Formadur - SCHMOLZ-BICKENBACH.US

Formadur - SCHMOLZ-BICKENBACH.US

Formadur - SCHMOLZ-BICKENBACH.US

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Formadur</strong><br />

(X19NiCrMo4)<br />

Steel properties<br />

Standards<br />

Physical properties<br />

2764<br />

C 0.19 Cr 1.30 Mo 0.20 Ni 4.10<br />

Case-hardening steel, high core strength, good polishability.<br />

AISI ~P21<br />

Coefficient of thermal expansion<br />

at °C 20 – 100 20 – 200 20 – 300 20 – 400<br />

10 -6 m/(m • K) 12.1 13.0 13.1 13.5<br />

Thermal conductivity<br />

at °C 20 350 700<br />

W/(m • K) 33.5 32.5 32.0<br />

Applications<br />

Heat treatment<br />

Highly stressed plastic moulds, tool holders for cutter picks.<br />

Soft annealing °C Cooling Hardness HB<br />

620 – 660 Furnace Max. 250<br />

Stress-relief annealing °C Cooling<br />

600 Furnace<br />

Carburizing °C Intermediate Hardening °C Quenching Hardness after<br />

annealing °C<br />

quenching HRC<br />

860 – 890 600 – 630 780 – 810 Oil or saltbath, 62<br />

180 – 220 °C<br />

860 – 890 600 – 630 800 – 830 Air 56<br />

Tempering °C 100 200 300 400 500 600<br />

after oil hardening HRC 62 60 58 56 52 49<br />

after air hardening HRC 56 55 53 51 48 45<br />

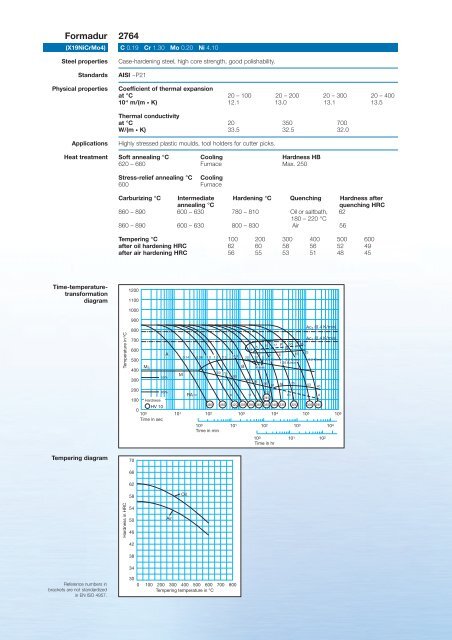

Time-temperaturetransformation<br />

diagram<br />

1200<br />

1100<br />

1000<br />

Temperature in o C<br />

900<br />

800<br />

Ac 3 (0.4 K/min)<br />

700<br />

Ac 1 (0.4 K/min)<br />

600<br />

2 5 10 17 F 30 35<br />

P<br />

A<br />

1 3 6 15<br />

23<br />

0.14 0.38 1.0 1.5 2.3 6.3<br />

20 10 5<br />

500<br />

2.5 K/min 0.4 K/min 0.2 K/min<br />

1.25 K/min<br />

M S<br />

B K/min<br />

400<br />

2<br />

50<br />

M<br />

75<br />

50%<br />

90<br />

300<br />

95 96<br />

95 91<br />

84 75<br />

53<br />

40<br />

200<br />

90%<br />

12<br />

RA =<br />

8 11<br />

10 8<br />

100 Hardness<br />

345<br />

HV 10<br />

480 465 420 405 390 365 355 340 335 325 305 295<br />

0<br />

10 0 10 1 10 2 10 3 10 4 10 5 10 6<br />

Time in sec<br />

10 0 10 1 10 2 10 3 10 4<br />

Time in min<br />

10 0 10 1 10 2<br />

Time in hr<br />

Tempering diagram<br />

70<br />

66<br />

62<br />

58<br />

Oil<br />

Hardness in HRC<br />

54<br />

50<br />

46<br />

42<br />

Air<br />

38<br />

34<br />

Reference numbers in<br />

brackets are not standardized<br />

in EN ISO 4957.<br />

30<br />

0 100 200 300 400 500 600 700 800<br />

Tempering temperature in °C