SiRiUS: Setting the Standards for Tool Presetting

SiRiUS: Setting the Standards for Tool Presetting

SiRiUS: Setting the Standards for Tool Presetting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Precision and Dynamics<br />

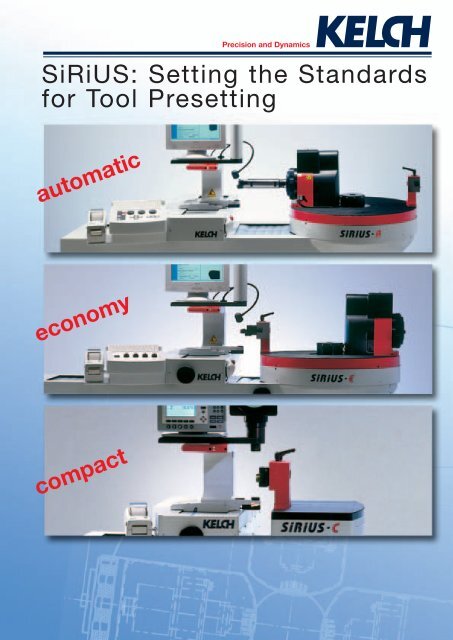

<strong>SiRiUS</strong>: <strong>Setting</strong> <strong>the</strong> <strong>Standards</strong><br />

<strong>for</strong> <strong>Tool</strong> <strong>Presetting</strong><br />

automatic<br />

economy<br />

compact

<strong>SiRiUS</strong> A: The model <strong>for</strong> tool presetting<br />

Newly designed, <strong>the</strong> <strong>SiRiUS</strong> A<br />

sets <strong>the</strong> standards <strong>for</strong> modern<br />

tool presetting.<br />

Unequaled precision, optimum<br />

repeatability, long-term stable<br />

construction and an ergonomic<br />

operation are <strong>the</strong> remarkable<br />

features of this device.<br />

To be used in <strong>the</strong> central tool<br />

room <strong>for</strong> measuring and setting<br />

simple and complex tools <strong>for</strong><br />

turning and milling where <strong>the</strong><br />

demands of accuracy and<br />

repeatability are required.<br />

Features:<br />

Self-supporting designed measuring<br />

and presetting machine with<br />

high inherent stability. Solid cast<br />

iron construction which will resist<br />

environmental influences like oscillations<br />

and vibrations.<br />

The large rotary table, optionally<br />

position-controlled, guarantees<br />

high flexibility when mounting various<br />

tool holders and toolholding<br />

spindles without changing any<br />

inserts or adaptors.<br />

Motor-driven axis control in three<br />

speeds with additional selective<br />

one-hand operation provides a<br />

manual and partly automatic operation<br />

with or without nominal data.<br />

The CNC drives in all levels<br />

allow fully automatic measuring<br />

processes, user-independent and<br />

at any time reproducible without<br />

machine know-how or setting<br />

knowledge.<br />

The driving control room offers a<br />

maximum of operation com<strong>for</strong>t<br />

and thus reduces operating errors<br />

as well as <strong>the</strong> time needed.<br />

The workshop-suitable design<br />

through integrated measuring control<br />

with industrial PC and standard<br />

control cabinet fulfills all<br />

requirements according to <strong>the</strong><br />

VDE, accident prevention, EMV<br />

and CE guidelines.<br />

2

<strong>SiRiUS</strong> A:<br />

Incredibly well<br />

Selective one-hand operation <strong>for</strong> optional<br />

single or common axis movement<br />

Motor-driven axis positioning directly at <strong>the</strong><br />

workshop-suitable operation panel<br />

Camera picture and control in<strong>for</strong>mation<br />

always at <strong>the</strong> measuring point<br />

3

<strong>SiRiUS</strong> E: The flexible solution <strong>for</strong> turning, drilling<br />

and milling tools<br />

The solid rotary table, <strong>the</strong> large<br />

measuring ranges as well as <strong>the</strong><br />

variety of available options give<br />

<strong>the</strong> <strong>SiRiUS</strong> E a whole host of<br />

features which predetermine it<br />

<strong>for</strong> tool presetting. The durable<br />

mechanics as well as <strong>the</strong> precise<br />

design combine low maintenance<br />

costs, simple operation<br />

and most accurate measuring<br />

results.<br />

Features:<br />

Self-supporting designed presetter<br />

with high inherent stability. Thus to<br />

a great extent resistant against<br />

environmental influences like oscillations<br />

and vibrations.<br />

The large rotary table guarantees<br />

high flexibility when mounting<br />

simultaneously various tool holders<br />

and toolholding spindles without<br />

changing any inserts or adaptors.<br />

The fine adjustment free from<br />

backlash via ready to hand placed<br />

handwheels provides toge<strong>the</strong>r with<br />

<strong>the</strong> selective one-hand operation a<br />

precise and quick positioning of<br />

<strong>the</strong> axes.<br />

The equipment is chosen -<br />

according to <strong>the</strong> field of use and<br />

<strong>the</strong> task - optionally with digital<br />

display or workshop PC as well<br />

as profile projector or highly precise<br />

image processing.<br />

Profile projector and digital display always<br />

in view of <strong>the</strong> operator<br />

4

<strong>SiRiUS</strong> C: The compact alternative<br />

In design and precision identical<br />

to <strong>the</strong> large presetters, <strong>the</strong><br />

<strong>SiRiUS</strong> C/CR is a real alternative<br />

<strong>for</strong> medium measuring ranges.<br />

Long-term stable and very<br />

accurate, this presetter is suitable<br />

<strong>for</strong> <strong>the</strong> tool room as well<br />

as <strong>for</strong> direct use in <strong>the</strong> manufacturing<br />

line.<br />

The most important<br />

summarized:<br />

The fine adjustment free from<br />

backlash via ready to hand placed<br />

handwheels provides toge<strong>the</strong>r with<br />

<strong>the</strong> selective one-hand operation a<br />

precise and quick positioning of<br />

<strong>the</strong> axes.<br />

The equipment is chosen -<br />

according to <strong>the</strong> field of use and<br />

<strong>the</strong> task - optionally with digital<br />

display or workshop PC as well as<br />

profile projector or highly precise<br />

image processing.<br />

Stable desktop device, which<br />

can be placed ei<strong>the</strong>r on <strong>the</strong><br />

workbench or on <strong>the</strong> specially<br />

designed TULRACK.<br />

The ample adaptor bridge or <strong>the</strong><br />

optionally available rotary table<br />

make possible to mount <strong>the</strong><br />

appropriate tool holder or toolholding<br />

spindle.<br />

5

Superior technology of <strong>the</strong> <strong>SiRiUS</strong> series<br />

Kelch has been providing solutions<br />

to <strong>the</strong> demands of manufacturing<br />

<strong>for</strong> 6 decades. Kelch<br />

has per<strong>for</strong>med indepth research<br />

and development of all components<br />

regarding hardware and<br />

software of our products including<br />

<strong>the</strong> new <strong>SiRiUS</strong> line of tool<br />

presetters.<br />

The development and production<br />

of our products is located<br />

at our main facility in Schorndorf<br />

Germany.<br />

<strong>SiRiUS</strong> tool presetters are an<br />

excellent investment <strong>for</strong> <strong>the</strong><br />

customer who expects <strong>the</strong><br />

highest quality and return.<br />

Durable and shop floor<br />

suitable <strong>for</strong> minimal<br />

investment<br />

High availability and minor maintenance<br />

expenditure are also superior<br />

features of all <strong>SiRiUS</strong> presetters.<br />

Control room <strong>SiRiUS</strong> A<br />

„OmniMotion“ <strong>for</strong><br />

perfect ergonomics<br />

The driving control column<br />

(OmniMotion) is an absolute highlight<br />

of all <strong>SiRiUS</strong> presetters and at <strong>the</strong><br />

same time a novelty with horizontal<br />

presetters. No matter whe<strong>the</strong>r with<br />

profile projector or image processing,<br />

<strong>the</strong> operator always has all in<strong>for</strong>mation<br />

exactly <strong>the</strong>re where it is required -<br />

directly at <strong>the</strong> measuring point.<br />

Horizontal presetters have <strong>the</strong> advantage<br />

that <strong>the</strong> tool cutting edge is<br />

always in one plain. This means that<br />

<strong>the</strong> operator has easy access <strong>for</strong> <strong>the</strong><br />

necessary setting tasks.<br />

This advantage on principal is even<br />

streng<strong>the</strong>ned if axis movement, spindle<br />

function and rotary table operation<br />

are executed directly in <strong>the</strong> measuring<br />

position and if <strong>the</strong>y can be controlled.<br />

Even <strong>the</strong> input, selection or correction<br />

of relevant data via <strong>the</strong> keys or trackball<br />

happens with OmniMotion always<br />

in <strong>the</strong> current position and in permanent<br />

sight control of all functions.<br />

OmniMotion perfects <strong>the</strong> user-friendliness<br />

of horizontal presetters, minimizes<br />

possible operating errors of <strong>the</strong><br />

control, increases <strong>the</strong> acceptance of<br />

<strong>the</strong> operator and guarantees constant<br />

accurate and reliable measuring<br />

results.<br />

All guideways are covered with metal<br />

way covers. These covers protect all<br />

axes against <strong>the</strong> accumulation of dirt,<br />

oil, dust and swarf. Also provides stable<br />

protection <strong>for</strong> <strong>the</strong> glass scales and<br />

<strong>the</strong> drive shafts. Unintentional damage<br />

of measuring components is almost<br />

impossible.<br />

Way Covers<br />

6

KELCH typical axis<br />

layout <strong>for</strong> mechanical<br />

precision<br />

In tool measurement, it is well-known<br />

that dynamic measuring deviations are<br />

minimized if measuring normal and<br />

measuring object sight out to each<br />

o<strong>the</strong>r. If this comparator principle is<br />

kept, <strong>the</strong> devices of <strong>the</strong> <strong>SiRiUS</strong> series<br />

achieve highest mechanical precision.<br />

Two precision guideways per axis on<br />

an extremely wide guiding base make<br />

room <strong>for</strong> <strong>the</strong> scales and <strong>the</strong> drive in<br />

<strong>the</strong> center of <strong>the</strong> axes and thus in true<br />

alignment to <strong>the</strong> tool cutting edge in<br />

<strong>the</strong> measuring position.<br />

Fur<strong>the</strong>rmore, <strong>the</strong> solid design made of<br />

long-term stable cast iron is to a great<br />

extent insensitive to temperature or<br />

vibration influences. Fur<strong>the</strong>r advantages<br />

of <strong>the</strong> cast iron are <strong>the</strong> favorable<br />

density of <strong>the</strong> material, <strong>the</strong> high design<br />

strength as well as <strong>the</strong> avoidance of<br />

<strong>the</strong> critical bimetal effect between <strong>the</strong><br />

presetter body and <strong>the</strong> linear guideway.<br />

The sum of <strong>the</strong>se and <strong>the</strong> variety of all<br />

of <strong>the</strong> optional features are a guarantee<br />

of <strong>the</strong> constant high mechanical<br />

accuracy of <strong>the</strong> <strong>SiRiUS</strong> series. This<br />

means finest measuring results in daily<br />

use. Reliable and consistent <strong>for</strong> many<br />

years in daily use.<br />

Z axis <strong>SiRiUS</strong>-E<br />

7

World-Class components and accessories<br />

Typical <strong>for</strong> horizontal presetters is <strong>the</strong><br />

rotary table, which allows <strong>the</strong> mounting<br />

of several tool holders or toolholding<br />

spindles. By this arrangement <strong>the</strong><br />

adaptor exchange can be eliminated<br />

partly or totally and <strong>the</strong> mounting of<br />

special tool holders is possible.<br />

<strong>SiRiUS</strong> A and <strong>SiRiUS</strong> E have a 800<br />

mm measuring range, very stable<br />

rotary table made of ribbed gray cast<br />

iron. The table is lifted and lowered by<br />

an integrated clamping cylinder pneumatically.<br />

The crown geared Hirth ring<br />

pair with 6° pitch serves <strong>for</strong> micrometer<br />

precise positioning.<br />

Modular precision spindle <strong>for</strong> highest<br />

repeatability when exchanging different<br />

insert modules quickly in just one base<br />

module.<br />

Highly precise and individual<br />

- <strong>Tool</strong> holders and<br />

toolholding spindles<br />

Highest concentricity, pneumatic functions<br />

and operations <strong>for</strong> manual or<br />

automatic measuring are <strong>the</strong> features<br />

of all high-precision spindles from<br />

KELCH. All <strong>SiRiUS</strong> presetters can be<br />

equipped optionally with:<br />

• Modular precision spindle<br />

• Universal toolholding spindle<br />

• Fixed tool holders<br />

8

Universal spindle adaptor with pneumatic<br />

clamping to insert <strong>the</strong> tool taper.<br />

Universal tool holding spindle and fixed tool holders in different versions<br />

<strong>for</strong> all kind of milling, drilling and turning tools with repeatable interface.<br />

Measuring:<br />

Mechanical, Optically<br />

or Automatically<br />

The intelligent image processing MEGAVISION with<br />

its still unique, true telecentric objective allows automatic<br />

measuring with user-independent reproducible<br />

measuring results<br />

A solid base <strong>for</strong> all <strong>SiRiUS</strong> devices is<br />

<strong>the</strong> specially developed optic carrier<br />

with integrated handwheel as a central<br />

element of <strong>the</strong> setting process.<br />

High quality profile projectors with 150<br />

mm or 250 mm focusing screen diameter<br />

and 10x, 20x or manifold magnifications<br />

draw a sharp picture of <strong>the</strong> tool<br />

cutting edge.<br />

As third linear axis <strong>for</strong> turning tools <strong>the</strong><br />

distance measure related to <strong>the</strong> turning<br />

center is often required. This can be measured<br />

at <strong>the</strong> SIRIUS presetters mechanically<br />

with a dial indicator or via <strong>the</strong> image<br />

processing.<br />

9

Extremely intelligent: The measuring electronics<br />

KELCH PICO LCD<br />

EASY Direct Link<br />

Integrated intelligent digital electronics<br />

<strong>for</strong> uncomplicated evaluation<br />

of <strong>the</strong> setting and measuring<br />

values. Com<strong>for</strong>table display of all<br />

program functions via key stroke.<br />

Suitable <strong>for</strong> <strong>the</strong> toolroom. Pico is a<br />

practical user friendly control.<br />

EASY Data Manager<br />

The efficient tool management<br />

directly at <strong>the</strong> presetter ensures<br />

<strong>the</strong> organized access to all relevant<br />

data of <strong>the</strong> tool with just one<br />

database. The EASY Data<br />

Manager includes <strong>the</strong> full functionality<br />

of <strong>the</strong> market leader TDM and<br />

is at any time scaleable - from <strong>the</strong><br />

single place up to group solutions.<br />

Direct access to <strong>the</strong> external database<br />

of <strong>the</strong> TDM tool management<br />

by Walter In<strong>for</strong>mationssysteme.<br />

No file transfer via associated network<br />

drives necessary.<br />

Simultaneous data access without<br />

double data existence. There<strong>for</strong>e,<br />

reduction of error sources.<br />

KELCH EASY-WebSet<br />

The new generation of <strong>the</strong> KELCH<br />

measuring control <strong>for</strong> presetters<br />

offers additional advantages -<br />

especially with regard to a userfriendly,<br />

quick operation: A com<strong>for</strong>table<br />

measuring control based<br />

on <strong>the</strong> graphic operating system<br />

Windows ® .<br />

A graphic-oriented user surface,<br />

consequently designed in consideration<br />

of <strong>the</strong> optimum positioning<br />

of all elements. The intuitive operation<br />

<strong>for</strong> <strong>the</strong> complete software on<br />

just two screens allows a short<br />

training. The KELCH Explorer<br />

gives an optimum overview of all<br />

correlations in <strong>the</strong> data management.<br />

10

First-Class-Service by KELCH<br />

Customer service<br />

System partner<br />

KELCH<br />

As a base <strong>for</strong> <strong>the</strong> rational production<br />

KELCH offers units, which<br />

perfectly fit with each o<strong>the</strong>r, round<br />

<strong>the</strong> machine tool up to complete<br />

toolroom equipment:<br />

• <strong>Tool</strong> holders and systems<br />

• Machine spindles<br />

• Automatic tool changers<br />

• Presetters<br />

• Measuring and inspection<br />

devices<br />

• Cleaning and assembly devices<br />

• TUL transport and storage systems<br />

Optimum care be<strong>for</strong>e, during and<br />

after <strong>the</strong> investment is self-evident.<br />

Our full service includes:<br />

• Training at <strong>the</strong> KELCH Training<br />

Center or directly at <strong>the</strong> customer<br />

• Comprehensive service and<br />

maintenance contracts<br />

• Regular update service <strong>for</strong> software<br />

System partner<br />

KELCH<br />

11

Precision and Dynamics<br />

<strong>SiRiUS</strong> Series – Technical Description<br />

<strong>SiRiUS</strong> A <strong>SiRiUS</strong> E <strong>SiRiUS</strong> C/CR<br />

Design • Self-supporting structure • Self-supporting structure • Desktop device<br />

Integrated control cabinet Integrated control cabinet optional on TULRACK II<br />

• Rotary table Ø 800 mm • Rotary table Ø 800 mm • Optional rotary table<br />

pneumatic pneumatic Ø 700 mm, pneumatic<br />

Drive • 2 axes CNC • 2 axes manual • 2 axes manual<br />

Quick adjustment • CNC, motor-driven or • Selective one-hand • Selective one-hand<br />

selective one-hand operation operation operation<br />

Fine adjustment • µ-precise with CNC or • µ-precise with ergonomically • µ-precise with ergonomically<br />

electronic handwheels arranged handwheels over arranged handwheels over<br />

over <strong>the</strong> whole measuring range <strong>the</strong> whole measuring range <strong>the</strong> whole measuring range<br />

<strong>Tool</strong>holding • Rotary table Ø 800 mm • Rotary table Ø 800 mm • Mounting bridge (<strong>SiRiUS</strong> C)<br />

Pneumatic clamping Pneumatic clamping • Rotary table Ø 700 mm,<br />

and lifting and lifting pneumatic (<strong>SiRiUS</strong> CR)<br />

• Universal precision spindles • Universal precision spindles • Universal precision spindles<br />

manual or CNC manual manual<br />

• Modular precision spindles • Modular precision spindles • Modular precision spindles<br />

manual or CNC manual manual<br />

• Fixed tool holders <strong>for</strong> • Fixed tool holders <strong>for</strong> • Fixed tool holders <strong>for</strong><br />

turning tools turning tools turning tools<br />

Cutting edge • Image processing • Profile projector or • Profile projector or<br />

inspection KELCH MEGAVISION image processing image processing<br />

KELCH MEGAVISION<br />

KELCH MEGAVISION<br />

Measuring control • EASY-WebSet on • Digital display PICO-LCD • Digital display PICO-LCD<br />

industrial PC or EASY-WebSet on or EASY-WebSet on<br />

workshop PC<br />

workshop PC<br />

Measuring ranges • X = 520 mm ø • X = 520 mm ø • X = 520 mm ø<br />

Z = 500 / 800 mm Z = 500 / 800 mm Z = 370 mm<br />

Dimensions<br />

max. L x W x H • 2440 x 1150 x 1760 mm • 2440 x 1150 x 1760 mm • 1380 x 1040 x 1740 mm<br />

Weight • 1300 kg • 1200 kg • 650 kg<br />

Sales Partner:<br />

Technical modifications subject to change without notice<br />

040604/2<br />

Kelch GmbH + Co. KG • POB 1440 • D - 73604 Schorndorf • Phone (+49) 7181/925-0 • Fax (+49) 7181/925-250 • info@kelch.de • www.kelch.de