Catalogue 204 - Fine Grinding and Polishing Tools - PFERD

Catalogue 204 - Fine Grinding and Polishing Tools - PFERD

Catalogue 204 - Fine Grinding and Polishing Tools - PFERD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COMBIDISC ® <strong>Grinding</strong> <strong>Tools</strong><br />

General Information<br />

COMBIDISC ® tools cover the full range of surface<br />

finishing applications. From coarse grinding<br />

through surface texturing to face-down<br />

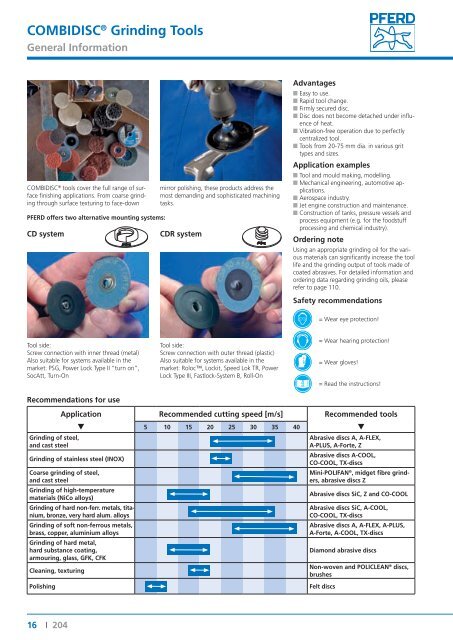

<strong>PFERD</strong> offers two alternative mounting systems:<br />

CD system<br />

mirror polishing, these products address the<br />

most dem<strong>and</strong>ing <strong>and</strong> sophisticated machining<br />

tasks.<br />

CDR system<br />

Advantages<br />

■■Easy to use.<br />

■■Rapid tool change.<br />

■■Firmly secured disc.<br />

■■Disc does not become detached under influence<br />

of heat.<br />

■■Vibration-free operation due to perfectly<br />

centralized tool.<br />

■■<strong>Tools</strong> from 20-75 mm dia. in various grit<br />

types <strong>and</strong> sizes.<br />

Application examples<br />

■■Tool <strong>and</strong> mould making, modelling.<br />

■■Mechanical engineering, automotive applications.<br />

■■Aerospace industry.<br />

■■Jet engine construction <strong>and</strong> maintenance.<br />

■■Construction of tanks, pressure vessels <strong>and</strong><br />

process equipment (e.g. for the foodstuff<br />

processing <strong>and</strong> chemical industry).<br />

Ordering note<br />

Using an appropriate grinding oil for the various<br />

materials can significantly increase the tool<br />

life <strong>and</strong> the grinding output of tools made of<br />

coated abrasives. For detailed information <strong>and</strong><br />

ordering data regarding grinding oils, please<br />

refer to page 110.<br />

Safety recommendations<br />

= Wear eye protection!<br />

Tool side:<br />

Screw connection with inner thread (metal)<br />

Also suitable for systems available in the<br />

market: PSG, Power Lock Type II “turn on”,<br />

SocAtt, Turn-On<br />

Recommendations for use<br />

Tool side:<br />

Screw connection with outer thread (plastic)<br />

Also suitable for systems available in the<br />

market: Roloc, Lockit, Speed Lok TR, Power<br />

Lock Type III, Fastlock-System B, Roll-On<br />

= Wear hearing protection!<br />

= Wear gloves!<br />

= Read the instructions!<br />

<strong>Grinding</strong> of steel,<br />

<strong>and</strong> cast steel<br />

Application Recommended cutting speed [m/s] Recommended tools<br />

<strong>Grinding</strong> of stainless steel (INOX)<br />

5 10 15 20 25 30 35 40 <br />

Coarse grinding of steel,<br />

<strong>and</strong> cast steel<br />

<strong>Grinding</strong> of high-temperature<br />

materials (NiCo alloys)<br />

<strong>Grinding</strong> of hard non-ferr. metals, titanium,<br />

bronze, very hard alum. alloys<br />

<strong>Grinding</strong> of soft non-ferrous metals,<br />

brass, copper, aluminium alloys<br />

<strong>Grinding</strong> of hard metal,<br />

hard substance coating,<br />

armouring, glass, GFK, CFK<br />

Cleaning, texturing<br />

Abrasive discs A, A-FLEX,<br />

A-PLUS, A-Forte, Z<br />

Abrasive discs A-COOL,<br />

CO-COOL, TX-discs<br />

Mini-POLIFAN ® , midget fibre grinders,<br />

abrasive discs Z<br />

Abrasive discs SiC, Z <strong>and</strong> CO-COOL<br />

Abrasive discs SiC, A-COOL,<br />

CO-COOL, TX-discs<br />

Abrasive discs A, A-FLEX, A-PLUS,<br />

A-Forte, A-COOL, TX-discs<br />

Diamond abrasive discs<br />

Non-woven <strong>and</strong> POLICLEAN ® discs,<br />

brushes<br />

<strong>Polishing</strong><br />

Felt discs<br />

16 I <strong>204</strong>