You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE WORLD’S MOST COMPLETE DRILL CHUCK PROGRAM<br />

www.llambrichusa.com Catalog 2012<br />

www.llambrichusa.com

5<br />

Llambrich® originated from the province of Barcelona, Spain and has been<br />

designing, engineering and manufacturing drill chucks and machine tool accessories since<br />

1957. In 2005, a partnership was formed between Llambrich® and <strong>EuroLink</strong> to offer<br />

products throughout North America under the name LlambrichUSA.<br />

5<br />

1957 - 2012<br />

GUARANTEE OF ACCURACY<br />

Llambrich® has been the pioneer and inventor of the precision keylessess chuck that<br />

guarantees the<br />

lowest<br />

run-out of concentricity since 1983. All high performance drill chucks come<br />

with<br />

a certificate of inspection<br />

that guarantees a maximum run-out of 0.0012” (valid for Hexa chucks only). All chucks are precision tested<br />

and certified. Inspections for concentricity are performed adhering to the most demanding standards in<br />

the metalworking industry.<br />

MANUFACTURER’S WARRANTY<br />

Llambrich® guarantees all products that it manufactures and markets to be free of any manuafacturing<br />

defects. Without notice, Llambrich® Manufacturing Company can reserve the right to change the design,<br />

material composition and dimensional specifications for all products offered in this catalog.<br />

PRODUCT INNOVATION<br />

106 West Ohio Avenue<br />

Mount Vernon, Ohio 43050<br />

740-392-1549<br />

www.eurolinkinc.com<br />

MEDICAL “INOX” LINE<br />

Llambrich® stainless chucks program for surgical instruments. Llambrich® offers the most complete Stainless<br />

Steel Drill Chuck range for use in manual, electric & pneumatic surgical Instruments. Llambrich® is the only drill<br />

chuck manufacturer in the world to hold the ISO 13485 certification for medical drill chuck products. Llambrich®<br />

INOX drill chucks are designed and manufactured for the most demanding medical applications.<br />

THE “HYBRID”<br />

THE HYBRID is a unique drill chuck developed and patented by Llambrich® combining the precision of a keyless<br />

chuck with the gripping force of a keyed chuck. THE HYBRID is available in steel for machining applications<br />

and Stainless steel for medical applications. THE HYBRID is another example of a solution first offered by<br />

Llambrich®, the worldwide leader in drill chucks based in Barcelona, Spain.<br />

TERMS & CONDITIONS<br />

Terms Net 30 days -<br />

Prices Subject to change without notice.<br />

Delivery All shipments are F.O.B. Mt. Vernon, Ohio<br />

USA<br />

Claims All claims must be made within five (5) days<br />

from the receipt of the merchandise. Please submit<br />

shortage and/or damage claims request with shipper<br />

and invoice number to expedite the claim settlement.<br />

Damages incurred with commercial shipments must<br />

be claimed from the common carrier.<br />

Return Policy In order to process a return a request<br />

for a RGA# must be made from our North American<br />

offices in Mt. Vernon, Ohio. Items shipped back without<br />

the RGA# identified on the outside of the box will<br />

be refused for delivery. A copy of the original invoice<br />

must accompany the merchandise in the package.<br />

Returns must be shipped back prepaid freight unless<br />

we errored in filling your order. Non-stock items and<br />

special sale items will not be accepted for return under<br />

any condition. We reserve the right to inspect and<br />

determine if the item has been abused or misused. If<br />

the item can not be returned to stock and sold in new<br />

condition we will not accept the return. All returns<br />

are subject to a 20% restocking charge.<br />

Safety Warning LlambrichUSA products are engineered<br />

and manufactured with safety in mind. The<br />

heat treat specifications exceed or meet all standards.<br />

All of the products manufactured by LlambrichUSA<br />

are designed to perform without any undue safety<br />

issues when caution, common sense and proper<br />

safety practices are followed. The use of cutting tools<br />

and toolholders is safe when proper application and<br />

protection guidelines are observed. Even when these<br />

proper precautions are taken, it is possible that fragments<br />

of a cutting tool, cutting material, or holding<br />

device may be thrown at a very high rate of speed<br />

and have potential to cause severe bodily harm. It is<br />

imperative that general safety precautions and safety<br />

glasses be used at all times.<br />

Llambrich USA <strong>Precision</strong> Chucks: Limited Lifetime<br />

Warranty. Llambrich USA <strong>Precision</strong> Chucks are<br />

warranted for life to be free of defects in material and<br />

workmanship. Products must be sent, at buyer’s cost<br />

for evaluation.<br />

Product meeting Warranty criteria will be repaired or<br />

replaced at Llambrich USA’s discretion.<br />

This Warranty shall not apply to products that have<br />

been misused, abused, damaged by accident or otherwise,<br />

repaired by anyone other than an Authorized<br />

Repair Center or modified by anyone other than<br />

Llambrich USA. Normal wear is also excluded.<br />

Sets as a whole will NOT be credited under warranty;<br />

only the individual components will be covered according<br />

to the product warranties described above.<br />

This Warranty is the sole warranty applicable to the<br />

products and is in lieu of all other warranties, whether<br />

express, implied or statutory. Buyer’s sole and<br />

exclusive remedy for breach of this Warranty is, at the<br />

option of Llambrich USA, repair or replacement of the<br />

defective product. In no event will Llambrich USA be<br />

liable for any indirect, special, incidental, consequential<br />

or punitive damages arising from breach of this<br />

warranty, even if Llambrich USA has been advised of<br />

the possibility of such damages.<br />

106 West Ohio Avenue<br />

Mount Vernon, Ohio 43050<br />

phone (740) 392-1549<br />

fax (740) 392-0230<br />

www.eurolinkinc.com<br />

sales@eurolinkinc.com

INDEX<br />

Pages 4 - 5<br />

HEXA<br />

HEXA BLACK & NPU NEW<br />

Page 6<br />

HYBRID<br />

NEW<br />

Page 7<br />

JKP, JKT, JK-SOLID, JK-INDUSTRIAL<br />

Pages 8 - 10<br />

Micro Drill<br />

NEW<br />

Page 11<br />

INOX Stainless Steel Drill Chucks<br />

NEW<br />

Pages 12 - 13<br />

CBB Heavy Duty Ball Bearing<br />

CY & Chuck Keys<br />

CPX & CPM<br />

CL & CY<br />

Live Centers<br />

Arbors, Sleeves, Ejecting Drifts & Adapters<br />

Cross Reference & Tech Info<br />

Page 14<br />

Page 15<br />

Page 16<br />

Page 17<br />

Pages 18 - 19<br />

Pages 20 - 21<br />

Pages 22 - 23<br />

3

<strong>High</strong> Performance CNC<br />

CERTIFIED<br />

accuracy<br />

HEXA<br />

<strong>High</strong> <strong>Precision</strong> Drill Chuck with<br />

Integrated Shank & Hexagonal Key Lock<br />

For use on high-speed CNC machines.<br />

Optional through the chuck coolant available.<br />

Hexagonal key lock system.<br />

Permits clockwise and counterclockwise turning.<br />

<strong>High</strong> gripping torque, exceeding 75 ft/lbs.<br />

Maximum total integrated run-out of 0.0012”<br />

Maximum coolant pressure: 725 PSI<br />

Maximum revolutions per minute without balancing: 8,000<br />

Optional balancing service up to 25,000 rpm G6.3<br />

Comes standard with hexagonal key.<br />

75 ft/lbs. of<br />

Gripping Torque<br />

Right / Left Rotation<br />

None Form B Form AD<br />

75 ft/lbs<br />

.0012”<br />

HEXA Key<br />

Chuck Part EDP<br />

Series Number Number<br />

HX-10 HX-10 L40068A<br />

HX-13 HX-13-16 L40069A<br />

HX-16 HX-13-16 L40069A<br />

4

<strong>High</strong> Performance CNC<br />

EDP Part Capacity Coolant Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Form Ø L1 L2<br />

CAT<br />

L40016B HX-10 CA40 1/32 - 3/8 CAT40 - - 1.693 3.937 4.272<br />

L40017B HX-10 CA40/R 1/32 - 3/8 CAT40 B+AD 1.693 3.937 4.272<br />

L40018B HX-10 CA-50 1/32 - 3/8 CAT50 - - 1.693 3.701 4.035<br />

L40019B HX-10 CA-50/R 1/32 - 3/8 CAT50 B+AD 1.693 3.701 4.035<br />

L40020B HX-13 CA40 1/32 - 1/2 CAT40 - - 2.126 4.213 4.567<br />

L40021B HX-13 CA40/R 1/32 - 1/2 CAT40 B+AD 2.126 4.213 4.567<br />

L40022B HX-13 CA50 1/32 - 1/2 CAT50 - - 2.126 3.465 3.819<br />

L40023B HX-13 CA50/R 1/32 - 1/2 CAT50 B+AD 2.126 3.701 4.055<br />

L40024B HX-16 CA40 1/8 - 5/8 CAT40 - - 2.244 4.331 4.606<br />

L40025B HX-16 CA40/R 1/8 - 5/8 CAT40 B+AD 2.244 4.331 4.606<br />

L40026B HX-16 CA50 1/8 - 5/8 CAT50 - - 2.244 3.583 3.858<br />

L40027B HX-16 CA50/R 1/8 - 5/8 CAT50 B+AD 2.244 3.819 4.094<br />

BT<br />

L40004B HX-10 BT-40 1/32 - 3/8 BT40 - - 1.693 3.386 3.740<br />

L40005B HX-10 BT-40/R 1/32 - 3/8 BT40 B+AD 1.693 3.386 3.740<br />

L40006B HX-10 BT-50 1/32 - 3/8 BT50 - - 1.693 3.818 4.173<br />

L40007B HX-10 BT-50/R 1/32 - 3/8 BT50 B+AD 1.693 3.818 4.173<br />

L40008B HX-13 BT-40 1/32 - 1/2 BT40 - - 2.126 3.780 4.134<br />

L40009B HX-13 BT-40/R 1/32 - 1/2 BT40 B+AD 2.126 3.780 4.134<br />

L40010B HX-13 BT-50 1/32- 1/2 BT50 - - 2.126 4.213 4.567<br />

L40011B HX-13 BT-50/R 1/32 - 1/2 BT50 B+AD 2.126 4.213 4.567<br />

L40012B HX-16 BT-40 1/8 - 5/8 BT40 - - 2.244 3.898 4.173<br />

L40013B HX-16 BT-40/R 1/8 - 5/8 BT40 B+AD 2.244 3.898 4.173<br />

L40014B HX-16 BT-50 1/8 - 5/8 BT50 - - 2.244 4.331 4.606<br />

L40015B HX-16 BT-50/R 1/8 - 5/8 BT50 B+AD 2.244 4.331 4.606<br />

HSK<br />

L40028B HX-13 HSK-63 1/32 - 1/2 HSK-63 - - 2.126 3.858 4.213<br />

L40029B HX-13 HSK-63 /R 1/32 - 1/2 HSK-63 AD 2.126 4.055 4.409<br />

L40030B HX-13 HSK-100 1/32 - 1/2 HSK-100 - - 2.126 4.331 4.685<br />

L40031B HX-13 HSK-100 /R 1/32 - 1/2 HSK-100 AD 2.126 3.858 4.213<br />

L40032B HX-16 HSK-63 1/8 - 5/8 HSK-63 - - 2.244 3.976 4.252<br />

L40033B HX-16 HSK-63 /R 1/8 - 5/8 HSK-63 AD 2.244 4.173 4.449<br />

L40034B HX-16 HSK-100 1/8 - 5/8 HSK-100 - - 2.244 4.449 4.724<br />

L40035B HX-16 HSK-100 /R 1/8 - 5/8 HSK-100 AD 2.244 3.976 4.252<br />

MORSE TAPER<br />

L40042B HX-13 MT-2 1/32 - 1/2 MT-2 - - 2.126 3.346 3.701<br />

L40043B HX-13 MT-3 1/32 - 1/2 MT-3 - - 2.126 3.346 3.701<br />

L40044B HX-13 MT-4 1/32 - 1/2 MT-4 - - 2.126 3.346 3.701<br />

L40045B HX-16 MT-2 1/8 - 5/8 MT-2 - - 2.244 3.465 3.740<br />

L40046B HX-16 MT-3 1/8 - 5/8 MT-3 - - 2.244 3.465 3.740<br />

L40047B HX-16 MT-4 1/8 - 5/8 MT-4 - - 2.244 3.465 3.740<br />

STRAIGHT SHANK<br />

L40048B HX-13 5/8 1/32-1/2 5/8 -- 2.090 3.760 4.200<br />

R-8<br />

L40049B HX-13 R-8 1/32 - 1/2 R-8 - - 2.126 3.346 3.701<br />

L40050B HX-16 R-8 1/8 - 5/8 R-8 - - 2.244 3.465 3.740<br />

CAT SHANK<br />

HSK<br />

MORSE TAPER<br />

STRAIGHT SHANK<br />

BT SHANK<br />

R-8<br />

5

<strong>High</strong> Performance CNC<br />

NEW<br />

HEXA BLACK<br />

Standard Drill Chuck with Integrated Shank<br />

and Hexagonal Key Lock<br />

For use on CNC machines.<br />

Hexagonal key lock system.<br />

Permits clockwise and counterclockwise rotating.<br />

<strong>High</strong> gripping torque exceeding 75 ft/lbs.<br />

Maximum total indicator run-out .0019”<br />

Maximum revolutions per minute without balancing 8,000 RPM<br />

9<br />

HEXA Key<br />

Chuck Part EDP<br />

Series Number Number<br />

HX-13 HX-13-16 L40069A<br />

HX-16 HX-13-16 L40069A<br />

EDP Part Capacity Coolant Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Form Ø L1 L2<br />

CAT<br />

L40660B HB-13 CA-40 1/32 - 1/2 CAT 40 -- 2.125 4.216 4.567<br />

L40661B HB-16 CA-40 1/8 - 5/8 CAT 40 -- 2.245 4.330 4.606<br />

BT<br />

L40662B HB-13 BT-40 1/32 - 1/2 BT 40 -- 2.125 3.780 4.139<br />

L40663B HB-16 BT-40 1/8 - 5/8 BT 40 -- 2.245 3.898 4.173<br />

NEW<br />

NPU<br />

Super <strong>Precision</strong> Short Keyless Drill Chuck with Integrated Shank<br />

For use on CNC machining centers.<br />

Single taper connection between drill chuck and shank eliminates<br />

intermediate arbors to ensure high tool rigidity and drilling accuracy.<br />

Engineered with milled flats for additional gripping torque with spanner wrench.<br />

Resistant to tool loosening on high-speed machines with instant spindle stop.<br />

Maximum total integrated run-out of 0.0016”<br />

Comes with wrench.<br />

6<br />

NPU Wrench<br />

Chuck Part EDP<br />

Series Number Number<br />

NPU-08 0812 L30622A<br />

NPU-13 1312 L40066A<br />

NPU-16 1612 L40067A<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

CAT<br />

L40286B NPU-08 CA 40-A 1/64 - 5/16 CAT40 1.496 3.228 3.464<br />

L40287B NPU-13 CA 40-A 1/32 - 1/2 CAT40 1.889 4.527 4.960<br />

L40289B NPU-13 CA 50-A 1/32 - 1/2 CAT50 1.889 3.779 4.212<br />

L40290B NPU-16 CA 40-A 1/8 - 5/8 CAT40 2.165 4.724 5.157<br />

L40291B NPU-16 CA 50-A 1/8 - 5/8 CAT50 2.165 3.700 4.133<br />

BT<br />

L40267B NPU-08 BT 40 1/64 - 5/16 BT40 1.496 3.070 3.307<br />

L6339B NPU-13 BT 40 1/32 - 1/2 BT40 1.889 3.385 3.818<br />

L40273B NPU-13 BT 50 1/32 - 1/2 BT50 1.889 3.818 4.251<br />

L40274B NPU-16 BT 40 1/8 - 5/8 BT40 2.165 4.133 4.566<br />

L40275B NPU-16 BT 50 1/8 - 5/8 BT50 2.165 3.740 4.173

<strong>High</strong> <strong>Precision</strong> <strong>High</strong> Torque<br />

HYBRID<br />

NEW<br />

This unique chuck, designed and patented by<br />

Llambrich combines the features and benefits of<br />

both a keyed and keyless drill chuck<br />

Another solution offered first by the world’s leader<br />

of drill chucks from Llambrich in Barcelona, Spain.<br />

The Hybrid combines the high accuracy of a<br />

keyless chuck with the gripping force of a keyed<br />

chuck.<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø1 Ø2 L1 L2<br />

L40674B SPH-100 J-2 1/32 - 3/8 2JT K2/S17 1.575 1.890 3.110 3.366<br />

L40675B SPH-100 J-33 1/32 - 3/8 33JT K2/S17 1.575 1.890 3.110 3.366<br />

L40676B SPH-130 J-2 1/32 - 1/2 2JT K3/S10 1.850 2.008 3.661 4.055<br />

L40677B SPH-130 J-33 1/32 - 1/2 33JT K3/S10 1.850 2.008 3.661 4.055<br />

L40668B SPH-130 J-6 1/32 - 1/2 6JT K3/S10 1.850 2.008 3.661 4.055<br />

L40678B SPH-160 J-6 1/8 - 5/8 6JT K3/S10 2.028 2.087 3.740 4.154<br />

L40679B SPH-200 J-3 13/64 - 3/4 3JT K4/S13 2.520 2.913 4.764 5.118<br />

Hybrid Key<br />

Chuck Part EDP<br />

Series Number Number<br />

SPH-100 J-2 K2 L40538A<br />

SPH-100 J-33 K2 L40538A<br />

SPH-130 J-2 K3 L40090A<br />

SPH-130 J-33 K3 L40090A<br />

SPH-130 J-6 K3 L40090A<br />

SPH-160 J-6 K3 L40090A<br />

SPH-200 J-3 K4 L40091A<br />

FEATURES & BENEFITS<br />

The Hybrid is furnished with a key to allow additional gripping torque.<br />

The tool better resists loosening on high speed machines that have instant spindle stop.<br />

Repeatability on taper mounted chucks of 0.0016”<br />

Special designs, sizes and mounts for all types of applications are available upon request.<br />

APPLICATIONS<br />

Specifically designed for high precision drilling. The Hybrid series is well suited for use on drill presses with high<br />

accuracy, jigbore machines, horizontal or vertical milling machines, lathes, high production turning centers and<br />

production drilling machines where the application requires higher feed rates.<br />

7

<strong>Precision</strong> Keyless<br />

JK-SOLID<br />

<strong>Precision</strong> Keyless Drill Chuck with Integrated Shank<br />

The JK-Solid is a high precision integrated shank keyless drill chuck.<br />

The one piece construction offers a tighter tolerance on T.I.R.<br />

100% of JK-Solid drill chucks are individually controlled to ensure<br />

a maximum total indicator run-out of 0.0016”<br />

JK-SOLID Wrench<br />

Chuck Part EDP<br />

Series Number Number<br />

JK-08 0812 L30622A<br />

JK-10 1012 L31123A<br />

JK-13 1312 L40066A<br />

JK-16 1612 L40067A<br />

CERTIFIED<br />

accuracy<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2 L3<br />

Morse Taper<br />

L31406B JK-08 MT2 1/64 - 5/16 Morse Taper 2 1.496 2.559 2.835 --<br />

L31407B JK-10 MT2 1/32 - 3/8 Morse Taper 2 1.693 2.874 3.228 --<br />

L31408B JK-13 MT2 1/32 - ½ Morse Taper 2 1.890 3.150 3.622 --<br />

L31409B JK-13 MT3 1/32 - ½ Morse Taper 3 1.890 3.150 3.622 --<br />

L31410B JK-13 MT4 1/32 - ½ Morse Taper 4 1.890 3.150 3.622 --<br />

L31413B JK-16 MT2 1/8 - 5/8 Morse Taper 2 2.126 3.346 3.780 --<br />

L31414B JK-16 MT3 1/8 - 5/8 Morse Taper 3 2.126 3.346 3.780 --<br />

L31415B JK-16 MT4 1/8 - 5/8 Morse Taper 4 2.126 3.346 3.780 --<br />

MORSE TAPER<br />

STRAIGHT SHANK<br />

Straight Shank<br />

L31412B JK-130 5/8 1/32 - ½ 5/8” SS 1.890 3.150 3.622 2.480<br />

R-8<br />

L31411B JK-130 R-8 1/32 - 1/2 R-8 1.890 3.228 3.543 --<br />

L31416B JK-160 R-8 1/8 - 5/8 R-8 2.126 3.425 3.858 --<br />

R-8<br />

8

<strong>Precision</strong> Keyless<br />

JKP<br />

Super <strong>Precision</strong> Keyless Drill Chuck<br />

100% of JKP drill chucks are individually controlled to ensure a<br />

maximum total indicator run-out of 0.0016”.<br />

Self-tightening mechanism automatically increases the clamping forces<br />

in proportion to the increase in torque during the drilling operation.<br />

This prevents tool slippage in clockwise rotation.<br />

Left hand rotation is available upon request.<br />

CERTIFIED<br />

accuracy<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

L31126B JKP-30 J-0 1/64 - 1/8 0JT 0.965 1.732 1.870<br />

L31127B JKP-30 J-1 1/64 - 1/8 1JT 0.965 1.732 1.870<br />

L31128B JKP-30 R-5/16 1/64 - 1/8 5/16-24 0.965 1.732 1.870<br />

L31121B JKP-65 J-1 1/64 - 1/4 1JT 1.299 2.441 2.756<br />

L40002B JKP-80 J-1 1/64 - 5/16 1JT 1.496 2.638 2.913<br />

L9679B JKP-80 J-2S 1/64 - 5/16 2JS 1.496 2.638 2.913<br />

L9681B JKP-100 J-2 1/32 - 3/8 2JT 1.693 3.189 3.504<br />

L9680B JKP-100 J-33 1/32 - 3/8 33JT 1.693 3.189 3.504<br />

L9683B JKP-130 J-2 1/32 - 1/2 2JT 1.929 3.583 4.055<br />

L9682B JKP-130 J-33 1/32 - 1/2 33JT 1.929 3.583 4.055<br />

L9684B JKP-130 J-6 1/32 - 1/2 6JT 1.929 3.583 4.055<br />

L40003B JKP-160 J-33 1/8 - 5/8 33JT 2.165 3.740 4.213<br />

L9685B JKP-160 J-6 1/8 - 5/8 6JT 2.165 3.740 4.213<br />

JKT<br />

<strong>Precision</strong> Keyless Drill Chuck, with supplementary gripping torque<br />

100% of JKT drill chucks are individually controlled to ensure a<br />

maximum total indicator run-out of 0.0016”.<br />

Self-tightening mechanism automatically increases the clamping forces<br />

in proportion to the increase in torque during the drilling operation.<br />

This prevents tool slippage in clockwise rotation.<br />

Left hand rotation is available upon request.<br />

Engineered with milled flats for additional<br />

gripping torque with spanner wrench.<br />

CERTIFIED<br />

accuracy<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

L31122B JKT-65 J-1 1/64 - 1/4 1JT 1.299 2.441 2.756<br />

L30526B JKT-80 J-2S 1/64 - 5/16 2JS 1.496 2.638 2.913<br />

L30533B JKT-100 J-2 1/32 - 3/8 2JS 1.693 3.189 3.504<br />

L30532B JKT-100 J-33 1/32 - 3/8 33JT 1.693 3.189 3.504<br />

L30527B JKT-130 J-2 1/32 - 1/2 2JT 1.929 3.583 4.055<br />

L30528B JKT-130 J-33 1/32 - 1/2 33JT 1.929 3.583 4.055<br />

L30529B JKT-130 J-6 1/32 - 1/2 6JT 1.929 3.583 4.055<br />

L30530B JKT-160 J-6 1/8 - 5/8 6JT 2.165 3.740 4.213<br />

JKT Wrench<br />

Chuck Part EDP<br />

Series Number Number<br />

JKT-65 0612 L31123A<br />

JKT-80 0812 L30622A<br />

JKT-100 1012 L31123A<br />

JKT-130 1312 L40066A<br />

JKT-160 1612 L40067A<br />

9

Medium Duty Keyless<br />

JK-Industrial<br />

Keyless Drill Chuck for portable drilling machines<br />

and stationary machines<br />

Standard screw thread mount for portable drilling machines.<br />

Standard tapered mount for stationary drilling machines.<br />

Self-tightening mechanism automatically increases the<br />

clamping forces in proportion to the increase in torque during<br />

the drilling operation. This prevents tool slippage in clockwise<br />

rotation.<br />

Tool capacity of up to 3/4” in diameter.<br />

BL* = Blister Pack<br />

Threaded Mount for Portable Machines<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

L40160B JK 06 R-3/8 1/64 - 1/4 3/8” x 24 1.339 2.480 2.756<br />

L40161B JK 08 R-3/8 1/32 - 5/16 3/8” x 24 1.457 2.835 3.071<br />

L40162B JK 08 R-1/2 1/32 - 5/16 1/2” x 20 1.457 2.835 3.071<br />

L40165B JK 10 R-3/8 1/32 - 3/8 3/8” x 24 1.457 2.835 3.071<br />

L40439B JK 10 R-3/8 BL* 1/32 - 3/8 3/8” x 24 1.457 2.835 3.071<br />

L40166B JK 10 R-1/2 1/32 - 3/8 1/2” x 20 1.457 2.835 3.071<br />

L40440B JK 10 R-1/2 BL* 1/32 - 3/8 1/2” x 20 1.457 2.835 3.071<br />

L40171B JK 13 R-3/8 1/16 - 1/2 3/8” x 24 1.575 2.992 3.268<br />

L40443B JK 13 R-3/8 BL* 1/16 - 1/2 3/8” x 24 1.575 2.992 3.268<br />

L40172B JK 13 R-1/2 1/16 - 1/2 1/2” x 20 1.575 2.992 3.268<br />

L40444B JK 13 R-1/2 BL* 1/16 - 1/2 1/2” x 20 1.575 2.992 3.268<br />

L40175B JK 16 R-1/2 1/8 - 5/8 1/2” x 20 2.047 3.740 4.134<br />

L40176B JK 16 R-5/8 1/8 - 5/8 5/8” x 16 2.047 3.740 4.134<br />

10<br />

Taper Mount for Stationary Machines<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

L40158B JK 04 J-1 1/64 - 5/32 J - 1 1.024 1.969 2.165<br />

L40159B JK 06 J-1 1/64 - 1/4 J - 1 1.339 2.480 2.756<br />

L40163B JK 08 J-1 1/32 - 5/16 J - 1 1.457 2.835 3.071<br />

L40164B JK 08 J-2S 1/32 - 5/16 J - 2 1.457 2.835 3.071<br />

L40167B JK 10 J-2 1/32 - 3/8 J - 2 1.575 3.110 3.386<br />

L40221B JK 10 J-33 1/32 - 3/8 J - 33 1.575 3.110 3.386<br />

L40168B JK 13 J-2 1/32 - 1/2 J - 2 1.850 3.661 4.055<br />

L40169B JK 13 J-33 1/32 - 1/2 J - 33 1.850 3.661 4.055<br />

L40170B JK 13 J-6 1/32 - 1/2 J - 6 1.850 3.661 4.055<br />

L40173B JK 16 J-33 1/8 - 5/8 J - 33 2.047 3.740 4.134<br />

L40174B JK 16 J-6 1/8 - 5/8 J - 6 2.047 3.740 4.134<br />

L40177B JK 20 J-3 3/16 - 3/4 J - 3 2.520 4.764 5.157

Keyed & Keyless Micro <strong>Precision</strong><br />

NEW<br />

Micro Drill<br />

Chucks & Adapters Ideal for Micro Hole Drilling<br />

Very Accurate & Sensitive for Precise Drilling<br />

Ideal for micro hole drilling.<br />

Capacity from 0.008” to 0.156”<br />

FEATURES & BENEFITS<br />

Maximum run-out 0.0016” (keyless only)<br />

Very accurate and sensitive for precise<br />

drilling.<br />

Longer tool life and less occurrence of<br />

catastrophic tool failure.<br />

To be used in mills, lathes, drill presses,<br />

jigbore and Swiss machines.<br />

Eliminates the need of secondary<br />

operations to drill small holes.<br />

Spindle speeds up to 50,000 RPM.<br />

Micro drill chucks and adapters can be<br />

supplied separately, or as part of a KIT<br />

(up to six combinations are available)<br />

SIMPLE TO USE<br />

Feed with gentle finger pressure.<br />

Free turning knurled ring.<br />

Spring return upon release.<br />

3/4” total travel.<br />

Standard 1/2” Ø straight shank or #1<br />

morse taper to go directly into the<br />

spindle of your machine.<br />

Micro Drill Keyed Chucks<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40129B CY-04 J-0 1/64 - 5/32 0JT K0 0.866 1.102 1.378<br />

Micro Drill Keyless Chucks<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L31125B JKP-15 J-0 .008 - 1/16 0JT -- 0.760 1.390 1.476<br />

L31126B JKP-30 J-0 1/64 - 1/8 0JT -- 0.965 1.732 1.870<br />

Sensitive Drill Adapters<br />

EDP Part<br />

Number Number Shank Mount<br />

L40687B EL-MT1/J-0 Morse Taper 1 J0<br />

L40688B ECIL-13/J-0 1/2” Straight J0<br />

Drill Chucks & Adapter Kits<br />

EDP Kit Drill<br />

Number Number Chuck Adapter<br />

L40689B KIT #1 JKP-15 J-0 ECIL-13/0JT<br />

L40690B KIT #2 JKP-15 J-0 EL-MT1/0JT<br />

L40691B KIT #3 JKP-30 J-0 ECIL-13/0JT<br />

L40692B KIT #4 JKP-30 J-0 EL-MT1/0JT<br />

L40693B KIT #5 CY-04 J-0 ECIL-13/0JT<br />

L40694B KIT #6 CY-04 J-0 EL-MT1/0JT<br />

KITS include wedge for removing chuck from adapter<br />

FOR A WIDE RANGE OF APPLICATIONS<br />

METALWORKING AEROSPACE ELECTRONICS WATCH & JEWELRY JOB SHOPS HOBBY INDUSTRY MEDICAL INDUSTRY<br />

11

Keyed & Keyless Non Corrosive<br />

INOX<br />

STAINLESS STEEL DRILL CHUCKS<br />

NEW<br />

The most complete stainless steel drill chuck program.<br />

Available in keyed, keyless and in Hybrid models.<br />

For use in medical, dental, food & chemical industries.<br />

MEDICAL INDUSTRY<br />

DENTAL INDUSTRY<br />

FOOD INDUSTRY<br />

CHEMICAL INDUSTRY<br />

FEATURES & BENEFITS<br />

Manufactured from stainless steel to withstand chemical corrosion.<br />

Identified with special laser markings to hold up to the autoclave process.<br />

FGE keyless chucks have milled instead of knurled grip areas to ensure non-slip hand<br />

tightening free of sharp edges. Excellent choice for use when operating with rubber gloves.<br />

All FGE and GE drill chucks models are bead blasted with glass balls and have a passivation treatment by an<br />

electro-polishing technique. This adds additional protection against all types of corrosion, eliminates<br />

undesirable residual contaminants and improves the finish of the surface profile.<br />

For the insertion of nails, screws, pins and other medical fasteners all chucks come with a through hole.<br />

Special designs, sizes and mounts for all types of applications are available upon request.<br />

Lubricated with a special FDA approved grease for food and medical applications.<br />

THE HYBRID<br />

A unique drill chuck developed by Llambrich combining features & benefits of both keyed and keyless chucks. Patented by<br />

Llambrich. Self-tightening feature automatically increases gripping force in proportion to increased torque to prevent tool<br />

slippage. The Hybrid is furnished with a key to allow supplementary gripping torque or permit clockwise and<br />

counterclockwise rotation of the tool. The HYBRID comes standard with rounded jaws.<br />

12

Keyed & Keyless Non Corrosive<br />

SP Series Keyless - Threaded Mount<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø1 L1 L2<br />

L40000B SP-03 R-3/8 SS .012 - .125 3/8-24 0.969 1.728 1.862<br />

L40695B SP-03 R-3/8 FGE .012 - .125 3/8-24 1.043 1.752 1.894<br />

L14717B SP-03 R-3/8 FGE-S .012 - .125 3/8 - 24 1.043 1.751 1.893<br />

L40706B SP-03 R-5/16 FGE .012 - .125 5/16 - 24 1.043 1.751 1.893<br />

L40001B SP-06 R-3/8 SS .012 - .250 3/8 - 24 1.323 2.453 2.740<br />

L14718B SP-06 R-3/8 FGE-H .012 - .250 3/8 - 24 1.346 1.751 2.736<br />

L40751B SP-07 R-3/8 FGE-C .012 - .291 3/8 - 24 1.181 2.205 2.470<br />

L40707B SP-07 R-5/16 FGE-C .012 - .291 5/16 - 24 1.181 2.468 2.470<br />

SP Series Keyless - Tapered Mount<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø1 L1 L2<br />

L40704B SP-15 J0 FGE .008 - .059 0JT .779 1.397 1.468<br />

L40705B SP-03 J0 FGE .012 - .125 0JT 1.043 1.751 1.893<br />

L40750B SP-07 J1 FGE-C .012 - .291 1JT 1.181 2.283 2.549<br />

CSS Series Keyed - Threaded Mount<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø1 L1 L2<br />

L13967B CSS-04 R-5/16 GE .020 - .156 5/16 - 24 K0M 0.866 1.181 1.366<br />

L40697B CSS-04 J0 .020 - .156 5/16 - 24 K0M 0.866 1.012 1.377<br />

L14720B CSS-06 R-3/8 GE DS .012 - .250 3/8 - 24 K1M 1.118 1.575 1.980<br />

L40699B CSS-06 R-5/16 GE-DS .012 - .250 5/16 - 24 K1M 1.118 1.575 1.980<br />

CSS Series Keyed - Tapered Mount<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø1 L1 L2<br />

L40680B CSS-04 J0 GE .020 - .156 0JT K0M 0.866 1.102 1.378<br />

L40681B CSS-06 J-1 GE .012 - .250 1JT K1M 1.118 1.574 1.980<br />

L40696B CSS-06 J1 GE-DS .012 - .250 1JT K1M 1.118 1.575 1.980<br />

CSS Series is also available with rounded jaws on demand only<br />

Hybrid Series - Threaded Mount<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø1 Ø 2 L1 L2<br />

L40683B SPH-03 R-3/8 FGE .012 - .125 3/8x24 K0T 1.063 1.181 1.752 1.890<br />

L40762B SPH-03 R-5/16 FGE .012 - .125 5/16 - 24 K0T 1.062 1.181 1.751 1.889<br />

L40702B SPH-07 R-3/8 FGE-C .012 - .291 3/8x24 K1T 1.181 1.339 2.224 2.480<br />

L40763B SPH-07 R-5/16 FGE-C .012 - .291 5/16 - 24 K1T 1.181 1.338 2.303 2.559<br />

Hybrid Series - Tapered Mount<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø1 Ø 2 L1 L2<br />

L40761B SPH-03 J-0 FGE .012 - .125 0JT K0T 1.062 1.181 1.751 1.889<br />

L40703B SPH-07 J-1 FGE-C .012 - .291 1JT K1T 1.181 1.339 2.303 2.559<br />

C= COMPACT VERSION FGE = NOSE & COLLAR HAVE MILLED SECTIONS, BEAD BLASTED GE = BEAD BLASTED SLEEVE<br />

H = HEAVY DUTY VERSION R = ROUNDED JAWS SS = NOSE & COLLAR HAVE KNURLED SECTIONS, NO BEAD BLAST<br />

13

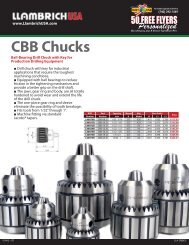

Keyed Heavy Duty Ball Bearing<br />

CBB<br />

Ball-Bearing Drill Chuck with Key for Production Drilling Equipment<br />

Drill chuck with key for industrial applications that require the toughest machining conditions.<br />

Equipped with ball bearings to reduce friction in the tightening mechanism and provide a better grip on the drill shaft.<br />

All pieces are hardened and ground.<br />

The one-piece gear ring and sleeve eliminate the possibility of tooth breakage.<br />

Fits tools up to 1” in diameter.<br />

Chucks come standard with Jacobs® taper mounts.<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40070B CBB-08 J2 1/32 - 5/16 2JT K30 1.850 2.165 2.756<br />

L40071B CBB-10 J2 1/32 - 3/8 2JT K32 1.850 2.165 2.756<br />

L40072B CBB-13 J3 1/32 - 1/2 6JT K3 2.441 2.953 3.701<br />

L40626B CBB-13 J6 1/32 - 1/2 3JT K3 2.441 2.953 3.701<br />

L40073B CBB-16 J3 1/32 - 5/8 3JT K4 2.638 3.189 4.016<br />

L40074B CBB-19 J4 1/32 - 3/4 4JT K4 2.953 3.898 4.921<br />

L40075B CBB-25 J5 13/64 - 1 5JT K5 3.661 4.409 5.787<br />

14

Keyed Heavy & Medium Duty Plain Bearing<br />

KD 1 = EQUIPPED WITH POSITIVE DRIVE SLOT<br />

PD 2 = EQUIPPED WITH PIN TYPE POSITIVE DRIVE<br />

C 3 = EQUIPPED WITH LOCKING COLLAR<br />

Drill Chuck Keys<br />

CBB<br />

Chuck Part EDP<br />

Series Number Number<br />

CBB-08 K30 L40088A<br />

CBB-10 K32 L40089A<br />

CBB-13 K3 L40090A<br />

CBB-16 K4 L40091A<br />

CBB-19 K4 L40091A<br />

CBB-25 K5 L40093A<br />

Hybrid<br />

Chuck Part EDP<br />

Series Number Number<br />

SPH-100 J-2 K2 L40538A<br />

SPH-100 J-33 K2 L40538A<br />

SPH-130 J-2 K3 L40090A<br />

SPH-130 J-33 K3 L40090A<br />

SPH-130 J-6 K3 L40090A<br />

SPH-160 J-6 K3 L40090A<br />

SPH-200 J-3 K4 L40091A<br />

CY<br />

Industrial Drill Chuck with Key for Stationary Machines<br />

Specially designed for stationary drilling, turning, milling and wood<br />

working machines.<br />

The one-piece gear ring and sleeve eliminates the possibility of tooth<br />

breakage.<br />

The jaws, gear ring and body are all totally hardened to avoid wear<br />

and lengthen the life of the drill chuck.<br />

Fits tools up to 3/4” in diameter.<br />

Chucks come standard with Jacobs® taper mounts.<br />

Heavy Duty Plain Bearing<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40131B CY-10 J-2 SP 1/32 - 3/8 2JT K34 1.693 2.165 2.677<br />

L40116B CYX-13 J-2 1/32 - 1/2 2JT K3 2.087 2.717 3.504<br />

L40117B CYX-13 J-6 1/32 - 1/2 6JT K3 2.087 2.717 3.504<br />

L40118B CYX-13 J-33 1/32 - 1/2 33JT K3 2.087 2.717 3.504<br />

Medium Duty Plain Bearing<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40129B CY-04 J-0 1/32 - 5/32 0JT K0 0.866 1.142 1.417<br />

L40130B CY-06 J-1 1/32 - 1/4 1JT CK4 1.260 1.575 1.929<br />

L40132B CY-10 J-1 1/32 - 3/8 1JT K34 1.457 2.008 2.362<br />

L40133B CY-10 J-2 1/32 - 3/8 2JT K34 1.457 2.008 2.362<br />

L40134B CY-13 J-33 1/32 - 1/2 33JT K2 1.811 2.441 3.031<br />

L40136B CY-13 J-33 KD 1 1/32 - 1/2 33JT K2 1.811 2.795 3.386<br />

L40119B CYX-13 J-33C 3 1/32 - 1/2 33JT K3 2.087 3.386 4.173<br />

L40528B CY-13-J6 1/32 - 1/2 6JT K2 1.811 2.440 3.031<br />

L40531B CY-16-J33 1/32 - 5/8 33JT K3 2.244 3.031 3.740<br />

L40532B CY-16 J-6 1/32 - 5/8 6JT K3 2.244 3.031 3.740<br />

L40113B CY-16 J-3 1/64 - 5/8 3JT K3 2.168 3.069 3.740<br />

L40114B CY-16 J-3 KD 1 1/32 - 5/8 3JT K3 2.244 3.346 4.016<br />

L40115B CY-16 J-3 PD 2 1/32 - 5/8 3JT K3 2.244 3.346 4.016<br />

L40120B CY-19 J-3 13/64 - 3/4 3JT K4 2.559 3.346 4.331<br />

L40121B CY-19 J-3 KD 1 13/64 - 3/4 3JT K4 2.559 3.504 4.567<br />

L40122B CY-19 J-3 PD 2 13/64 - 3/4 3JT K4 2.559 3.504 4.567<br />

CY<br />

Chuck Part EDP<br />

Series Number Number<br />

CY-04 K0 L40535A<br />

CY-06 CK4 L40578A<br />

CY-06 SP CK4 L40578A<br />

CY-10 K34 L40537A<br />

CY-10 SP K34 L40537A<br />

CY-13 K2 L40538A<br />

CYX-13 K3 L40090A<br />

CY-16 K3 L40090A<br />

CY-19 K4 L40091A<br />

CL<br />

Chuck Part EDP<br />

Series Number Number<br />

CL-06 & CL-10 KG L40577A<br />

CL13 K34 L40537A<br />

INOX CSS<br />

Chuck Part EDP<br />

Series Number Number<br />

CSS-04 J0 GE K0M L40235A<br />

CSS-06 J-1 GE K1M L40233A<br />

CSS-04 R-5/16 GE K0M L40235A<br />

CSS-06 J1 GE-DS K1M L40233A<br />

CSS-04 J0 K0M L40235A<br />

CSS-06 R-3/8 GE DS K1M L40233A<br />

CSS-06 R-5/16 GE-DS K1M L40233A<br />

CSS-04 J0 GE K0M L40235A<br />

CSS-04 R-5/16 GE K0M L40235A<br />

CSS-06 J1 GE-DS K1M L40235A<br />

CSS-06 R-3/8 GE-DS K1M L40233A<br />

CSS-06 R-5/16 GE-DS K1M L40233A<br />

INOX Hybrid<br />

Chuck Part EDP<br />

Series Number Number<br />

SPH-03 R-3/8 FGE K0T L40232A<br />

SPH-07 R-3/8 FGE-C K1T L40234A<br />

SPH-07 J-1 FGE-C K1T L40234A<br />

15

Keyless Heavy Duty for Portable Machines<br />

CPX<br />

Keyless Drill Chuck with Plastic Body,<br />

Locking Mechanism and Carbide Jaw Inserts<br />

Comes with a locking mechanism, no key is required for closing or opening.<br />

For hammer drilling.<br />

For fastener assembly and screwdriver operations.<br />

Carbide jaw-inserts (for 1/2” capacity) reduce bit slippage and enhance wear resistance.<br />

Ergonomic design utilizing materials that eliminate the possibility of rust.<br />

With through hole for clockwise and counterclockwise rotation.<br />

Standard screw thread mount for portable drilling machines.<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

L40197B CPX-10 R-3/8 1/32 - 3/8 3/8 - 24 1.614 2.244 2.598<br />

L40226B CPX-10 R-3/8 BL* 1/32 - 3/8 3/8 - 24 1.614 2.244 2.598<br />

L40198B CPX-10 R-1/2 1/32 - 3/8 1/2 - 20 1.614 2.244 2.598<br />

L40227B CPX-10 R-1/2 BL* 1/32 - 3/8 1/2 - 20 1.614 2.244 2.598<br />

L40199B CPX-13 R-3/8 1/16 - 1/2 3/8 - 24 1.654 2.559 2.953<br />

L40485B CPX-13 R-3/8 BL* 1/16 - 1/2 3/8 x 24 1.654 2.559 2.953<br />

L40200B CPX-13 R-1/2 1/16 - 1/2 1/2 - 20 1.654 2.559 2.953<br />

L40488B CPX-13 R-1/2 BL* 1/16 - 1/2 1/2 x 20 1.654 2.559 2.953<br />

BL* = Blister Pack<br />

CPM<br />

Keyless Drill Chuck with Metal Body,<br />

Locking Mechanism and Carbide Jaw Inserts<br />

Comes with a locking mechanism, no key is required for closing or opening<br />

For hammer drilling.<br />

For fastener assembly and screwdriver operations.<br />

Carbide jaw-inserts (for 1/2” capacity) reduce bit slippage and enhance wear resistance.<br />

Ergonomic and strong design with a full metal sleeve in black oxide finish that<br />

eliminates the possibility of rust.<br />

With through hole for clockwise and counterclockwise rotation.<br />

Standard screw thread mount for portable drilling machines.<br />

EDP Part Capacity Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Ø L1 L2<br />

L40201B CPM-10 R-3/8 1/32 - 3/8 3/8 - 24 1.614 2.146 2.539<br />

L40472B CPM-10 R-3/8 BL* 1/32 - 3/8 3/8 - 24 1.614 2.146 2.539<br />

L40202B CPM-10 R-1/2 1/32 - 3/8 1/2 - 20 1.614 2.146 2.539<br />

L40475B CPM-10 R-1/2 BL* 1/32 - 3/8 1/2 - 20 1.614 2.146 2.539<br />

L40203B CPM-13 R-3/8 1/16 - 1/2 3/8 - 24 1.693 2.461 2.933<br />

L40476B CPM-13 R-3/8 BL* 1/16 - 1/2 3/8 - 24 1.693 2.461 2.933<br />

L40204B CPM-13 R-1/2 1/16 - 1/2 1/2 - 20 1.693 2.461 2.933<br />

L40479B CPM-13 R-1/2 BL* 1/16 - 1/2 1/2 - 20 1.693 2.461 2.933<br />

BL* = Blister Pack<br />

16

Keyed for Heavy, Medium & Light Duty Portable Machines<br />

CY<br />

Industrial Drill Chuck with Key for Portable Drilling Machines<br />

Standard screw thread mount for portable drilling machines.<br />

The one-piece gear ring and sleeve eliminate the possibility of tooth breakage.<br />

The jaws, gear ring and body are all totally hardened to avoid wear and lengthen the life of the drill chuck.<br />

Fits tools of up to 3/4” in diameter.<br />

Machine fitting via UNF screw fittings.<br />

CY Heavy Duty<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40124B CY-06 R-3/8 SP 1/64 - 1/4 3/8 - 24 CK4 1.456 2.007 2.480<br />

L40125B CY-10 R-1/2 SP 1/64 - 3/8 1/2 - 20 K34 1.692 2.086 2.677<br />

L40126B CY-16 R-1/2 1/64 - 5/8 1/2 - 20 K3 2.244 3.031 3.740<br />

L40139B CY-10 R-3/8 SP 1/32 - 3/8 3/8 - 24 K34 1.693 2.087 2.677<br />

CY Medium Duty<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40137B CY-04 R-5/16 1/32 - 5/32 5/16 - 24 K0 0.866 1.496 1.732<br />

L40138B CY-06 R-3/8 1/32 - 1/4 3/8 - 24 CK4 1.260 1.654 2.047<br />

L40140B CY-10 R-3/8 1/32 - 3/8 3/8 - 24 K34 1.457 2.008 2.362<br />

L40142B CY-10 R-1/2 1/32 - 3/8 1/2 - 20 K34 1.457 2.008 2.362<br />

L40144B CY-13 R-3/8 1/32 - 1/2 3/8 - 24 K2 1.811 2.441 3.031<br />

L40143B CY-13 R-1/2 1/32 - 1/2 1/2 - 20 K2 1.811 2.441 3.031<br />

L40145B CY-13 R-5/8 1/32 - 1/2 5/8 - 16 K2 1.811 2.441 3.031<br />

L40126B CY-16 R-1/2 1/32 - 5/8 1/2 - 20 K3 2.244 3.031 3.740<br />

L40123B CY-16 R-5/8 1/32 - 5/8 5/8 - 16 K3 2.244 3.031 3.740<br />

L40127B CY-19 R-3/4 13/64 - 3/4 3/4 - 16 K4 2.559 3.346 4.331<br />

L40128B CY-19 R-5/8 13/64 - 3/4 5/8 - 16 K4 2.559 3.346 4.331<br />

CL<br />

Do-It<br />

Yourself Hobbyist Drill Chuck with Key for Portable Drilling Machines<br />

Standard screw thread mount for portable drilling machines.<br />

Ideal for portable drilling machines.<br />

Reversible or non reversible cutting direction.<br />

Fits to machine via UNF screw fittings, male and female.<br />

Fits tools up to ½” diameter”.<br />

EDP Part Capacity Key Sizes (<strong>Inc</strong>h)<br />

Number Number <strong>Inc</strong>h Mount Model Ø L1 L2<br />

L40220B CL-06 R-3/8 1/32 - 1/4 3/8 - 24 KG 1.181 1.732 2.165<br />

L40215B CL-10 R-3/8 1/32 - 3/8 3/8 - 24 KG 1.299 1.969 2.362<br />

L40216B CL-10 R-1/2 1/32 - 3/8 1/2 - 20 KG 1.299 1.969 2.362<br />

L40217B CL-13 R-3/8 3/64 - 1/2 3/8 - 24 K34 1.693 2.323 2.874<br />

L40501B CL-13 R-3/8 BL* 3/64 - 1/2 3/8 - 24 K34 1.693 2.323 2.874<br />

L40218B CL-13 R-1/2 3/64 - 1/2 1/2 - 20 K34 1.693 2.323 2.874<br />

L40504B CL-13 R-1/2 BL* 3/64 - 1/2 1/2”x20 K34 1.693 2.323 2.874<br />

BL* = Blister Pack<br />

17

Heavy Duty - <strong>High</strong> <strong>Precision</strong><br />

Live Centers<br />

For accurate work holding in conventional or CNC lathes<br />

Llambrich revolving lathe centers are of high precision.<br />

Capable of bearing up to 2,200 lbs workload and speeds of up<br />

to 5,000 rpm.<br />

Fully hardened and precision ground.<br />

Standard or extended nose configurations.<br />

Maintenance free.<br />

Model N<br />

For a wide range of general turning work.<br />

Model C<br />

<strong>Inc</strong>reases tool clearance and operator visibility for work on small<br />

parts or machining close to workpiece end.<br />

EDP Part Morse Load Factor Sizes (<strong>Inc</strong>h)<br />

Number Number Taper lbs Ø 1 Ø 2 Ø 3 L1 L2 L3<br />

Model N<br />

LGN200B R-200-N 2 400 0.709 1.654 -- 0.945 1.378 5.039<br />

LGN300B R-300-N 3 890 0.866 1.929 -- 1.142 1.850 6.417<br />

LGN400B R-400-N 4 1,765 1.181 2.480 -- 1.378 2.047 7.717<br />

LGN500B R-500-N 5 3,860 1.299 3.346 -- 1.890 2.520 9.843<br />

Model C<br />

LGC300B R-300-C 3 890 0.866 1.929 0.394 1.496 1.850 6.850<br />

LGC400B R-400-C 4 1,765 1.181 2.480 0.433 1.811 2.047 8.150<br />

LGC500B R-500-C 5 3,860 1.299 3.346 0.709 2.520 2.520 10.472<br />

18<br />

Model Maximum Run-Out<br />

R-200 0.00012”<br />

R-300 0.00012”<br />

R-400 0.00012”<br />

R-500 0.00016”

Medium Duty - <strong>High</strong> <strong>Precision</strong><br />

Live Centers<br />

With small casing diameter<br />

With small diameter for optimum accessibility.<br />

Additional bearings to compensate the axial load.<br />

Morse tapers hardened and ground.<br />

<strong>High</strong> concentricity.<br />

Lubricated for life.<br />

Maintenance free.<br />

Model RN<br />

For a wide range of general turning work.<br />

Model RC<br />

<strong>Inc</strong>reases tool clearance and operator visibility for work on small parts or machining close to workpiece end.<br />

Model RE<br />

Maximum tool clearance and operator visibility for work on small parts or machining close to workpiece end.<br />

EDP Part Morse Load Factor Sizes (<strong>Inc</strong>h)<br />

Number Number Taper lbs Ø 1 Ø 2 Ø 3 L1 L2 L3<br />

Model RN<br />

L40548B R-200-RN 2 440 0.591 1.260 -- 0.787 1.535 5.000<br />

L40549B R-300-RN 3 880 0.591 1.339 -- 0.787 1.575 5.709<br />

L40550B R-400-RN 4 1765 0.787 1.693 -- 1.024 1.654 7.087<br />

L40551B R-500-RN 5 2645 1.181 2.283 -- 1.457 2.362 9.252<br />

Model RC<br />

L40552B R-200-RC 2 330 0.591 1.260 0.315 1.181 1.535 5.394<br />

L40553B R-300-RC 3 660 0.591 1.339 0.315 1.181 1.575 6.102<br />

L40554B R-400-RC 4 1545 0.787 1.693 0.394 1.417 1.654 7.480<br />

L40555B R-500-RC 5 2200 1.181 2.283 0.472 2.008 2.362 9.646<br />

Model RE<br />

L40556B R-200-RE 2 285 0.591 1.260 0.236 1.181 1.535 5.394<br />

L40557B R-300-RE 3 615 0.591 1.339 0.315 1.220 1.575 6.102<br />

L40558B R-400-RE 4 1435 0.787 1.693 0.394 1.496 1.654 7.480<br />

L40559B R-500-RE 5 2050 1.181 2.283 0.472 1.929 2.362 9.646<br />

Model Maximum Run-Out<br />

R-200 0.00019”<br />

R-300 0.00019”<br />

R-400 0.00019”<br />

R-500 0.00031”<br />

19

Accessories<br />

Arbors for Drill Chucks<br />

Taper Arbors: DIN-238 and Jacobs®Threaded arbors: UNF<br />

Llambrich arbors are totally hardened and precision ground.<br />

Llambrich arbors ensure a close fit for maximum concentricity.<br />

®<br />

Morse Taper to Jacobs® Taper<br />

EDP<br />

Part<br />

Number Number Morse Jacobs®<br />

LEJ010B E-J0/1 1 0<br />

LEJ011B E-J1/1 1 1<br />

LEJ012B E-J2/1 1 2<br />

LEJ013B E-J3/1 1 3<br />

LEJ016B E-J6/1 1 6<br />

LEJ133B E-J33/1 1 33<br />

LEJ021B E-J1/2 2 1<br />

LEJ022B E-J2/2 2 2<br />

LEJ023B E-J3/2 2 3<br />

LEJ026B E-J6/2 2 6<br />

LEJ233B E-J33/2 2 33<br />

LEJ031B E-J1/3 3 1<br />

LEJ032B E-J2/3 3 2<br />

LEJ033B E-J3/3 3 3<br />

LEJ036B E-J6/3 3 6<br />

LEJ333B E-J33/3 3 33<br />

LEJ034B E-J4/3 3 4<br />

LEJ035B E-J5/3 3 5<br />

LEJ042B E-J2/4 4 2<br />

LEJ043B E-J3/4 4 3<br />

LEJ046B E-J6/4 4 6<br />

LEJ433B E-J33/4 4 33<br />

LEJ044B E-J4/4 4 4<br />

LEJ045B E-J5/4 4 5<br />

LEJ055B E-J5/5 5 5<br />

Straight Shank to Jacobs® Taper<br />

EDP<br />

Part<br />

Number Number Morse Jacobs®<br />

L40588B E-1/2-J0 1/2 0<br />

L40589B E-1/2-J1 1/2 1<br />

L40590B E-1/2-J2 1/2 2<br />

L40591B E-1/2-J3 1/2 3<br />

L40592B E-1/2-J33 1/2 33<br />

L40593B E-1/2-J4 1/2 4<br />

L40594B E-1/2-J6 1/2 6<br />

L40595B E-5/8-J1 5/8 1<br />

L40596B E-5/8-J2 5/8 2<br />

L40597B E-5/8-J3 5/8 3<br />

L40598B E-5/8-J33 5/8 33<br />

L40599B E-5/8-J4 5/8 4<br />

L40600B E-5/8-J6 5/8 6<br />

L40601B E-3/4-J2 3/4 2<br />

L40602B E-3/4-J3 3/4 3<br />

L40603B E-3/4-J33 3/4 33<br />

L40604B E-3/4-J4 3/4 4<br />

L40605B E-3/4-J6 3/4 6<br />

L40606B E-1-J2 1 2<br />

L40607B E-1-J3 1 3<br />

L40608B E-1-J33 1 33<br />

L40609B E-1-J4 1 4<br />

L40610B E-1-J6 1 6<br />

L40611B E-1-1/2-J3 1-1/2 3<br />

L40612B E-1-1/2-J4 1-1/2 4<br />

20<br />

R-8 Shank to Jacobs® Taper<br />

EDP Part<br />

Number Number Taper<br />

L40579B E-R8-J1 1<br />

L40580B E-R8-J2 2<br />

L40581B E-R8-J3 3<br />

L40582B E-R8-J33 33<br />

L40583B E-R8-J4 4<br />

L40584B E-R8-J6 6<br />

Morse Taper to Threaded Shank<br />

EDP Part<br />

Number Number Threaded Jacobs®<br />

L40585B E-MT2-3/8 3/8”x24 0<br />

L40586B E-MT2-1/2 1/2”x20 1<br />

L40587B E-MT2-5/8 5/8”x16 2<br />

CAT Shank to Jacobs® Taper<br />

EDP Part<br />

Number Number CAT Jacobs®<br />

L11088C CA-40/J33 40 33<br />

L11089C CA-40/J6 40 6<br />

L11090C CA-50/J33 50 33<br />

L11091C CA-50/J6 50 6

Accessories<br />

Drill Sleeves<br />

DIN-2185<br />

Completely hardened and ground, both internally and externally.<br />

Wide range.<br />

Drill Sleeves DIN-2185<br />

EDP Part Morse Taper<br />

Number Number Outside Inside<br />

LCR021B CR-2 x 1 2 1<br />

LCR031B CR-3 x 1 3 1<br />

LCR032B CR-3 x 2 3 2<br />

LCR041B CR-4 x 1 4 1<br />

LCR042B CR-4 x 2 4 2<br />

LCR043B CR-4 x 3 4 3<br />

LCR051B CR-5 x 1 5 1<br />

LCR052B CR-5 x 2 5 2<br />

LCR053B CR-5 x 3 5 3<br />

LCR054B CR-5 x 4 5 4<br />

Ejectors<br />

DIN-317<br />

Tempered steel.<br />

To eject Morse tapers arbors from sleeves or machine spindle.<br />

Ejecting Drifts for Drill Sleeves<br />

EDP Part<br />

Number Number Morse<br />

L40418B CE 1-2 1, 2<br />

L40419B CE 2-3 2, 3<br />

L40420B CE 3-4 3, 4<br />

L40421B CE 4-5 4, 5<br />

L40422B CE 5-6 5, 6<br />

Portable Drill Chuck Mounts<br />

Converts drill chuck’s female threaded mounts into male threaded mounts,<br />

SDS-Plus TM or 1/4” Hexagonal bit, to fit drill chuck to all kinds of machines.<br />

Adapters<br />

EDP Part Mount Fitting<br />

Number Number K (female) to machine (male)<br />

L40540B C51 3/8” - 24 3/8” - 24<br />

L40541B C52 3/8” - 24 1/2” - 20<br />

L40542B C53 1/2” - 20 SDS-PLUS TM*<br />

L40543B C54 3/8” - 24 HEX<br />

L40544B C56 M6 1/2” - 20<br />

L40545B C57 M5 3/8” - 24<br />

* C-53 includes an M6 screw<br />

21

Cross Reference<br />

KEYLESS<br />

JKP<br />

EDP Llambrich Jacobs®<br />

L31126B JKP-30 J-0 JKP 30-J0<br />

L31127B JKP-30 J-1 JKP 30-J1<br />

L31128B JKP-30 R-5/16 JKP 30-5/16<br />

L31121B JKP-65 J-1 JKP 65-J1<br />

L40002B JKP-80 J-1 JKP 80-J1<br />

L9679B JKP-80 J-2S JKP 80-J2S<br />

L9681B JKP-100 J-2 JKP 100-J2<br />

L9680B JKP-100 J-33 JKP 100-J33<br />

L9683B JKP-130 J-2 JKP 130-J2<br />

L9682B JKP-130 J-33 JKP 130-J33<br />

L9684B JKP-130 J-6 JKP 130-J6<br />

L40003B JKP-160 J-33 JKP 160-J33<br />

L9685B JKP-160 J-6 JKP 160-J6<br />

JK INDUSTRIAL<br />

EDP Llambrich Jacobs®<br />

L40158B JK 04 J-1 --<br />

L40159B JK 06 J-1 --<br />

L40160B JK 06 R-3/8 --<br />

L40161B JK 08 R-3/8 JK 80 3/8<br />

L40162B JK 08 R-1/2 JK 80 1/2<br />

L40163B JK 08 J-1 JK 80 J1<br />

L40164B JK 08 J-2S JK 80 J2<br />

L40165B JK 10 R-3/8 JK 100 3/8<br />

L40166B JK 10 R-1/2 JK 100 1/2<br />

L40167B JK 10 J-2 JK 100 J2<br />

L40221B JK 10 J-33 JK 100 J33<br />

L40168B JK 13 J-2 JK 130 J2<br />

L40169B JK 13 J-33 JK 130 J33<br />

L40170B JK 13 J-6 JK 130 J6<br />

L40171B JK 13 R-3/8 JK 130 3/8<br />

L40172B JK 13 R-1/2 JK 130 1/2<br />

L40173B JK 16 J-33 JK 160 J33<br />

L40174B JK 16 J-6 JK 160 J6<br />

L40175B JK 16 R-1/2 JK 160 1/2<br />

L40176B JK 16 R-5/8 JK 160 5/8<br />

L40177B JK 20 J-3 JK 200 J3<br />

JKT<br />

EDP Llambrich Jacobs®<br />

L31122B JKT-65 J-1 JKT 65-J1<br />

L30526B JKT-80 J-2S JKT 80-J2S<br />

L30533B JKT-100 J-2 JKT 100-J2<br />

L30532B JKT-100 J-33 JKT 100-J33<br />

L30527B JKT-130 J-2 JKT 130-J2<br />

L30528B JKT-130 J-33 JKT 130-J33<br />

L30529B JKT-130 J-6 JKT 130-J6<br />

L30530B JKT-160 J-6 JKT 160-J6<br />

JK SOLID R-8<br />

EDP Llambrich Jacobs®<br />

L31411B JK-130 R-8 JK 130-R8<br />

L31416B JK-160 R-8 JK 160-R8<br />

CPX<br />

EDP Llambrich Jacobs®<br />

L40197B CPX-10 R-3/8 510-2P 3/8X24<br />

L40198B CPX-10 R-1/2 510-2P 1/2X20<br />

L40199B CPX-13 R-3/8 513-2P 3/8X24<br />

L40200B CPX-13 R-1/2 513-2P 1/2X20<br />

JK SOLID MORSE<br />

EDP Llambrich Jacobs®<br />

L31406B JK-08 MT2 JK 80-MT2<br />

L31407B JK-10 MT2 JK 100-MT2<br />

L31408B JK-13 MT2 JK 130-MT2<br />

L31409B JK-13 MT3 JK 130-MT3<br />

L31410B JK-13 MT4 JK 130-MT4<br />

L31413B JK-16 MT2 JK 160-MT2<br />

L31414B JK-16 MT3 JK 160-MT3<br />

L31415B JK-16 MT4 JK 160-MT4<br />

JK SOLID STRAIGHT SHANK<br />

EDP Llambrich Jacobs®<br />

L31412B JK-130 5/8 JK 130-5/8”<br />

CPM<br />

EDP Llambrich Jacobs®<br />

L40201B CPM-10 R-3/8 --<br />

L40202B CPM-10 R-1/2 --<br />

L40203B CPM-13 R-3/8 713-2M 3/8X24<br />

L40204B CPM-13 R-1/2 713-2M 1/2X20<br />

KEYED<br />

CY<br />

EDP Llambrich Jacobs®<br />

L40129B CY-04 J-0 0<br />

L40130B CY-06 J-1 1A<br />

L40132B CY-10 J-1 31-01<br />

L40133B CY-10 J-2 31-02<br />

L40131B CY-10 J-2 SP 2A<br />

L40134B CY-13 J-33 33<br />

L40528B CY-13 J-6 --<br />

L40116B CYX-13 J-2 34-02<br />

L40118B CYX-13 J-33 34-33<br />

L40117B CYX-13 J-6 34-06<br />

L40531B CY-16 J-33 --<br />

L40532B CY-16 J-6 --<br />

L40113B CY-16 J-3 3A<br />

L40120B CY-19 J-3 36<br />

L40534B CY-19 J-4 --<br />

CY THREADED MOUNTS<br />

EDP Llambrich Jacobs®<br />

L40137B CY-04 R-5/16 OB 5/16<br />

L40138B CY-06 R-3/8 1B 3/8<br />

L40124B CY-06 R-3/8 SP 7BA 3/8<br />

L40140B CY-10 R-3/8 41BA 3/8<br />

L40139B CY-10 R-3/8 SP 2BA 3/8<br />

L40142B CY-10 R-1/2 41BA 1/2<br />

L40125B CY-10 R-1/2 SP 32BA 1/2<br />

L40144B CY-13 R-3/8 33BA 3/8<br />

L40143B CY-13 R-1/2 33BA 1/2<br />

L40145B CY-13 R-5/8 33BA 5/8<br />

L40126B CY-16 R-1/2 35B 1/2<br />

L40123B CY-16 R-5/8 3B 5/8<br />

L40128B CY-19 R-5/8 36B 5/8<br />

L40127B CY-19 R-3/4 36B 3/4<br />

CL LIGHT DUTY<br />

EDP Llambrich Jacobs®<br />

L40220B CL-06 R-3/8 30243<br />

L40215B CL-10 R-3/8 30247<br />

L40216B CL-10 R-1/2 --<br />

L40217B CL-13 R-3/8 30598<br />

L40218B CL-13 R-1/2 30602<br />

CBB<br />

EDP Llambrich Jacobs®<br />

L40070B CBB-08 J2 8-1/2 N<br />

L40071B CBB-10 J2 11N<br />

L40072B CBB-13 J3 14N<br />

L40626B CBB-13 J6 ---<br />

L40073B CBB-16 J3 16N<br />

L40074B CBB-19 J4 18N<br />

L40075B CBB-25 J5 20N<br />

C-INOX<br />

EDP Llambrich Jacobs®<br />

L40205B CSS-04 R-3/8 --<br />

L40206B CSS-06 R-3/8 1BM 3/8<br />

L40207B CSS-10 R-3/8 --

Tech Info<br />

Parts of a Drill Chuck<br />

Types of Drill Chucks & What They are Used For<br />

Mounting Systems<br />

<br />

<br />

<br />

Sleeve<br />

Gear Teeth<br />

Body<br />

Jaws<br />

Collar<br />

Ball Retainer<br />

Ball Bearings<br />

Internal Socket<br />

Jaw-Guide<br />

Lead Screw<br />

Nose<br />

Jaws<br />

KEYED DRILL CHUCKS<br />

1 Super Ball Bearing Keyed Chucks : Keyed chucks require a key for<br />

tightening or loosening, and permit clockwise and counterclokwise<br />

turning. The Super Ball Bearing Chucks are equipped with ball bearings<br />

to reduce friction in the tightening mechanism and provide a<br />

better grip on the drill. Used for industrial applications that require the<br />

toughest machining conditions, where high accuracy drilling is not a<br />

must (max. run-out .003” approx). Available with tapered mounts only<br />

(Jacobs®).<br />

2 Plain Bearing Keyed Chucks : Equipped with one-piece gearing<br />

and sleeve that reduces the possibility of teeth breaking. Used for<br />

stationary drilling, turning, milling and wood working machines. For<br />

medium duty industrial use, available with threaded mount for hand<br />

held drilling machines and with tapered mounts for stationary drilling<br />

machines where run-out is not a must (max. .004” approx.)<br />

Mounting & Removing Chucks<br />

A B C E F G<br />

On Threaded Spindle Portable Tools Unplug drill or disconnect battery pack. Open jaws of existing chuck completely. Remove<br />

left-hand thread screw of any from inside chuck and save for re-use (illus. A). Insert hex-type wrench into chuck body and<br />

tighten jaws on wrench. Strike wrench counterclockwise with mallet to free and unscrew chuck (illus. B). Screw new chuck<br />

onto spindle (clockwise). Insert hex-type wrench in jaws and tighten jaws on wrench. Strike wrench clockwise with mallet<br />

several times (illus. C)<br />

On Tapered Shank Arbors To Mount Chucks Clean both tapers of all grease and grit. With the jaws retracted into the chuck<br />

and with the chuck nose resting on a wooden bench, strike the tang of the arbor lightly to seal it into the chuck.<br />

To Remove Chucks Insert wedge between the back of the chuck and the shoulder of the arbor (illus. E & F). In case the<br />

mounting taper of the arbor does not provide a shoulder, a cross hole should be drilled through the neck of the arbor<br />

(illus. G) and a cross pin inserted. Then the wedge can be used between the chuck back and the cross pin.<br />

How to Select the Right Drill Chuck<br />

Power Tools Stationary Tools CNC Machine Medical, Food<br />

2,3,7,9 1,2,6,7,10 5,6,10 4,8<br />

11 Arbors : Are chuck mounting devices used to adapt<br />

standardized chuck mounts to various machine spindle<br />

tapers.<br />

12 Sleeves : Are adapter for arbors when the machine<br />

spindle requires a larger taper than is available on the<br />

arbor.<br />

13 Extension Sockets : Are adapting devices which<br />

increases effective spindle length and provides more<br />

flexibility when adapting to various taper sizes.<br />

Tool Holders for Drill Chucks<br />

Machine Spindle<br />

Adapters for Power Tools<br />

Drilling<br />

Machine Type<br />

or<br />

Application<br />

Suggested Drill<br />

Chuck Types<br />

14 Adapters for Power Tools : To fit drill chucks to all kind of portable drilling, hammerdrilling or screwdrive machines. 14.1 Adapter<br />

converts drill chuck’s female threaded mounts into male threaded mounts ; 14.2 Adapter forHammer Drills with SDS-Plus mount; 14.3<br />

Adapter ,is a ¼” Hexagonal bit to fit drill chucks to screwdriver.<br />

11<br />

11<br />

12<br />

13<br />

3 Light Duty Keyed Chucks : Equipped in most power tools for DIY<br />

for decades, this is a good and cheap chuck for light duty applications.<br />

Nowadays are replaced by keyless chucks more and more. For electric<br />

hand held drilling machines, reversible or non-reversible.<br />

4 Stainless Steel Keyed Chucks : Manufactured out of stainless steel.<br />

For use in the food, medical and dental industries, where tools must be<br />

sterilized. Same design as a Plain Bearing chuck, but in stanless steel.<br />

5 CNC <strong>Precision</strong> Keyed Chucks w/integrated shank : Ideal for CNC<br />

machines. Short design, maximum concentricity, max. run-out .0012”<br />

or better sometimes supplied with a certification, high clamping<br />

forces, over 75 ft/lbs, and optional through coolant and balance.<br />

Permits clockwise and counterclockwise turning. For use in high speed<br />

CNC equipment for milling, drilling, reaming and tapping.<br />

KEYLESS DRILL CHUCKS<br />

6 Keyless Chucks for <strong>High</strong> <strong>Precision</strong> / <strong>High</strong> Torque applications:<br />

Keyless chuck does not require a key for tightening or loosening.<br />

<strong>Inc</strong>orporates a self-tightening feature that causes them to grip tighter<br />

as more torque is applied. Permits clockwise turning only. Automatic<br />

fitting for efficient, fast change tools. Minimum run-out for accurate<br />

hole sizing, sometimes certified by the producer (max. TIR .0016” or<br />

better). For high accuracy drill presses, jig borers, milling machines<br />

and production drilling equipment, CNC’s included. Also available with<br />

through hole for EDM machines. <strong>High</strong> Torque versions are supplied<br />

with wrench for 3 times increased clamping force to better resist tool<br />

loosening on high speed machines that have instant spindle stop.<br />

7 Keyless Chucks for medium duty applications : Same self-tightening<br />

feature as <strong>High</strong> <strong>Precision</strong> or <strong>High</strong> Torque chucks, but with wider<br />

run-outs (about .006”). Automatic fitting for efficient, fast change tools.<br />

For medium duty industrial use, available with threaded mount for<br />

hand held drilling machines and with tapered mounts for stationary<br />

drilling machines. Clockwise turning only.<br />

8 Keyless Chucks in Stainless Steel : Manufactured out of stainless<br />

steel. <strong>High</strong> precision and selftightening design. For use in the food,<br />

medical and dental industries, where tools must be sterilized.<br />

Clockwise turning only.<br />

9 Keyless Drill Chuck for portable drilling machines : These are the<br />

latest generation chucks for power tools. Does not require a key for<br />

tightening or loosening. Some are equipped with a locking<br />

mechanism for hammer drilling and also screwdriver operations<br />

(clockwise and counterclockwise). Ergonomic Design, offered with<br />

plastic or metal sleeves. For hand held drills, reversible or<br />

non-reversible.<br />

10 CNC <strong>Precision</strong> Keyless Chucks w/integrated shank : Same as<br />

type no.5 (See “How to Select a Drill Chuck” on the left) also ideal for<br />

CNC machines but for applications requiring clockwise turning only<br />

as it has a self-tightening feature. Compact construction, maximum<br />

connection rigidity, higher precision (TIR .0016” or better, certified by<br />

some producers only). For use on CNC machine centers, milling and<br />

turning machines, or other stationary equipment.<br />

14.1 Adapter for female<br />

threaded spindles<br />

14.2 Adapter for hammer<br />

drills w/SDS-Plus mount<br />

14.3 Adapter for electric<br />

Screwdrivers

INDUSTRIAL SUPPLY ASSOCIATION<br />

Linking Channel Partners<br />

COMMITTED TO INDEPENDENT TECHNICAL<br />

MANUFACTURER’S REPRESENTATIVES.<br />

SOLD ONLY THROUGH<br />

INDUSTRIAL DISTRIBUTION.<br />

5 5<br />

1957 - 2012<br />

WHAT WE SELL<br />

www. w.llambrichusa.com<br />

for spare parts<br />

Customer Committment<br />

To work hard everyday to be regarded in the metal<br />

working marketplace as a supplier that is friendly, helpful and<br />

easy to do business with - EVERYDAY, EVERYTIME.<br />

To offer innovative high quality<br />

solutions at a competitive price.<br />

To be receptive & proactive in identifying solutions<br />

for our customers needs & requirements.<br />

Another Quality Product from <br />

EDP: LL-CAT12<br />

106 West Ohio Avenue<br />

Mount Vernon, Ohio 43050<br />

phone (740) 392-1549<br />

fax (740) 392-0230<br />

www.eurolinkinc.com<br />

sales@eurolinkinc.com<br />

Published April 2012