Sustainability Report 2011 - Finlays

Sustainability Report 2011 - Finlays

Sustainability Report 2011 - Finlays

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong><br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 1

We understand that sustainability<br />

is the only future we have and<br />

our commitment to sustainability<br />

is central to our long-term<br />

business strategy.

Contents<br />

Section 1 – Introduction<br />

1.1 Foreword – Managing Director James Finlay Limited, Ron Mathison 4<br />

1.2 A year in review – key highlights 6<br />

1.3 Scope of report 8<br />

1.4 Management approach to sustainability 9<br />

1.5 <strong>Sustainability</strong> commitments and supporting actions 10<br />

Section 2 – About <strong>Finlays</strong><br />

2.1 Corporate profile 12<br />

2.2 Fast facts 14<br />

2.3 Group structure 16<br />

2.4 Global network 17<br />

Section 3 – Group performance review <strong>2011</strong><br />

3.1 Environment – Energy, Water, Waste, Carbon 18<br />

3.2 Economic Contribution 22<br />

3.3 People – Occupational Health & Safety, Training, Community 23<br />

Section 4 – Business unit performance<br />

4.1 Tea Estates – Kenya and Sri Lanka 29<br />

4.2 Leaf Tea Trading and Tea Extracts 41<br />

4.3 Finlay Beverages 50<br />

4.4 <strong>Finlays</strong> Colombo 54<br />

4.5 <strong>Finlays</strong> Horticulture 58<br />

Section 5 – Governance<br />

5.1 Group Operating Companies 68<br />

5.2 Legal Form and Governance 69<br />

Appendices<br />

i) Swire Group Sustainable Development Policy 70<br />

ii) Performance Data 71<br />

This report has been printed on 100% recycled paper<br />

using environmentally friendly vegetable based inks.<br />

3

Introduction<br />

1.1 Foreword – Managing Director James Finlay Limited, Ron Mathison<br />

As an agribusiness, we have a high level of dependence on the natural environment. We operate in markets<br />

where natural resources are scarce and ecosystems are fragile. Many of our businesses are cyclical and most<br />

of our investments have relatively long pay back periods. This requires us to take a long term view when<br />

investing and taking this long term view is fundamental to any sustainable business. We have a long heritage<br />

of taking good care of our people, looking after our land, husbanding resources, and helping the communities<br />

in which we operate. We understand that sustainability is the only future we have and our commitment to<br />

sustainability is central to our long-term business strategy.<br />

In this report, the third of its kind, we measure progress<br />

against the sustainability targets we have set ourselves<br />

over the last year and set new targets that build on the<br />

achievements so far for future years. Our key areas of<br />

focus remain energy, water, waste, carbon emissions and<br />

people, but we are also increasing the amount of resources<br />

allocated to biodiversity and community engagement.<br />

Working with others for a sustainable future<br />

As was the case last year, in some of our operations we<br />

have not achieved as much as we targeted, while in other<br />

parts of our business we have made more progress than<br />

expected. We have continued to make good progress on<br />

reducing packaging waste and increasing rainwater capture<br />

and recycling. We are proud of our contribution to the<br />

success of the Imarisha initiative which seems to have<br />

gained real traction in addressing the water management<br />

challenges surrounding Lake Naivasha, Kenya. Similarly,<br />

after several years of preparation, we have achieved<br />

4<br />

<strong>Finlays</strong> has a long established reputation for integrity,<br />

professionalism and quality, but the common thread that<br />

pulls all our businesses together, the glue that binds the<br />

Group, is our enduring commitment to sustainability.<br />

Fairtrade and Rainforest Alliance accreditation for 11,200<br />

of our smallholders in Kericho, Kenya. This is the Kibagenge<br />

project that we have engaged in, in partnership with the<br />

Department for International Development (DFID), The<br />

Co-operative Group, The Co-operative College, and Africa<br />

Now (now called Self Help Africa).<br />

We recognize that we cannot achieve sustainability on our<br />

own. We need to engage with the communities around us<br />

and partner with like-minded institutions that understand<br />

the healthy symbiosis between smallholders and large<br />

estates. Empowerment of smallholders is only beneficial if<br />

it results in a sustainable business model. The key is mutual<br />

dependence built on trust and respect, where the rewards are<br />

fair and socially just for both smallholders and large estates.<br />

Learning more every year<br />

Data cleansing and data capture continue to be areas that<br />

require improvement. We have fallen behind on some of<br />

our water usage and energy usage targets and this needs<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Introduction<br />

1.1 Foreword – Managing Director James Finlay Limited, Ron Mathison<br />

rectification in the years ahead. We continue to learn from<br />

our mistakes and improve on our successes. Much remains<br />

to be done but we are committed to achieving our goals<br />

and we are confident that we can make a real difference.<br />

Part of the process is learning how to manage some of the<br />

interesting trade-offs that are now emerging as we delve<br />

deeper into sustainability.<br />

For example, when the weather is wet we benefit from<br />

increased amounts of hydro electric energy but we then<br />

need to expend more of that energy to dry tea and firewood<br />

that has more moisture content. Similarly, when we use<br />

more sea freight instead of air freight we reduce our carbon<br />

emissions but we then need to use more water to rehydrate<br />

the flowers.<br />

Factoring in social impacts of sustainability initiatives gives<br />

rise to another set of potentially competing considerations.<br />

For example, growing flowers in Kenya provides social<br />

benefits in the form of employment, education, improved<br />

welfare and local wealth creation, but the requirement to air<br />

freight flowers to Europe creates large amounts of carbon<br />

emissions. We don’t pretend to have all the answers but<br />

again we are determined to do our best to find the right<br />

balance between environmental and social impacts.<br />

Reducing unnecessary waste<br />

Looking ahead, it is clear that the challenge for most<br />

businesses is sustainable growth: how can we reduce<br />

environmental impacts and at the same time achieve<br />

growth? This is a real challenge but I believe part of the<br />

solution lies in reducing unnecessary waste throughout the<br />

supply chain. This is particularly pertinent to food scarcity<br />

when you consider how much food is wasted as a result of<br />

overly stringent specifications on length, colour, shape –<br />

none of which have anything to do with shelf life, taste or<br />

nutritional value. At the same time as concerns about food<br />

scarcity are rising we are seeing an alarming rise in obesity.<br />

Something is deeply wrong when 1 in 10 of the world adult<br />

population is obese yet 1 billion people go hungry.<br />

What is required is behaviour change in the way<br />

we consume and I believe that suppliers, brands and<br />

retailers must all play an important part in driving this<br />

change in shopping and consumption habits. Instead of<br />

incentivizing shoppers to buy more stuff than they need<br />

through ‘buy one get one free’ promotions, we should do<br />

more to encourage shoppers to purchase lower grade food<br />

products that may not have the perfect shape or colour but<br />

nevertheless have the same taste and nutritional value. This<br />

approach is already being embraced by many enlightened<br />

retailers but there is still so much unnecessary waste that<br />

is being driven by unsustainable consumption behaviour.<br />

We will continue to do our part in trying to reduce discards<br />

and we will continue to work together with retailers to<br />

encourage consumers to embrace change. Change is<br />

never easy but where there is a will there is a way.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 5

Introduction<br />

1.2 A year in review – key highlights<br />

Key Highlights<br />

For the first time we have a full year of data on all indicators<br />

having made investments in installing more water meters in<br />

our tea estates in Sri Lanka and improving data collection<br />

processes on waste in <strong>Finlays</strong> Colombo.<br />

Data management has been a challenge but, with the help of<br />

our internal audit function, our <strong>Sustainability</strong> Managers have<br />

made a vast improvement in the accuracy of data collected. This<br />

now allows us to make informed decisions based on accurate<br />

data to improve the business. The challenge in the future is<br />

to make sure this data continues to be used as the basis of<br />

actionable analyses and, most importantly, used to help us<br />

identify actions and interventions to improve our performance<br />

and drive down costs associated with these indicators.<br />

Our performance in <strong>2011</strong> has been heavily impacted by:<br />

• The closure of the Tea Extracts factory at Mara Mara,<br />

with production being consolidated into the nearby Saosa<br />

site. We have achieved significantly improved energy and<br />

water performance in the Tea Extracts business as a result<br />

of this move.<br />

• The variability of weather. As an agribusiness our<br />

performance is very weather dependent. A high yield<br />

crop in Tea Estates Kenya resulted in significant firewood<br />

usage, and we benefited from good water availability<br />

for hydro-electric operations on our estates. This has<br />

enabled us to increase the contribution of renewables to<br />

our energy numbers. Encouragingly, the trend over the<br />

last 4 years has seen a steady increase in our renewable<br />

component. The higher air temperatures also resulted in<br />

increased water usage in <strong>Finlays</strong> Horticulture; this would<br />

have been higher if we had not installed the closed loop<br />

and rainwater systems. Year-on-year comparisons do<br />

not always accurately reflect the true meaning of shifts<br />

in metrics. In order to gain a better understanding of<br />

performance we will be comparing like-for-like years<br />

with regard to temperature and the water requirement<br />

of a specific crop.<br />

6<br />

In <strong>2011</strong>, <strong>Finlays</strong> achieved a number of its key medium-term<br />

objectives, with <strong>Finlays</strong> Horticulture in the UK achieving their<br />

target of 0% waste to landfill, and there was an impressive<br />

increase in the Group’s use of renewable energy up to 73%.<br />

We still have some work to do on other key indicators.<br />

We have increased the resource in all businesses to help meet the increasing needs of coverage and<br />

reporting of sustainability, whilst still ensuring that current management activities address these<br />

needs. We are now committed to reporting to GRI C+ level in the next two years, with <strong>Sustainability</strong><br />

Managers and Head Office Managers recently attending a GRI <strong>Report</strong>ing master class.<br />

Energy<br />

We are making incremental progress but with<br />

significant activity across the business engaged in<br />

energy efficiency improvements we aim to return<br />

improved numbers next year.<br />

Water<br />

We continue to dramatically reduce water usage using<br />

innovative techniques in the industry, especially<br />

across our horticulture businesses. This has resulted<br />

in a 20% net reduction across the Group.<br />

Waste management<br />

Waste management is showing sustained improvement<br />

with our horticulture businesses in the UK having 0% to<br />

landfill across all UK sites. As most of our waste is green<br />

waste we have further opportunities to reduce it and also<br />

to divert it to more valuable alternatives such as using it<br />

in biomax composting converters or biogas plants.<br />

Carbon<br />

We are continuing to develop sea freighting in <strong>Finlays</strong><br />

Horticulture, whilst Finlay Beverages have been at<br />

the forefront of transferring movement of tea to rail<br />

transport - resulting in big carbon savings.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Introduction<br />

1.2 A year in review – key highlights<br />

Supporting the wellbeing of the community<br />

<strong>Finlays</strong> Horticulture employs over 6,500 people across<br />

6 sites. The company has an on-going investment<br />

programme in training, including supervisory, vocational<br />

and employment-based training as well as life skills support<br />

to help reduce stress. Workers receive teaching in literacy<br />

and simple financial management, to help them cope with<br />

the impact on wages of high Kenyan inflation. Over 3,000<br />

local farmers also receive technical support to help them<br />

increase yield and income in sustainable ways.<br />

Biodiversity at its best: supporting the Mau and the Bongo<br />

(see full story on page 36)<br />

<strong>Finlays</strong> has supported conservation of the Mau for many<br />

years through funding of Friends of the Mau Watershed<br />

(FOMAWA), which seeks to educate local farmers and<br />

school children about the importance of protecting their<br />

environment. Spreading the conservation message to a<br />

wider and more influential audience, however, has proved<br />

more difficult. An ‘island’ of pristine forest, supporting a<br />

wide variety of flora and fauna, but surrounded by human<br />

settlement, Eburu has been decimated over the years by<br />

illegal logging and charcoal burning, as well as poaching<br />

and bush meat hunting.<br />

Now there is a glimmer of hope, with the discovery that<br />

Eburu is one of the last remaining refuges for the critically<br />

endangered antelope, the Eastern Mountain Bongo; research<br />

suggests a small population of between 7 and 12 of these<br />

beautiful animals lives in the South West Mau Forest, close<br />

to <strong>Finlays</strong>’ tea estates. This finding by the Mountain Bongo<br />

Surveillance Project, which <strong>Finlays</strong> also funds, has at last<br />

drawn the plight of Eburu to international attention.<br />

Imarisha: working with stakeholders<br />

(see full story on page 66)<br />

A three-person secretariat has been formed to execute<br />

the functions of Imarisha Naivasha. The first funding<br />

was received from the Kenya Government and from<br />

UK retailers ASDA, Co-operative Sainsburys, Marks and<br />

Spencer, Morrisons and Tesco. These retailers recognised<br />

the importance of identifying lasting solutions to the<br />

challenges facing the Lake Naivasha basin, particularly<br />

water, and were quick to seize the opportunity to<br />

enthusiastically support Imarisha Naivasha.<br />

Encouragingly, the trend over the last<br />

4 years has seen a steady increase in<br />

our renewable component.<br />

Examples of how the funds have helped:<br />

• Repairing the mechanical aeration equipment at the<br />

Naivasha sewage treatment works.<br />

• Planting 600,000 tree seedlings provided by the Ministry<br />

of Environment and Mineral Resources throughout the<br />

catchment. The planted seedlings cover approximately<br />

950 hectares of previously degraded areas.<br />

• Enabling 5 community forest associations to plant and<br />

nurture tree seedlings purchased from community nurseries.<br />

• Helping fishermen to improve sanitary standards of fish<br />

processing facilities and to install deep freezers.<br />

• Enabling pastoralist groups to install pilot domestic<br />

biogas plants, fencing to protect water springs, troughs<br />

for livestock and to restore water pans rainwater storage.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 7

Introduction<br />

1.3 Scope of report<br />

Scope of report<br />

The report covers all our business units within Tea and Horticulture that have a significant social<br />

or environmental impact or which constitute a key financial component of <strong>Finlays</strong>’ operations.<br />

All the main business units in <strong>Finlays</strong> are covered,<br />

with the following exclusions:<br />

• James Finlay Pakistan, whose main business is shipping<br />

and insurance.<br />

• The tea trading offices in Dubai, Indonesia, Vietnam<br />

and Malawi only report on EN16, LA7, LA1 given the<br />

small size of these offices.<br />

Our partners in instant tea manufacture, Tres Montes Lucchetti<br />

(Chile) and Damin Foodstuffs (China) and our decaffeination<br />

business with AV Thomas (India) are included in sales numbers.<br />

For the first time, Finlay Flowers BV are included in the report.<br />

In reporting on carbon we include Scope 3 given the<br />

importance of transportation to market in our horticulture<br />

and tea trading businesses.<br />

Performance is reported against two sets of objectives:<br />

i. <strong>Finlays</strong> group indicators, which are those that apply<br />

to all our businesses.<br />

ii. <strong>Finlays</strong> business unit indicators, which are selected by each<br />

business unit to reflect its main challenges, details of which<br />

can be found within the individual business unit reports.<br />

Changes in measurement<br />

Our Tea Extracts and Leaf Tea numbers will now be<br />

displayed as sales volume rather than production volume,<br />

given the trading nature of the business.<br />

Carbon data has changed slightly, due to changes with the<br />

carbon calculator software. These changes are minimal.<br />

Kenya Tea Estates have separated the measurement<br />

of domestic water and water for production sites.<br />

<strong>Finlays</strong> Colombo have re-assessed their energy use for<br />

the period 2008-9.<br />

Group sustainability objectives<br />

• Energy<br />

Continuously improve our resource management<br />

• Wa t e r<br />

Practice excellence in our management of water resources<br />

• Wa s t e<br />

Continuously improve our resource management<br />

and reduce our waste generation<br />

• C a r b o n<br />

Undertake to be carbon restorative and minimise<br />

emissions of other greenhouse gases<br />

8<br />

GRI Indicators<br />

We identified the Group GRI Indicators through an<br />

exhaustive review project called ‘A sustainable future<br />

for <strong>Finlays</strong>’, with the aim of developing a long-term and<br />

stretching sustainable development strategy for <strong>Finlays</strong>.<br />

We involved a range of stakeholders from across the group<br />

including some from our parent company Swire. We will be<br />

reporting under the following GRI Indicators:<br />

• Energy<br />

EN3 – Direct energy consumption by primary energy source.<br />

EN4 – Indirect energy consumption by primary source.<br />

• Water<br />

EN8 – Total water withdrawal by source.<br />

EN10 – Percentage and total volume of water recycled<br />

and reused.<br />

• Waste<br />

EN22 – Total weight of waste by type and disposal method.<br />

• C a r b o n<br />

EN16 – Total direct and indirect greenhouse gas<br />

emissions by weight.<br />

• Economic<br />

EC1 – Direct economic value generated and distributed,<br />

including revenues, operating costs, employee<br />

compensation, donations and other community<br />

investments, retained earnings, and payments to<br />

capital providers and governments.<br />

• Occupational Health & Safety<br />

LA1 - Total workforce by employment type, employment<br />

contract, and region, broken down by gender.<br />

LA7 – Rates of injury, occupational diseases, lost days,<br />

and absenteeism, and number of work related fatalities<br />

by region and by gender.<br />

<strong>Report</strong>ing period<br />

The report is for the calendar year <strong>2011</strong>. This follows<br />

on from our initial annual reports of 2009 and 2010.<br />

Our methodology uses the indicators based on Global<br />

<strong>Report</strong>ing Initiative (GRI) guidelines and carbon<br />

measurement is based on WRI/WBCSD GHG protocols.<br />

If there are any queries about this report please contact<br />

sustainability@finlays.net or write to:<br />

<strong>Sustainability</strong> <strong>Report</strong>,<br />

James Finlay Limited,<br />

Swire House,<br />

59, Buckingham Gate,<br />

London, SW1E 6AJ.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Introduction<br />

1.4 Management approach to sustainability<br />

Each <strong>Finlays</strong> Business Unit faces different challenges<br />

depending on its location, products or stakeholders.<br />

Our management approach is one of ownership by senior<br />

management of each business whereby sustainability is<br />

embedded within the responsibility of the Business Unit.<br />

Management approach to sustainability<br />

The Head Office role is to provide oversight, facilitation<br />

and guidance but it is the responsibility of each business<br />

unit to prioritise objectives relevant to its business.<br />

<strong>Sustainability</strong> objectives are aligned with business<br />

objectives and owned by the relevant function in those<br />

businesses, with clear responsibilities and measurable<br />

targets. This is backed up by accountability and<br />

transparency through public reporting of performance.<br />

Essentially, we are committed to sustainability as a total business<br />

concept, driven by the senior management team within each<br />

business unit, supported and guided by Head Office.<br />

A Group <strong>Sustainability</strong> Committee was set up in early<br />

2009 to ensure that we bring appropriate expertise<br />

together on a regular basis to highlight emerging issues.<br />

The Committee also monitors the Group’s response to<br />

dealing with sustainability challenges and keeps abreast<br />

of external factors impacting our strategy. It has the remit<br />

to set targets, review and monitor our performance and<br />

where necessary, to commission Group sustainability<br />

projects addressing specific issues. It is also responsible<br />

for promoting and spreading best practice from outside or<br />

within the organisation, recognising notable achievements<br />

and reviewing participation in accreditation and<br />

certification schemes.<br />

The Group has many experts in water, energy, waste,<br />

certification schemes, labour relations and packaging and<br />

we are trying to use our subject matter experts as thought<br />

leaders to facilitate the spread of knowledge across the Group.<br />

The targets we set are designed to balance specific business<br />

priorities with a common approach across the group.<br />

<strong>Sustainability</strong> Managers are now in place in each of the<br />

businesses, in full time or part time roles, reporting to<br />

the Managing Director of each business. Generally acting<br />

in an advisory capacity, they are charged with objectives<br />

specific to the business in which they operate, and many<br />

of them have specialist skills pertinent to these objectives.<br />

Increasingly, sustainability metrics are being built into<br />

individual personal performance reviews as part of their<br />

Key Performance Indicators (KPIs).<br />

In a business characterised by diversified activities, setting<br />

common sustainability targets can be a complex process.<br />

Some of the medium term targets for incremental<br />

improvement are more easily achievable for some<br />

businesses than for others. To clarify our performance,<br />

we have provided data on total usage and carbon footprint<br />

as well as normalised data. Whilst we understand that<br />

carbon footprints have to reduce in total, normalised data<br />

in the short term helps the business demonstrate progress<br />

in terms of efficiency and cost reduction in addition to<br />

efficiencies driven purely by volume. Some areas are crucial<br />

to the long term viability within some businesses. Where<br />

this is the case, the Business Unit has taken a leadership<br />

position in the Group. Examples are energy use in Tea<br />

Estates and water use by Horticulture in Kenya.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 9

Introduction<br />

1.5 <strong>Sustainability</strong> commitments and supporting actions<br />

<strong>Sustainability</strong> commitments<br />

and supporting actions<br />

In 2008 we conducted an extensive review across<br />

the business with the purpose of formulating an<br />

uplifting yet realistic strategy to guide our actions.<br />

Working with our partners, Forum for the Future,<br />

we explored the major trends and uncertainties that<br />

the company could be facing over the coming years.<br />

The project, ‘A sustainable future for <strong>Finlays</strong>’, examined the<br />

possible impacts on the organisation and how it could become<br />

a more resilient and sustainable company and, at the same time,<br />

make as great a contribution as possible to the wider goal of<br />

sustainable development. In short, the aim was to develop a longterm<br />

and stretching sustainable development strategy for <strong>Finlays</strong>.<br />

From this process we identified a set of five high level group<br />

sustainability commitments by which we now guide our actions<br />

and evaluate our success.<br />

10<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Introduction<br />

1.5 <strong>Sustainability</strong> commitments and supporting actions<br />

Business<br />

We will address social, political and environmental issues<br />

by demonstrating that it is more financially rewarding<br />

to be sustainable:<br />

• Undertake regular business performance reviews, taking<br />

action to increase the long-term sustainability of our<br />

business portfolio over time;<br />

• Explore new business opportunities in keeping with<br />

our sustainability goals;<br />

• Maintain sufficient diversity in our markets and<br />

our products to ensure resilience;<br />

• Make the true cost of production (economic, environmental<br />

and social) clear and ensure, over time, that it is reflected<br />

in the price of the product;<br />

• Communicate openly with our supply chain, the local<br />

community, pressure groups and the wider public about<br />

the case for sustainable development;<br />

• Behave with honesty and integrity.<br />

Environment<br />

We aim to have ‘zero net impact’ as our minimum<br />

environmental standard. Overall we commit to<br />

making a positive contribution to environmental<br />

recovery and resilience:<br />

• Develop a comprehensive understanding of the likely<br />

impact of climate change and implement appropriate<br />

adaptation measures for our operations and the<br />

communities in which we operate;<br />

• Undertake to be carbon restorative and minimise<br />

emission of other greenhouse gases;<br />

• Continuously improve our resource management, practice<br />

excellence in our management of water resources and<br />

reduce our waste generation; reduce and eliminate the<br />

use and release of pollutants wherever possible;<br />

• Lead the way in community watershed management;<br />

• Protect and enhance biodiversity in the countries in<br />

which we operate;<br />

• Demonstrate and promote sustainable pest and<br />

disease management, eliminating any negative impact<br />

on the environment;<br />

• Maintain soil health through sustainable agricultural<br />

practices and avoid soil degradation by taking measures<br />

to prevent contamination and erosion;<br />

• Demonstrate excellence in forestry management.<br />

People<br />

We strive to make <strong>Finlays</strong> an enjoyable and rewarding place<br />

to work, an organisation that nurtures and develops its<br />

people for the benefit of the individual, the company, and<br />

the community:<br />

• Employ our workforce according to universal international<br />

standards and treat employees fairly, with dignity and respect;<br />

• Protect the health of our workforce and promote<br />

healthier lifestyles;<br />

• Ensure that all employees, and their resident dependents,<br />

have access to food and shelter, sanitation, clean water<br />

and primary healthcare;<br />

• Develop our employees’ life and business skills and<br />

empower all our employees to make their voices heard<br />

through democratic worker representative bodies;<br />

• Demonstrate leadership in equal opportunity<br />

employment, thriving as an ethnically and culturally<br />

diverse company; encourage and facilitate female<br />

representation and the contribution of women to<br />

the business;<br />

• Reward our employees for achieving the company’s<br />

business objectives;<br />

• Educate our employees on the values and principles<br />

of sustainable development.<br />

Communities and Partners<br />

We will take an active leadership role in dealing<br />

with sustainability issues, and share our knowledge<br />

for the benefit of our suppliers, communities and society<br />

in general:<br />

• A collaborative approach to addressing sustainability<br />

challenges and policy, engaging with growers, suppliers,<br />

customers, government, NGOs, union and industry bodies;<br />

• Adopt a leadership role in supplier and smallholder<br />

development; demonstrating and providing best practice for<br />

our suppliers in crop selection, sustainable farming techniques,<br />

production processes and environmental management;<br />

• Make sure we become a catalyst for positive change<br />

in the communities we serve.<br />

Products<br />

We will develop and provide sustainable products and<br />

services that contribute positively to the health and<br />

well-being of society:<br />

• Reduce the lifecycle impact of each of our products<br />

and ensure sustainability is built into our New Product<br />

Development processes;<br />

• Provide research and development capability exploring<br />

innovative, sustainable processes and products;<br />

• Deploy sustainable processing technologies to increase<br />

product efficiency and competitiveness;<br />

• Package our products in the most sustainable way<br />

possible using sustainable packaging innovation;<br />

• Transport our goods in the most efficient and sustainable<br />

manner possible;<br />

• Be proactive in supporting an equitable and ethical<br />

trading environment for our products.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 11

About <strong>Finlays</strong><br />

2.1 Corporate profile<br />

12<br />

<strong>Finlays</strong> is a vertically integrated and geographically<br />

diversified agribusiness conglomerate taking a leadership<br />

role in sustainability. <strong>Sustainability</strong> is pivotal to our success;<br />

it lies at the very heart of what we do and what we stand<br />

for. It provides the common thread that pulls the group’s<br />

different business units together.<br />

Founded in Glasgow, Scotland, in 1750, <strong>Finlays</strong> began as a trader<br />

and manufacturer of cotton before expanding into tea in the 19th<br />

century, following the collapse of the British cotton industry.<br />

Over the years, <strong>Finlays</strong> has diversified to reduce its reliance on<br />

tea plantations. Diversification into horticulture began around<br />

30 years ago and, with the acquisition of Flamingo (now <strong>Finlays</strong><br />

Horticulture) in 2007 <strong>Finlays</strong> is now one of the leading players<br />

in the UK cut flower and fresh produce industry.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

About <strong>Finlays</strong><br />

2.1 Corporate profile<br />

Tea, Coffee, Rubber and Timber<br />

Our Tea Estates in Kenya and Sri Lanka cover more than<br />

15,000 hectares, producing 40 million kilos of black tea<br />

annually. We are one of the only tea companies in the world<br />

to be involved in every aspect of the complex process of<br />

growing, trading, blending, extracting, packaging and<br />

distributing tea. <strong>Finlays</strong> is the largest trader of Fairtrade<br />

tea in the world and largest roaster of coffee in the UK.<br />

<strong>Finlays</strong> is also one of the largest independent tea traders in<br />

the world, trading more than 70 million kilos of tea each year.<br />

We are one of the world’s largest suppliers of quality tea<br />

extracts, including instant teas and aromas, dealing with<br />

the world’s top beverages companies. Our beverage packing<br />

businesses in the UK and Sri Lanka source, blend and package<br />

private label tea and coffee for customers in the UK, the Middle<br />

East and Japan. As well as managing 6,000 hectares of timber<br />

in Kenya and Sri Lanka, the Company also produces 1 million<br />

kilos of rubber latex annually in Sri Lanka, 204,000 stacked<br />

metres cubed (stm 3 ) of Eucalyptus and Cyprus per year.<br />

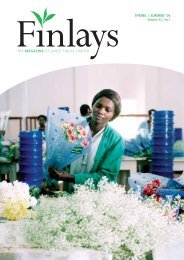

Flowers and Fresh Produce<br />

<strong>Finlays</strong> Horticulture is involved in the growing, processing,<br />

packaging, marketing and distribution of cut flowers and<br />

premium prepared fresh vegetables. <strong>Finlays</strong> Horticulture is a<br />

supplier to most of the UK’s leading retailers, including Marks<br />

& Spencer, Tesco, Sainsbury’s, the Co-operative, Morrisons,<br />

Asda and Next.<br />

The company has major farming interests in Kenya<br />

and South Africa through its wholly-owned subsidiaries,<br />

<strong>Finlays</strong> Horticulture Kenya and <strong>Finlays</strong> Horticulture South<br />

Africa. We are the largest vertically integrated added-value<br />

horticultural producer and exporter of fresh produce and<br />

flowers from Africa to the EU.<br />

<strong>Finlays</strong> markets and sells flowers in continental Europe<br />

through Omniflora, a wholly-owned subsidiary based<br />

in Frankfurt. Omniflora supplies fresh flowers to major<br />

retail multiples in Germany, Austria, Switzerland, Norway<br />

and Luxembourg. Omniflora is committed to supplying<br />

ethical flowers, sourced from socially and environmentally<br />

responsible growers. The company trades almost exclusively<br />

in Fairtrade accredited roses sourced from FLO (Fairtrade<br />

Labelling Organisation) certified farms.<br />

Established in 2007, Taikoo Flowers, in Kunming, China,<br />

is a wholly-owned subsidiary of <strong>Finlays</strong>. This cut flower<br />

production facility supplies high quality carnations<br />

principally to the Japanese market. Taikoo Flowers has<br />

established a joint venture with Hilverda Kooij to develop<br />

state-of-the-art plant breeding and propagation programmes.<br />

FV SeleQt is a joint venture business between <strong>Finlays</strong><br />

Horticulture and the Best Fresh Group formed to market<br />

premium fresh vegetables in Europe. The operation is<br />

based in Poeldijk in The Netherlands. The Best Fresh<br />

Group brings an expertise of marketing and distributing<br />

salads, vegetables and fruits in Continental Europe and<br />

this combined with <strong>Finlays</strong> expertise of both growing<br />

and sourcing vegetables makes FV SeleQt a compelling<br />

proposition for European customers. FV SeleQt currently<br />

supplies 15 customers all over Europe and is fully accredited<br />

for Fairtrade, Max Havelaar and the International Food<br />

Standard (IFS).<br />

Other activities<br />

Our subsidiary Dudutech, an integrated pest management<br />

company produces large quantities of biological control<br />

organisms to control common pests and diseases at its insect<br />

production facilities in Naivasha, Kenya. These indigenous<br />

beneficial insects have helped Kenyan growers to reduce their<br />

dependence on synthetic pesticides by almost 70% since 2004.<br />

Equally important, Dudutech also provides training to ensure<br />

that all its customers can maximise the benefits of Integrated<br />

Crop Management (ICM). ICM is a total approach to farming;<br />

it is not merely the use of biological products.<br />

Another <strong>Finlays</strong> subsidiary, Skytrain, is a dedicated cargohandling<br />

and freight forwarding agency, with facilities at<br />

Jomo Kenyatta International Airport in Nairobi, handling sea<br />

and air freight export for fresh produce from East Africa.<br />

We are the world’s largest supplier<br />

of quality tea extracts, including<br />

instant teas and aromas…<br />

<strong>Finlays</strong> has a controlling interest in <strong>Finlays</strong> Colombo,<br />

a Sri Lankan based business quoted on the Colombo<br />

Stock Exchange. Its activities include warehousing of tea,<br />

blending and packaging tea for export, insurance broking,<br />

environmental services and representation for Cathay<br />

Pacific, for which it acts as General Sales Agent. <strong>Finlays</strong><br />

Colombo also owns Sri Lanka’s largest and technologically<br />

most advanced cold storage facility, together with a factory<br />

which manufactures green tea.<br />

<strong>Finlays</strong> and its subsidiaries are well experienced in<br />

the environmental and social issues that come with the<br />

cultivation of tea, timber, flowers, vegetables and other<br />

such crops.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 13

About <strong>Finlays</strong><br />

2.2 <strong>Finlays</strong> fast facts<br />

14<br />

Tea<br />

Produces 40 million kg per annum from 15,000 hectares in Kenya and Sri Lanka.<br />

Trades over 70 million kg from offices in the UK, Kenya, Sri Lanka, UAE, Malawi, Vietnam,<br />

Indonesia, Mainland China and the USA; blends and packs over 18 million kg per annum.<br />

Manufactures and trades over 6 million kg of extracts per annum. Trades over 4 million kg<br />

of decaffeinated tea.<br />

Coffee<br />

Blends and packs 2.3 million kg of coffee per annum.<br />

Flowers<br />

300 hectares under greenhouse or polytunnel in Kenya, South Africa and Mainland China<br />

producing over 450 million stems per annum for the UK, continental Europe and Japan.<br />

Sources and processes 850 million stems in Kenya, UK, China, Germany and Holland.<br />

One of the world’s largest producers and packers of Fairtrade roses and lilies.<br />

Fresh Produce<br />

Grows and processes 7 million kg per annum and sources 28 million kg per annum.<br />

First supplier of Fairtrade vegetables into the UK.<br />

Insects (Integrated Pest Management)<br />

12 hectares of insect production facilities in Kenya yield 956 million insects a month.<br />

Rubber<br />

2,000 hectares in Sri Lanka producing 1,000,000 kg rubber latex per annum.<br />

Timber<br />

5,000 hectares in Kenya and Sri Lanka producing 204,000 stm3 of Eucalyptus and Cyprus.<br />

Coconuts<br />

600,000 nuts per annum in Sri Lanka.<br />

Cold Storage<br />

Operating a 2.2 million cu-ft facility in Sri Lanka.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

About <strong>Finlays</strong><br />

2.2 <strong>Finlays</strong> fast facts<br />

Awards<br />

<strong>Finlays</strong> Tea Estates – Kenya<br />

• Gold medal for Kijani Mark, Chomogonday estate,<br />

Tea Board of Kenya<br />

• Silver medal for Tiluet Mark, Chomogonday estate,<br />

Tea Board of Kenya<br />

• Silver medal for Sisiba Mark, Kymulot estate,<br />

Tea Board of Kenya<br />

• Silver medal for Black Orthodox Tea, Kitumbe estate,<br />

Tea Board of Kenya<br />

• Bronze medal for best set of samples for special<br />

manufacture, Chomogonday estate<br />

• Fairtrade certification for Kitumbe Group<br />

• Rainforest Alliance Certification maintained<br />

for all factories and tea estates<br />

• Organic certification by Soil association of the UK<br />

maintained for Kitumbe factory, Chemase Estate<br />

and Chomogonday factory<br />

• Food safety certification (ISO 22000) maintained<br />

in four factories (Kitumbe, Changana, Kymulot<br />

and Chomogonday)<br />

Finlay Beverages<br />

• Asda Private Label Supplier of the Year Award <strong>2011</strong><br />

• Co-operative Retail Trading Group’s Ethical Supplier<br />

of the Year Award <strong>2011</strong><br />

<strong>Finlays</strong> Horticulture<br />

• Sainsbury’s Innovation Award<br />

• Plan A Award for Supply Chain work in supporting<br />

small scale farmers and Fairtrade development<br />

• Plan A Award to Richard Fox for outstanding personal<br />

contribution to water stewardship around Lake Naivasha<br />

• Contribution to the Industry Award, Grower of the Year,<br />

awarded to Bob Ellis<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 15

About <strong>Finlays</strong><br />

2.3 Group structure<br />

Group structure<br />

The Group comprises of eight businesses encompassing Tea Estates, Leaf Tea,<br />

Tea Extracts, Beverage Packing, Flowers, Fresh Produce, Logistics & Services,<br />

and Forestry & Rubber. Each business has a number of business units<br />

operating in various countries around the world.<br />

Tea Estates<br />

Our tea estates are in<br />

Kenya and Sri Lanka<br />

Beverage Packing<br />

Expertise in sourcing,<br />

blending and packing in<br />

both the UK and Sri Lanka<br />

Leaf Tea<br />

We are black and green tea<br />

suppliers and manufacturers<br />

of decaffeinated tea<br />

Tea Extracts<br />

We’re one of the world’s<br />

largest suppliers of<br />

quality tea extracts<br />

Fresh Produce<br />

We grow a wide variety<br />

of fresh vegetables<br />

Logistics & Services<br />

We have logistics<br />

businesses in Sri Lanka<br />

and Pakistan<br />

Flowers<br />

We grow roses, carnations,<br />

chrysanthemums<br />

and lilies<br />

Rubber & Forestry<br />

We own rubber and<br />

forestry plantations<br />

16<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

About <strong>Finlays</strong><br />

2.4 Global network<br />

<strong>Finlays</strong> worldwide<br />

We employ over 39,000 employees on flower farms in Kenya, South Africa and China,<br />

and tea estates in Kenya and Sri Lanka.<br />

Our primary markets are in the UK, USA, Asia and, increasingly, continental Europe.<br />

Total Net sales: £590,936,000.<br />

Total capitalization broken down in terms of debt and equity: £222,152,000<br />

(Equity £172,490,000 Debt: £49,662,000).<br />

South America<br />

1 Buenos Aires<br />

2 Santiago<br />

4<br />

2<br />

3<br />

1<br />

North America<br />

3 New Jersey<br />

4 Toronto<br />

Europe<br />

7<br />

5<br />

6<br />

5 Germany<br />

6 Holland<br />

7 United<br />

Kingdom<br />

London<br />

South Elmsall<br />

Stevenage<br />

Spalding<br />

Sandy<br />

Hull<br />

Africa<br />

8 Malawi<br />

9 Kenya<br />

Kericho<br />

Mombasa<br />

10 South Africa<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 17<br />

10<br />

8<br />

9<br />

12<br />

15<br />

16<br />

Asia<br />

17<br />

11 China<br />

12 Dubai<br />

13 Hong Kong<br />

14 Indonesia<br />

15 Pakistan<br />

16 Sri Lanka<br />

17 Vietnam<br />

11<br />

13<br />

14

Group performance review <strong>2011</strong><br />

3.1 Environment<br />

Energy<br />

Overall performance<br />

Overall there has been a 5% reduction in total energy<br />

usage across <strong>Finlays</strong>. There has been an increase in the<br />

renewable component to 73% of total energy used from 63%.<br />

This is due to an increased hydro-electric contribution in<br />

Kenya and higher firewood usage over 2010. Whether we<br />

can sustain the increased renewable status and continue<br />

to reduce overall energy requirements will be a major<br />

challenge for 2012.<br />

Finlay Beverages have entered into an energy contract<br />

with a higher percentage for renewable energy and <strong>Finlays</strong><br />

Colombo have completed the switch from furnace oil to<br />

sustainable firewood at the Haldamullah factory in Sri<br />

Lanka, increasing their renewable energy contribution<br />

from 40% to 60%.<br />

<strong>2011</strong> Highlights<br />

• Horticulture’s total energy use is down by 9%<br />

• <strong>Finlays</strong> Leaf Tea & Tea Extracts total energy use<br />

is down by 17%<br />

• Sri Lanka Tea Estates have seen an 8% reduction<br />

per unit of production and a 16% reduction overall<br />

• Finlay Beverages saw a 7% reduction per unit<br />

of production<br />

In 2012 we will be examining areas where we can make<br />

more significant changes to our energy usage by using<br />

our in-house energy knowledge experts across the business.<br />

We will also conduct detailed energy assessments across<br />

all sites to drive small-scale savings in machinery, methods<br />

and people’s behaviour.<br />

We are making progress on performance in Sri Lanka by<br />

converting steam to hot water boilers; this should greatly<br />

assist energy saving commitments.<br />

Our GRI Indicators are: EN3, EN4<br />

Medium term targets<br />

to be achieved by 2014<br />

• Reduction of 10% total energy usage<br />

on 2009 base year<br />

• Increase of 10% renewable energy over<br />

non-renewable energy<br />

18<br />

GJ (Thousands)<br />

2,500<br />

2,000<br />

1,500<br />

1,000<br />

500<br />

0<br />

<strong>Finlays</strong> Group energy usage<br />

2008 2009 2010 <strong>2011</strong><br />

Indirect<br />

renewable<br />

Indirect<br />

non-renewable<br />

Direct<br />

non-renewable<br />

Direct<br />

renewable<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Group performance review <strong>2011</strong><br />

3.1 Environment<br />

Water<br />

Overall performance<br />

For the first time all business units have reported full<br />

year water figures, with Sri Lanka Tea Estates metering<br />

all sites. There has been a 20% reduction in net water<br />

across the Group. This figure excludes the water used by the<br />

community in our Tea Estates in Kenya, which if calculated<br />

on the same basis equates to a 7% reduction overall.<br />

Improvements have been noted elsewhere with the<br />

shutting of the Mara Mara tea extracts factory which had<br />

a non-closed cooling system. These savings and changes<br />

in measurement have resulted in Horticulture Africa now<br />

being accountable for 92% of all water used in the Group,<br />

compared to 65% in 2010.<br />

With water consumption directly related to climate,<br />

in <strong>2011</strong> Horticulture Africa experienced a slight increase.<br />

An accurate comparison can only be made when years<br />

of similar climatic temperatures are reviewed against<br />

each other. Work continues on increasing the reuse and<br />

recycling quotas.<br />

Overall the Group saw a 12% increase in reused water<br />

and a 4% increase in rainwater capture, which shows<br />

a sustained positive trend on water management.<br />

These are the areas we should see further progress<br />

across all businesses.<br />

<strong>2011</strong> Highlights<br />

• <strong>Finlays</strong> Leaf Tea & Tea Extracts has seen<br />

a reduction of 84% in net water<br />

• Flowers Europe have seen a 13% reduction<br />

in net water<br />

• Fresh Produce UK show a reduction of 4% in net water<br />

• Finlay Beverages have seen a 39% reduction<br />

in net water<br />

• Kenya Tea Estates installed their first rainwater<br />

capture system at Chomogonday factory<br />

In 2012 our businesses will continue to implement<br />

more water reduction measures, through extended<br />

water measurement and water efficiency assessment<br />

tools. The data collected will be used to make informed<br />

decisions on water use and sourcing water.<br />

Our GRI Indicators are: EN8, EN10<br />

<strong>Finlays</strong> Group water usage<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 19<br />

Water m 3 (Millions)<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

2008 2009 2010 <strong>2011</strong><br />

Reused Net water -<br />

Rainwater<br />

Rainwater as<br />

component<br />

of net water<br />

Medium term targets<br />

to be achieved by 2014<br />

• 15% reduction in water usage<br />

• 0% untreated water discharge to open ground<br />

• 20% of water to be recycled or reused

Group performance review <strong>2011</strong><br />

3.1 Environment<br />

Waste<br />

Overall performance<br />

Overall waste numbers are down 13%, with a significant<br />

38% reduction of waste to landfill, showing a sustained<br />

year-on-year performance improvement. Encouragingly,<br />

there was a 25% reduction in waste recovered; the majority<br />

of this being green waste. The supply chain in which we<br />

operate means we have variable demand, stringent product<br />

specifications and sensitivity to outside factors. This waste<br />

stream will continue to be difficult to eliminate but is an<br />

area in which we will continue to challenge all stakeholders<br />

in the supply chain.<br />

<strong>2011</strong> Highlights<br />

• <strong>Finlays</strong> Fresh Produce UK<br />

0% to landfill<br />

32% reduction in total waste<br />

• Finlay Flowers UK<br />

0% to landfill<br />

• Omniflora<br />

0% to landfill<br />

• Leaf Tea & Tea Extracts<br />

34% reduction in total waste<br />

• Finlay Flowers Europe<br />

3% reduction in total waste<br />

• <strong>Finlays</strong> Colombo is reporting waste<br />

for the first time<br />

The volume of green waste presents opportunities to gain<br />

value from recovering as much as possible for use either as<br />

a fuel or to improve soil health. Projects in both these areas<br />

are a priority for 2012.<br />

Medium term targets<br />

to be achieved by 2014<br />

• 0% to landfill<br />

20<br />

Tonnes (Thousands)<br />

Tonnes (Thousands)<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

<strong>Finlays</strong> Group waste<br />

2008<br />

Waste to<br />

landfill<br />

Waste<br />

recovered<br />

<strong>Finlays</strong> Group waste to landfill<br />

2008<br />

Horticulture<br />

Beverages<br />

2009<br />

2009<br />

2010<br />

Waste recycled<br />

Waste reused<br />

2010<br />

Leaf and<br />

Extracts<br />

Tea Estates<br />

<strong>2011</strong><br />

<strong>2011</strong><br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Group performance review <strong>2011</strong><br />

3.1 Environment<br />

Carbon<br />

Overall performance<br />

Overall there has been a 2% increase in total carbon<br />

emissions. Scope 1 emissions show a 6% reduction and<br />

Scope 2 emissions, a 21% reduction. This is due to a good<br />

performance across Finlay Flowers Europe and helped by<br />

the closure of the Mara Mara tea extracts factory in Kenya.<br />

Scope 3 numbers increased slightly, which is attributed<br />

to better data collection at Leaf Tea and Tea Extracts on<br />

tea shipping and increased air freighting of product. We<br />

continue to make progress on shipping and rail but Scope 3<br />

emissions, by nature, are controlled by others in the supply<br />

chain. We do not have total control on these emissions,<br />

therefore a long-term approach to monitoring change<br />

needs to be taken.<br />

<strong>2011</strong> Highlights<br />

• <strong>Finlays</strong> Horticulture Africa<br />

Scope 1 reduction of emissions by 15%<br />

• Finlay Beverages<br />

Scope 1 & 2 reduction of emissions by 4%<br />

Scope 3 reduction of 19% total carbon<br />

usage and 5% per unit of production<br />

• <strong>Finlays</strong> Fresh Produce<br />

Scope 3 reduction of emissions by 5%<br />

<strong>Finlays</strong> Group carbon footprint<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 21<br />

CO 2 Tonnes (Thousands)<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

2008 2009 2010 <strong>2011</strong><br />

Scope 3 Scope 1<br />

Scope 2<br />

Medium term targets<br />

to be achieved by 2014<br />

• Scope 1: 15% reduction on 2009 base year<br />

• Scope 2: 15% reduction on 2009 base year

Group performance review <strong>2011</strong><br />

3.2 Economic Contribution<br />

Economic Contribution<br />

<strong>Finlays</strong> is committed to addressing social, political and environmental issues by demonstrating<br />

that it is more financially rewarding to be sustainable.<br />

In seeking to be financially profitable, our business<br />

understands that we need to take an active leadership role<br />

in dealing with sustainability issues, and we need to share<br />

1. This table is constructed based on data contained within the <strong>2011</strong> James<br />

Finlay Annual <strong>Report</strong> and follows guidance recommended by the Global<br />

<strong>Report</strong>ing Initiative (GRI EC1).<br />

22<br />

Direct economic value generated<br />

Revenues<br />

Revenues plus interest<br />

and dividend receipts,<br />

royalty income and<br />

proceeds of sales<br />

and assets<br />

£593.5m<br />

Our economic contribution includes: direct employment,<br />

buying from local, regional and global suppliers, and the<br />

distribution and retailing of our products.<br />

Investment over many years and far into the future - in our<br />

fields and factories and on our land - has resulted, and will<br />

continue to result, in significant economic contributions<br />

to the countries in which we operate, creating direct<br />

employment for thousands and indirect employment<br />

for many more.<br />

In the year ended 31 December <strong>2011</strong>, <strong>Finlays</strong> generated<br />

£593.4 million in economic value, of which the majority<br />

was distributed through the course of our business to our<br />

employees, shareholders, suppliers and governments as well<br />

as to local communities through our sustainability activities.<br />

We look for opportunities to work collaboratively with small<br />

holders in many markets and our various projects involve<br />

over 40,000 farmers. We help provide them with an income<br />

so they can support their dependents and contribute to the<br />

development of the communities in which they live and<br />

where we operate. In many cases <strong>Finlays</strong> assist the farmers<br />

with marketing activity, logistical support and essential<br />

farming expertise and good agricultural practice.<br />

Economic value distributed<br />

knowledge and engage with the communities in which we<br />

operate. This will benefit our suppliers, our communities<br />

and society in general.<br />

Operating costs<br />

Cost of materials, services<br />

and facilities<br />

£458.2m<br />

Employee wages and Benefits<br />

Cost of employees salaries<br />

and benefits<br />

£73.6m<br />

Payments to providers of capital<br />

All financial payments made to the<br />

providers of the organisations capital<br />

£13.8m<br />

Payments to Government<br />

Tax paid including remittance taxes<br />

and excise taxes<br />

£28.8m<br />

Community Investments<br />

Voluntary contributions and investment<br />

of funds in the broader community<br />

£4.4m<br />

Economic value<br />

retained<br />

£14.6m<br />

2. Value retained to fund future capital expenditure and acquisitions.<br />

Economic value retained by region<br />

Economic Value retained (millions)<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

-2<br />

-4<br />

-6<br />

UK<br />

North & South<br />

America<br />

Africa<br />

Asia &<br />

Middle East<br />

Rest of<br />

Europe<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Group performance review <strong>2011</strong><br />

3.3 People - Occupational Health & Safety, Training, Community<br />

Occupational Health & Safety<br />

All our businesses are expected to embrace a health and safety culture which aims to provide a safe working<br />

environment for employees<br />

During <strong>2011</strong> we continued to focus our attention on strengthening the awareness of<br />

Health & Safety across all of our businesses whilst ensuring that they complied both<br />

with local labour laws and with internationally recognised standards.<br />

We now have a well embedded<br />

structure which features local<br />

Health and Safety Committees for<br />

each business unit supported by<br />

qualified Health and Safety personnel.<br />

These committees are designed<br />

to empower employees to make<br />

proactive suggestions to eliminate<br />

hazards which could result in<br />

accidents. A Group Health & Safety<br />

Committee coordinates policy which<br />

is encompassed in a Health and Safety<br />

Management System. This sets out<br />

standard guidelines and reporting<br />

structures to which businesses are<br />

expected to adhere. The system is<br />

currently being reviewed to take into<br />

account lessons learnt. We expect that<br />

actions arising from the review will<br />

be implemented by the middle of 2012<br />

and will help to further standardise<br />

health and safety arrangements and<br />

reporting across the Group.<br />

The Group Health & Safety Committee,<br />

which comprises of health and safety<br />

experts from around the Group,<br />

together with external consultants and<br />

a main Board executive director, meets<br />

four times a year ahead of the quarterly<br />

round of board and management<br />

meetings. Its remit is to review health<br />

and safety performance across the<br />

Group by analysing reports received<br />

from each business. Special attention<br />

is paid to investigating serious or fatal<br />

accidents where recommendations<br />

are made to help ensure that these<br />

do not reoccur. The committee also<br />

commissions health & safety audits of<br />

individual businesses which are carried<br />

out by external consultants or internal<br />

health and safety experts from other<br />

businesses in the Group. The committee<br />

reports directly to the Board of James<br />

Finlay Limited. In addition, Health<br />

and Safety performance is reported<br />

and reviewed at all management and<br />

statutory board meetings.<br />

During <strong>2011</strong> we continued work<br />

on implementing a standardised<br />

proactive reporting regime across<br />

the Group. Key Performance measures<br />

include workplace inspections,<br />

systems checks, achievement of HS<br />

Improvement activities, the number<br />

of safety meetings, and corrective<br />

actions closed out. All businesses are<br />

now reporting, other than Sri Lanka,<br />

which is expected to agree a programme<br />

which will be implemented during 2012.<br />

As can be seen from the key<br />

performance measures detailed<br />

below, further work is required to<br />

reduce incident rates and to ensure<br />

consistency of reporting. Unfortunately<br />

we suffered five fatalities in <strong>2011</strong>;<br />

all of which were the subject of both<br />

external and internal investigations.<br />

Recommendations have been<br />

implemented. Last year saw a fall in<br />

major incidents when compared to<br />

2010 and, although it might seem that<br />

this has been offset by a rise<br />

in minor incidents, it is felt that this is<br />

due to better reporting rather than an<br />

increase in actual accidents. As can be<br />

seen, there is still a lack of awareness<br />

of what constitutes occupational<br />

illness in some of our smaller overseas<br />

businesses. We are working to ensure<br />

more accurate reporting in this<br />

area. Similarly, we are encouraging<br />

businesses to improve reporting<br />

of near-miss incidents and the<br />

identification of hazards. In the case<br />

of the latter, these are now included<br />

as a proactive measure.<br />

In conclusion, the reduction in the<br />

rate for lost time is encouraging and<br />

it is hoped that this can be further<br />

improved as employees become more<br />

aware of the importance of thinking<br />

safety and working safely.<br />

Occupational Health and Safety - key performance measures<br />

2010 <strong>2011</strong><br />

Incidents Rates per<br />

100,000<br />

hrs<br />

Incidents Rates per<br />

100,000<br />

hrs<br />

Fatality 4 0.005 5 0.006<br />

Major 389 0.45 314 0.36<br />

Minor 2,870 3.29 3,132 3.62<br />

Occupational Illness 2 0.00 3 0.0035<br />

Property Damage 253 0.29 263 0.30<br />

Near Miss 354 0.41 450 0.52<br />

Claims 326 0.37 199 0.23<br />

Lost time hrs 71,374 81.84 59,743 69.06<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 23

Group performance review <strong>2011</strong><br />

3.3 People - Occupational Health & Safety, Training, Community<br />

It is due to our committed and skilled<br />

workforce that <strong>Finlays</strong> is known for its<br />

‘bush to cup’ expertise in tea, ‘farm to<br />

shelf’ expertise in horticulture and long<br />

term commitment to sustainability and<br />

ethical trading. We deal with products<br />

and services that require significant<br />

manpower and application of skills, from<br />

harvesting to preparation to processing.<br />

<strong>Sustainability</strong> is at the heart<br />

of everything we do.<br />

Producing natural, sustainable and<br />

quality services and products that<br />

enhance quality of life is important to<br />

us and an explicit part of our company<br />

strategy. <strong>Finlays</strong> has subscribed to<br />

these values and activities for over<br />

260 years, and we support them by<br />

working to internationally agreed<br />

standards, with strict criteria. We<br />

are members of several bodies<br />

which independently audit our<br />

estates and farms; a process which<br />

helps to continuously improve our<br />

transparency and accountability.<br />

We continue to nurture a wide range<br />

of partnerships with organisations,<br />

including Fairtrade, Rainforest Alliance,<br />

Forum for the Future, FRICH, Ethical<br />

Trading Initiative and *Imarisha.<br />

Community<br />

<strong>Finlays</strong> are helping more than 3000<br />

small scale vegetable growers in<br />

Kenya and Guatemala providing<br />

access to export markets and<br />

supplying the technical expertise<br />

they need to meet European and<br />

UK retailers’ expectations for Good<br />

Agricultural Practice (GAP) and Good<br />

Manufacturing Practice (GMP).<br />

24<br />

Training and ‘Routes to Grow’<br />

Our commitment to people is central to our business<br />

and our sustainability strategy<br />

We strive to make <strong>Finlays</strong> an enjoyable and rewarding<br />

place to work, an organisation that nurtures and<br />

develops its people to the benefit of the individual,<br />

the company, and the community.<br />

A similar model is used for our tea<br />

out-growers and we have helped 11,<br />

200 farmers gain Fairtrade status<br />

in Kenya.<br />

Maintaining these standards demands<br />

time, dedication, and training to ensure<br />

we meet the needs of the markets in<br />

which we operate. The standards also<br />

improve the knowledge and capacity of<br />

our workforce, both at work and in their<br />

private lives.<br />

Our integrated management<br />

succession and development process<br />

– ‘Routes to Grow’ came from our<br />

commitment to build a sustainable<br />

business, a key component of which<br />

is our commitment to our employees.<br />

In formulating Routes to Grow, we<br />

worked closely with the management<br />

in each business, and asked ourselves<br />

key questions about where the leadership<br />

of tomorrow would come from and if<br />

we could foster internal talent within a<br />

timeframe to fill key succession gaps.<br />

We also wanted to ensure that when<br />

we attract talent, our environment<br />

and processes enable us to retain<br />

and develop it.<br />

Since its inception, over 200 management<br />

employees have been through the Routes<br />

to Grow programme in Kenya, Sri Lanka<br />

and the UK. We have made consistent<br />

progress in creating an enduring<br />

pipeline of talented managers with the<br />

experience and competencies to lead<br />

our business, now and into the future.<br />

The Routes to Grow programme is also<br />

supported by the normal pre-existing<br />

training and development activity<br />

delivered within the businesses,<br />

and by Group, through such means<br />

as INSEAD courses. These activities<br />

culminate in individual development<br />

plans to build on participants’<br />

strengths in their current roles,<br />

address any weaknesses, and provide<br />

clarity of the possible career routes.<br />

A key feature of Routes to Grow, in<br />

common with any other management<br />

process, is that it is driven by individual<br />

business needs and it must reflect and<br />

adapt to those needs as they change.<br />

This means that the programme will<br />

always be run to a timescale and<br />

frequency identified by each individual<br />

business. In some, it will be run<br />

annually, in others, less frequently.<br />

Nonetheless the commitment to develop<br />

our people, both within their current<br />

roles and in preparation for potential<br />

future roles, continues.<br />

We are fortunate in having a rich<br />

and broad pool of talent in <strong>Finlays</strong>,<br />

with depth of technical knowledge<br />

across our many and varied business<br />

disciplines. By being systematic about<br />

developing this talent we continue to<br />

invest in the long-term sustainability<br />

of our management capability.<br />

We have also embarked on an extensive<br />

supervisor training initiative based on<br />

Ethical Trading Initiative Supervisors<br />

Training Course and we also provide<br />

training in life skills, such as kitchen<br />

gardening for the tea estates residents<br />

in Kenya and Sri Lanka. Additionally,<br />

to assist our people in improving their<br />

lives, we provide community waste<br />

management schemes, and teaching<br />

in the construction of cooking<br />

jikos (stoves).<br />

* This is the Lake Naivasha catchment restoration programme, supported by the Government of Kenya and the Princes Trust. It builds on the significant progress<br />

that <strong>Finlays</strong> has made in meeting its objective to play a leadership role in watershed management.<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

Group performance review <strong>2011</strong><br />

3.3 People - Occupational Health & Safety, Training, Community<br />

Human Resources <strong>Report</strong><br />

Total Kenya Sri Lanka Europe Others<br />

Head count Total number - male 22,609 14,671 6,201 1,502 235<br />

Total number - female 17,556 8,401 7,861 700 594<br />

Total Employees 40,165 23,072 14,062 2,202 829<br />

Perm employees - male 17,871 10,659 5,982 1,094 136<br />

Perm employees - female 14,331 5,609 7,720 552 450<br />

Perm employees - total 32,202 16,268 13,702 1,646 586<br />

Temp / Agency - male 4,734 4,011 219 409 95<br />

Temp / Agency - female 3,229 2,793 141 147 148<br />

Temp / Agency - total 7,963 6,804 360 556 243<br />

Training Man hours training 319,230 270,824 31,403 7,532 9,471<br />

It is due to our committed and skilled<br />

workforce that <strong>Finlays</strong> is known for its<br />

‘bush to cup’ expertise in tea, ‘farm to<br />

shelf’ expertise in horticulture…<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong> 25

Leading by example<br />

26<br />

Empowering Supervisors<br />

Gender discrimination is endemic in many workplaces, across many countries. Poorer<br />

and less educated women are often particularly vulnerable. They may know they are<br />

being harassed, but may be unaware of their rights and unaware of the protection<br />

they can gain through the law. Cultural norms mean that these women are often<br />

unaccustomed to speaking up for themselves, and this increases their vulnerability.<br />

<strong>Finlays</strong> Horticulture Kenya has over 6,500 employees, about half of them<br />

women, across six sites.<br />

We recognised that we had to ensure that we had a clear policy on gender<br />

discrimination back in 2004, when we received our first social audit. This<br />

recommended that <strong>Finlays</strong> Horticulture set up an internal training department<br />

and women’s committees. These were duly established, along with welfare, and<br />

health and safety committees.<br />

We found that the gender committee had a very beneficial impact.<br />

Empowering supervisors<br />

<strong>Finlays</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2011</strong>

8.1 Soil Health And Quality, A Review Of <strong>Finlays</strong> Tea Plantations Article<br />

Empowering supervisors<br />

Leading by example<br />

Despite these initiatives, problems persisted. It<br />

was reported that some supervisors were behaving<br />

inappropriately towards women workers, and some also<br />