KAD-300 Tech Manual.pdf

KAD-300 Tech Manual.pdf

KAD-300 Tech Manual.pdf

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

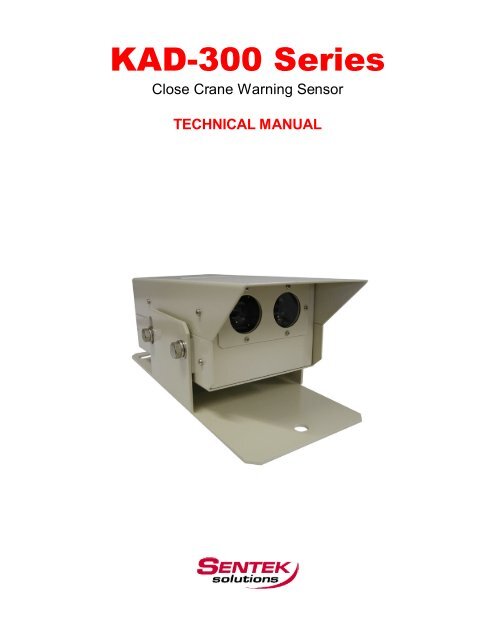

<strong>KAD</strong>-<strong>300</strong> Series<br />

Close Crane Warning Sensor<br />

TECHNICAL MANUAL

GENERAL<br />

The <strong>KAD</strong>-<strong>300</strong> close crane warning sensor is intended for use on overhead bridge cranes to prevent<br />

crane- to-wall collisions or limit the approach of adjacent cranes within the same bay. The system is a<br />

self- contained hardware unit with three separate outputs for controlling slow-down and stop zones.<br />

In addition<br />

to the three outputs, the <strong>KAD</strong>-<strong>300</strong> is<br />

equipped with a trouble (FAULT) output<br />

that will energize<br />

in the event a failure occurs with the internal infrared emitter and<br />

receiver<br />

unit.<br />

SPECIFICATIONS<br />

Type<br />

Model<br />

Power Source<br />

Power Consumption<br />

Retro-reflective infrared sensor<br />

<strong>KAD</strong>-<strong>300</strong><br />

85 to 264 VAC - 50/60Hz<br />

10VA or less when 100VAC<br />

15VA or less when 200 VAC<br />

Output Control Output – 1C Relay (250VAC 3A, 30VDC 3A) Out 1, 2, and 3<br />

Relay not energized and LED lights up when reflector is within setting distance<br />

Sensing Range<br />

Detectable Object<br />

Hysteresis<br />

Operation Mode<br />

Trouble Output – 1C Relay (250VAC 3A, 30VDC 3A) – FAULT<br />

Relay not energized 1. When light-emission amount decreases<br />

2. When light-reception amount decreases<br />

3. When Fault Occurs<br />

1 to 30 meters (100 feet) - Standard<br />

Retro-reflective Target (diamond-grade reflective surface)<br />

500mm (Approximately 20 inches)<br />

LIGHT-ON mode

Indicators<br />

Response Time<br />

Delay at Power Up<br />

Ambient Luminescence<br />

POWER – Lights up when power is ON (Green LED)<br />

OUTPUT 1,2,3 – Lights up when target is within setting distance (Orange LED)<br />

FAULT (Emitter) – Lights up when emitter strength decreases (Red LED)<br />

FAULT (Receiver) – Lights up when fault occurs (Red LED)<br />

FAULT (Receiver) - Flickers when light-reception decreases (Red LED)<br />

LEVEL – Lights up in relation to light-reception & optical alignment (5 Green LEDS)<br />

50 milliseconds or less<br />

Approximately 2 seconds<br />

Halogen and Mercury light: 10,000 lux or less<br />

Operating Conditions Temperature: -10 to +55 degrees C (14 degrees F to 130 degrees F)<br />

Relative Humidity: 85% or less (Non-condensing or frozen)<br />

Insulation Resistance<br />

Withstand Voltage<br />

100Mohm or more (Between power and contact)<br />

1,500 VAC – 1 min. (Between power and contact)<br />

Noise Resistance COM mode pulse width: 100nsec, Polarity: + and -, Phase: Phase A and B,<br />

Pulse Cycle: Power cycle 0 to 360 degrees, Pulse Voltage: 1,500V or more<br />

(By high-frequency noise simulator)<br />

Protective Structure<br />

Vibration Resistance<br />

Impact Resistance<br />

Case<br />

Metal Housing<br />

Frequency: 10 to 55 Hz, Double Amplitude: 1.5mm, Each 2 hour in X, Y and Z<br />

directions<br />

490 m/s2 (50G), Each 10 times in X, Y and Z directions<br />

SPCC<br />

Paint Munsell 5Y8/1<br />

Sensor Unit Weight<br />

Connection<br />

3 Kg (Approximately 7 lbs.)<br />

Terminal Strip<br />

CONNECTION DIAGRAM

Control Output (OUT 1, 2, and 3)<br />

Terminal Number 1 - 2 2 - 3 4 - 5 5 - 6 7 - 8 8 - 15<br />

Power-O FF State OPEN CLOSE OPEN CLOSE OPEN CLOSE<br />

Power-O N S tate (within s etting distance) OPEN CLOSE OPEN CLOSE OPEN CLOSE<br />

Power-O N S tate (over setting distanc e) CLOSE OPEN CLOSE OPEN CLOSE OPEN<br />

Trouble Output (FAULT)<br />

Terminal Number 9 - 10 10 - 11<br />

Power-O FF State OPEN CLOSE<br />

Power-ON State (normal conditions) CLOSE OPEN<br />

Power-ON State (when fault occurs) OPEN CLOSE<br />

EXTERNAL DIMENSIONS<br />

Top View<br />

Front View<br />

Side View

SET-UP PROCEDURE - Output setting switch<br />

Control Outputs (Out 1, Out 2 and 3) can be set at various distances based on requirements. The reflector is to be<br />

set at each desired distance for which an output is required to slow-down and stop the crane.<br />

1) Set the reflector at the desired distance for Output 1<br />

and push the OUT 1 switch in and hold it for 3 seconds.<br />

The Output lamp will flicker and then stop. Upon<br />

releasing the switch, the output lamp will light up to<br />

indicate that the zone has been set.<br />

2) Repeat the above procedure to set Output 2 using OUT 2.<br />

3) If Output 3 is to be set for a third zone, push both the<br />

OUT 1 and OUT 2 switches at the same time and hold<br />

for 3 seconds. Upon releasing the switches, the Output lamp<br />

will light up to indicate that a third zone has been set.<br />

Europe’s Official<br />

Distributor<br />

1010 Cambourne Business Park, Cambridge, CB23 6DP UK.<br />

Tel +44 (1223) 923 930 : Fax +44 (1223) 923 940<br />

info@sentekeurope.com : www.sentekeurope.com