Speciality Lubricants for Processing Plants in the Mining Industry

Speciality Lubricants for Processing Plants in the Mining Industry

Speciality Lubricants for Processing Plants in the Mining Industry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Lubricants</strong> <strong>for</strong> enclosed gearboxes<br />

The KlüberComp Lube Technology concept comb<strong>in</strong>es all that is required <strong>for</strong> <strong>the</strong> needs of<br />

modern power transmission technology.<br />

––<br />

Composition: Formulations <strong>for</strong> lubricants based on high-quality raw materials that<br />

are, <strong>for</strong> example, resistant to age<strong>in</strong>g, free of heavy metals and have a low tendency<br />

to <strong>for</strong>m residues.<br />

––<br />

Components: All lubricated components are taken <strong>in</strong>to account, e.g. gear teeth,<br />

roll<strong>in</strong>g bear<strong>in</strong>gs, radial shaft seals.<br />

––<br />

Competitive: Maximum per<strong>for</strong>mance, standardised and application-related test<strong>in</strong>g<br />

under extreme conditions.<br />

––<br />

Competence: Consultation and tailored services, optimum product selection, wide<br />

range of lubricants, staff tra<strong>in</strong><strong>in</strong>g.<br />

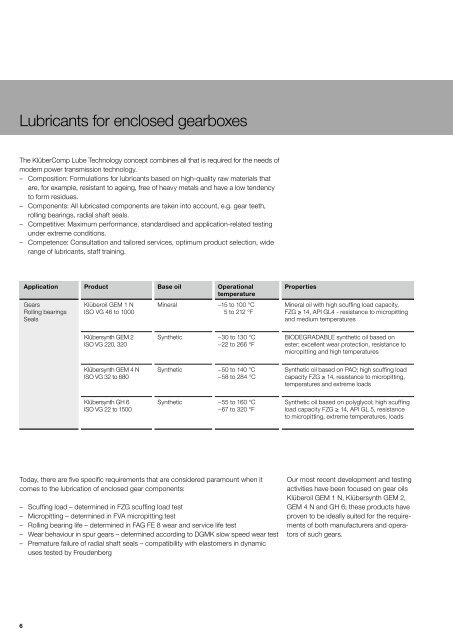

Application Product Base oil Operational<br />

temperature<br />

Gears<br />

Roll<strong>in</strong>g bear<strong>in</strong>gs<br />

Seals<br />

Klüberoil GEM 1 N<br />

ISO VG 46 to 1000<br />

M<strong>in</strong>eral −15 to 100 °C<br />

5 to 212 °F<br />

Properties<br />

M<strong>in</strong>eral oil with high scuff<strong>in</strong>g load capacity,<br />

FZG ≥ 14, API GL4 - resistance to micropitt<strong>in</strong>g<br />

and medium temperatures<br />

Klübersynth GEM 2<br />

ISO VG 220, 320<br />

Syn<strong>the</strong>tic −30 to 130 °C<br />

−22 to 266 °F<br />

BIODEGRADABLE syn<strong>the</strong>tic oil based on<br />

ester; excellent wear protection, resistance to<br />

micropitt<strong>in</strong>g and high temperatures<br />

Klübersynth GEM 4 N<br />

ISO VG 32 to 680<br />

Syn<strong>the</strong>tic −50 to 140 °C<br />

−58 to 284 °C<br />

Syn<strong>the</strong>tic oil based on PAO; high scuff<strong>in</strong>g load<br />

capacity FZG ≥ 14, resistance to micropitt<strong>in</strong>g,<br />

temperatures and extreme loads<br />

Klübersynth GH 6<br />

ISO VG 22 to 1500<br />

Syn<strong>the</strong>tic −55 to 160 °C<br />

−67 to 320 °F<br />

Syn<strong>the</strong>tic oil based on polyglycol; high scuff<strong>in</strong>g<br />

load capacity FZG ≥ 14, API GL 5, resistance<br />

to micropitt<strong>in</strong>g, extreme temperatures, loads<br />

Today, <strong>the</strong>re are five specific requirements that are considered paramount when it<br />

comes to <strong>the</strong> lubrication of enclosed gear components:<br />

––<br />

Scuff<strong>in</strong>g load – determ<strong>in</strong>ed <strong>in</strong> FZG scuff<strong>in</strong>g load test<br />

––<br />

Micropitt<strong>in</strong>g – determ<strong>in</strong>ed <strong>in</strong> FVA micropitt<strong>in</strong>g test<br />

––<br />

Roll<strong>in</strong>g bear<strong>in</strong>g life – determ<strong>in</strong>ed <strong>in</strong> FAG FE 8 wear and service life test<br />

––<br />

Wear behaviour <strong>in</strong> spur gears – determ<strong>in</strong>ed accord<strong>in</strong>g to DGMK slow speed wear test<br />

––<br />

Premature failure of radial shaft seals – compatibility with elastomers <strong>in</strong> dynamic<br />

uses tested by Freudenberg<br />

Our most recent development and test<strong>in</strong>g<br />

activities have been focused on gear oils<br />

Klüberoil GEM 1 N, Klübersynth GEM 2,<br />

GEM 4 N and GH 6; <strong>the</strong>se products have<br />

proven to be ideally suited <strong>for</strong> <strong>the</strong> requirements<br />

of both manufacturers and operators<br />

of such gears.<br />

6