allowing the table to<br />

remain in a horizontal position at all times.<br />

Jeff Gebel,<br />

Superintendent:<br />

“<strong>PERI</strong> offers us timely service by<br />

meeting all of our schedule dem<strong>and</strong>s.<br />

This is the reason we chose the<br />

innovative SKYTABLE truss system,<br />

which allows us faster cycles while<br />

increasing safety.”<br />

Centene Plaza is a 17 story office<br />

tower located near St. Louis in Clayton,<br />

Missouri.<br />

53 <strong>PERI</strong> SKYTABLEs flying truss tables<br />

are used to construct a typical 28,000 ft²<br />

floor. The challenge was to find an<br />

efficient way to form the structure’s<br />

beam <strong>and</strong> slab decks using an efficient<br />

large format table form. The solution<br />

was to attach the 16” high slab<br />

box-outs to the SKYTABLEs so that<br />

the entire shoring system moved intact.<br />

This allows Concrete Strategies to<br />

achieve a seven day cycle with the floor<br />

cast in two pours. Because the local<br />

building code restricts equipment from<br />

being flown above the streets, many<br />

of the tables are rolled across the floor<br />

to be lifted from the opposite side of<br />

the building to the next level.<br />

The unique configuration of SKYTABLEs is used<br />

for the fast construction of the beam <strong>and</strong> slab<br />

decks with slab box-outs built into the tables.<br />

SKYTABLE trusses are quickly moved <strong>and</strong><br />

reset to form a large area of the slab.<br />

Contractor<br />

Concrete Strategies, St. Louis, MO<br />

Field Service<br />

<strong>PERI</strong> Indianapolis, IN<br />

The unique solution of the beam-<strong>and</strong>-box slab<br />

flying tables allows extremely fast forming of the<br />

decks.

Tremendous Time Savings<br />

through Quick SKYTABLE Installation<br />

Mirabella, Portl<strong>and</strong>, Oregon<br />

Mike Graver, Foreman:<br />

“The SKYTABLEs save us a tremendous<br />

amount of time because we can<br />

install them much faster, only taking<br />

9 minutes compared to the other conventional<br />

slab tables which average<br />

20 to 25 minutes to lift <strong>and</strong> install.”<br />

Ten ACS G units are used to self-climb the<br />

VARIO wall formwork for the large core.<br />

Mirabella Continuing Care Retirement<br />

Community is located at Portl<strong>and</strong>‘s<br />

South Waterfront <strong>and</strong> will offer<br />

30 floors of senior living apartments<br />

with spectacular views of Mt. Hood, the<br />

West Hills, the Willamette River <strong>and</strong> the<br />

Portl<strong>and</strong> skyline.<br />

<strong>PERI</strong> is supplying the full scope of formwork<br />

for this project. The 11’ tall core<br />

walls are formed with VARIO that is<br />

self-climbed using ten ACS G units. This<br />

configuration allows for the slabs <strong>and</strong><br />

walls to be cast monolithically saving a<br />

day in the con struction cycle.<br />

SKYDECK is the perfect solution for the slab<br />

areas that cannot be formed with SKYTABLEs.<br />

29 SKYTABLEs that range between<br />

20‘ x 12‘ <strong>and</strong> 44‘ x 10‘ are used to<br />

form the 15,000 ft² of 7 ½“ slabs for<br />

the typical floor. The slab tables are<br />

each stripped <strong>and</strong> reset in only nine<br />

minutes which allows Hoffman to<br />

achieve a seven day pour cycle.<br />

Contractor<br />

Hoffman Construction & Hoffman Structures,<br />

Portl<strong>and</strong>, OR<br />

Field Service<br />

<strong>PERI</strong> Woodl<strong>and</strong>, WA<br />

29 SKYTABLEs covering 15,000 ft² are stripped<br />

<strong>and</strong> re-set in less than one day.<br />

7

8<br />

Revolutionary New ACS Core System<br />

for Crane-Independent Climbing<br />

University of Chicago — New Hospital Pavilion, Chicago, Illinois<br />

Seamless integration of the ACS 100 climbing<br />

system with an hydraulic climbing mechanism.<br />

A New Hospital Pavilion is currently<br />

under construction at the University of<br />

Chicago <strong>and</strong> will focus on adult programs<br />

in cancer, GI, neuroscience, advanced<br />

surgery <strong>and</strong> high-tech imaging.<br />

McHugh Construction selected <strong>PERI</strong><br />

to provide a wide range of wall forming<br />

systems for this project.<br />

A total of nearly 30,000 ft² of DOMINO,<br />

TRIO <strong>and</strong> VARIO is in use on this jobsite.<br />

TRIO is being used for the foundation<br />

walls. The three lift stair cores also<br />

employ TRIO which is supported with<br />

CB 240 climbing platforms.<br />

Contractor<br />

James McHugh Construction Co.,<br />

Chicago, IL<br />

Field Service<br />

<strong>PERI</strong> Chicago, IL <strong>and</strong><br />

<strong>PERI</strong> Weissenhorn, Germany<br />

Paul Treacy,<br />

Concrete Superintendent:<br />

“I am very satisfied with the<br />

engineering <strong>and</strong> also the convenience<br />

of having a full-time<br />

site supervisor help with the<br />

assembly. The new ACS Core<br />

system performs well <strong>and</strong><br />

meets my expectations.”<br />

<strong>PERI</strong> Stair Towers are also being used on<br />

this project to give workers easy access to<br />

this jobsite (information on the <strong>PERI</strong> UP Stair<br />

tower is available on page 16).<br />

The ACS working brackets support the loads on<br />

the platform while pouring the concrete.<br />

The four elevator cores are formed<br />

with VARIO which is hydraulically selfclimbed<br />

with the new ACS Core system.<br />

The four elevator cores are formed<br />

with VARIO which is hydraulically selfclimbed<br />

with the new ACS Core system<br />

in combination with the well proven<br />

variants ACS R <strong>and</strong> ACS G. The system<br />

allows McHugh to climb the formwork<br />

without the use of a crane from the very<br />

first full height lift. This feature was critical<br />

on this project because of the tight<br />

schedule <strong>and</strong> limited crane time allotted<br />

to the concrete operations.<br />

1’-2’’ 25’- 6”<br />

1’-2’’<br />

The ACS Core system<br />

in combination<br />

with the ACS R.<br />

18’<br />

The climbing brackets support the platform during<br />

the climbing process.<br />

<strong>PERI</strong> outfitted each core with a proprietary<br />

concrete distributor to be able to<br />

pump the core walls without the use of<br />

a placing boom or spider.

ACS G is the optimal fit for the small spaces<br />

between the two cores.<br />

VARIO <strong>and</strong> TRIO are used to form the elevator<br />

<strong>and</strong> stair core walls.<br />

The new ACS Core was developed<br />

specifically for concrete cores of<br />

buildings. This addition to the proven<br />

ACS self climbing system consists<br />

almost entirely of rentable items.<br />

Optimized Climbing Sequence<br />

During the crane independent stripping<br />

procedure, the new VARIO<br />

inside corner is simply released.<br />

Retracting the inside wall forms is no<br />

longer necessary.<br />

Immediately after releasing the corners,<br />

the platform system is hydraulically<br />

raised. This leads to significant<br />

time savings in the construction<br />

cycle.<br />

Climbing during any kind of<br />

weather<br />

The <strong>PERI</strong> ACS system can be<br />

climbed during just about any<br />

weather. Therefore, delays in the<br />

construction cycle can be minimized.<br />

ACS platforms can also be enclosed,<br />

which protects the workers <strong>and</strong><br />

results in working conditions like they<br />

are on the ground level.<br />

High capacity <strong>and</strong> safety<br />

The extremely reliable <strong>and</strong> robust<br />

ACS 100 self climbing jacks are being<br />

used to climb the ACS platforms as<br />

well as a placing boom, if required.<br />

The integrated flow dividing technology<br />

ensures the synchronized<br />

extension of all cylinders <strong>and</strong> makes<br />

climbing easy.<br />

Flexibility<br />

The system is three dimensionally<br />

adaptable through the integrated<br />

125 mm raster. This allows the utilization<br />

of almost all rentable components.<br />

9

10<br />

BEAMDECK <strong>and</strong> UNIPORTAL Table Forms<br />

for Efficient <strong>and</strong> Fast Construction Cycle<br />

Valley View Casino, San Diego, California<br />

MULTIPROPs are used for the shoring of the<br />

BEAMDECK system on the interior of the slabs.<br />

For the triangular core, VARIO formwork is used<br />

to achieve the required architectural finish <strong>and</strong><br />

CB 240 climbing scaffolds provide safe working<br />

platforms.<br />

The Valley View Casino located outside<br />

of San Diego is adding a twelve story<br />

hotel to the existing casino. The slabs<br />

are formed safely <strong>and</strong> efficiently using<br />

a combination of UNIPORTAL tables<br />

for the perimeter <strong>and</strong> BEAMDECK<br />

on the interior. It takes only eight<br />

minutes to strip, lift <strong>and</strong> re-set each<br />

of the UNIPORTAL slab tables, saving<br />

the contractor an enormous amount of<br />

time. A five-man crew can strip, set <strong>and</strong><br />

lay the plywood to complete the slab<br />

formwork in only three days.<br />

Contractor<br />

Morley Construction Company, San Diego, CA<br />

Field Service<br />

<strong>PERI</strong> Irvine, CA<br />

BEAMDECK <strong>and</strong> UNIPORTAL tables are used for<br />

the forming of the slabs with unsurpassed safety<br />

<strong>and</strong> efficiency.<br />

Bill Gates, Superintendent (right)<br />

<strong>and</strong> Jamie Equiza, Foreman:<br />

“The simplicity <strong>and</strong> efficiency of the<br />

UNIPORTAL <strong>and</strong> BEAMDECK slab<br />

systems allows us to beat our<br />

contract schedule while maintaining<br />

lower labor costs <strong>and</strong> providing<br />

our clients a high quality concrete<br />

product.”

New GARAGEDECK System<br />

for Beam <strong>and</strong> Slab Parking Garages<br />

Garl<strong>and</strong> Avenue Parking Garage, Fayetteville, Arkansas<br />

The 444,000 ft² Garl<strong>and</strong> Avenue Parking<br />

Garage is located at the University of<br />

Arkansas in Fayetteville <strong>and</strong> provides<br />

1,516 parking spaces <strong>and</strong> retail space<br />

on the ground level.<br />

Harcon Forming selected <strong>PERI</strong>’s new<br />

GARAGEDECK system for this beam<br />

<strong>and</strong> slab post-tensioned parking structure.<br />

GARAGEDECK uses all st<strong>and</strong>ard<br />

rentable components <strong>and</strong> the units are<br />

Two 30’ GARAGEDECK beam tables support the<br />

slab tables spanning 18’ which reduces shores<br />

<strong>and</strong> opens up the working area for the contractor.<br />

The beam table is lowered onto a trolley to be<br />

moved to the next pour.<br />

assembled into beam tables <strong>and</strong> slab<br />

tables to be reused from pour to pour.<br />

Two 30’ long beam tables form the<br />

14” x 36” x 60’ PT beams. The 8’ x 18’<br />

slab tables span from MPB 24<br />

stringers on adjacent beam tables. This<br />

eliminates the need for stringers <strong>and</strong><br />

shores at the middle of the bays.<br />

The entire load of a typical 20’ x 60’<br />

bay is carried by 16 MULTIPROP<br />

Contractor<br />

Harcon Forming, Inc., Atlanta, GA<br />

Field Service<br />

<strong>PERI</strong> Atlanta, GA<br />

shores on each beam table. A trolley or<br />

forklift supports the beam table as the<br />

MULTIPROPs are hinged up so that the<br />

unit can be stripped <strong>and</strong> moved intact.<br />

After the beam tables are repositioned,<br />

the eight slab tables in a typical bay are<br />

stripped. Approximately 4,000 ft² of<br />

formwork is stripped, moved <strong>and</strong> reset<br />

each day using a small crew. Harcon has<br />

achieved a four day pour cycle.<br />

David Showalter,<br />

Superintendent:<br />

“I really enjoy working with the<br />

GARAGEDECK system. It is great to<br />

use on the parking deck, <strong>and</strong> very<br />

clean <strong>and</strong> easy to use with a minimal<br />

number of parts. <strong>PERI</strong>’s response to<br />

job conditions has been excellent.”<br />

11

12<br />

Fast, Safe <strong>and</strong> Cost-effective Solution<br />

through Versatile VARIOKIT System<br />

SR 50 Overpass, Orl<strong>and</strong>o, Florida<br />

The SR 50 Overpass project in Orl<strong>and</strong>o<br />

replaces an at grade intersection with<br />

SR 436 <strong>and</strong> consists of eastbound <strong>and</strong><br />

westbound bridges.<br />

Lane Construction selected <strong>PERI</strong> to<br />

provide bridge bracket assemblies<br />

to form the bridge deck between<br />

the box girders <strong>and</strong> along the outside<br />

of each bridge. The brackets are<br />

comprised entirely from VARIOKIT<br />

st<strong>and</strong>ard components. The units are<br />

preassembled on the ground <strong>and</strong><br />

quickly set in place using a lifting fork<br />

for maximum productivity <strong>and</strong> safety.<br />

59’-3’’<br />

The ability to preassemble complete units on<br />

the ground <strong>and</strong> the economy of 100% rentable<br />

st<strong>and</strong>ard system components make VARIOKIT<br />

extremely cost-effective for projects with tight<br />

schedules <strong>and</strong> strict budgets.<br />

Contractor<br />

Lane Construction Corp., Maitl<strong>and</strong>, FL<br />

Field Service<br />

<strong>PERI</strong> Orl<strong>and</strong>o, FL<br />

R<strong>and</strong>y Gore,<br />

Superintendent:<br />

“We chose the <strong>PERI</strong> system because<br />

of our past experience with the company<br />

<strong>and</strong> the excellent support they<br />

provide. The system has helped us to<br />

keep the project ahead of schedule.”

VARIO <strong>and</strong> RCS Provide Efficient <strong>and</strong> Safe<br />

Construction of Bridge Pylons<br />

Indian River Inlet Bridge, Rehoboth Beach, Delaware<br />

Contractor<br />

Skanska USA Civil Southeast, Inc.,<br />

Virginia Beach, VA<br />

Field Service<br />

<strong>PERI</strong> Baltimore, MD<br />

Everett Gibbs,<br />

Superintendent:<br />

“This system is fast, works well,<br />

<strong>and</strong> fits well. I have used <strong>PERI</strong><br />

before <strong>and</strong> <strong>PERI</strong> has always been<br />

good in every way.”<br />

Two pylons are constructed using VARIO formwork<br />

<strong>and</strong> RCS climbing formwork scaffolding.<br />

When fully assembled, each unit will provide a<br />

total of six work levels completely enclosing each<br />

pylon.<br />

RCS easily adapts to the tapered pylons while<br />

providing a completely enclosed <strong>and</strong> safe working<br />

platform.<br />

The new Indian River Inlet Bridge will<br />

replace the existing structurally deficient<br />

span along the Coastal Highway<br />

between Rehoboth Beach <strong>and</strong> Bethany<br />

Beach. The cable stayed bridge consists<br />

of four 240’ tall pylons with a cast-inplace<br />

deck for the two 400’ back spans<br />

<strong>and</strong> 950’ main span.<br />

<strong>PERI</strong> is supplying four sets of VARIO<br />

formwork <strong>and</strong> Rail Climbing System<br />

(RCS) platforms to construct the pylons.<br />

The VARIO was designed with only two<br />

rows of ties for the 18’ typical lift height<br />

<strong>and</strong> to accommodate the longitudinal<br />

VARIO formwork on the self-locking carriage of<br />

the RCS platform.<br />

taper of the pylons without the need<br />

for field cutting. <strong>PERI</strong> preassembled<br />

the 2’ - 6” radius outside corners to<br />

expedite the onsite assembly of the<br />

formwork. Skanska specified the<br />

RCS crane-climbing shuttering scaffold<br />

because it is always connected to the<br />

structure during the climbing process<br />

which is important for this windy site<br />

location along the Delaware shore. The<br />

RCS system allows the formwork to<br />

VARIO panel retracted on the RCS shuttering<br />

scaffold ready to be closed for the next pour.<br />

be retracted 36” to facilitate the installation<br />

of the reinforcing steel. Currently<br />

the contractor is completing one lift per<br />

week for each pylon.<br />

<strong>PERI</strong> is also supplying <strong>PERI</strong> UP stair<br />

towers to access the pylon formwork<br />

<strong>and</strong> the bridge deck. In 2010 the traveler<br />

formwork for the main span will be<br />

delivered by <strong>PERI</strong> for the 24 pours of<br />

the main span over the inlet.<br />

13

14<br />

TRIO System Simplifies Forming<br />

Complex Bridge Abutments<br />

Parksville 17 Bypass, Parksville, New York<br />

TRIO formwork is quickly <strong>and</strong> easily reconfigured<br />

to the varying geometry of the different<br />

abutments.<br />

Contractor<br />

Delaney Group, Inc.,<br />

Mayfield, NY<br />

Field Service<br />

<strong>PERI</strong> New York, NY<br />

Dennis Hartford, Superintendent:<br />

“My guys really like the TRIO<br />

system. They like the single clamp<br />

system <strong>and</strong> the few vertical walers<br />

<strong>and</strong> ties required.”<br />

TRIO formwork with working platform utilized for<br />

the construction of a bridge abutment.<br />

The Parksville 17 Bypass project includes<br />

the construction of thirteen new<br />

bridges. Once completed, it will re-route<br />

traffic around the town of Parksville, NY<br />

to establish economic <strong>and</strong> residential<br />

growth. Delaney selected <strong>PERI</strong> TRIO for<br />

the bridges’ complex abutments, wing<br />

High quality concrete finish achieved on the abutments<br />

due to TRIO’s Finnform plywood facing.<br />

walls <strong>and</strong> piers because of the systems<br />

versatility <strong>and</strong> efficiency.<br />

<strong>PERI</strong> also designed custom TRIO panels<br />

requiring far fewer ties to accommodate<br />

the sharp angles on some of the abutment<br />

walls.

2’-9 ½‘‘<br />

24’-6 5 /8’’<br />

VARIO Wall <strong>Formwork</strong> for Excellent Finish<br />

on Battered Bridge Walls<br />

Freya Street Bridge, Spokane, Washington<br />

The formwork<br />

for the pier<br />

beam is supported<br />

by SKS<br />

brackets, which<br />

also provide<br />

for convenient<br />

bracing <strong>and</strong><br />

safe working<br />

platforms.<br />

FB 180 <strong>and</strong> KG 180 platforms provide safe<br />

access for the second pours of an abutment<br />

wall.<br />

The new Freya Street Bridge in<br />

Spokane will span over an active existing<br />

railroad track. The variety of <strong>PERI</strong><br />

systems supplied to this project meet<br />

the stringent specifications set by the<br />

Washington State DOT.<br />

HDT beam spanning between SKS<br />

brackets support the weight of the<br />

pier caps <strong>and</strong> provide a safe working<br />

platform. The <strong>PERI</strong> FB 180 Folding<br />

Platforms arrive on the site ready to<br />

use. The contractor simply unfolds the<br />

platform, pins the brace, <strong>and</strong> hangs<br />

the platform on the wall. The SK Tie<br />

System created a water tight seal on<br />

the tie holes for all of the walls on<br />

the Freya Street Bridge.<br />

VARIO wall formwork is used to form the battered<br />

walls for an excellent concrete finish.<br />

Buzz Schauer,<br />

Superintendent:<br />

“<strong>PERI</strong>‘s engineering, equipment, <strong>and</strong><br />

site service is a tremendous asset<br />

throughout the entire project.”<br />

Contractor<br />

Garco Construction, Spokane, WA<br />

Field Service<br />

<strong>PERI</strong> Woodl<strong>and</strong>, WA<br />

VARIO formwork with working platforms <strong>and</strong><br />

RSS braces used for the construction of the<br />

abutment walls.<br />

15

<strong>PERI</strong> UP Stair Towers<br />

Safe Access to all Work Areas<br />

<strong>PERI</strong> offers two stair<br />

tower configurations from<br />

the <strong>PERI</strong> UP Rosett Flex<br />

scaffolding system to<br />

provide the appropriate<br />

access to work areas on<br />

any jobsite.<br />

The illustrations featured in this brochure<br />

are photographs taken at a particular<br />

time on a construction site. This is why<br />

the safety details shown cannot be<br />

considered as final.<br />

© Copyright by <strong>PERI</strong> GmbH<br />

The <strong>PERI</strong> UP Stair Tower<br />

is a conventional four-leg<br />

tower used for access to<br />

work areas for heights up to<br />

300’. Assembly of the system<br />

is simple <strong>and</strong> fast due<br />

to high strength aluminum<br />

staircase units which have a<br />

width of 30”. Tall towers can<br />

be assembled in modules on<br />

the ground <strong>and</strong> flown into<br />

place with use of a crane.<br />

The permissible load is<br />

42 lbs/ft².<br />

The <strong>PERI</strong> UP Site Stair<br />

is used for applications with<br />

high traffic or load requirements<br />

for heights up to 164’.<br />

It is erected as a ten-leg tower<br />

with step <strong>and</strong> l<strong>and</strong>ing widths<br />

of 40” providing room enough<br />

to pass. Erection of the<br />

system is simple <strong>and</strong> fast<br />

with the stringers mounted<br />

first followed by the steps<br />

which interlock during installation.<br />

The permissible<br />

load is 63 lbs/ft².<br />

<strong>PERI</strong> USA<br />

7135 Dorsey Run Road<br />

Elkridge, MD 21075<br />

Phone +1 410-712-7225<br />

Fax +1 410-712-7080<br />

info@peri-usa.com<br />

www.peri-usa.com<br />

US en 01/2010 15.5eb Art. Nr.: 792557 © Copyright by <strong>PERI</strong> GmbH

Welcome to bauma 2010<br />

April 19 - 25 in Munich, Germany<br />

bauma in Munich features more than<br />

five million square feet of exhibition<br />

space, making it by far the largest<br />

<strong>and</strong> certainly the most impressive<br />

exhibition worldwide.<br />

From April 19 - 25, 2010, we will be<br />

exhibiting at the bauma trade fair.<br />

Visit us to better underst<strong>and</strong> how we<br />

can support you in improving your<br />

construction processes, reduce costs<br />

<strong>and</strong> to increase on-site safety levels<br />

of your personnel. In our 45,000 ft²<br />

exhibition hall, we provide comprehensive<br />

information on new developments<br />

in formwork, scaffolding <strong>and</strong><br />

engineering.<br />

We will be presenting<br />

■ new innovative products<br />

■ successful use of <strong>PERI</strong> systems<br />

around the world<br />

■ solution-oriented services<br />

■ our know-how <strong>and</strong> expertise to<br />

optimize your projects<br />

The main attractions are<br />

■ live demonstrations of our products<br />

■ multimedia presentations of<br />

<strong>PERI</strong> systems in use<br />

■ films on reference projects,<br />

products <strong>and</strong> our company in<br />

the <strong>PERI</strong> cinema<br />

■ individual discussions with our<br />

sales engineers<br />

Impressions of bauma 2007<br />

Opening times<br />

Monday to Friday 9.30 am - 6.30 pm<br />

Saturday 8.30 am - 6.30 pm<br />

Sunday 9.30 am - 4.30 pm<br />

We are looking forward to welcoming<br />

you at the <strong>PERI</strong> hall located in the<br />

open-air area north.<br />

www.bauma.de

The <strong>PERI</strong> Offices in USA<br />

Your Partners to help you find<br />

the most cost-effective Solution for your Jobsite<br />

6.2 Seattle<br />

6.0 Portl<strong>and</strong><br />

3.2 San Francisco<br />

3.0 Los Angeles<br />

Legend<br />

Corporate <strong>and</strong> Regional Offices<br />

Offices<br />

Regional Offices USA<br />

Northeast<br />

1.0 <strong>PERI</strong> Baltimore<br />

7135 Dorsey Run Road<br />

Elkridge, MD 21075<br />

Phone 410-712-7225<br />

Fax 410-712-7080<br />

Midwest<br />

2.0 <strong>PERI</strong> Chicago<br />

12150 S. Paulina Street<br />

Calumet Park, IL 60827<br />

Phone 708-489-6800<br />

Fax 708-489-6735<br />

6.1 Salt Lake City<br />

3.1 Phoenix<br />

4.2 Denver<br />

4.0 Fort Worth<br />

4.3 Houston<br />

4.1 San Antonio<br />

2.3 Minneapolis<br />

Southwest<br />

3.0 <strong>PERI</strong> Los Angeles<br />

9 Executive Circle, Suite 220<br />

Irvine, CA 92614<br />

Phone 949-474-1930<br />

Fax 949-474-0989<br />

South Central<br />

4.0 <strong>PERI</strong> Fort Worth<br />

400 Industrial Boulevard, Suite 210<br />

Mansfield, TX 76063<br />

Phone 817-413-0424<br />

Fax 817-413-0425<br />

1.2 New York<br />

2.0 Chicago<br />

2.4 Toledo<br />

1.3 Philadelphia<br />

1.4 Pittsburgh<br />

2.2 Indianapolis 1.0 Baltimore<br />

2.1 Cincinnati<br />

2.5 St. Louis<br />

5.3 Nashville<br />

5.1 Atlanta<br />

5.2 Raleigh<br />

5.0 Orl<strong>and</strong>o<br />

1.1 Boston<br />

Southeast<br />

5.0 <strong>PERI</strong> Orl<strong>and</strong>o<br />

19914 Independence Blvd.<br />

Grovel<strong>and</strong>, FL 34736<br />

Phone 352-429-6400<br />

Fax 352-429-6401<br />

Northwest<br />

6.0 <strong>PERI</strong> Portl<strong>and</strong><br />

1475 Port Way<br />

Woodl<strong>and</strong>, WA 98674<br />

Phone 360-817-8200<br />

Fax 360-225-9982<br />

<strong>Formwork</strong>,<br />

<strong>Shoring</strong> <strong>and</strong><br />

<strong>Scaffolding</strong><br />

www.peri-usa.com