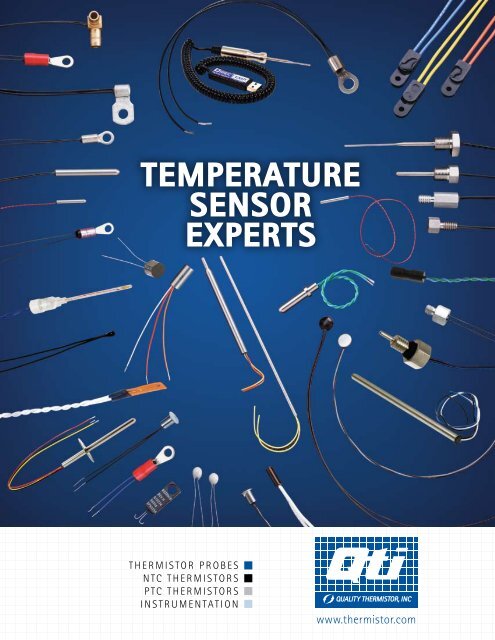

TEMPERATURE SENSOR EXPERTS - Quality Thermistor Inc.

TEMPERATURE SENSOR EXPERTS - Quality Thermistor Inc.

TEMPERATURE SENSOR EXPERTS - Quality Thermistor Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

temperature<br />

sensor<br />

experts<br />

THERMISTOR PROBES<br />

NTC THERMISTORS<br />

PTC THERMISTORS<br />

INSTRUMENTATION<br />

www.thermistor.com

Surface<br />

They have been used for many years to measure<br />

probes<br />

hat is an RTD<br />

sistance Temperature Detectors (RTDs) are<br />

mperature sensors that contain a resistor that<br />

anges resistance value as its temperature changes.<br />

ey have been used for many years to measure<br />

mperature in laboratory and industrial processes,<br />

d have developed a reputation for accuracy,<br />

peatability, and stability.<br />

What is an RTD<br />

Resistance Temperature Detectors (RTDs) are<br />

temperature sensors that contain a resistor that<br />

changes resistance value as its temperature changes.<br />

temperature in laboratory and industrial processes,<br />

and have developed a reputation for accuracy,<br />

repeatability, and stability.<br />

Custom solutions:<br />

ture Detectors (RTDs) are<br />

s that contain With a resistor QTI Probes that you have the flexiblilty of applying a<br />

value as its temperature changes.<br />

variety of sensor options with the housing of your choice.<br />

d for many years to measure<br />

ratory and industrial processes,<br />

a reputation for accuracy,<br />

ability.<br />

THERMISTOR USB HERMETICALLY SEALED <strong>SENSOR</strong><br />

Flag ring lug probes<br />

n Available in a variety of sizes with or without insulation<br />

n Standard lug sizes #4 to #12 with additional styles available<br />

n Recommended wire sizes #24-28 AWG<br />

n Material: Tinned Copper or ni plated steel<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

ring lug probes<br />

n Available in a variety of sizes with or without insulation<br />

n Standard lug sizes #4 to #12 with additional styles available<br />

n Recommended wire sizes #24-28 AWG<br />

n Material: Tinned Copper or ni plated steel<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

.<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

flat disc probes<br />

n Versatile, multi-purpose surface sensor<br />

n Standard sizes are 0.33” and 0.21”<br />

n Recommended wire sizes #24-28 AWG<br />

n Can be overmolded<br />

n Material: Stainless Steel, Copper, Aluminum<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

MOlded Ring luG probes<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

n Ideal for high humidity environments<br />

n Operating Temp range: -40ºC - to 80ºC<br />

n Recommended wire sizes #22 AWG<br />

n Material: Molded Plastic<br />

.<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Pipe mount probes<br />

100%<br />

n GUARANTEED Ideal for high humidity environments<br />

HERMETICALLY<br />

SEALED<br />

n Operating Temp range: -40ºC - to 80ºC<br />

n Recommended wire sizes #22 AWG<br />

n Material: Molded Plastic<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

2 www.thermistor.com | Probes<br />

100%<br />

GUARANTEED

Waterproof<br />

Temperature<br />

sensor<br />

IP68 rated product<br />

QTI’s Hydroguard IP68 Series of parts combines a highly stable precision thermistor<br />

encapsulated with an extremely durable waterproof housing. The temperature sensor<br />

offers excellent performance during harsh freeze thaw cycles. The over molded probes<br />

are a great solution where waterproof and moisture resistance is critical.<br />

Features<br />

n Precision NTC <strong>Thermistor</strong><br />

n Long term stability<br />

n Double insulated thermoplastic rubber<br />

n Ruggedized housing and corrosion resistant cable<br />

n Waterproof rating to IP68<br />

n Based on the most common curves in the industry<br />

Applications<br />

n Refrigeration and freezer applications<br />

n Air-conditioning<br />

n Under floor heating<br />

n Climate control systems<br />

n High humidity environments<br />

n Maximizing refrigerator equipment life<br />

temperature range<br />

cable<br />

resistance values @ 25ºC<br />

dielectric strength<br />

-55ºC to 105ºC (-67ºF to 221ºF) continuous<br />

Also avialable up to 150º C (302ºF)<br />

2’, 5’, 10’, 25’ (custom lengths available)<br />

#24 AWG stranded copper, VDE Approved<br />

Insulation Resistance 100MOhm at 1000 VDC<br />

Color coded wire available<br />

2.25k, 5k, 10k, 20k, 100k, Other values available.<br />

3750 VAC<br />

accuracy Point Matched: +/- 1%, 2%, 5% and 10%<br />

Interchangeable 0º-70ºC (32-158ºF): +/- 0.2ºC<br />

moisture resistance<br />

Meets or exceeds IP68<br />

Probes | www.thermistor.com<br />

3

Liquid<br />

probes<br />

Pipe & SAE Threaded Fitting with Tube<br />

n General purpose, rugged high pressure design<br />

n Recommended wire sizes #22-28 AWG<br />

n Material: Stainless Steel, Brass, Titanium<br />

n Straight thread option with or without O-rings.<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Closed End Tube<br />

n 100%<br />

GUARANTEED<br />

Versatile, multi-purpose sensor<br />

HERMETICALLY<br />

n SEALED<br />

Standard sizes are 0.040” to .250” in diameter<br />

n Recommended wire sizes #22-32 AWG<br />

n Material: Stainless Steel, Brass, Titanium, <strong>Inc</strong>onel, Hastelloy<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Composite Probes<br />

n 100% Ideal for reducing thermal time response<br />

GUARANTEED<br />

HERMETICALLY<br />

n Materials: Brass or Stainless Steel with high temp plastic<br />

SEALED<br />

n Available with or without O-rings.<br />

n Wide selection of connectors and strain relief.<br />

n NPT or straight threads<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Hex Nut Probes<br />

n 100% Available in a variety of sizes .060” to 0.50”<br />

GUARANTEED<br />

HERMETICALLY<br />

n General purpose, rugged high pressure design<br />

SEALED<br />

n Recommended wire sizes #26-28 AWG<br />

n Material: Stainless Steel, Brass, Titanium, Aluminum<br />

n Available with or without O-rings.<br />

n Available in Metric and reverse threads.<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Inspection Probes<br />

n 100% Ideal for spot inspection<br />

GUARANTEED<br />

HERMETICALLY<br />

n Recommended wire/cable sizes #22-28 AWG<br />

SEALED<br />

n Material: Stainless Steel with plastic or metal handle<br />

n Available with straight or T handle<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Fast Response-Stepped Housings<br />

n Available in a variety of sizes from .040” to 0.080”<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

n Recommended wire sizes #32-38 AWG<br />

SEALED<br />

n Material: Stainless Steel<br />

n Available with stepped housings<br />

n Food Grade Stainless Steel<br />

100%<br />

100%<br />

GUARANTEED<br />

GUARANTEED<br />

HERMETICALLY<br />

HERMETICALLY<br />

SEALED<br />

4 SEALED<br />

www.thermistor.com | Probes

Air-Gas<br />

probes<br />

rivet style probes<br />

n Available in a variety of sizes<br />

n Designed for harsh environments<br />

n Ideal for over molding<br />

n Material: Stainless Steel, Anodized Aluminum<br />

T0220 Style Probes<br />

n Ideal for heat sink surface temperature<br />

n Standard T0220 package size<br />

n Material: Thermoset Plastic<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

flanged, open tip<br />

n Available in a variety of sizes with or without brazed flange<br />

n Flange can be screwed or riveted in place<br />

n Recommended wire sizes #22-28 AWG<br />

n Material: Stainless Steel<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

polyimide tube<br />

n Versatile, multi-purpose sensor with high dielectric strength<br />

n Standard sizes are 0.040” and 0.136” in diameter<br />

n Recommended wire sizes #22-28 AWG<br />

n Material: Polyimide tube<br />

.<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

MOlded tube probes<br />

n Ideal for high humidity environments<br />

n Operating Temp range: -40ºC - to 80ºC<br />

n Recommended wire sizes #22 AWG<br />

n Material: Molded Plastic<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

SEALED<br />

Probes | www.thermistor.com<br />

100%<br />

GUARANTEED<br />

HERMETICALLY<br />

5

how do I<br />

use a<br />

thermistor<br />

Closed end tube with flange,<br />

ideal for rivet mounting.<br />

What is meant by “Interchangeability”<br />

or “Curve tracking”<br />

A thermistor can be defined as having an interchangeability<br />

tolerance of ±0.1°C over the range from 0° to<br />

70°C. This means that all points between 0° and 70°C,<br />

are within 0.1°C of the nominal resistance values for<br />

that particular thermistor curve. This feature results<br />

in temperature measurements accurate to ±0.1°C no<br />

matter how many different thermistors are substituted<br />

in the application.<br />

What is meant by ‘”Point Matched”<br />

A standard thermistor is calibrated and tested at 25°C<br />

to a tolerance of ± 1%, 2%, 5% or 10%. Since these<br />

thermistors only have one controlled point of reference<br />

or ‘point matched’ temperature, the resistance<br />

at other temperatures are given by the "Resistance vs.<br />

Temperature Conversion Tables" for the appropriate<br />

material curve. The resistance value at any temperature<br />

is the ratio factor times the resistance at 25°C.<br />

In addition to the industry standard of point matching<br />

thermistors at 25°C, <strong>Quality</strong> <strong>Thermistor</strong> can point match<br />

to a specific temperature range. Examples of this would<br />

be the freezing point of water (0°C) or human body<br />

temperature (37°C).<br />

Available Interchangeable Tolerances<br />

-20Cº to +50ºC<br />

A2 = +/- 1ºC<br />

B2 = +/- 0.5ºC<br />

C2 = +/- 0.2ºC<br />

0Cº to 100ºC<br />

A4 = +/- 1°C<br />

B4 = +/- 0.5°C<br />

C4 = +/- 0.2°C<br />

+20Cº to +50ºC<br />

A6 = +/- 1ºC<br />

B6 = +/- 0.5ºC<br />

C6 = +/- 0.2ºC<br />

D6 = +/- 0.1ºC<br />

0Cº to +70ºC<br />

A3 = +/- 1ºC<br />

B3 = +/- 0.5ºC<br />

C3 = +/- 0.2ºC<br />

D3 = +/- 0.1ºC<br />

+20Cº to +90ºC<br />

A5 = +/- 1ºC<br />

B5 = +/- 0.5ºC<br />

C5 = +/- 0.2ºC<br />

What is<br />

Thermal<br />

Dissipation<br />

Thermal Dissipation<br />

The thermal dissipation of a thermistor is the power<br />

required to raise the thermistor’s body temperature<br />

by 1°C. The dissipation is expressed in units of<br />

mW/°C (milliwatts per degree Celcius).<br />

Dissipation can be affected by:<br />

4 Mass of the thermistor probe<br />

4 How the probe and sensor are mounted<br />

4 Thermal dynamics of the environment<br />

The dissipation is an important factor in applications<br />

that are based on the self-heating effect of thermistors.<br />

Specifically, the change in resistance of the<br />

thermistor due to change in dissipation can be used<br />

to monitor levels or flow rates of liquids or gasses.<br />

As an example, as the flow rate increases, the dissipation<br />

of the thermistor in a fluid path will increase<br />

and the resistance will change and can be correlated<br />

to the flow rate.<br />

Stated another way, the dissipation is a measure of<br />

the thermal connection of the thermistor to its surroundings.<br />

It is generally given for the thermistor in<br />

still air, but sometimes in well-stirred oil.<br />

What is<br />

self-heating<br />

Self-heating effects<br />

When current flows through a thermistor, it generates<br />

heat, which raises the temperature of the thermistor<br />

above that of its environment. If this effect is not<br />

compensated, it will cause an error in measurement.<br />

Typically, the smaller the thermistor, the lower the<br />

amount of current needed to self-heat.<br />

The electrical power input to the thermistor is just<br />

PE = IV<br />

where I is current and V is the voltage drop across<br />

the thermistor. This power is converted to heat, and<br />

this heat energy is transferred to the surrounding<br />

environment. The rate of transfer is well described by<br />

Newton’s law of cooling: PT = K(T(R) - T0)<br />

where T(R) is the temperature of the thermistor as a<br />

function of its resistance R, T0 is the temperature of<br />

the surroundings, and K is the dissipation constant,<br />

usually expressed in units of milliwatts per °C. At<br />

equilibrium, the two rates must be equal.<br />

PE = PT<br />

The current and voltage across the thermistor will<br />

depend on the particular circuit configuration. As a<br />

simple example, if the voltage across the thermistor<br />

is held fixed, then by Ohm’s Law we have I = V / R<br />

and the equilibrium equation can be solved for the<br />

ambient temperature as a function of the measured<br />

resistance of the thermistor:<br />

V 2<br />

T0 = T(R) -<br />

KR<br />

The dissipation constant is a measure of the thermal<br />

connection of the thermistor to its surroundings. It is<br />

generally given for the thermistor in still air, and in<br />

well-stirred oil. Typical values for a small glass bead<br />

thermistor are 1.5 mw/°C in still air and 6.0 mw/°C<br />

in stirred oil. If the temperature of the environment<br />

is known beforehand, then a thermistor may be used<br />

to measure the value of the dissipation constant. For<br />

example, the thermistor may be used as a flow rate<br />

sensor, since the dissipation constant increases with<br />

the rate of flow of a fluid past the thermistor.<br />

6 www.thermistor.com | THERMISTORS

Available<br />

Tolerances<br />

Precision USB<br />

thermometer<br />

precision temperature 0.1º C: 0 ºC to 100 acquisition ºC or +/- 0.5°C (0-70°) system<br />

1.5º C: -55 ºC to 150 ºC<br />

n Accuracy +/- 0.1°C (0-100°C) or +/- 0.5°C (0-70°)<br />

n Custom probe and cable configuration<br />

n NIST Traceable - Certification available<br />

n Data logging and alert notification software included<br />

n Able to run multiple sensors<br />

Customizable USB Probe<br />

AVAILABLE<br />

TOLERANCES<br />

RESOLUTION<br />

RoHS COMPLIANT<br />

CURRENT DRAW<br />

+/- 0.5°C (0-70°C)<br />

+/- 0.1°C (0-100°C)<br />

+/- 0.05°C (0-70°C)<br />

0.01 ºC<br />

Yes<br />

< 100mA<br />

DirecTempº Software<br />

(HID configuration only)<br />

Available Interface Options<br />

HID Configuration<br />

(Plug & Play, DirecTempº Software <strong>Inc</strong>luded)<br />

n Automatic driver installation in MS Windows<br />

n DirecTemp data logging software included for Windows<br />

n Stream data to a plot and record to file for future analysis<br />

n Compatible with Windows 2000 and newer 32 bit systems<br />

USB-Serial Configuration<br />

(Virtual Com Port, For OEM & Proprietary Software Applications)<br />

n Virtual serial device<br />

n Designed for integration with custom third party software applications<br />

n Free demo software & LabVIEW VI included<br />

n Communication protocol information available upon request<br />

n Compatible with Linux, Windows, and MacOS systems<br />

n Additional programming language examples available.<br />

*Windows 32 bit versions work with included DirecTempº software<br />

**User specified single point temperatures and tolerances available<br />

Warning: Do not use in human life support applications.<br />

This device is not designed nor intended to operate in situations where human injury will result in the event of a failure.<br />

THERMISTORS | www.thermistor.com<br />

7

NTC<br />

thermistor<br />

Elements<br />

Why QTI<br />

Brand<br />

www.thermistor.com<br />

The QTI brand temperature sensing probes found<br />

in this catalog use NTC thermistor technology. NTC<br />

thermistors are the most reliable, sensitive, and cost<br />

effective technology for temperature measurement<br />

& control.<br />

Experts in <strong>Thermistor</strong> Manufacturing:<br />

<strong>Quality</strong> <strong>Thermistor</strong> manufactures the ceramic based NTC<br />

thermistor elements used in our temperature probes.<br />

We assure our customers are receiving the most stable,<br />

accurate, and reliable sensors available.<br />

100% Final Testing:<br />

All of the temperature probes manufactured by <strong>Quality</strong><br />

<strong>Thermistor</strong> are 100% inspected for accuracy in temperature<br />

controlled baths to ensure proper electrical<br />

and curve-fit tolerances. “Set-point” tolerances can be<br />

specified at any temperature between -55C & +200C.<br />

Calibration data is available as an option on all of the<br />

probes we manufacture.<br />

Attention to Detail:<br />

The proprietary manufacturing processes and materials<br />

used in manufacturing our temperature probes ensure<br />

proper sensor placement to optimize thermal time<br />

response. Closed-end Stainless Steel probe housings<br />

feature “rolled” ends which maintain the specified wall<br />

thickness throughout the entire enclosure. This optimizes<br />

thermal time response and minimizes the thermal<br />

load on the sensing element.<br />

design assistance:<br />

QTI is AS9100 and ISO 9001 registered.<br />

While we trust that the information provided within<br />

this design guide will assist you in the selection of the<br />

appropriate materials, there is no substitute for candid<br />

one-to-one dialog. We encourage you to contact the<br />

<strong>Quality</strong> <strong>Thermistor</strong> factory or field sales representative<br />

in your area to discuss specific design, sales or customer<br />

support needs. “Live” design assistance is also available<br />

Monday through Friday (8 am - 5 pm MST) at www.<br />

thermistor.com<br />

Why use a<br />

thermistor<br />

Resolution - Large change in resistance for a small<br />

change in temperature<br />

Another advantage of the thermistor is its relatively high<br />

resistance. <strong>Thermistor</strong>s are available with base resistances<br />

(at 25° C) ranging from tens to millions of ohms.<br />

This high resistance reduces the effect of resistance in<br />

the lead wires, which can cause significant errors with<br />

low resistance devices such as RTD’s. An example of this<br />

is the traditional RTD, which typically requires 3-wire<br />

or 4-wire connections to reduce errors, caused by lead<br />

wire resistance; 2-wire connections to thermistors are<br />

usually adequate.<br />

The thermistor has been used primarily for high-resolution<br />

measurements over limited temperature ranges<br />

(-55° to 150°C). The classic example of this would be a<br />

medical application where the user is only concerned<br />

with body temperature. However, widespread improvements<br />

in thermistor stability, accuracy, and interchangeability<br />

have prompted increased usage of thermistors in<br />

all types of industries.<br />

Cost<br />

<strong>Thermistor</strong>s are by far the most economical choice<br />

when it comes to temperature sensors. Not only are<br />

they less expensive to purchase, but also there are no<br />

calibration costs during installation or during the service<br />

life of the sensor. In addition, if there is a failure in the<br />

field, interchangeable thermistors can be swapped out<br />

without calibration.<br />

Speed<br />

Due to their small size, thermistors can respond very<br />

quickly to slight changes in temperature. Caution must<br />

be taken when designing probes because materials and<br />

mass play an important role in the reaction time of the<br />

sensor. See section on “Thermal Time Constant” and<br />

“How do I design a probe” for further details.<br />

No Calibration Required<br />

Properly manufactured thermistors are aged to reduce<br />

drift before leaving the factory. Therefore, thermistors<br />

can provide a stable resistance output over long periods<br />

of time.<br />

8 www.thermistor.com | THERMISTORS

NTC<br />

thermistor<br />

Elements<br />

Epoxy Coated NTC <strong>Thermistor</strong>s (QTMC, QTLC)<br />

n Available in a variety of wire types and lengths<br />

n Recommended wire sizes #26-30 AWG<br />

n Leads: Kynar, PVC, Teflon, Tin Plated Copper<br />

n Resistance values from 100 ohms to 9.8 M ohms<br />

n Typical dissipation Constant = 2mW/°C in still air<br />

n Typical time constant in still air = 10 seconds<br />

n Temp Range: -55°C to 155°C<br />

n RoHS compliant parts available<br />

glass beAd - qtgb<br />

n High Stability<br />

n Ideal for high temperature environments<br />

n Available as interchangeable or point matched<br />

n Hermetic, glass encapsulated bead<br />

n Operating temp range -55°C to 300°C<br />

n Dissipation Constant: .75mW/°C in still air<br />

n #36 AWG Platinum clad, Ni-Fe wires<br />

n Standard 10k and 30K ohms at 150°C<br />

n RoHS compliant parts available<br />

high temperature glass beAd - qtgbht<br />

n High Stability<br />

n Ideal for high temperature environments<br />

n Available as interchangeable or point matched<br />

n Hermetic, glass encapsulated bead<br />

n Operating temp range -55°C to 300°C<br />

n Dissipation Constant: .75mW/°C in still air<br />

n #36 AWG Platinum clad, Ni-Fe wires<br />

n Standard 2252, 5000 and 10k ohms at 25°C<br />

n RoHS compliant parts available<br />

Miniature <strong>Thermistor</strong>s (QTUT, QTMB)<br />

n Available in 0.020” and 0.040” diameter<br />

n Operating Temp range: -55°C –to 125°C<br />

n Recommended wire sizes #34-38 AWG<br />

n Leads: Poly Nylon, Bi-Filar<br />

n Material: Epoxy coated or Polyimide tube<br />

n Typical dissipation Constant = 1mW/°C in still air<br />

n Typical time constant in still air = 1 second<br />

n RoHS compliant parts available<br />

THERMISTORS | www.thermistor.com<br />

9

NTC SMD<br />

thermistor<br />

Elements<br />

ntc thermistor die (QTC11)<br />

n Part Size: 0.040” x 0.040” x 0.020”<br />

n Resistance values from: 100 ohms to 20 Mohms<br />

n Available with Gold or Silver terminations<br />

n Hybrid attachment (wire bond/epoxy)<br />

n RoHS compliant<br />

n Typical dissipation Constant = .0625W, derate to 0 at 125C<br />

n Typical time constant in still air = 10 seconds<br />

n Tolerances: 1%, 2%, 5%, 10%<br />

qt0805 ntc series thermistors<br />

n Standard EIA 0805 package size<br />

n Resistance values from: 50 ohms to 10 Mohms<br />

n Available with Gold, pure tin or Tin/lead terminations<br />

n Typical dissipation Constant = 2 mW/°C in still air<br />

n Typical time constant in still air = 8 seconds max<br />

n Tolerances: 1%, 2%, 5%, 10%<br />

n Operating range: -65°C to 150°C<br />

n Power rating: 0.125 watts max<br />

n Available waffle packed or tape and reel<br />

n Available in K, X, T, Y, Z,P, S & V curves<br />

How Much Resistance Do I Need<br />

With an NTC thermistor, resistance decreases as the temperature rises. One main factor in 1determining = a + how b 1n much (R) resistance + c 1n you 3 (R) need at 25°C is to calculate<br />

how much resistance you will have at your critical temperature range. If the total wire resistance T is a substantial percentage of the resistance change at your<br />

critical temperature range, you should consider increasing your base resistance at 25°C. Determine if the resistance change at your critical temperature is<br />

large enough to compensate for any other errors in your systems design. If not, you should increase your base resistance at 25°C.<br />

T<br />

1<br />

EXAMPLE:<br />

ºc = – 273.15<br />

C+B (1n R) + C (1n R) 3<br />

<br />

1,000 ohm curve Z thermistor at 25°C Between –29°C and –28° C, there is a resistance change of 990 ohms.<br />

Between 118° and 119° C, there is only a resistance change of 1.1 ohms.<br />

What’s a Curve And Which Curve Do I Choose<br />

A thermistor is an electrical resistor whose resistance varies sharply in a very predictable<br />

manner with temperature. We can use the Stein-Hart Hart equation to predict how the<br />

thermistor reacts to temperature.<br />

If we plot these points on a graph, it forms a repeatable curve. <strong>Thermistor</strong> manufacturers can alter the chemistry of a thermistor, thereby changing the slope<br />

of a curve. Your curve selection should be based on how steep the curve is for your critical temperature range, size constraints and the target resistance value.<br />

Since a thermistor is based on bulk resistivity, the size of the sensor may not be feasible for your application. Unlike the RTD and thermocouples, thermistors do<br />

not have industry standards for their curves. However, most thermistor manufacturers have curves that are similar. An example of this is <strong>Quality</strong> <strong>Thermistor</strong>’s<br />

‘Z’ curve. It’s by far the most common curve in the industry and most major thermistor manufacturers have very similar curve offerings.<br />

Resistance vs. Temperature tables and calculators are available online at www.thermistor.com<br />

10 www.thermistor.com | THERMISTORS

NTC Military and Space Level<br />

thermistor Elements<br />

RTH44 MIL-PRF-23648/20<br />

n Resistance values from 300 ohms to 500k ohms<br />

n Operating temp range -55°C to 125°C<br />

n Meets or exceeds MIL-PRF 23648<br />

n Typical dissipation Constant = 2mW/°C in still air<br />

n Tolerance: 1, 2, 5, 10%<br />

n Power rating: 0.2 watts @25°C max<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

RTH06 MIL-PRF-23648/1<br />

n Resistance values from 68 ohms to 75k ohms<br />

n Typical dissipation Constant = 5mW/°C in still air<br />

n Thermal time constant in still air or = 80 seconds max<br />

n Temp Range: -55°C to 125°C<br />

n Meets or exceeds MIL-PRF 23648<br />

n Power rating: 0.5 watts @25°C max<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

M32192/3 NTC <strong>Thermistor</strong> die<br />

n Resistance values from 15 ohms to 20 Mohms<br />

n Typical dissipation Constant = .625mW/°C in still air<br />

n Thermal time constant in still air = 10 seconds max<br />

n Power rating: 0.0625W, derate to 0 at 125<br />

n Available with a variety of termination finishes<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

M32192/4 NTC EIA 0805 package<br />

n Typical dissipation Constant = 2mW/°C in still air<br />

n Thermal time constant in still air = 8 seconds max<br />

n Power rating: 0.125 watts @25°C max<br />

n Available with a variety of termination finishes<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

THERMISTORS | www.thermistor.com<br />

M32192/5 NTC EIA 1206 package<br />

n M32192/5 NTC EIA 1206 PACKAGE<br />

n Thermal Time Constant: 8 seconds max in still air<br />

n *Dissipation Constant: 2 mW/°C min in still air<br />

n *Power Rating: 0.25 W at 25°C, derate to 0 W at 125°C<br />

n Resistance @25°C: 470 ohm to 10 Mohm<br />

n Operating temperature range: -55°C to 125°C<br />

n Storage temperature range: -65°C to 150°C<br />

n *Thermal Time Constant and Dissipation Constant may vary<br />

depending on mounting<br />

space level NASA GSFC S-311-P-827/01, 02, 03 & 04<br />

n Available in 50k and 100k ohms<br />

n Interchangeable tolerances to +/- 0.5°C (0-70°C)<br />

n Acceptable for use in NASA space programs specifying<br />

quality level (Grade) 1 parts<br />

n Available with Sn/Pb or Gold termination<br />

n Meets Level 1 classification per EEE-INST-002<br />

n Single lot traceability<br />

11

PTC Military<br />

thermistor<br />

Elements<br />

RTH22 MIL-PRF-23648/9<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

n Resistance values from 10 ohms to 10k ohms<br />

n Operating temp range -55°C to 125°C<br />

n Meets or exceeds MIL-PRF 23648<br />

n Tolerance: 5, 10%<br />

n Power rating: 0.5 watts @25°C<br />

n Thermal time constant in still air = 60 seconds max<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

RTH42 MIL-PRF-23648/19<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

n Resistance values from 10 ohms to 10k ohms<br />

n Operating temp range -55°C to 125°C<br />

n Meets or exceeds MIL-PRF 23648<br />

n Tolerance: 5, 10%<br />

n Power rating: 0.250 watts @25°C<br />

n Thermal time constant in still air = 60 seconds max<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

M32192/1 PTC <strong>Thermistor</strong> die<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

n Resistance values from 10 ohms to 10k ohms<br />

n Typical dissipation Constant = 1.25mW/°C in still air<br />

n Thermal time constant in still air = 30 seconds max<br />

n Power rating: 0.125W, derate to 0 at 125<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

M32192/2 PTC EIA 0805 package<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

n Typical dissipation Constant = 2.5mW/°C in still air<br />

n Thermal time constant in still air = 30 seconds max<br />

n Power rating: 0.250 watts @25°C max<br />

n Available with a variety of termination finishes<br />

n Complete specifications can be obtained by contacting DSCC<br />

(Defense Supply Center, Columbus)<br />

12 www.thermistor.com | THERMISTORS

PTC Space Level<br />

thermistor<br />

Elements<br />

space level NASA GSFC S-311-P-827/31, 32<br />

n Resistance values from 150 ohms to 2k ohms<br />

n Acceptable for use in NASA space programs specifying<br />

quality level (Grade) 1 parts<br />

n Available with Sn/Pb or Gold termination<br />

n Meets Level 1 classification per EEE-INST-002<br />

n Single lot traceability<br />

space level NASA GSFC S-311-P-827/33,34<br />

n Resistance values from 75 ohms to1.5k ohms<br />

n Acceptable for use in NASA space programs specifying<br />

quality level (Grade) 1 parts<br />

n Meets Level 1 classification per EEE-INST-002<br />

n Single lot traceability<br />

design engineers for high-reliablity military and aerospace markets are faced with challenges when given the assignment of redesigning legacy<br />

applications which have a high count of radial and axial leaded passive components, or generating a new design which needs to incorporate a high percentage of<br />

surface mount passive components. <strong>Quality</strong> <strong>Thermistor</strong>’s high reliablity surface mount thermistors are manufactured to meet or exceed the MIL-PRF-32192 military<br />

specification, as well as the newly introduced NASA-GSFC S-311-P-827 specifications.<br />

The Defense Supply Center Columbus (DSCC)<br />

introduced a new surface mount thermistor specification<br />

in November of 2006. MIL-PRF-32192 now gives<br />

the design Engineer fully qualified DSCC options for<br />

two PTC and three NTC surface mount package styles.<br />

MIL-PRF-32192/1<br />

Bare PTC thermistor die available in resistance values<br />

from 10 ohms to 10,000 ohms. This specification<br />

should be considered in new designs and for<br />

legacy designs which used either MIL-PRF-23648/9<br />

or MIL-PRF-23648/19.<br />

MIL-PRF-32192/2<br />

Basic EIA 0805 PTC surface mount package avaialble<br />

in resistance values from 22 ohms to 5,600 ohms.<br />

This specification should be considered for nw designs<br />

as well as an alternative to MIL-PRF-23648/9<br />

and MIL-PRF-23648/19.<br />

MIL-PRF-32192/3<br />

Bare NTC thermistor die avaialble in resitance values<br />

from 15 ohms to 20 Mohms. This is ideal for new<br />

board designs which contain other bare die, wire<br />

bondable components could easily integrate this<br />

part style. This specification should be considered<br />

for legacy replacements which usd either MIL-<br />

PRF-23648/1 or MIL-PRF-23648/20.<br />

THERMISTORS | www.thermistor.com<br />

MIL-PRF-32192/4<br />

Basic EIA 0805 NTC surface mount package. Any<br />

new high reliablilty application PCB design can<br />

take advantage of this part style. This specification<br />

should be considered for new designs as well as<br />

an alternative to MIL-PRF-23648/1 and MIL-<br />

PRF-23648/20.<br />

MIL-PRF-32192/5<br />

Basic EIA 1206 NTC surface mount package. Any<br />

new high reliability application PCB design can<br />

take advantage of this part style. This specification<br />

should be considered for new designs as well as<br />

an alternative to MIL-PRF-23648/1 and MIL-<br />

PRF-23648/20.<br />

GSFC approved thermistor specification<br />

S-311-P-827 gives the Aerospace engineers a costeffective<br />

option and more.<br />

As the Aerospace market continues to thrive and<br />

grow, the push for smaller, lighter, more accurate and<br />

reliable parts intensifies. While the new DSCC MIL-<br />

PRF-32192 Specification is sufficient for Defense/Military<br />

requirements, the Aerospace community requires<br />

additional screening to qualify parts for flight.<br />

Many customers have chosen to create their own<br />

SCD’s that incorporate all or part of the M32192<br />

specification but also added additional 100% screening<br />

requirements. This escalates customer costs internally<br />

and increases the unit cost due to a lack of standardization.<br />

To meet the demands of our Aerospace customers<br />

and help “standardize” the aerospace test regimen,<br />

<strong>Quality</strong> <strong>Thermistor</strong> engineers worked jointly with<br />

engineers at NASA/GSFC to create a GSFC approved<br />

SMD thermistor specification. This new specification,<br />

S-311-P-827, incorporates PTC thermistors (both EIA<br />

0805 and hybrid 0303 die) and NTC thermistors (EIA<br />

0805). All devices procured to this specification will<br />

meet the requirements for Level I classification per<br />

EEE-INST-002.<br />

There are two NTC thermistors currently listed in<br />

the specification. These parts are availble in “interchangeable”<br />

tolerances of either ± 0.5C or ± 1.0C<br />

over the range of 0C to 70C. The PTC thermistors are<br />

all available in 1% or 2% tolerances at the reference<br />

temperature of 25ºC.<br />

For more information, contact the engineering<br />

staff at <strong>Quality</strong> <strong>Thermistor</strong>, or see the link below for<br />

the complete specification on the NASA NEPP website:<br />

nepp.nasa.gov.<br />

13

PTC<br />

thermistor<br />

Elements<br />

PTC <strong>Thermistor</strong> Die (QTC11)<br />

n Part Size: 0.032” x 0.032” square<br />

n Part thickness: 0.028”, 0.050” or 0.072”<br />

n Resistance values from: 10 ohms to 10k ohms<br />

n Gold terminations<br />

n Board attachment by either wire bonding or conductive epoxy.<br />

n RoHS compliant<br />

n Typical dissipation Constant = 2mW/°C in still air<br />

n Typical time constant in still air = 8 seconds<br />

n Tolerances: 1%, 2%, 5%, 10%<br />

n Operating range: -55°C to 125°C<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

QT0805 PTC Series <strong>Thermistor</strong>s<br />

n Standard EIA 0805 package size<br />

n Resistance values from: 22 ohms to 36k ohms<br />

n Available with Gold or Silver terminations<br />

n Typical dissipation Constant = 2.5mW/°C in still air<br />

n Typical time constant in still air = 30 seconds max<br />

n Tolerances: 1%, 2%, 5%, 10%<br />

n Operating range: -55°C to 100°C<br />

n Power rating: 0.250 watts @ 25C derated to 100C (table 1)<br />

n Available waffle packed or tape and reel<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

Glass Axial PTC <strong>Thermistor</strong>s (QTG12, QTG10)<br />

n Standard DO35 package size<br />

n Resistance values from: 10 ohms to 10k ohms<br />

n Typical time constant in still air = 55 seconds max<br />

n Tolerances: 1%, 2%, 5%, 10%<br />

n Operating range: -65°C to 125°C<br />

n Power rating: 0.125 watts @ 100C (table 1)<br />

n Available loose or tape and reel<br />

n RoHS compliant available<br />

n Commercial version of RTH42 (MIL-PRF 23648)<br />

n Positive Temperature Coefficient: 0.7%/°C<br />

TABLE 1 Power Derating Curve<br />

% Rated Power<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 25 50 75 85 100 125 150<br />

Temperature (°C)<br />

14 www.thermistor.com | FREQUENTLY ASKED QUESTIONS

how do I design a probe<br />

Another problem with selecting material based<br />

on thermal conductivity alone is that the mass of<br />

the highly conductive probe housing can actually<br />

act like a heat sink and pull additional heat out of<br />

the system. This can obviously create measuring<br />

inaccuracies.<br />

To offset this, you can combine different materials<br />

while designing your probe. A low thermally<br />

conductive housing with a small highly conductive<br />

probe tip is a good solution.<br />

In some cases, your application may require a slow<br />

thermal time response. An example of this would<br />

be an outdoor sign that displays the temperature.<br />

A large over molded probe will insulate the thermistor<br />

and even out quick fluctuations in temperature<br />

changes.<br />

Confined Space<br />

Due to a thermistor’s miniature size, it can be<br />

potted into almost any size housing. Currently,<br />

the smallest available thermistor is 0.020” max<br />

diameter. Hollow-tube rivets, set screws, hypodermic<br />

needles and direct epoxy attach are some<br />

common methods for confined space thermistor<br />

applications.<br />

Liquid<br />

For liquid applications, it’s best to use a threaded<br />

probe. Possibly, with some type of elastomeric seal<br />

like an o-ring. QTI also offers a complete line of<br />

NPT probe housings. Some applications require<br />

over molding the thermistor into the plastic housing<br />

of the product. Another option is to use a<br />

glass encapsulated bead. It provides a hermetic<br />

seal that is as close to ‘waterproof’ as Mother<br />

Nature will allow. Remember the Titanic<br />

Gas/Air<br />

Gas and air applications have a variety of choices.<br />

Probes can be surface mounted in the flow stream<br />

or they can be projected into the air stream by<br />

means of a closed or open-end tube. When measuring<br />

gas or air under pressure, we recommend<br />

using some type of thread/o-ring combination.<br />

SURFACE<br />

By far the most common method for surface measurement<br />

is the ring lug. Due to the small size of<br />

the thermistor element, it can be potted into most<br />

ring lug barrels. Be careful that the wire gauge<br />

does not exceed the inside dimension of the barrel.<br />

Another option for surface measurement is<br />

direct attachment of a thermistor using a stainless<br />

steel disc.<br />

frequently asked questions<br />

How does aging affect thermistor stability<br />

“Thermometric drift” is a specific type of instability in which the deviation in<br />

measured temperature is the same at all temperatures to which the thermistor<br />

is exposed. For example, a thermistor that exhibits a -0.02°C shift at 0°,<br />

40° and 70°C (even though this is a different percentage change in resistance<br />

in each case) would be exhibiting thermometric drift. Thermometric drift:<br />

(1) occurs over time at varying rates, based on thermistor type and exposure<br />

temperature, and (2) as a general rule, increases as the exposure temperature<br />

increases. Most drift is thermometric.<br />

What happens if my application exceeds the<br />

temperature rating<br />

Intermittent temperature incursions above and below the operating range will<br />

not affect long-term survivability. Encapsulate epoxy typically begins to break<br />

down at 150°C and the solder attaching leads to the thermistor body typically<br />

reflows at about 180°C. Either condition could result in failure of the thermistor.<br />

Are thermistors ESD sensitive<br />

Per MIL-DTL-39032E, Table 1, thermistors by definition are not ESD sensitive.<br />

What is the resolution of a thermistor<br />

There is no limit to the resolution of a thermistor. The limitations are in the<br />

electronics needed to measure to a specified resolution. Limitations also exist<br />

in determining the accuracy of the measurement at a specified resolution.<br />

Are QTI thermistors RoHS compliant<br />

(What if I don’t want a lead free part)<br />

<strong>Quality</strong> <strong>Thermistor</strong> maintains two separate manufacturing lines to meet the<br />

specific environmental needs of our customers. One line is dedicated to RoHS<br />

compliance and the other is maintained for traditional tin/lead parts for military,<br />

aerospace and medical applications.<br />

Does the length of wire impact the accuracy<br />

of a thermistor<br />

With a thermistor, you have the benefit of choosing a higher base resistance<br />

if the wire resistance is a substantial percentage of the total resistance. An<br />

example of this would be a 100-ohm thermistor vs a 50,000 ohm thermistor<br />

with 10’ of 24 AWG wire.<br />

Total wire resistance = 10’ x 2 wires x 0.02567 ohms per foot = 0.5134 ohms<br />

Probes | www.thermistor.com<br />

15

<strong>Quality</strong> <strong>Thermistor</strong>, <strong>Inc</strong>.<br />

2108 Century Way<br />

Boise, ID 83709<br />

www.thermistor.com<br />

800-554-4784 U.S.<br />

208-377-3373 Worldwide<br />

208-376-4754 FAX<br />

qti@thermistor.com