belchatow-poland-supercritical-steam-coal-power-plant-editorial

belchatow-poland-supercritical-steam-coal-power-plant-editorial

belchatow-poland-supercritical-steam-coal-power-plant-editorial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LIGNITE POWER<br />

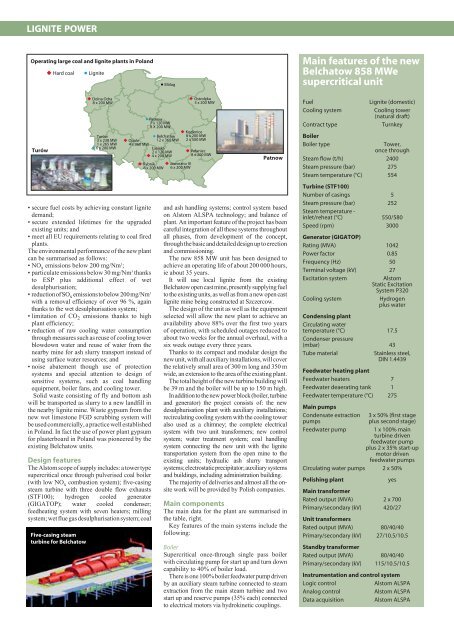

Operating large <strong>coal</strong> and lignite <strong>plant</strong>s in Poland<br />

R Hard <strong>coal</strong><br />

4 Lignite<br />

4 Elblag<br />

Main features of the new<br />

Belchatow 858 MWe<br />

<strong>supercritical</strong> unit<br />

Turów<br />

• secure fuel costs by achieving constant lignite<br />

demand;<br />

• secure extended lifetimes for the upgraded<br />

existing units; and<br />

• meet all EU requirements relating to <strong>coal</strong> fired<br />

<strong>plant</strong>s.<br />

The environmental performance of the new <strong>plant</strong><br />

can be summarised as follows:<br />

• NO x emissions below 200 mg/Nm 3 ;<br />

• particulate emissions below 30 mg/Nm 3 thanks<br />

to ESP plus additional effect of wet<br />

desulphurisation;<br />

• reduction of SO x emissions to below 200 mg/Nm 3<br />

with a removal efficiency of over 96 %, again<br />

thanks to the wet desulphurisation system;<br />

• limitation of CO 2 emissions thanks to high<br />

<strong>plant</strong> efficiency;<br />

• reduction of raw cooling water consumption<br />

through measures such as reuse of cooling tower<br />

blowdown water and reuse of water from the<br />

nearby mine for ash slurry transport instead of<br />

using surface water resources; and<br />

• noise abatement though use of protection<br />

systems and special attention to design of<br />

sensitive systems, such as <strong>coal</strong> handling<br />

equipment, boiler fans, and cooling tower.<br />

Solid waste consisting of fly and bottom ash<br />

will be transported as slurry to a new landfill in<br />

the nearby lignite mine. Waste gypsum from the<br />

new wet limestone FGD scrubbing system will<br />

be used commercially, a practice well established<br />

in Poland. In fact the use of <strong>power</strong> <strong>plant</strong> gypsum<br />

for plasterboard in Poland was pioneered by the<br />

existing Belchatow units.<br />

Design features<br />

The Alstom scope of supply includes: a tower type<br />

<strong>supercritical</strong> once through pulverised <strong>coal</strong> boiler<br />

(with low NO x combustion system); five-casing<br />

<strong>steam</strong> turbine with three double flow exhausts<br />

(STF100); hydrogen cooled generator<br />

(GIGATOP); water cooled condenser;<br />

feedheating system with seven heaters; milling<br />

system; wet flue gas desulphurisation system; <strong>coal</strong><br />

Five-casing <strong>steam</strong><br />

turbine for Belchatow<br />

R Dolna Odra<br />

8 x 200 MW<br />

Turów<br />

3 x 238 MW<br />

1 x 265 MW<br />

4 6 x 200 MW<br />

R Opole<br />

4 x 360 MW<br />

4 Patnow<br />

7 x 120 MW<br />

8 X 200 MW<br />

4 Bełchatów<br />

12 x 360 MW<br />

Łayiska<br />

2 x 120 MW<br />

R 4 x 200 MW<br />

R Rybnik R Jaworzno III<br />

8 x 200 MW 6 x 200 MW<br />

R Ostrolęka<br />

3 x 200 MW<br />

R Kozienice<br />

8 x 200 MW<br />

2 x 500 MW<br />

R Połaniec<br />

8 x 200 MW<br />

Patnow<br />

and ash handling systems; control system based<br />

on Alstom ALSPA technology; and balance of<br />

<strong>plant</strong>. An important feature of the project has been<br />

careful integration of all these systems throughout<br />

all phases, from development of the concept,<br />

through the basic and detailed design up to erection<br />

and commissioning.<br />

The new 858 MW unit has been designed to<br />

achieve an operating life of about 200 000 hours,<br />

ie about 35 years.<br />

It will use local lignite from the existing<br />

Belchatow open cast mine, presently supplying fuel<br />

to the existing units, as well as from a new open cast<br />

lignite mine being constructed at Szczercow.<br />

The design of the unit as well as the equipment<br />

selected will allow the new <strong>plant</strong> to achieve an<br />

availability above 88% over the first two years<br />

of operation, with scheduled outages reduced to<br />

about two weeks for the annual overhaul, with a<br />

six week outage every three years.<br />

Thanks to its compact and modular design the<br />

new unit, with all auxiliary installations, will cover<br />

the relatively small area of 300 m long and 350 m<br />

wide, an extension to the area of the existing <strong>plant</strong>.<br />

The total height of the new turbine building will<br />

be 39 m and the boiler will be up to 150 m high.<br />

In addition to the new <strong>power</strong> block (boiler, turbine<br />

and generator) the project consists of: the new<br />

desulphurisation <strong>plant</strong> with auxiliary installations;<br />

recirculating cooling system with the cooling tower<br />

also used as a chimney; the complete electrical<br />

system with two unit transformers; new control<br />

system; water treatment system; <strong>coal</strong> handling<br />

system connecting the new unit with the lignite<br />

transportation system from the open mine to the<br />

existing units; hydraulic ash slurry transport<br />

systems; electrostatic precipitator; auxiliary systems<br />

and buildings, including administration building.<br />

The majority of deliveries and almost all the onsite<br />

work will be provided by Polish companies.<br />

Main components<br />

The main data for the <strong>plant</strong> are summarised in<br />

the table, right.<br />

Key features of the main systems include the<br />

following:<br />

Boiler<br />

Supercritical once-through single pass boiler<br />

with circulating pump for start up and turn down<br />

capability to 40% of boiler load.<br />

There is one 100% boiler feedwater pump driven<br />

by an auxiliary <strong>steam</strong> turbine connected to <strong>steam</strong><br />

extraction from the main <strong>steam</strong> turbine and two<br />

start up and reserve pumps (35% each) connected<br />

to electrical motors via hydrokinetic couplings.<br />

Fuel<br />

Cooling system<br />

Contract type<br />

Boiler<br />

Boiler type<br />

Lignite (domestic)<br />

Cooling tower<br />

(natural draft)<br />

Turnkey<br />

Tower,<br />

once through<br />

Steam flow (t/h) 2400<br />

Steam pressure (bar) 275<br />

Steam temperature (°C) 554<br />

Turbine (STF100)<br />

Number of casings 5<br />

Steam pressure (bar) 252<br />

Steam temperature -<br />

inlet/reheat (°C) 550/580<br />

Speed (rpm) 3000<br />

Generator (GIGATOP)<br />

Rating (MVA) 1042<br />

Power factor 0.85<br />

Frequency (Hz) 50<br />

Terminal voltage (kV) 27<br />

Excitation system<br />

Alstom<br />

Static Excitation<br />

System P320<br />

Cooling system<br />

Hydrogen<br />

plus water<br />

Condensing <strong>plant</strong><br />

Circulating water<br />

temperature (°C) 17.5<br />

Condenser pressure<br />

(mbar) 43<br />

Tube material<br />

Stainless steel,<br />

DIN 1.4439<br />

Feedwater heating <strong>plant</strong><br />

Feedwater heaters 7<br />

Feedwater deaerating tank 1<br />

Feedwater temperature (°C) 275<br />

Main pumps<br />

Condensate extraction 3 x 50% (first stage<br />

pumps<br />

plus second stage)<br />

Feedwater pump<br />

1 x 100% main<br />

turbine driven<br />

feedwater pump<br />

plus 2 x 35% start-up<br />

motor driven<br />

feedwater pumps<br />

Circulating water pumps 2 x 50%<br />

Polishing <strong>plant</strong><br />

yes<br />

Main transformer<br />

Rated output (MVA) 2 x 700<br />

Primary/secondary (kV) 420/27<br />

Unit transformers<br />

Rated output (MVA) 80/40/40<br />

Primary/secondary (kV) 27/10.5/10.5<br />

Standby transformer<br />

Rated output (MVA) 80/40/40<br />

Primary/secondary (kV) 115/10.5/10.5<br />

Instrumentation and control system<br />

Logic control<br />

Alstom ALSPA<br />

Analog control<br />

Alstom ALSPA<br />

Data acquisition<br />

Alstom ALSPA