View PDF - GMA Garnet

View PDF - GMA Garnet

View PDF - GMA Garnet

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

JULY 2011 EDITION<br />

ABRASIVE MATTERS<br />

First-of-its-kind mobile application to calculate the<br />

true cost of your blasting project<br />

A first in the industry, the <strong>GMA</strong> <strong>Garnet</strong> Abrasive Blasting Calculator is the perfect tool for project estimators and contractors<br />

to estimate their abrasive blasting budgets with just a few buttons and swipes on their mobile phones.<br />

The Group developed a new mobile application, a<br />

first-of-its-kind in the abrasive blasting industry for<br />

calculating the true cost of a blasting project using <strong>GMA</strong><br />

<strong>Garnet</strong> abrasives as well as other existing abrasives.<br />

Launched in June 2011, the <strong>GMA</strong> <strong>Garnet</strong> Abrasive Blasting<br />

Calculator is available as a free mobile application and users can<br />

download the application from Apple iTunes and Android Market.<br />

A web version is also be available on the Group’s website.<br />

Visit: www.garnetsales.com/gmacalc<br />

“The calculator is the perfect tool for project estimators and<br />

contractors to calculate the true cost of blasting with <strong>GMA</strong><br />

<strong>Garnet</strong> abrasives,” says Chief Operating Officer Aaron Williams.<br />

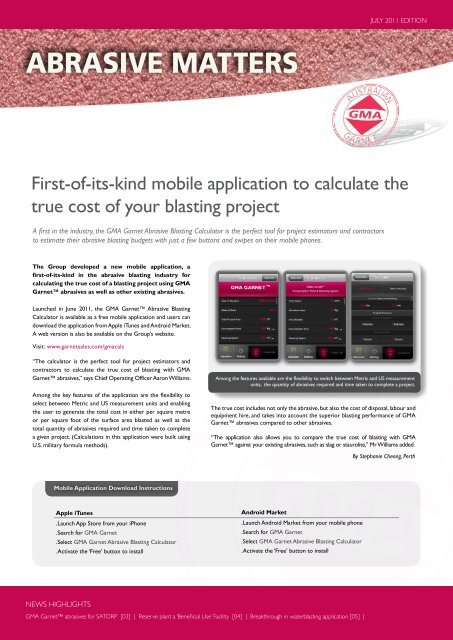

Among the key features of the application are the flexibility to<br />

select between Metric and US measurement units and enabling<br />

the user to generate the total cost in either per square metre<br />

or per square foot of the surface area blasted as well as the<br />

total quantity of abrasives required and time taken to complete<br />

a given project. (Calculations in this application were built using<br />

U.S. military formula methods).<br />

Among the features available are the flexibility to switch between Metric and US measurement<br />

units, the quantity of abrasives required and time taken to complete a project.<br />

The true cost includes not only the abrasive, but also the cost of disposal, labour and<br />

equipment hire, and takes into account the superior blasting performance of <strong>GMA</strong><br />

<strong>Garnet</strong> abrasives compared to other abrasives.<br />

“The application also allows you to compare the true cost of blasting with <strong>GMA</strong><br />

<strong>Garnet</strong> against your existing abrasives, such as slag or staurolite,” Mr Williams added.<br />

By Stephanie Cheong, Perth<br />

Mobile Application Download Instructions<br />

Apple iTunes<br />

.Launch App Store from your iPhone<br />

.Search for <strong>GMA</strong> <strong>Garnet</strong><br />

.Select <strong>GMA</strong> <strong>Garnet</strong> Abrasive Blasting Calculator<br />

.Activate the ‘Free’ button to install<br />

Android Market<br />

.Launch Android Market from your mobile phone<br />

.Search for <strong>GMA</strong> <strong>Garnet</strong><br />

.Select <strong>GMA</strong> <strong>Garnet</strong> Abrasive Blasting Calculator<br />

.Activate the ‘Free’ button to install<br />

News highlights<br />

<strong>GMA</strong> <strong>Garnet</strong> abrasives for SATORP [03] | Reserve plant a ‘Beneficial Use’ Facility [04] | Breakthrough in waterblasting application [05] |

CORPORATE<br />

Customer Focus<br />

Message from the Chief Executive Officer<br />

Torsten Ketelsen<br />

On its own, this is perhaps the most widely (mis-)used<br />

business mantra that is found in most companies’<br />

“Vision Statement”.<br />

More often than not, Customer Focus is regarded<br />

as a generic virtue to which management should<br />

aspire, without the internal organisational and<br />

policy structures to clearly identify and understand<br />

the “customer”. At every level of the <strong>GMA</strong> <strong>Garnet</strong><br />

Group (<strong>GMA</strong>), however, from mining and production,<br />

quality control, logistics and distribution to the final<br />

end user, we focus on understanding our customers’<br />

needs and circumstances as our strategic choice that<br />

involves each and every employee of <strong>GMA</strong> – around<br />

the world!<br />

We connect with our customers through realtime<br />

information, online interaction and, wherever<br />

possible, in person at the customer’s premises and<br />

work sites, to develop deep relationships based<br />

on trust, performance and providing value. We<br />

believe that the best investment is to prioritise<br />

the understanding of our customers’ needs and<br />

aspirations and to provide the best solution to meet<br />

those needs.<br />

<strong>GMA</strong> is recognised as the world’s largest producer<br />

of the highest quality industrial garnet abrasives but<br />

what our customers really require is not a tonne<br />

of abrasive but an area of blast cleaned steel or<br />

length of WaterJet cut marble. With this realisation,<br />

<strong>GMA</strong> has over the past 20 years developed a global<br />

<strong>GMA</strong> Distribution and Customer Service network<br />

that integrates our products and services with<br />

the operations of our key customers, based on an<br />

intimate understanding of our clients’ problems<br />

and objectives. <strong>GMA</strong>’s global presence in all of<br />

our established markets enforces and ensures<br />

the uniformly high levels of customer and technical<br />

service that our customers rightfully expect from<br />

the world’s leading garnet brand.<br />

This proximity to our customers provides direct and<br />

timely insight into our customers’ shifting perceptions,<br />

requirements or objectives and we have in place<br />

efficient feedback cycles that allow us to adopt<br />

internal changes to meet that new situation on<br />

the ground. Over the years, <strong>GMA</strong> has developed<br />

specific products in response to specific customer<br />

needs and introduced new product formulations for<br />

special job applications that help our customers to<br />

complete their workload faster, with less environmental<br />

impact and at lower overall job cost.<br />

Over the past 20 years, <strong>GMA</strong> has developed a<br />

Recycling Strategy to effectively and efficiently<br />

reprocess used <strong>Garnet</strong> from field operations for<br />

re-use, directly responding to the challenge of our<br />

customers’ needs for environmentally safe disposal<br />

of used <strong>Garnet</strong> and the maximum utilisation of a<br />

non-renewable resource. <strong>GMA</strong> now operates major<br />

industrial Recycling Facilities in the Middle East,<br />

Europe and the USA.<br />

For all of us at <strong>GMA</strong>, Customer Focus is much<br />

more than a trivial mention in a Vision Statement<br />

– it is about truly understanding our customer and<br />

working towards solutions with win-win outcomes.<br />

In Memoriam<br />

On 17th February 2011, Jebsen & Jessen Group of Companies South East Asia (JJSEA) company<br />

founder and former chairman Mr Arwed Peter Jessen passed away at the age of 86 in his<br />

hometown of Aabenraa, Denmark.<br />

After a long struggle with Parkinson’s disease, AP Jessen departed peacefully surrounded by his<br />

family. AP Jessen is the Father of Mr Heinrich Jessen, a co-owner of <strong>GMA</strong> <strong>Garnet</strong> Group.<br />

AP Jessen started his career in the family enterprise Jebsen & Co in Shanghai. He was made<br />

family partner in 1952 and moved to Hong Kong in 1954 where he lived until 1964. During his<br />

time in Hong Kong, AP Jessen was chairman of the Hong Kong Philharmonics, founding member<br />

of the Hong Kong Country Club and board member of the Hong Kong and Kowloon Wharf &<br />

Godown Company.<br />

In 1963, AP Jessen incorporated what is today the Jebsen & Jessen Group of Companies South<br />

East Asia in Singapore and Malaysia. As chairman and principal family shareholder, AP Jessen<br />

oversaw his company’s affairs across the region. Four decades after the establishment of the<br />

Jebsen & Jessen Group of Companies South East Asia, AP Jessen stepped down as chairman and<br />

moved back to Aabenraa.<br />

AP Jessen was an outstanding musician, passionate sportsman, great businessman and dedicated<br />

father of seven. Mr Jessen will be deeply missed by his family, friends and colleagues.<br />

Mr Arwed Peter Jessen<br />

By Laja Mensdorff-Pouilly, JJSEA, Singapore<br />

02

CORPOrATE / middle east<br />

Abrasive Cost or Abrasive Value<br />

What really matters<br />

In your abrasive blasting project, what really matters is the cost per<br />

square metre of blasted surface - not the cost per tonne of abrasive!<br />

Higher Cost<br />

per m2<br />

True Cost<br />

of Abrasive Blast Cleaning<br />

Higher Disposal<br />

DISPOSAL COST<br />

Lower Cost<br />

per m2<br />

Lower Disposal<br />

Great savings can be achieved by selecting a high performance abrasive,<br />

that uses less abrasive and does the job faster - covering more square<br />

metres in less time!<br />

High performance garnet - <strong>GMA</strong> <strong>Garnet</strong> cleans the surface at twice<br />

the speed of slag and uses less than half the quantity of abrasive. At the<br />

same time, you get superior surface finish while operating in a health and<br />

environmentally safe condition. By Torsten Ketelsen, Perth<br />

Higher Equipment<br />

Running Cost<br />

EQUIPMENT COST<br />

LABOUR COST<br />

Lower Equipment<br />

Running Cost<br />

Lower<br />

Labour Cost<br />

Higher<br />

Labour Cost<br />

Lower Abrasive<br />

Cost per Tonne<br />

A<br />

SLAG<br />

ABRASIVE COST<br />

B<br />

<strong>GMA</strong> GARNET<br />

Higher Abrasive<br />

Cost per Tonne<br />

Call our office near you or write to sales@garnetsales.com today<br />

to find out how much you can save with <strong>GMA</strong> <strong>Garnet</strong> TM including<br />

recycling options to help you save even more!<br />

<strong>GMA</strong> <strong>Garnet</strong> abrasives for SATORP<br />

<strong>GMA</strong> <strong>Garnet</strong> abrasives are being utilised for the construction of SATORP – one of the largest and most<br />

complex petrochemical refineries in the world.<br />

<strong>GMA</strong> <strong>Garnet</strong> abrasives are being utilised by a majority of<br />

the contractors working on the construction of Saudi Aramco<br />

TOTAL Refinery and Petrochemical Company (SATORP).<br />

SATORP, which is targeted to be completed in 2013 will be one of the<br />

largest and most complex petrochemical refineries in the world.<br />

For this project, <strong>Garnet</strong> Arabia Company provided an environmentally<br />

friendly package programme that was well received by customers and<br />

supported by the management at SATORP. The package comprised of<br />

the supply of <strong>GMA</strong> <strong>Garnet</strong> natural abrasives and the collection of<br />

used garnet from the site.<br />

SATORP, also known as Jubail Export Refinery Project (JERP) is a joint<br />

venture between Saudi Aramco and TOTAL of France. It is one of the<br />

world’s largest refinery & petrochemical projects under construction in<br />

the Kingdom of Saudi Arabia. Upon completion, the refinery will be the<br />

seventh most complex refiner in the world.<br />

The refinery located in Jubail Industrial City on the eastern province of<br />

the Kingdom is expected to be fully operational by 2013 with a projected<br />

output of 400,000 barrels per day. It will produce a high proportion of<br />

white products such as diesel, gasoline, LPG, petrochemicals and jet<br />

fuels from Arabian heavy crude oil. By Soni John, Jubail<br />

<strong>Garnet</strong> Arabia Company provides an environmentally friendly package programme<br />

comprised of the supply of <strong>GMA</strong> <strong>Garnet</strong> abrasives and the collection of used garnet.<br />

03

UNITED STATES / MIDDLE EAST<br />

State government approves Reserve recycling<br />

plant as ‘Beneficial Use’ Facility<br />

The recognition by the Louisiana Department of Environment Quality provides a healthy boost to the plant’s<br />

ongoing GMR recycling programme.<br />

The State of Louisiana Department of Environment Quality<br />

(LDEQ) has approved the Group’s recycling plant in Reserve as<br />

a ‘Beneficial Use’ facility for returned garnet on 4th May 2011.<br />

The Beneficial Use Plan is a green initiative by the state government to<br />

turn waste material into reusable resources.<br />

According to <strong>GMA</strong> <strong>Garnet</strong> USA Vice President Matt Cain, the application<br />

to be part of this initiative commenced in November last year.<br />

“The certification goes hand in hand with our ongoing GMR Recycling<br />

programme where we encourage our customers to send their used garnet<br />

to our facility to be processed for reuse and therefore, saving precious<br />

resources from going to landfills. The recognition by LDEQ provides the<br />

added legitimacy for us as a certified facility and a healthy boost to our<br />

recycling programme efforts,” Mr Cain said.<br />

Customers participating in this programme will be awarded with a<br />

“Certificate of Recycling” every year as an acknowledgment to their<br />

ongoing support. The certificate, which is certified by the State will reflect<br />

the tonnage of used garnet that has been processed and saved from landfills.<br />

The certification goes hand in hand with the Group’s ongoing GMR<br />

Recycling programme where customers are encouraged to send in their<br />

used garnet to be processed for reuse.<br />

Currently, there are around 20 participants in this programme although<br />

the participants are expected to rise, especially from major garnet users in<br />

the sandblasting and waterjet industries. By Aaron Williams, Houston<br />

Roots Group to expand garnet distribution to the<br />

abrasive blasting sector in Saudi Arabia<br />

Over 70 professionals representing Saudi Aramco and major contracting<br />

companies attended the event held in Al Khobar.<br />

From left: RGA Managing Director Asia Pacific Fouad M. Ghandour, RGA General<br />

Manager Marwan Ghalayini, <strong>GMA</strong> <strong>Garnet</strong> Group CEO Torsten Ketelsen, RGA CEO<br />

Ousama Fansa and <strong>Garnet</strong> Arabia Company General Manager Soni John.<br />

Roots Group, the <strong>GMA</strong> <strong>Garnet</strong> Group’s<br />

(<strong>GMA</strong>) distributor for waterjet cutting<br />

abrasives in Saudi Arabia will be expanding<br />

its garnet distribution to some users in the<br />

abrasive blasting sector in Jeddah and Riyadh.<br />

The Roots Group Arabia Company Limited<br />

(RGA) formerly known as Arabian Roots Stone<br />

Industry Supplies Division is a long standing and<br />

dedicated distributor of <strong>GMA</strong> <strong>Garnet</strong> waterjet<br />

abrasives for over 15 years.<br />

Sales of <strong>GMA</strong> <strong>Garnet</strong> 80 Mesh waterjet abrasives<br />

have steadily increased over the years. RGA holds<br />

and impressive market share for <strong>GMA</strong> <strong>Garnet</strong> in<br />

the Saudi waterjet abrasives market.<br />

<strong>GMA</strong> ships containerised cargo to RGA warehouses<br />

in Jeddah, Riyadh and Dammam as well as directly<br />

to their customers in Saudi Arabia. <strong>GMA</strong> <strong>Garnet</strong><br />

80 Mesh is also available from Unimar Trading in<br />

Egypt, a distribution arm of Roots Group.<br />

<strong>GMA</strong> CEO Torsten Ketelsen and <strong>Garnet</strong> Arabia<br />

Company General Manager Soni John visited Roots<br />

Group headquarters in Jeddah on 30th May 2011<br />

for discussions with Roots Group CEO Ousama<br />

Fansa and General Manager Marwan Ghalayini,<br />

aimed at strengthening and expanding the excellent<br />

business relations between the two companies.<br />

By Soni John, Jubail & Mary Fay, Perth<br />

04

UNITED STATES<br />

Breakthrough in waterblasting application using<br />

<strong>GMA</strong> <strong>Garnet</strong><br />

An exclusive case reference on a wet abrasive blasting project where the combination of <strong>GMA</strong> <strong>Garnet</strong><br />

abrasives and GEOBLASTER equipment had successfully performed on par with dry blasting techniques<br />

by John McIntyre Sr., President and owner of GEOBLASTER company.<br />

Pipeline transportation and energy storage company - Kinder<br />

Morgan has over 6,000 linear feet (1,828m) of “sheet piling” at its<br />

South East Terminal on the Elizabeth River in Chesapeake, Virginia.<br />

Installed in 1922, these interlocking style pilings are old and stand 10 to<br />

12 feet (3 to 3.7m) above the waterline. The company was looking into<br />

cleaning these sheet pilings 6 feet (1.82m) under the mean tide mark.<br />

The surface preparation method to be selected was based on the<br />

capability to clean with little or no dust, effectively remove 40 mils<br />

of existing coating and to create a 2.5 mil to 3.5 mil profile to allow a<br />

heavy specialty coating that is 100% solids to be applied under water.<br />

Precon, an experienced surface preparation contractor recommended<br />

wet abrasive blasting as a viable solution in view of the unique situation<br />

where the cleaning was performed on water in an environmentally<br />

sensitive area of the river.<br />

GEOBLASTER was contacted to perform a blast trial. The GEOBLASTER<br />

systems use air pressure and abrasive media combined with water that<br />

are then pressurised to 120-130psi. This new technology has been<br />

proven effective in cleaning and surface preparation without dust.<br />

The initial blast trial was performed using medium-grain recycled<br />

crushed glass and results from the trial were not promising. The<br />

removal was far too slow to be considered effective and the profile<br />

was less than desirable. The GEOBLASTER equipment is originally set<br />

up to run with softer abrasives such as recycled glass, plastic beads and<br />

corn cobs. It is also a common industry perception that waterblasting<br />

technology is best suited for cleaning surfaces and not for profile and<br />

deep anchor patterns for technical coatings.<br />

I began to search for a more aggressive and clean media and through<br />

a business associate, I was told <strong>GMA</strong> <strong>Garnet</strong> natural abrasives work<br />

very well with GEOBLASTER units. I contacted <strong>GMA</strong> <strong>Garnet</strong> USA for<br />

some <strong>GMA</strong> <strong>Garnet</strong> 30/60 mesh and put it to the test.<br />

During the testing, I knew from the first blast that this was going to<br />

meet the needs of the project.<br />

Using <strong>GMA</strong> <strong>Garnet</strong> 30/60 mesh, we doubled our production speed<br />

and met the necessary 3.5 mil profile requirement. <strong>GMA</strong> <strong>Garnet</strong><br />

abrasives has successfully placed GEOBLASTER toe-to-toe with dry<br />

blasting techniques without the dust!<br />

The GEOBLASTER, GB 400 unit was able to achieve 150 ft 2 (14 m 2 ) per<br />

hour at consumption rates of a very reasonable 1 litre of water per minute<br />

and 0.8 kilogrammes of <strong>GMA</strong> <strong>Garnet</strong> abrasives per minute.<br />

Since the first successful demonstration with <strong>GMA</strong> <strong>Garnet</strong>, we have<br />

placed <strong>GMA</strong> <strong>Garnet</strong> as the recommended abrasive media and each<br />

new GEOBLASTER unit delivered comes with a few buckets of <strong>GMA</strong><br />

<strong>Garnet</strong> 30/60 mesh.<br />

By John McIntyre Sr., GEOBLASTER, Ontario and Carl Borgh, <strong>GMA</strong> <strong>Garnet</strong><br />

Group, New York<br />

05

EUROPE<br />

New Sales Manager (designate) for United Kingdom<br />

Cliff Hall<br />

Mr Cliff Hall joined the Group as the new Sales<br />

Manager (designate) for <strong>GMA</strong> <strong>Garnet</strong> United<br />

Kingdom on 1st April 2011.<br />

Cliff will head the implementation of Group strategies<br />

for United Kingdom and to further develop and expand<br />

the sales of <strong>GMA</strong> <strong>Garnet</strong> abrasives within the<br />

Waterjet and Blast Cleaning industries.<br />

In addition, Cliff will be responsible for the daily<br />

operations of the office including full after sales<br />

customer support as well as the performance of the<br />

business in the country.<br />

Trained in computer aided engineering design and<br />

engineering drawing, Cliff has spent a number of years<br />

in the machine tool industry handling customer support<br />

and direct sales. Prior to this appointment, Cliff was a<br />

Product Manager for a multi-national waterjet cutting<br />

company for five years.<br />

The Group welcomes Cliff on board and wishes him a<br />

great start to his new role.<br />

By Andreas Höfner, Hamburg<br />

New warehouse in Casablanca to enhance market<br />

presence in Morocco and North African Region<br />

In cooperation with Quimialmel Maroc S.A.R.L., the Group established a new warehouse in Casablanca to enhance its market presence<br />

in Morocco as well as in the North African Region.<br />

The new warehouse, which is also the Group’s first facility in the North African Region began its operation on 1st April 2011 and will cater for customers<br />

in the whole of Morocco and beyond to Algeria and Tunisia. A range of <strong>GMA</strong> <strong>Garnet</strong> waterjet cutting (80, 120 and 200 Mesh) and blast cleaning abrasives<br />

are available in 25kg bags on one metric tonne pallets. By Tiziano Cher, Frankfurt<br />

Warehouse Address<br />

Quimialmel Maroc S.A.R.L.<br />

c/o <strong>GMA</strong> <strong>Garnet</strong> ( Europe ) GmbH<br />

Parc d’Activités Oukacha 1<br />

16 Allée des Lauriers, Hangar N° 56<br />

Ain Sebaà - Casablanca, Morocco<br />

Attn: Mr. Yassine Lemsagued<br />

Tel: +212 522342587 / 88<br />

Fax: +212 522342590<br />

t <strong>GMA</strong> <strong>Garnet</strong> Europe Sales Manager Tiziano<br />

Cher (right) with Quimialmel Morocco General<br />

Manager Yassine Lemsagued (left).<br />

06

staff news<br />

25th year milestone for Wayne<br />

Mr Wayne Dawson has accomplished<br />

many milestones in his career<br />

journey with the Group.<br />

Starting as a plant hand, Wayne<br />

has progressed and developed his<br />

career to his current management<br />

position as HSE (Health, Safety and<br />

Environment) and Quality Manager.<br />

In March this year, Wayne attained a significant milestone -<br />

25 years of service with the Group.<br />

Through the years, Wayne has been involved in most aspects of<br />

the Group’s dry plant operations in Geraldton and has shown<br />

particular aptitude, largely self-motivated, in setting up and<br />

administering health, safety and environmental systems for all of<br />

the Group’s Mid-West operations.<br />

Wayne has been instrumental in obtaining and maintaining the<br />

plant’s accreditations for Quality (ISO 9001), Health and Safety<br />

(AS/NZS 4801) and Environment (ISO 14001) standards.<br />

On top of career growth, Wayne cites that the flexible work<br />

hours enabled him to enjoy a balanced life of work and play.<br />

“I get to do plenty of surfing and windsurfing and spend time with my<br />

family,” Wayne added.<br />

Wayne (3rd from right) being congratulated for his 25 years of service by CEO Torsten<br />

Ketelsen (4th from right) and German Parliamentary Delegates on a site visit to the plant.<br />

Wayne is also well-known for his community work. Together with his wife Sandra, they are<br />

closely involved with Variety Club charity fund raising events. Wayne also dabbles in oil<br />

paintings which sell well at Variety Club auctions.<br />

By Martin Taylor & Dean Schwarz, Geraldton<br />

Getting to know the people, place and product<br />

Logistics Representative Thomas Heinrich travelled across continents from Europe to Australia for a short work and holiday visit during<br />

the end of summer in March this year. Here is the account of his first Down Under experience.<br />

My first impressions of Australia are…beautiful, huge and hot.<br />

It is very different from Europe. Even the plants<br />

and animals are different.<br />

Perth is a beautiful and calm city and the people are<br />

very kind and relaxed. Our Group’s head office is<br />

located in a beautiful building in the city, very near<br />

the Swan River. The colleagues in the office are kind<br />

and helpful and welcomed me like a member of the<br />

family. I can see that all are very happy to work with<br />

the Group.<br />

At the office, it was interesting to observe the daily<br />

operations and ongoing activities and I found in<br />

particular, the weekly meetings to be very helpful in<br />

keeping everyone updated on current matters and<br />

to discuss new issues as well.<br />

I also had the opportunity to visit the garnet mine site<br />

at Geraldton in the Mid-West of Western Australia. It<br />

was an eye-opener to see the entire production cycle<br />

starting from the mine site to garnet processing and<br />

packaging at the plant.<br />

Prior to this trip, my understanding of garnet begins<br />

at the point where we receive the garnet at our<br />

office in Hamburg and now, I have a good grasp of<br />

how it is being processed, stored and transported.<br />

I can now identify myself with the product more,<br />

knowing what it is and where it comes from.<br />

As with the friendly and relaxed environment in<br />

Perth, the business culture is very much different<br />

from what I expected. Meetings with the customers<br />

are conducted in a manner more like visiting a friend<br />

than a business partner. By Thomas Heinrich, Hamburg<br />

Thomas has been with the Group for almost four years. He joined sister Group Jebsen & Jessen<br />

Hamburg for two years before coming on board to <strong>GMA</strong> <strong>Garnet</strong> Group in 2009.<br />

07

staff news<br />

Appointments<br />

United States<br />

Ms Ernestine McDaniel, also known as Ernie joined the Group as Abrasive Blasting Sales in Houston, Texas late<br />

last year.<br />

A former board member of NACE (National Association of Corrosion Engineers) Houston section, Ernie has<br />

been working in the mineral industry for over 35 years with experience in various abrasives such as garnet, sand,<br />

slags and bicarbonate soda. With her sound knowledge of the abrasive blasting market, Ernie will be instrumental<br />

in promoting the benefits of using <strong>GMA</strong> <strong>Garnet</strong> natural abrasives in the industrial sector.<br />

Middle East<br />

Ernie McDaniel<br />

Mr Saneesh Joy joined the Group on 4th<br />

April 2011 as Sales/Accounts Coordinator<br />

for <strong>Garnet</strong> Arabia Company in Jubail,<br />

Saudi Arabia.<br />

Saneesh holds a Master’s Degree in<br />

Commerce from India and has previously<br />

worked as a Financial Analyst for a Global<br />

Outsourcing Company based in the<br />

southern Indian city of Trivandrum for<br />

three and a half years.<br />

Within the same month, Mr Abdullah<br />

Al Zain joined the Group as the new<br />

Receptionist for <strong>Garnet</strong> Arabia Company<br />

on 21st April 2011.<br />

Prior to this appointment, Abdullah was<br />

employed in a similar position with a<br />

local company for one year.<br />

Saneesh Joy<br />

Abdullah Al Zain<br />

Europe<br />

Mr Fabien Reneaux joined the Group as Sales & Marketing Assistant for France and North Africa on 17th January this year.<br />

Reporting to the Sales Manager for <strong>GMA</strong> <strong>Garnet</strong> in Europe, Fabien is responsible for the administration and sales activities<br />

of the Group’s branch office in Griesheim, Frankfurt.<br />

Fabien holds a bachelor’s degree in Commerce and Foreign Languages and prior to joining the Group, he has a brief working<br />

engagement with Rolls Royce Deutschland in Project Risk Management.<br />

The Group welcomes Ernie, Fabien, Saneesh and Abdullah on board and wishes them a great start to their careers.<br />

Fabien Reneaux<br />

By Pete Mitchell, Houston, Tiziano Cher, Frankfurt and Soni John, Jubail<br />

Anniversary<br />

Donald Rex Hook<br />

Leading Hand Donald Rex Hook celebrated 10 years of<br />

service with the Group in April this year.<br />

Donald, also known as Rex joined the Group on 2nd April<br />

2001 as a Plant Operator and in June 2008, he was promoted<br />

to Leading Hand at the mine site in Port Gregory, Australia.<br />

Prior to joining, Rex was working away from home and<br />

could only travel home every three months. Working with<br />

<strong>GMA</strong> enabled him to enjoy a better family life and being able<br />

to come home every night.<br />

“<strong>GMA</strong> is a reasonably good company to work for”, Rex added.<br />

Happy Anniversary to employees who have achieved 5 years<br />

of service from January to June 2011.<br />

Geraldton<br />

Amanda Gundry & Jeffrey Allan Brockwell<br />

Dubai<br />

Ajay Thanki<br />

The Group values your contribution and looks forward to your<br />

personal and career growth with the Group for many years to<br />

come. By Aaron Williams, Perth & Dean Schwarz , Geraldton<br />

<strong>GMA</strong> GARNET GROUP<br />

when your abrasive matters!<br />

Level 18, Exchange Plaza, The Esplanade, Perth, Western Australia 6000<br />

Tel: +61 8 9287 3200 Fax: +61 8 9287 3201 Email sales@garnetsales.com<br />

Website: www.garnetsales.com<br />

<strong>GMA</strong> <strong>Garnet</strong> Group is the leading producer of industrial garnet for blast cleaning and waterjet cutting with advanced mining and processing operations established within Western Australia and<br />

strategically located warehouses worldwide. The Group has pioneered the operation of large-scale garnet recycling facilities in Italy, Saudi Arabia, UAE and USA offering an environmentally friendly solution<br />

to the disposal of used garnet. Headquartered in Perth with <strong>GMA</strong> Group of Companies in Europe, Middle East and America, the Group is supported by a dedicated and professional global distribution<br />

network offering professional solutions and extensive technical support to the industry for over 20 years.<br />

• Australia • Denmark • Germany • Italy • Saudi Arabia • United Arab Emirates • United Kingdom • United States