The effects of latex coalescence and interfacial crosslinking on the ...

The effects of latex coalescence and interfacial crosslinking on the ...

The effects of latex coalescence and interfacial crosslinking on the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1288<br />

D.I. Lee / Polymer 46 (2005) 1287–1293<br />

crosslinked backb<strong>on</strong>e polymers. As a matter <str<strong>on</strong>g>of</str<strong>on</strong>g> fact, this<br />

c<strong>on</strong>cept was thought to achieve a homogeneous <str<strong>on</strong>g>crosslinking</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> films by <str<strong>on</strong>g>interfacial</str<strong>on</strong>g>ly <str<strong>on</strong>g>crosslinking</str<strong>on</strong>g> <strong>the</strong> crosslinked<br />

<str<strong>on</strong>g>latex</str<strong>on</strong>g> particles. For this reas<strong>on</strong>, it was fur<strong>the</strong>r decided to test<br />

this c<strong>on</strong>cept with a series <str<strong>on</strong>g>of</str<strong>on</strong>g> carboxylated <str<strong>on</strong>g>latex</str<strong>on</strong>g>es by varying<br />

<strong>the</strong> backb<strong>on</strong>e polymer <str<strong>on</strong>g>crosslinking</str<strong>on</strong>g>, <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>n to develop<br />

self-curable <str<strong>on</strong>g>latex</str<strong>on</strong>g> blends <str<strong>on</strong>g>and</str<strong>on</strong>g> structured latxes c<strong>on</strong>taining 2-<br />

isopropenyl-2-oxazoline (IPO) <str<strong>on</strong>g>and</str<strong>on</strong>g> vinyl acids [2,3].<br />

2. Experimental<br />

2.1. Crosslinked model <str<strong>on</strong>g>latex</str<strong>on</strong>g>es<br />

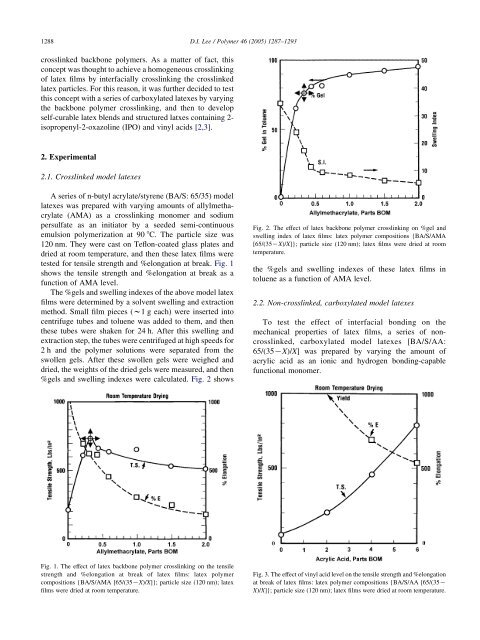

A series <str<strong>on</strong>g>of</str<strong>on</strong>g> n-butyl acrylate/styrene (BA/S: 65/35) model<br />

<str<strong>on</strong>g>latex</str<strong>on</strong>g>es was prepared with varying amounts <str<strong>on</strong>g>of</str<strong>on</strong>g> allylmethacrylate<br />

(AMA) as a <str<strong>on</strong>g>crosslinking</str<strong>on</strong>g> m<strong>on</strong>omer <str<strong>on</strong>g>and</str<strong>on</strong>g> sodium<br />

persulfate as an initiator by a seeded semi-c<strong>on</strong>tinuous<br />

emulsi<strong>on</strong> polymerizati<strong>on</strong> at 90 8C. <str<strong>on</strong>g>The</str<strong>on</strong>g> particle size was<br />

120 nm. <str<strong>on</strong>g>The</str<strong>on</strong>g>y were cast <strong>on</strong> Tefl<strong>on</strong>-coated glass plates <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

dried at room temperature, <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>n <strong>the</strong>se <str<strong>on</strong>g>latex</str<strong>on</strong>g> films were<br />

tested for tensile strength <str<strong>on</strong>g>and</str<strong>on</strong>g> %el<strong>on</strong>gati<strong>on</strong> at break. Fig. 1<br />

shows <strong>the</strong> tensile strength <str<strong>on</strong>g>and</str<strong>on</strong>g> %el<strong>on</strong>gati<strong>on</strong> at break as a<br />

functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> AMA level.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> %gels <str<strong>on</strong>g>and</str<strong>on</strong>g> swelling indexes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> above model <str<strong>on</strong>g>latex</str<strong>on</strong>g><br />

films were determined by a solvent swelling <str<strong>on</strong>g>and</str<strong>on</strong>g> extracti<strong>on</strong><br />

method. Small film pieces (w1 g each) were inserted into<br />

centrifuge tubes <str<strong>on</strong>g>and</str<strong>on</strong>g> toluene was added to <strong>the</strong>m, <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>n<br />

<strong>the</strong>se tubes were shaken for 24 h. After this swelling <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

extracti<strong>on</strong> step, <strong>the</strong> tubes were centrifuged at high speeds for<br />

2 h <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong> polymer soluti<strong>on</strong>s were separated from <strong>the</strong><br />

swollen gels. After <strong>the</strong>se swollen gels were weighed <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

dried, <strong>the</strong> weights <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> dried gels were measured, <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>the</strong>n<br />

%gels <str<strong>on</strong>g>and</str<strong>on</strong>g> swelling indexes were calculated. Fig. 2 shows<br />

Fig. 2. <str<strong>on</strong>g>The</str<strong>on</strong>g> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> backb<strong>on</strong>e polymer <str<strong>on</strong>g>crosslinking</str<strong>on</strong>g> <strong>on</strong> %gel <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

swelling index <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> films: <str<strong>on</strong>g>latex</str<strong>on</strong>g> polymer compositi<strong>on</strong>s {BA/S/AMA<br />

[65/(35KX)/X]}; particle size (120 nm); <str<strong>on</strong>g>latex</str<strong>on</strong>g> films were dried at room<br />

temperature.<br />

<strong>the</strong> %gels <str<strong>on</strong>g>and</str<strong>on</strong>g> swelling indexes <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se <str<strong>on</strong>g>latex</str<strong>on</strong>g> films in<br />

toluene as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> AMA level.<br />

2.2. N<strong>on</strong>-crosslinked, carboxylated model <str<strong>on</strong>g>latex</str<strong>on</strong>g>es<br />

To test <strong>the</strong> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>interfacial</str<strong>on</strong>g> b<strong>on</strong>ding <strong>on</strong> <strong>the</strong><br />

mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> films, a series <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>crosslinked,<br />

carboxylated model <str<strong>on</strong>g>latex</str<strong>on</strong>g>es [BA/S/AA:<br />

65/(35KX)/X] was prepared by varying <strong>the</strong> amount <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

acrylic acid as an i<strong>on</strong>ic <str<strong>on</strong>g>and</str<strong>on</strong>g> hydrogen b<strong>on</strong>ding-capable<br />

functi<strong>on</strong>al m<strong>on</strong>omer.<br />

Fig. 1. <str<strong>on</strong>g>The</str<strong>on</strong>g> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> backb<strong>on</strong>e polymer <str<strong>on</strong>g>crosslinking</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> tensile<br />

strength <str<strong>on</strong>g>and</str<strong>on</strong>g> %el<strong>on</strong>gati<strong>on</strong> at break <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> films: <str<strong>on</strong>g>latex</str<strong>on</strong>g> polymer<br />

compositi<strong>on</strong>s {BA/S/AMA [65/(35KX)/X]}; particle size (120 nm); <str<strong>on</strong>g>latex</str<strong>on</strong>g><br />

films were dried at room temperature.<br />

Fig. 3. <str<strong>on</strong>g>The</str<strong>on</strong>g> effect <str<strong>on</strong>g>of</str<strong>on</strong>g> vinyl acid level <strong>on</strong> <strong>the</strong> tensile strength <str<strong>on</strong>g>and</str<strong>on</strong>g> %el<strong>on</strong>gati<strong>on</strong><br />

at break <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>latex</str<strong>on</strong>g> films: <str<strong>on</strong>g>latex</str<strong>on</strong>g> polymer compositi<strong>on</strong>s {BA/S/AA [65/(35K<br />

X)/X]}; particle size (120 nm); <str<strong>on</strong>g>latex</str<strong>on</strong>g> films were dried at room temperature.