Deep Panuke Project - Bredero Shaw

Deep Panuke Project - Bredero Shaw

Deep Panuke Project - Bredero Shaw

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

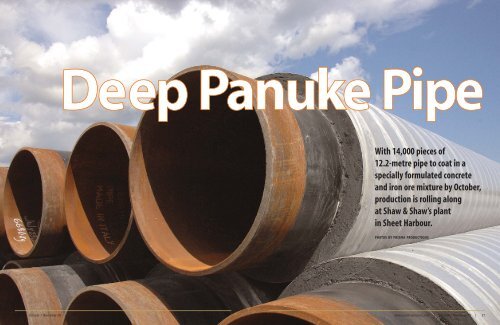

<strong>Deep</strong> <strong>Panuke</strong> Pipe<br />

With 14,000 pieces of<br />

12.2-metre pipe to coat in a<br />

specially formulated concrete<br />

and iron ore mixture by October,<br />

production is rolling along<br />

at <strong>Shaw</strong> & <strong>Shaw</strong>’s plant<br />

in Sheet Harbour.<br />

PHOTOS BY PRISMA PRODUCTIONS<br />

26 | October / November 08 | www.ocean-resources.com<br />

www.ocean-resources.com | October / November 08 | 27

A SECTION OF CONCRETE COATING IS BEING REMOVED SO A SACRIFICIAL ANODE CAN<br />

BE INSTALLED. IT IS TERMED “SACRIFICIAL,” AS IT WILL CORRODE FIRST, ACTING AS A<br />

BARRIER AGAINST CORROSION FOR THE PROTECTED METAL.<br />

About every four and a half minutes, another 12.2-metre<br />

length of pipe rolls off the processing line at <strong>Shaw</strong> &<br />

<strong>Shaw</strong>'s plant in Sheet Harbour on Nova Scotia’s Eastern<br />

Shore.When it enters the coatings plant, the steel pipe is slightly<br />

less than 56 centimetres in diameter. By the time it exits, it’s<br />

encased in a 60-, 80- or 100-millimetre coating of specially<br />

formulated concrete and iron ore. The thickness of the coating<br />

depends on where the pipe will be located, with the 60mmcoating<br />

applied to the pipes in shallower water, closer to shore.<br />

When the pipe is installed next year, this negative buoyancy<br />

coating will help to hold the 22-inch diameter pipeline safely on<br />

the ocean floor.<br />

“The plant has been operating around the clock, six days a week<br />

on a 10-hour shift basis since early July,” says Mike Kontak,<br />

spokesperson for <strong>Shaw</strong> & <strong>Shaw</strong>.“We have a production team of<br />

over 100 people, a large percentage of whom are residents of<br />

Sheet Harbour and the surrounding communities.” Recruitment<br />

for the project began last April. Close to 300 applications were<br />

received, with some 250 interviews conducted. Recruitment ads<br />

were run in various community newspapers throughout the<br />

province, including Port Hawkesbury’s The Reporter, the<br />

Guysborough Journal and the Mi’kmaq Maliseet Nations News.<br />

In addition to hiring locally, Kontak says preference was also<br />

given to acquiring products and services from the local area first.<br />

In all, <strong>Shaw</strong> & <strong>Shaw</strong> let contracts valued at $50,000 for goods and<br />

services such cement, loaders, cranes, fuel, trucking, water<br />

services, site preparation and disposal services. “Items such as<br />

waste disposal, hardware supplies, yard preparation and sand for<br />

berms were available in the local community, and we were able<br />

to meet our needs for items such as heavy equipment and<br />

concrete in the greater metro area,” says Kontak.<br />

THE SITE IS A HIVE OF ACTIVITY, WITH PIPE CONTINUALLY BEING LOADED AND UNLOADED.<br />

HERE, IN THE FOREGROUND, A PIECE OF PIPE IS LOADED INTO THE COMPRESSION-COAT CONCRETE WEIGHT COATINGS PLANT.<br />

28 | October / November 08 | www.ocean-resources.com<br />

www.ocean-resources.com | October / November 08 | 29

CLEANING OF THE PIPE, PRIOR TO INSPECTION.<br />

The first shipment of 5,979 pieces of carbon steel pipe arrived in<br />

Sheet Harbour on July 7, having been manufactured by Ilva S.A.<br />

of Italy. By the time the project concludes this fall, <strong>Shaw</strong> & <strong>Shaw</strong><br />

will have coated over 14,000 pieces of pipe for the 175-kilometre<br />

pipeline that will transport natural gas from the <strong>Deep</strong> <strong>Panuke</strong><br />

Production Field Centre to Goldboro, where it will enter the<br />

Maritimes & Northeast Pipeline<br />

system. The finished pipe will remain<br />

at the Sheet Harbour site until next<br />

spring, when it will be loaded onto<br />

barges for installation offshore.<br />

<strong>Shaw</strong> & <strong>Shaw</strong>, owned by <strong>Shaw</strong> Pipe<br />

Protection., a subsidiary of <strong>Shaw</strong>Cor of<br />

Toronto, and The <strong>Shaw</strong> Group of<br />

Halifax, was awarded the $40 million<br />

pipe coatings contract by EnCana last<br />

January. It also provided pipe coating<br />

services for the Sable Offshore Energy<br />

Tier I and 2 projects in 1998 and 2002,<br />

processing a total of 434 kilometres of<br />

pipe at Sheet Harbour. The site was<br />

restored for the <strong>Deep</strong> <strong>Panuke</strong> project,<br />

with <strong>Shaw</strong> Pipe Protection bringing<br />

one of its compression-coat concrete<br />

weight coatings plants from Texas. The plant will be dismantled<br />

in November, once the project is completed. As with those two<br />

other projects, <strong>Shaw</strong> Pipe Protection is supplying its pipecoating<br />

expertise, with The <strong>Shaw</strong> Group providing project support,<br />

liaison with local suppliers, logistics and administrative support.<br />

TAPE IS PUT AROUND THE PIPE TO PROVIDE PROTECTION FOR THE CONCRETE MIX PRIOR TO IT<br />

HARDENING. IT WILL BE REMOVED ONCE LOADED ON THE BARGES, NEXT YEAR. HERE, THE CONCRETE<br />

COATING IS BEING CUT BACK TO PROVIDE SPACE FOR THE LAY BARGE TO WELD THE PIPES TOGETHER.<br />

AFTERWARD, A CONCRETE COATING WILL BE REAPPLIED.<br />

30 | October / November 08 | www.ocean-resources.com