Superior Abrasives Catalogs.pdf - JW Donchin CO.

Superior Abrasives Catalogs.pdf - JW Donchin CO.

Superior Abrasives Catalogs.pdf - JW Donchin CO.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FD or Finish Duty products enable the operator<br />

to prepare the work piece with a required surface<br />

finish.<br />

FEATURES:<br />

• Provide a consistent cut rate<br />

• Maintain a repeatable measured finish<br />

• Added flexibility<br />

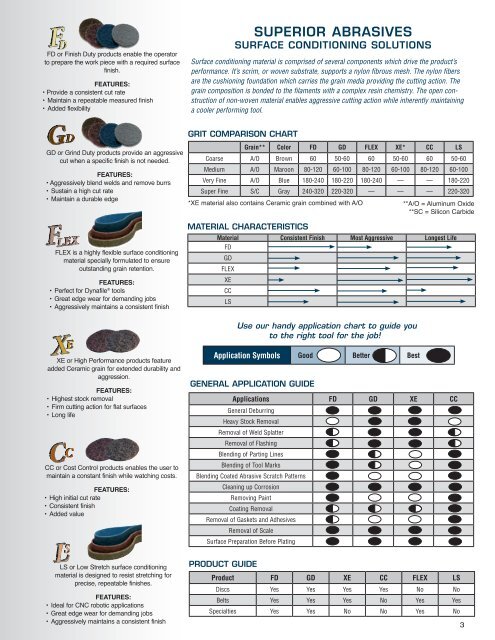

<strong>Superior</strong> abrasives<br />

sURFACE <strong>CO</strong>NDITIONING SOLUTIONS<br />

Surface conditioning material is comprised of several components which drive the product’s<br />

performance. It’s scrim, or woven substrate, supports a nylon fibrous mesh. The nylon fibers<br />

are the cushioning foundation which carries the grain media providing the cutting action. The<br />

grain composition is bonded to the filaments with a complex resin chemistry. The open construction<br />

of non-woven material enables aggressive cutting action while inherently maintaining<br />

a cooler performing tool.<br />

GRIT <strong>CO</strong>MPARISON CHART<br />

GD or Grind Duty products provide an aggressive<br />

cut when a specific finish is not needed.<br />

FEATURES:<br />

• Aggressively blend welds and remove burrs<br />

• Sustain a high cut rate<br />

• Maintain a durable edge<br />

FLEX is a highly flexible surface conditioning<br />

material specially formulated to ensure<br />

outstanding grain retention.<br />

FEATURES:<br />

• Perfect for Dynafile ® tools<br />

• Great edge wear for demanding jobs<br />

• Aggressively maintains a consistent finish<br />

Grain** Color FD GD FLEX XE* CC LS<br />

Coarse A/O Brown 60 50-60 60 50-60 60 50-60<br />

Medium A/O Maroon 80-120 60-100 80-120 60-100 80-120 60-100<br />

Very Fine A/O Blue 180-240 180-220 180-240 — — 180-220<br />

Super Fine S/C Gray 240-320 220-320 — — — 220-320<br />

*XE material also contains Ceramic grain combined with A/O<br />

**A/O = Aluminum Oxide<br />

**SC = Silicon Carbide<br />

MATERIAL CHARACTERISTICS<br />

Material Consistent Finish Most Aggressive Longest Life<br />

FD<br />

GD<br />

FLEX<br />

XE<br />

CC<br />

LS<br />

Use our handy application chart to guide you<br />

to the right tool for the job!<br />

XE or High Performance products feature<br />

added Ceramic grain for extended durability and<br />

aggression.<br />

FEATURES:<br />

• Highest stock removal<br />

• Firm cutting action for flat surfaces<br />

• Long life<br />

CC or Cost Control products enables the user to<br />

maintain a constant finish while watching costs.<br />

FEATURES:<br />

• High initial cut rate<br />

• Consistent finish<br />

• Added value<br />

Application Symbols Good Better Best<br />

GENERAL APPLICATION GUIDE<br />

Applications FD GD XE CC<br />

General Deburring<br />

Heavy Stock Removal<br />

Removal of Weld Splatter<br />

Removal of Flashing<br />

Blending of Parting Lines<br />

Blending of Tool Marks<br />

Blending Coated Abrasive Scratch Patterns<br />

Cleaning up Corrosion<br />

Removing Paint<br />

Coating Removal<br />

Removal of Gaskets and Adhesives<br />

Removal of Scale<br />

Surface Preparation Before Plating<br />

LS or Low Stretch surface conditioning<br />

material is designed to resist stretching for<br />

precise, repeatable finishes.<br />

FEATURES:<br />

• Ideal for CNC robotic applications<br />

• Great edge wear for demanding jobs<br />

• Aggressively maintains a consistent finish<br />

PRODUCT GUIDE<br />

Product FD GD XE CC FLEX LS<br />

Discs Yes Yes Yes Yes No No<br />

Belts Yes Yes Yes No Yes Yes<br />

Specialties Yes Yes No No Yes No