Multifunctional propyleneimines-new generation of crosslinkers for ...

Multifunctional propyleneimines-new generation of crosslinkers for ...

Multifunctional propyleneimines-new generation of crosslinkers for ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

504<br />

ARTICLE IN PRESS<br />

Z. Czech / International Journal <strong>of</strong> Adhesion & Adhesives 24 (2004) 503–511<br />

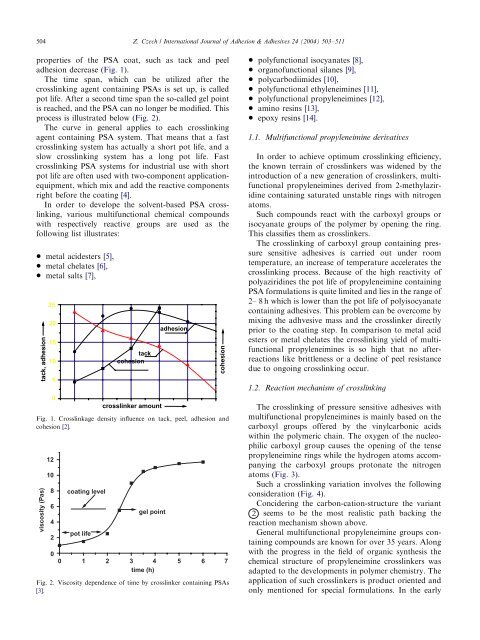

properties <strong>of</strong> the PSA coat, such as tack and peel<br />

adhesion decrease (Fig. 1).<br />

The time span, which can be utilized after the<br />

crosslinking agent containing PSAs is set up, is called<br />

pot life. After a second time span the so-called gel point<br />

is reached, and the PSA can no longer be modified. This<br />

process is illustrated below (Fig. 2).<br />

The curve in general applies to each crosslinking<br />

agent containing PSA system. That means that a fast<br />

crosslinking systemhas actually a short pot life, and a<br />

slow crosslinking systemhas a long pot life. Fast<br />

crosslinking PSA systems <strong>for</strong> industrial use with short<br />

pot life are <strong>of</strong>ten used with two-component applicationequipment,<br />

which mix and add the reactive components<br />

right be<strong>for</strong>e the coating [4].<br />

In order to develope the solvent-based PSA crosslinking,<br />

various multifunctional chemical compounds<br />

with respectively reactive groups are used as the<br />

following list illustrates:<br />

* metal acidesters [5],<br />

* metal chelates [6],<br />

* metal salts [7],<br />

tack, adhesion<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

tack<br />

cohesion<br />

crosslinker amount<br />

adhesion<br />

Fig. 1. Crosslinkage density influence on tack, peel, adhesion and<br />

cohesion [2].<br />

viscosity (Pas)<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

coating level<br />

pot life<br />

gel point<br />

0<br />

0 1 2 3 4 5 6 7<br />

time (h)<br />

Fig. 2. Viscosity dependence <strong>of</strong> time by crosslinker containing PSAs<br />

[3].<br />

cohesion<br />

* polyfunctional isocyanates [8],<br />

* organ<strong>of</strong>unctional silanes [9],<br />

* polycarbodiimides [10],<br />

* polyfunctional ethyleneimines [11],<br />

* polyfunctional <strong>propyleneimines</strong> [12],<br />

* amino resins [13],<br />

* epoxy resins [14].<br />

1.1. <strong>Multifunctional</strong> propyleneimine derivatives<br />

In order to achieve optimum crosslinking efficiency,<br />

the known terrain <strong>of</strong> <strong>crosslinkers</strong> was widened by the<br />

introduction <strong>of</strong> a <strong>new</strong> <strong>generation</strong> <strong>of</strong> <strong>crosslinkers</strong>, multifunctional<br />

<strong>propyleneimines</strong> derived from 2-methylaziridine<br />

containing saturated unstable rings with nitrogen<br />

atoms.<br />

Such compounds react with the carboxyl groups or<br />

isocyanate groups <strong>of</strong> the polymer by opening the ring.<br />

This classifies themas <strong>crosslinkers</strong>.<br />

The crosslinking <strong>of</strong> carboxyl group containing pressure<br />

sensitive adhesives is carried out under room<br />

temperature, an increase <strong>of</strong> temperature accelerates the<br />

crosslinking process. Because <strong>of</strong> the high reactivity <strong>of</strong><br />

polyaziridines the pot life <strong>of</strong> propyleneimine containing<br />

PSA <strong>for</strong>mulations is quite limited and lies in the range <strong>of</strong><br />

2– 8 h which is lower than the pot life <strong>of</strong> polyisocyanate<br />

containing adhesives. This problemcan be overcome by<br />

mixing the adhvesive mass and the crosslinker directly<br />

prior to the coating step. In comparison to metal acid<br />

esters or metal chelates the crosslinking yield <strong>of</strong> multifunctional<br />

<strong>propyleneimines</strong> is so high that no afterreactions<br />

like brittleness or a decline <strong>of</strong> peel resistance<br />

due to ongoing crosslinking occur.<br />

1.2. Reaction mechanism <strong>of</strong> crosslinking<br />

The crosslinking <strong>of</strong> pressure sensitive adhesives with<br />

multifunctional <strong>propyleneimines</strong> is mainly based on the<br />

carboxyl groups <strong>of</strong>fered by the vinylcarbonic acids<br />

within the polymeric chain. The oxygen <strong>of</strong> the nucleophilic<br />

carboxyl group causes the opening <strong>of</strong> the tense<br />

propyleneimine rings while the hydrogen atoms accompanying<br />

the carboxyl groups protonate the nitrogen<br />

atoms (Fig. 3).<br />

Such a crosslinking variation involves the following<br />

consideration (Fig. 4).<br />

Concidering the carbon-cation-structure the variant<br />

2 seems to be the most realistic path backing the<br />

reaction mechanism shown above.<br />

General multifunctional propyleneimine groups containing<br />

compounds are known <strong>for</strong> over 35 years. Along<br />

with the progress in the field <strong>of</strong> organic synthesis the<br />

chemical structure <strong>of</strong> propyleneimine <strong>crosslinkers</strong> was<br />

adapted to the developments in polymer chemistry. The<br />

application <strong>of</strong> such <strong>crosslinkers</strong> is product oriented and<br />

only mentioned <strong>for</strong> special <strong>for</strong>mulations. In the early