belchatow-poland-supercritical-steam-coal-power-plant-editorial

belchatow-poland-supercritical-steam-coal-power-plant-editorial

belchatow-poland-supercritical-steam-coal-power-plant-editorial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

October 2007<br />

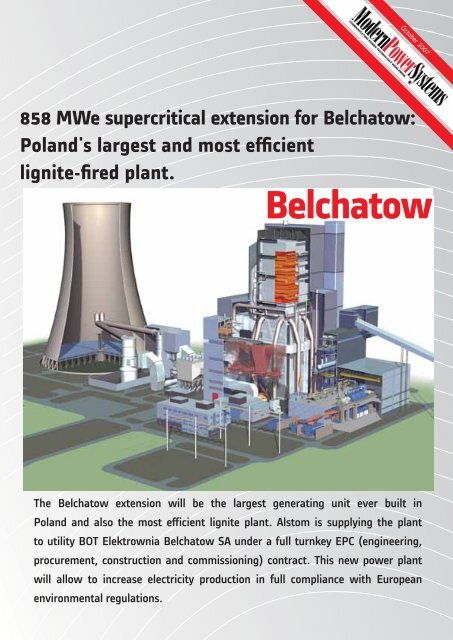

858 MWe <strong>supercritical</strong> extension for Belchatow:<br />

Poland's largest and most efficient<br />

lignite-fired <strong>plant</strong>.<br />

Belchatow<br />

The Belchatow extension will be the largest generating unit ever built in<br />

Poland and also the most efficient lignite <strong>plant</strong>. Alstom is supplying the <strong>plant</strong><br />

to utility BOT Elektrownia Belchatow SA under a full turnkey EPC (engineering,<br />

procurement, construction and commissioning) contract. This new <strong>power</strong> <strong>plant</strong><br />

will allow to increase electricity production in full compliance with European<br />

environmental regulations.

LIGNITE POWER<br />

858 MWe <strong>supercritical</strong><br />

extension for Belchatow<br />

The <strong>supercritical</strong> unit under construction at Belchatow will be Poland's<br />

largest and most efficient lignite fired <strong>plant</strong>.<br />

Supercritical<br />

boiler<br />

Andrzej Twardowski, Alstom, Poland<br />

From the early 1990s onwards it was clear<br />

that major investment was needed to<br />

rehabilitate and/or replace Polish <strong>power</strong><br />

<strong>plant</strong>s, to improve operating performance<br />

and to address the effects of ageing and<br />

obsolescent technology.<br />

Furthermore, after a brief period when<br />

electricity consumption decreased, due to closure<br />

of obsolete production facilities and a decline in<br />

the <strong>power</strong>-intensive sectors of industry, over the<br />

past few years <strong>power</strong> demand has been increasing<br />

steadily in tandem with the country's GDP<br />

growth.<br />

The situation in the <strong>power</strong> sector was<br />

exacerbated by Poland's joining of the European<br />

Union in May 2005, which brought the burden of<br />

additional emissions reduction obligations, with<br />

limitations on emissions by Poland as a whole and<br />

by the Polish <strong>power</strong> sector specifically.<br />

All these factors created the necessity for the<br />

Polish <strong>power</strong> sector to embark on a very large<br />

investment programme to meet the<br />

requirements of growing <strong>power</strong> demand,<br />

increased market competition and tightening<br />

environmental regulations.<br />

Estimates suggest that to meet these<br />

requirements some 9 GW of new or radically<br />

rehabilitated generating capacity will need to be<br />

put in operation between now and 2015.<br />

Indigenous <strong>coal</strong> remains the mainstay of Polish<br />

<strong>power</strong>, accounting for about 152 TWh of the 162<br />

TWh gross production in 2006 (some 94%, with<br />

oil, gas and hydro providing the rest). Lignite<br />

accounts for about a third of the <strong>coal</strong> generation.<br />

The first big project was rehabilitation of units<br />

1-6 of the Turow lignite fired <strong>plant</strong>, a huge<br />

undertaking that started in 1994 (with the<br />

awarding to an Alstom-led consortium of a<br />

contract to rehabilitate all six LMZ-designed 200<br />

MW units) and continued until 2005. The first<br />

three units were uprated to 235 MWe, and the<br />

subsequent three units to 262 MWe.<br />

Another significant project was the construction<br />

of a 460 MW <strong>supercritical</strong> lignite fired <strong>plant</strong> at<br />

Patnow (replacing two old 200 MW LMZ<br />

designed oil fired units), for which Alstom was<br />

awarded the turbine island and boiler contracts in<br />

2001 and which is currently under commissioning.<br />

The next key phase in the replacement of old<br />

generating capacity in Poland was the start of<br />

construction of the world's first <strong>supercritical</strong> CFB<br />

<strong>plant</strong>, at the Lagisza site of PKE (Southern<br />

Poland Power Company). Lagisza is scheduled<br />

to enter commercial operation in early 2009. The<br />

boiler for this 460 MW unit is being supplied by<br />

Foster Wheeler, while in December 2003 Alstom<br />

received an EPC contract covering the turbine<br />

island package (including civil works) and the<br />

cooling system, including cooling tower.<br />

The new 858 MWe lignite fired <strong>supercritical</strong><br />

unit to be built at Belchatow represents a further<br />

key stage in the modernisation of Poland's <strong>power</strong><br />

generation infrastructure.

LIGNITE POWER<br />

Belchatow, pillar of Polish <strong>power</strong> – a utility perspective<br />

Piotr Szmaj, chief engineer, new unit, BOT Elektrownia Belchatow<br />

Even before the addition of the new 858 MWe <strong>supercritical</strong> unit (described in the<br />

main article), Belchatow hosted the largest <strong>coal</strong> (lignite) fired <strong>plant</strong> in Europe –<br />

with a current installed capacity of 4400 MWe (12 x 370 MWe) – and has been<br />

called the capital of the Polish <strong>power</strong> generation industry. Following completion<br />

of the modernisation programme started in 1997, which added 120 MWe to the<br />

installed capacity (by modernisation of the turbine LP stages), the <strong>plant</strong> fulfils all<br />

EU requirements and standards.<br />

Indeed, BOT Elektrownia Belchatow was the first company in Poland to receive<br />

a permit under the EU's Integrated Pollution Prevention Control (IPPC) scheme to<br />

run its installations in line with the IPPC directive.<br />

The <strong>power</strong> station being the lowest cost and the most efficient electricity<br />

producer in the country is a pillar of the Polish <strong>power</strong> generation industry,<br />

helping to stabilise the national energy market. Since the late 1990s, with an<br />

annual electricity output of about 28 TWh, Belchatow has provided some 20% of<br />

Poland's <strong>power</strong>, well ahead of any other <strong>power</strong> station.<br />

The design of the original Belchatow units was developed in the 1970s and did<br />

not anticipate any measures to limit emissions of sulphur oxides emissions because<br />

at that time flue gas desulphurisation technologies were largely unknown and only<br />

in the development phase. However, in the years 1988 to 1990, BOT Elektrownia<br />

Belchatow turned its attention to developments in Polish desulphurisation<br />

technologies as well as those being applied worldwide, and subsequently fitted<br />

FGD to ten of the 12 Belchatow units (numbers 3 to 12).<br />

To maintain a leading position in the Polish electricity market BOT Elektrownia<br />

Belchatow has adopted a strategy for capacity development, which entails<br />

comprehensive modernisation of Belchatow units 3 to 12, starting in 2007 – with the<br />

aim of enabling them to reach 320 thousand hours of operation, ie to operate until<br />

around 2035 – plus construction of the new unit, as described in the main article.<br />

The strategy, which assumes maintenance of high <strong>power</strong> production<br />

capabilities in association with optimal utilisation of available <strong>coal</strong> deposits<br />

(about 1 billion tonnes of lignite) in the Belchatow and Szczercow open cast<br />

mines, can be summarised as follows:<br />

• Construction of the new 858 MW <strong>power</strong> unit, with commercial operation scheduled<br />

for October 2010. This represents the largest investment of its kind yet in Poland.<br />

In 2001, official acceptance from the Ministry of the Treasury was obtained to<br />

commence a project to build a new 833 MW <strong>power</strong> unit. The capacity was<br />

subsequently increased to 858 MW, thanks to improved <strong>plant</strong> integration by EPC<br />

contractor Alstom. The tender procedure began in 2002 resulted in the selection<br />

of the Alstom consortium. The design was approved in 2005 and a construction<br />

permit issued. Construction work began in October 2006. The <strong>power</strong> <strong>plant</strong> will<br />

use best available technology (BAT), as required under IPPC, and will also fulfil the<br />

requirements of the EU Large Combustion Plant directive. First synchronisation<br />

with the Polish national grid is anticipated in February 2010. The project includes<br />

a new transmission link to the system switching station in Trebaczew.<br />

• Reconstruction and modernisation programme. Refurbishment of units 1 and 2<br />

(which do not have FGD) was done in 2004 and 2005, while modernisation of<br />

units 3-12 will be done according to the following schedule: unit 3 in 2007, unit 4<br />

Germany<br />

Belchatow<br />

in 2009, units 5 and 6 in 2010, units 7 and 8 in 2011, units 9 and 10 in 2012, and units 11 and 12 in 2013. The basic goals of the modernisation process<br />

include: extension of the operating lifetime of units 1 and 2 (to 2016) and of units 3-12 (to 2030-2035); improvement of operating performance; reduction<br />

in environmental impact, including compliance with EU Directive 2001/80/EC; and increase in turbine-generator unit <strong>power</strong> from 370 MW to 380 MW.<br />

The total investment cost (new build plus refurbishment) is 1.6 billion euro, with banks providing 880 million euro. The project won the<br />

Euromoney/Project Finance award for best European <strong>power</strong> deal of 2006.<br />

The new unit and the refurbishment programme are in line with BOT Elektrownia Belchatow's policy of striving to continuously upgrade and improve<br />

its <strong>power</strong> technology assets. The management system is also being continuously improved. The <strong>power</strong> <strong>plant</strong> holds a PCBC and IQNet certificate for an<br />

Integrated Management System for Quality, Environment, Occupational Safety and Information Security (IMS-ISO), compliant with the requirements of<br />

the PN-EN ISO 9001:2001, PN-N-18001:1999, PN-EN ISO 14001:1998 and PN-I-07799-2.<br />

Lodz<br />

Baltic Sea<br />

Piotrkow<br />

Trybunalski<br />

Poland<br />

Lodz<br />

Warsaw<br />

Slovakia<br />

Lithuania<br />

Belarus<br />

Ukraine<br />

Belchatow site, showing<br />

the 12 existing units<br />

Visualisation of the new 858 MWe unit at Belchatow, with<br />

existing units, right<br />

Poland's biggest<br />

The Belchatow extension will be the largest<br />

generating unit ever built in Poland and also the<br />

most efficient lignite <strong>plant</strong>, expected to achieve<br />

almost 42%.<br />

Alstom is supplying the <strong>plant</strong> to utility BOT<br />

Elektrownia Belchatow SA (which is owned by<br />

the state <strong>power</strong> generation holding company<br />

BOT Gornictwo i Energetyka) under a full<br />

turnkey EPC (engineering, procurement,<br />

construction and commissioning) contract. The<br />

contract was signed in December 2004 and the<br />

pre-engineering phase started immediately.<br />

Financial close and the official launch of the<br />

project (notice to proceed) was obtained in<br />

October 2006. Commercial operation is<br />

scheduled for the last quarter of 2010.<br />

There are already twelve 370 MWe lignite fired<br />

units at the Belchatow site, which started operation<br />

in the early 1980s and run in baseload mode. There<br />

was an urgent need to rehabilitate these units due<br />

to their age, emissions and economics.<br />

Ten of the units will be upgraded, over the period<br />

2007 to 2013, while the oldest two will be shut<br />

down permanently before 2016, with the new <strong>plant</strong><br />

more than making up the loss of <strong>power</strong> production.<br />

The end result will be increased electricity<br />

production in full compliance with European<br />

environmental regulations, including the Large<br />

Combustion Plant and Integrated Pollution<br />

Prevention and Control Directives.<br />

The total cost of the new <strong>plant</strong> plus the<br />

refurbishment of the existing units is estimated<br />

to be around 1.7 billion euros. The EBRD is<br />

providing a loan of 125 million euros for the<br />

new <strong>plant</strong>. Other investors include EIB, 220<br />

million euro, Nordic Investment Bank, 150<br />

million euro, and ING and Citibank, which are<br />

providing various facilities totalling 604<br />

million euro.<br />

BOT Elektrownia Belchatow decided to build<br />

the new 858 MWe unit as an extension of the<br />

existing unit in order to secure continuous<br />

deliveries of electricity to customers as well as<br />

maintaining a constant level of lignite<br />

consumption from the local open mine (a major<br />

cost factor for the <strong>power</strong> <strong>plant</strong>).<br />

Thanks to the project BOT Elektrownia<br />

Belchatow will:<br />

• secure its income by maintaining electricity<br />

production;

LIGNITE POWER<br />

Operating large <strong>coal</strong> and lignite <strong>plant</strong>s in Poland<br />

R Hard <strong>coal</strong><br />

4 Lignite<br />

4 Elblag<br />

Main features of the new<br />

Belchatow 858 MWe<br />

<strong>supercritical</strong> unit<br />

Turów<br />

• secure fuel costs by achieving constant lignite<br />

demand;<br />

• secure extended lifetimes for the upgraded<br />

existing units; and<br />

• meet all EU requirements relating to <strong>coal</strong> fired<br />

<strong>plant</strong>s.<br />

The environmental performance of the new <strong>plant</strong><br />

can be summarised as follows:<br />

• NO x emissions below 200 mg/Nm 3 ;<br />

• particulate emissions below 30 mg/Nm 3 thanks<br />

to ESP plus additional effect of wet<br />

desulphurisation;<br />

• reduction of SO x emissions to below 200 mg/Nm 3<br />

with a removal efficiency of over 96 %, again<br />

thanks to the wet desulphurisation system;<br />

• limitation of CO 2 emissions thanks to high<br />

<strong>plant</strong> efficiency;<br />

• reduction of raw cooling water consumption<br />

through measures such as reuse of cooling tower<br />

blowdown water and reuse of water from the<br />

nearby mine for ash slurry transport instead of<br />

using surface water resources; and<br />

• noise abatement though use of protection<br />

systems and special attention to design of<br />

sensitive systems, such as <strong>coal</strong> handling<br />

equipment, boiler fans, and cooling tower.<br />

Solid waste consisting of fly and bottom ash<br />

will be transported as slurry to a new landfill in<br />

the nearby lignite mine. Waste gypsum from the<br />

new wet limestone FGD scrubbing system will<br />

be used commercially, a practice well established<br />

in Poland. In fact the use of <strong>power</strong> <strong>plant</strong> gypsum<br />

for plasterboard in Poland was pioneered by the<br />

existing Belchatow units.<br />

Design features<br />

The Alstom scope of supply includes: a tower type<br />

<strong>supercritical</strong> once through pulverised <strong>coal</strong> boiler<br />

(with low NO x combustion system); five-casing<br />

<strong>steam</strong> turbine with three double flow exhausts<br />

(STF100); hydrogen cooled generator<br />

(GIGATOP); water cooled condenser;<br />

feedheating system with seven heaters; milling<br />

system; wet flue gas desulphurisation system; <strong>coal</strong><br />

Five-casing <strong>steam</strong><br />

turbine for Belchatow<br />

R Dolna Odra<br />

8 x 200 MW<br />

Turów<br />

3 x 238 MW<br />

1 x 265 MW<br />

4 6 x 200 MW<br />

R Opole<br />

4 x 360 MW<br />

4 Patnow<br />

7 x 120 MW<br />

8 X 200 MW<br />

4 Bełchatów<br />

12 x 360 MW<br />

Łayiska<br />

2 x 120 MW<br />

R 4 x 200 MW<br />

R Rybnik R Jaworzno III<br />

8 x 200 MW 6 x 200 MW<br />

R Ostrolęka<br />

3 x 200 MW<br />

R Kozienice<br />

8 x 200 MW<br />

2 x 500 MW<br />

R Połaniec<br />

8 x 200 MW<br />

Patnow<br />

and ash handling systems; control system based<br />

on Alstom ALSPA technology; and balance of<br />

<strong>plant</strong>. An important feature of the project has been<br />

careful integration of all these systems throughout<br />

all phases, from development of the concept,<br />

through the basic and detailed design up to erection<br />

and commissioning.<br />

The new 858 MW unit has been designed to<br />

achieve an operating life of about 200 000 hours,<br />

ie about 35 years.<br />

It will use local lignite from the existing<br />

Belchatow open cast mine, presently supplying fuel<br />

to the existing units, as well as from a new open cast<br />

lignite mine being constructed at Szczercow.<br />

The design of the unit as well as the equipment<br />

selected will allow the new <strong>plant</strong> to achieve an<br />

availability above 88% over the first two years<br />

of operation, with scheduled outages reduced to<br />

about two weeks for the annual overhaul, with a<br />

six week outage every three years.<br />

Thanks to its compact and modular design the<br />

new unit, with all auxiliary installations, will cover<br />

the relatively small area of 300 m long and 350 m<br />

wide, an extension to the area of the existing <strong>plant</strong>.<br />

The total height of the new turbine building will<br />

be 39 m and the boiler will be up to 150 m high.<br />

In addition to the new <strong>power</strong> block (boiler, turbine<br />

and generator) the project consists of: the new<br />

desulphurisation <strong>plant</strong> with auxiliary installations;<br />

recirculating cooling system with the cooling tower<br />

also used as a chimney; the complete electrical<br />

system with two unit transformers; new control<br />

system; water treatment system; <strong>coal</strong> handling<br />

system connecting the new unit with the lignite<br />

transportation system from the open mine to the<br />

existing units; hydraulic ash slurry transport<br />

systems; electrostatic precipitator; auxiliary systems<br />

and buildings, including administration building.<br />

The majority of deliveries and almost all the onsite<br />

work will be provided by Polish companies.<br />

Main components<br />

The main data for the <strong>plant</strong> are summarised in<br />

the table, right.<br />

Key features of the main systems include the<br />

following:<br />

Boiler<br />

Supercritical once-through single pass boiler<br />

with circulating pump for start up and turn down<br />

capability to 40% of boiler load.<br />

There is one 100% boiler feedwater pump driven<br />

by an auxiliary <strong>steam</strong> turbine connected to <strong>steam</strong><br />

extraction from the main <strong>steam</strong> turbine and two<br />

start up and reserve pumps (35% each) connected<br />

to electrical motors via hydrokinetic couplings.<br />

Fuel<br />

Cooling system<br />

Contract type<br />

Boiler<br />

Boiler type<br />

Lignite (domestic)<br />

Cooling tower<br />

(natural draft)<br />

Turnkey<br />

Tower,<br />

once through<br />

Steam flow (t/h) 2400<br />

Steam pressure (bar) 275<br />

Steam temperature (°C) 554<br />

Turbine (STF100)<br />

Number of casings 5<br />

Steam pressure (bar) 252<br />

Steam temperature -<br />

inlet/reheat (°C) 550/580<br />

Speed (rpm) 3000<br />

Generator (GIGATOP)<br />

Rating (MVA) 1042<br />

Power factor 0.85<br />

Frequency (Hz) 50<br />

Terminal voltage (kV) 27<br />

Excitation system<br />

Alstom<br />

Static Excitation<br />

System P320<br />

Cooling system<br />

Hydrogen<br />

plus water<br />

Condensing <strong>plant</strong><br />

Circulating water<br />

temperature (°C) 17.5<br />

Condenser pressure<br />

(mbar) 43<br />

Tube material<br />

Stainless steel,<br />

DIN 1.4439<br />

Feedwater heating <strong>plant</strong><br />

Feedwater heaters 7<br />

Feedwater deaerating tank 1<br />

Feedwater temperature (°C) 275<br />

Main pumps<br />

Condensate extraction 3 x 50% (first stage<br />

pumps<br />

plus second stage)<br />

Feedwater pump<br />

1 x 100% main<br />

turbine driven<br />

feedwater pump<br />

plus 2 x 35% start-up<br />

motor driven<br />

feedwater pumps<br />

Circulating water pumps 2 x 50%<br />

Polishing <strong>plant</strong><br />

yes<br />

Main transformer<br />

Rated output (MVA) 2 x 700<br />

Primary/secondary (kV) 420/27<br />

Unit transformers<br />

Rated output (MVA) 80/40/40<br />

Primary/secondary (kV) 27/10.5/10.5<br />

Standby transformer<br />

Rated output (MVA) 80/40/40<br />

Primary/secondary (kV) 115/10.5/10.5<br />

Instrumentation and control system<br />

Logic control<br />

Alstom ALSPA<br />

Analog control<br />

Alstom ALSPA<br />

Data acquisition<br />

Alstom ALSPA

LIGNITE POWER<br />

Process schematic of the new 858 MWe unit at Belchatow<br />

Cooling tower<br />

Boiler<br />

Cold reheat <strong>steam</strong> from HP cylinder<br />

Coal bunker<br />

Live <strong>steam</strong> to HP<br />

cylinder<br />

Absorber<br />

Electrostatic<br />

precipitator<br />

Turbine<br />

Generator<br />

Feedwater<br />

from<br />

feedwater<br />

pump<br />

Transformer<br />

GYPSUM COLLECTION<br />

Steam<br />

Cooling tower<br />

Feedwater<br />

Gypsum<br />

Limestone<br />

The design of the boiler has been done in<br />

Stuttgart, Germany, and production of most of the<br />

boiler components is being done in Raciborz,<br />

Poland.<br />

Turbine-generator<br />

The five-casing <strong>steam</strong> turbine (STF100) is of the<br />

reaction type and is being manufactured in Elblag,<br />

Poland. The GIGATOP generator is being produced<br />

in Wroclaw, Poland, and Birr, Switzerland.<br />

Control system<br />

The new unit will be equipped with an ALSPA<br />

P320 control system, which includes a<br />

CENTRALOG integrated monitoring and<br />

supervision system and CONTROBLOCK P320<br />

control blocks.<br />

Integration<br />

With Alstom the single EPC supplier, and<br />

through the use of its Plant Integrator<br />

capabilities, the project also provides a good<br />

example of the benefits of integration between<br />

systems, coupled with close co-operation<br />

between contractor and utility, during all phases<br />

of the project, from conceptual development of<br />

the concept, through basic and then detailed<br />

design up to erection and commissioning of the<br />

new <strong>plant</strong>.<br />

All major components of the new unit have<br />

been analysed as elements of the overall <strong>power</strong><br />

<strong>plant</strong> system to achieve the best balance between<br />

technology, costs, <strong>power</strong> production etc.<br />

Also, all major systems and the interfaces<br />

between them have been optimised to arrive at<br />

the most compact solution, matched to the<br />

limited area available for the new unit.<br />

In addition, integration combined with<br />

modularisation has contributed to reducing the<br />

expected project execution time to 48 months,<br />

from notice to proceed (October 2006) to<br />

obtaining of the provisional acceptance<br />

certificate (PAC) (October 2010).<br />

New drivers<br />

Ever more stringent environmental regulations<br />

and the emergence of open and competitive<br />

markets, with the need for increased productivity,<br />

are currently strong drivers in Central and Eastern<br />

European countries including Poland. The new<br />

Belchatow unit can be seen as a product of these<br />

combined forces.<br />

MPS<br />

Gypsum and<br />

limestone<br />

storage<br />

Cooling<br />

tower<br />

Water<br />

treatment<br />

Fuel oil<br />

area<br />

Switchyard<br />

Twice gas<br />

desulphurisation<br />

Turbine<br />

building<br />

Lignite<br />

crusher<br />

Boiler<br />

ESP<br />

Lignite<br />

conveyor<br />

Site plan of the new 858<br />

MWe unit at Belchatow<br />

Construction underway on the new unit

www.<strong>power</strong>.alstom.com<br />

Printed in England, TBC 1007E