V & M Report #03 - VAM Services

V & M Report #03 - VAM Services

V & M Report #03 - VAM Services

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

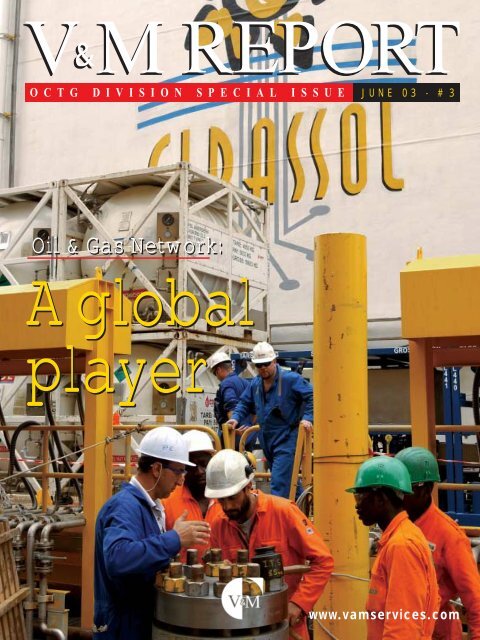

V&MREPORT<br />

O C T G D I V I S I O N S P E C I A L I S S U E JUNE 03 - # 3<br />

Oil & Gas Network:<br />

A global<br />

player<br />

www.vamservices.com

Reaching the inaccessible<br />

© P. Atkinson/Image Bank<br />

Beneath the ocean’s great depths lie undeveloped hydrocarbon reserves yet to be<br />

discovered. Access to these reserves represents for TotalFinaElf the accomplishment of<br />

40 years experience and innovation in the offshore industry. Their exploration<br />

and development will require the highest levels of technical expertise. Thanks to its<br />

technological know-how, TotalFinaElf is pushing back the frontiers, exploring in water depths<br />

of more than 2,800 metres offshore Gabon and developing the resources of the Girassol<br />

field in 1,400 metres of water offshore Angola.<br />

To bring people the energy they need to keep moving ahead, to deliver the energy solutions in<br />

order to meet today’s changing demands. Energy - it’s our business and it’s our driving force!<br />

Award<br />

2003<br />

www.totalfinaelf.com

Summary<br />

Editorial<br />

Frame Agreement<br />

signed with TOTAL<br />

TOTAL /V & M TUBES:<br />

A win-win commitment for<br />

the long term<br />

Strategic investment<br />

in the United States<br />

V & M STAR:<br />

An ideal addition in terms<br />

of markets and products<br />

An expanded Horizon<br />

Vallourec, a major player<br />

on the expandable market<br />

Spotlights<br />

V&MREPORT<br />

O C T G D I V I S I O N S P E C I A L I S S U E<br />

Publisher<br />

VALLOUREC & MANNESMANN TUBES<br />

130, rue de Silly, 92100 Boulogne - France<br />

Editorial Team<br />

Hassna Belmalek - Phone: + 33 1 49 09 35 83<br />

E-mail: hassna.belmalek@vmtubes.fr<br />

Alain Lancry - Phone: + 33 1 49 09 37 77<br />

E-mail: alain.lancry@vmtubes.fr<br />

Fax: + 33 1 49 09 37 13<br />

Production<br />

Zabriskie., Paris<br />

Design<br />

LeGrand8, Paris<br />

Photographs<br />

Shell, TOTAL, Vallourec, Thierry Truck, or as mentioned<br />

otherwise<br />

All rights reserved<br />

4<br />

6<br />

10<br />

14<br />

The Oil and Gas industry consolidation of these last<br />

years has deeply modified our customers purchasing<br />

policies. Many customers of V&M OCTG division have<br />

adopted a global sourcing policy, or at least a regional<br />

one, based on long term contracts that include different<br />

levels of services. The frame agreement with Total is<br />

one of the most accomplished example of this trend.<br />

Although such contracts are defined to last several years,<br />

it is essential to actively manage them on a day to day<br />

basis by developing them through a continuous<br />

improvement methodology and by building a more<br />

comprehensive understanding of our customer needs.<br />

During these last years V&M have<br />

grown their size and their organisation<br />

to be better prepared to respond<br />

to these global purchasing policies.<br />

Successive acquisitions have made<br />

V&M a first class player on the<br />

OCTG worldwide scene. The latest<br />

acquisition, V&M Star, consolidates<br />

further this leadership position by<br />

strengthening our presence on the<br />

USA reference market.<br />

In order to respond to our customers<br />

expectations for global sourcing, it is<br />

certainly not enough to be big, you<br />

have also to offer a wide and diversified<br />

range of products and services in<br />

Alain Lancry<br />

all the areas of the world where our customers operate,<br />

even the most remote. The range of V&M steel grades<br />

as well as the <strong>VAM</strong> premium line supported by a strong<br />

R&D effort participate to this global offer. Indeed, we<br />

have to acknowledge the fact that it was a great success<br />

of the teams who worked before us in this market to<br />

recognise at an early stage that developing the global<br />

presence of <strong>VAM</strong> through strategic partnerships and<br />

licensees was a strategic issue. It was before “ global<br />

sourcing “ was a buzz word.<br />

Alain Lancry,<br />

Marketing and Development Director<br />

VALLOUREC MANNESMANN OIL & GAS FRANCE<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

Frame Agreement signed with TOTAL<br />

TOTAL/V & M TUBES:<br />

A win-win<br />

commitment for<br />

the long term<br />

4<br />

Following a review triggered by the Total group’s change in size, and subsequent to a<br />

succession of mergers that has made it what it is today, the procurements managers of its<br />

Exploration & Production activity published a call for tender of a type that is unprecedented<br />

in the oil sector. The group was looking for a partner with the capacity to commit to a longterm<br />

Frame Agreement for all the tubes it would have to supply. Just over nine months have<br />

passed since VALLOUREC & MANNESMANN TUBES’ OCTG Division was awarded the contract.<br />

Those involved in this unique experience review the situation thus far…<br />

The result of the merger<br />

between Total, Fina and<br />

Elf Aquitaine, Total is<br />

the largest French company and<br />

!<br />

Henry Delafon,<br />

vice-president Contracts<br />

and Procurement at Total<br />

Exploration & Production<br />

the fourth largest oil and gas<br />

group in the world. With operations<br />

worldwide, Total covers all<br />

activities in the oil industry chain:<br />

exploration and production, gas<br />

and power, refining and marketing,<br />

and trading . Total is also<br />

a major player in the chemicals<br />

sector through its chemicals<br />

branch Atofina.<br />

Like all global groups, Total<br />

strives to rationalise its various<br />

operations including, of course,<br />

procurements. “In this area”,<br />

explains Henry Delafon, vicepresident<br />

Contracts and Procurement<br />

at Total Exploration &<br />

Production , “our task involves<br />

collating and analysing all data<br />

relating to the needs of our<br />

various entities and cross-checking<br />

it against our suppliers’<br />

proposals. The aim is not to<br />

centralise procurements, but rather<br />

to synchronise the work by the<br />

relevant teams and provide them<br />

with the means to make the best<br />

choices. This was the rationale<br />

behind wanting to trial the<br />

relevance of a Frame Agreement<br />

for the supply of drilling tubulars.<br />

While many of our buyers are<br />

now aware of the existence of<br />

this agreement, they are, as I have<br />

just said, free to use the Frame<br />

agreement or publish their own<br />

call for tenders.”<br />

Converging interests<br />

The scope of a contract of this<br />

type is not limited to a mere<br />

reciprocal agreement of the<br />

‘guaranteed volume against a<br />

minimum price’ type. “It is very<br />

important”, explains Henry<br />

Delafon, “to be able to initiate<br />

and maintain clear, formalised<br />

relations over the long term<br />

between the company and its<br />

strategic suppliers. The Frame<br />

Agreement that we have signed<br />

with V & M TUBES reflects<br />

this approach. It is designed to test<br />

our organisations’ commitment<br />

and ability to truly synchronise<br />

their internal strengths to create<br />

and develop converging interests<br />

over the long term. The aim is<br />

not just to buy the best products<br />

at the best price – even if this is<br />

still an essential aspect – but also<br />

to find other potential sources of<br />

value added: work organisation,<br />

joint planning, improvement<br />

plans, etc.”<br />

The agreement, which covers<br />

V & M TUBES’ entire OCTG<br />

range, refers in particular to<br />

product availability with, for<br />

example, the establish-<br />

▼ ▼<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

Girassol, floating storage,<br />

production and offloading unit<br />

(FPSO), lying 150 kilometres off<br />

the Angola coast, is the first<br />

deep-offshore field (1,400 metres)<br />

to be developed using a subsea<br />

scheme<br />

Number 4 worldwide…<br />

Key data about a multinational<br />

organisation:<br />

• 1999: merger with Pétrofina<br />

• 2000: merger with Elf Aquitaine<br />

• 5.94 billion euros net earnings<br />

in 2002<br />

• 900 consolidated companies<br />

• 2.4 million barrels per day oil<br />

equivalent production (SEC)<br />

in 2002<br />

• 11.2 billion barrels proven oil<br />

and gas reserves<br />

• Interest in 5 liquefied natural<br />

gas complexes<br />

Total is also one of the world’s<br />

leading producers in the<br />

chemicals sector.<br />

5<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

Frame Agreement signed with TOTAL<br />

6<br />

▼ ▼<br />

Bernard Wyss, Global Contract Sales Manager, Valérie Juillard, Export<br />

Sales Assistant, Nathalie Blot, Export Sales Assistant, and Pierre-Marie<br />

Reymondon, Global Contract Sales Manager at V&M<br />

ment of stocks of the most<br />

standard tubes and reserved<br />

production capacity for the more<br />

specific ones, as well as the buy<br />

back clauses for non used<br />

products. “All this is pretty<br />

standard”, said John Foulkes,<br />

Head of the Drilling, Wells and<br />

Logistics Contracts Department<br />

at Total. “What is less so is that<br />

our contract also makes provision<br />

for periodic meetings. This<br />

obligation enables us to review<br />

current business, of course, but<br />

also to drive the improvement<br />

plan under the co-operative spirit<br />

to which we are jointly committed.<br />

We are discovering together<br />

this new way of approaching the<br />

relations between a customer and<br />

its supplier. We believe that the<br />

potential for progress for both our<br />

organisations is very promising.”<br />

A process to be nurtured<br />

After nine months’ experience<br />

with this first Frame Agreement,<br />

TOTAL and Vallourec a long common history<br />

We have found some important milestones in the relationship between Vallourec and TOTAL:<br />

• 1935: First line pipe orders for the Irak operations: For those who have been working<br />

in the seventies by Vallourec the expression "grille Irak" was a famous part of the Aulnoye<br />

as well as Anzin mills In the thirties the French company " compagnie francaise des<br />

pétroles" started to operate in Irak, and placed such large orders to Vallourec and<br />

Lorraine Escaut the 2 French seamless pipe suppliers in those days that special<br />

workshops were created for that purpose and the name remained for almost 50 years.<br />

• 1950/60: The big challenge of the french oil industry was at that time to develop<br />

the sour gas Lacq field. Huge common studies between what became Elf and Vallourec<br />

were made to find a steel resisting to that corrosion. A connection, the ancestor of<br />

the <strong>VAM</strong> was also designed.<br />

• 1960/70: The development of gas was requesting a premium gas tight connection,<br />

again the common work between Vallourec and TotalFinaElf was at the origin of<br />

the <strong>VAM</strong> connection, which has been the origin of the famous <strong>VAM</strong> family products<br />

representing still to day more than 50 % of the world premium joint market.<br />

• 1970/1980: That has been the development of the North sea.<br />

• 1980/90: Again new developments between Vallourec and Total and Elf for all the<br />

challenging new projects: the North sea even deeper, the always more corrosive<br />

environments, the HPHT wells, the deviated wells…<br />

• 2002: Signature of a frame agreement between TOTAL and Vallourec.<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

!<br />

TOTAL, Vallourec, Citra Tubindo and Co…<br />

the parties agree that the process<br />

is in place, but it now needs<br />

nurturing. “I don’t think this<br />

agreement raises any particular<br />

difficulty between V & M TUBES<br />

and us”, adds John Foulkes.<br />

“We have always had excellent<br />

relations; now they are even<br />

better. On the other hand, this way<br />

of operating is fairly demanding<br />

in terms of internal organisation.<br />

It forces us to collect all the necessary<br />

data so that we can capitalise<br />

fully on its advantages, notably<br />

with regard to planning for<br />

upcoming operations. We have<br />

to convince our teams of its<br />

John Foulkes, Head of the<br />

Drilling, Wells and Logistics<br />

Contracts Department at TOTAL<br />

The Girassol FPSO,<br />

the largest of its kind in the<br />

world, produces 200,000 barrels<br />

per day and can store 2 millions<br />

barrels for offloading into<br />

tankers via an export Buoy.<br />

It has accomodating for<br />

140 people<br />

validity so that they stand fully<br />

behind it. We had perhaps<br />

underestimated the amount<br />

of information gathering and<br />

explanation needed.”<br />

In any event, the results speak<br />

for themselves: the quantities<br />

delivered, which should gradually<br />

increase over the first three years,<br />

are on target.<br />

“Insofar as Total manages to<br />

demonstrate its ability to sustain<br />

the relation and providing V & M<br />

TUBES proves its performance<br />

on a competitive level”, concludes<br />

Henry Delafon, “it would seem<br />

that we are on the point of proving<br />

the concept. We can thus hope<br />

to achieve the necessary support<br />

for it to be extended to other types<br />

of products – why not pipelines –<br />

and to many of our local facilities.<br />

There can be no doubt<br />

that current campaigns in our<br />

subsidiaries will benefit from<br />

this Frame Agreement which is<br />

truly proving to be a win-win<br />

solution.”<br />

When Total Indonésie started their operation in the sixties,<br />

and from the beginning they were using our <strong>VAM</strong> products.<br />

They used to buy all the tubular goods on the open market.<br />

In 1982 the indonesian government realised the contribution<br />

such large foreign companies could bring to the country.<br />

Further to the direct and indirect employment, the<br />

Indonesian legislation constantly tended to increase local<br />

content in all activities including of course the oil & gas<br />

industry.<br />

Through Pertamina and Migas all tenders shall include a<br />

part of local manufacturing to be taken into consideration.<br />

In order to secure their tubular supply Total Indonésie<br />

requested Vallourec their co-operation to establish in<br />

Indonesia a manufacturing plant. It has not been an easy<br />

decision to take and quite a risky one! however Vallourec<br />

replied “present” and founded with a local partner Citra<br />

Tubindo on the Batam island in the Malacca strait. Since<br />

then Vallourec with Citra Tubindo constantly followed<br />

the increasing demand of TOTAL operations with even<br />

more request of local manufacturing from the indonesian<br />

government.<br />

• 1982 Founding of Citra Tubindo in Batu Ampar<br />

first threading line for plain end pipes from France:<br />

Out put of 45000 T°<br />

• 1988 Start of the Kabil heat treatment plant able to<br />

achieve all the most used steel grades from “Green<br />

pipes” from the Vallourec mills<br />

• 1990 Move of the Batu Ampar threading plant to Kabil<br />

to create a vast integrated plant<br />

Today PT Citra Tubindo has reached a production of<br />

80,000 Tons to serve the indonesian market and for a large<br />

part TOTAL.<br />

7<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

Strategic investment in the United States<br />

V & M STAR:<br />

terms of markets and<br />

8<br />

!<br />

Charging the 85-tonne<br />

electric-arc furnace<br />

with scrap<br />

Steel melting<br />

in the electric-arc<br />

furnace<br />

Tapping the<br />

hot metal<br />

!<br />

V & M TUBES has acquired an 80% stake in North Star Tubular Division, a subsidiary of the<br />

US Cargill Inc. group. Just seven weeks of intense negotiations involving the shareholders<br />

of V & M TUBES (the Vallourec group and Mannesmannröhren-Werke AG) resulted in this<br />

strategically important investment in the United States being pulled off. The remaining 20%<br />

stake was taken over by the Japanese Sumitomo group, V & M TUBES’ partner of over 25 years<br />

in oilfield tube development, most notably the <strong>VAM</strong> ® .<br />

With this new subsidiary called V & M STAR, V & M TUBES now has an independent production<br />

chain in the US, from steel production through pipe manufacture and even threading.<br />

!<br />

At the helm of<br />

V & M STAR:<br />

Jean-Yves LeCuziat,<br />

Chairman and CEO<br />

Jean-Yves Le Cuziat, Chairman<br />

of V & M STAR, explains very<br />

simply the reasons that led<br />

the Cargill group to divest itself<br />

of its seamless tubes activities,<br />

and how this disposal has been<br />

received. “the Cargill Group<br />

operates chiefly in the food<br />

production industry, but it’s also<br />

involved in many other areas,<br />

and steel tube doesn’t form part of<br />

its core business. The fact of<br />

having sold this branch to the<br />

Vallourec group, whose entire<br />

business revolves around seamless<br />

steel tubes, should reassure the 560<br />

or so employees in Youngstown<br />

and Houston.”<br />

It is well know that V & M TUBES<br />

has been present on the US<br />

market for many years through<br />

its two units based in Houston:<br />

the sales entity of VALLOUREC<br />

& MANNESMANN TUBES<br />

CORP., which has successfully<br />

marketed V & M TUBES’ products<br />

in the United States, particularly<br />

to the oil and gas sector; and<br />

<strong>VAM</strong> PTS (a joint subsidiary of<br />

V & M TUBES and Sumitomo),<br />

which specializes in the manufacture<br />

of <strong>VAM</strong> ® premium connections<br />

for oilfield tubulars and<br />

related services.<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

an ideal addition in<br />

products<br />

9<br />

!<br />

Three-strand continuous caster<br />

With an annual production capacity<br />

of some 500,000 tons, V & M STAR<br />

will substantially boost V & M<br />

TUBES’ position, making it the<br />

world’s leading manufacturer<br />

of seamless tubes. In particular,<br />

V & M TUBES’ presence is now<br />

significantly stronger in the US<br />

oil and gas industry.<br />

Around 80% of V & M STAR’s<br />

products are OCTG, the remainder<br />

are line pipe, also mainly supplied<br />

to this same major market.<br />

Besides V & M STAR’s own<br />

manufacturing program, which<br />

covers the 5” to 10 3 /4” range (API<br />

standard), major US customers will<br />

now be able to access the complete<br />

V & M TUBES’ manufacturing<br />

program for larger and smaller<br />

sizes, higher alloyed materials, etc.,<br />

through its facilities in Germany,<br />

France and Brazil.<br />

“Our reputation as one of the<br />

leading manufacturers of oilfield<br />

tubular products and line pipe in<br />

the USA and our quality standards<br />

are excellent”, explains Jean-Yves<br />

Le Cuziat. “V & M STAR is<br />

committed to protecting this<br />

reputation, and even to improving<br />

it if possible. The upcoming close<br />

cooperation with our colleagues<br />

in France, Germany and Brazil<br />

has opened a vast potential for<br />

the intensive exchange of ideas<br />

and experience and consequent<br />

improvement.”<br />

The Youngstown works<br />

Youngstown is located about<br />

midway between Cleveland and<br />

Pittsburgh. It is named after one<br />

of the city’s founding fathers,<br />

one certain John Young, who built<br />

the first settlement there in 1797.<br />

The first steelworks was built here<br />

in 1855, and by around 1920,<br />

Pittsburgh, Cleveland, Chicago<br />

and Youngstown were known<br />

collectively as the “steel towns of<br />

the USA”. For several decades,<br />

Youngstown mainly survived on<br />

the iron and steel industry. In the<br />

1940s, the town’s population was<br />

140,000 (82,000 today), but the<br />

various crises in the US steel<br />

industry led to layoffs and closures.<br />

At the end of the 1970s, there<br />

were still six active steelworks<br />

in Youngstown; today, only one<br />

remains, V & M STAR.<br />

Modernized in 1999 and equipped<br />

with a new electric-arc furnace<br />

with a capacity of 85 tons per heat,<br />

it smelts scrap iron to produce the<br />

new steel. After tapping, the steel<br />

is subjected to secondary metallurgical<br />

treatment in the ladle and<br />

alloyed to specified requirements.<br />

The raw steel is then continuously<br />

cast into tube-making rounds with<br />

a diameter of 8 3 /4” and 11 1 /4”.<br />

The pipe rolling mill is a Multiple<br />

Pass Mill (MPM), also referred<br />

to as a Retained Mandrel Mill, and<br />

is located just behind the steelworks.<br />

Here, the tube-making<br />

rounds are heated to the forming<br />

temperature in a reheating furnace<br />

and rolled to 5” to 10 3 /4” seamless<br />

steel tubes.<br />

Line pipe with machined ends and<br />

marking in accordance with API<br />

5L is supplied directly to the<br />

customer, while the oilfield tubulars<br />

go onto rail trucks after marking<br />

for further processing, to Houston,<br />

Texas, V & M STAR’s second<br />

works.<br />

▼ ▼<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

Strategic investment in the United States<br />

!<br />

Continuously cast rounds<br />

are the starting material<br />

for tube production<br />

Rolling<br />

seamless tubes<br />

The finish-rolled<br />

tubes being cut<br />

to length<br />

!<br />

10<br />

▼ ▼<br />

The Houston works<br />

With almost two million inhabitants,<br />

Houston ranks among the<br />

largest cities in the USA. It is not<br />

only famous worldwide for its<br />

NASA Space Center, but it is also<br />

regarded as the hub of the North<br />

American oil and gas industry.<br />

No less than 200 petrochemical<br />

companies are based here. Founded<br />

in 1836 by Sam Houston, it was<br />

the first capital of Texas. It is hardly<br />

surprising then that V & M TUBES<br />

is also present there today ... now<br />

with three companies.<br />

“The area used to be a rice field”,<br />

explains Dave Garver, manager of<br />

V & M STAR Houston, as he<br />

proudly shows us round the large<br />

premises owned by V&M STAR<br />

in Sheldon Road on the outskirts<br />

of Houston. “We purchased the<br />

land in December 1986, set up<br />

our heat treatment and threading<br />

capacities step by step, and started<br />

production here in 1988. Over the<br />

past ten years we have succeeded<br />

in upping our US market share in<br />

API threading from an insignificant<br />

level to 40%.” These figures<br />

speak for themselves, or, to be<br />

more precise, for the sales and<br />

production teams in Houston and<br />

the service they provide.<br />

The ultramodern heat treatment<br />

plant includes precise temperature<br />

control for the furnaces and efficient<br />

water hardening. After heat<br />

treatment, the oilfield tubes pass<br />

The Houston management<br />

team: Plant Manager Dave Garver<br />

(right) with Ronny Clark, General<br />

Manager Sales and Marketing<br />

!<br />

Oilfield tubes with API thread<br />

or plain ends ready for shipment<br />

from the Houston works<br />

!<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

V & M STAR<br />

Formerly: North Star Steel Company, Tubular Division,<br />

a subsidiary of Cargill Inc.<br />

Shareholders since 1 July 2002:<br />

80 % VALLOUREC & MANNESMANN TUBES<br />

20 % SUMITOMO<br />

V & M STAR in Youngstown<br />

through a straightening and sizing<br />

mill and go on to hydrostatic<br />

testing. Then the pipe ends are<br />

threaded in accordance with the<br />

applicable API standards.<br />

“We have an output capability<br />

of 30,000 to 35,000 tons of heat<br />

treated material per month”,<br />

explains Ronny Clark, General<br />

Manager Sales and Marketing at<br />

V & M STAR. “We are one of the<br />

two big OCTG manufacturers in<br />

the United States. Service is writ<br />

large in our company, and flexibility<br />

is what our customers expect<br />

from us. This includes JIT deliveries<br />

as well as managing their<br />

tube stocks.” It is obvious that<br />

V & M STAR’s success is proof<br />

that its managers are right on<br />

target with their approach.<br />

Address: 2669 Dr. Martin Luther King Jr. Boulevard,<br />

Youngstown (Ohio) 44510-1033<br />

Phone: +1 (330) 7 42 63 00 - Fax: +1 (330) 7 42 63 15<br />

• An 85-ton electric-arc furnace<br />

• A continuous caster<br />

• A reheating furnace<br />

• An MPM pipe rolling mill<br />

V & M STAR in Houston<br />

11<br />

Loading threaded and<br />

coupled oilfield tubes<br />

!<br />

Address: 8603 Sheldon Road, Houston (Texas) 77049<br />

Phone: +1 (281) 4 56 60 00 - Fax: +1 (281) 4 56 02 70<br />

• Heat treatment facilities<br />

• Straightening and sizing machines<br />

• Finishing lines, complete with hydrostatic pipe tester<br />

• Threading lines<br />

Manufacturing program<br />

Seamless hot rolled steel tubes sized 5" to 10 3 /4",<br />

with or without heat treatment, mainly:<br />

• OCTG tubes in accordance with API 5CT,<br />

ends plain or threaded to API<br />

• Line pipe in accordance with API 5L<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

!<br />

An expanded Horizon<br />

Vallourec, a major<br />

on the expandable<br />

Multiple-record installation of<br />

a Solid Expandable Tubular<br />

(SET) liner in a NAM producing<br />

well in the Netherlands<br />

Groningen Field<br />

12<br />

In September 2002, thanks to<br />

the expansion technology,<br />

a 5 1 /2-in gas producer was<br />

worked over and converted to a<br />

7 5 /8” producer, resulting in 60%<br />

increase in well capacity.<br />

The existing 5 1 /2-in tubing has<br />

been removed and a new 6-in<br />

18.6 ppf CRA expandable has been<br />

expanded in the existing 7 5 /8 -in.<br />

39 ppf, 33.7 ppf and 29.7 ppf<br />

casing, with elastomer seals in each<br />

section. Combined mechanical<br />

and hydraulic forces used to expand<br />

the chrome pipe by 9.8 % averaged<br />

approximately 92,000 lbs. Postexpansion<br />

ID of the 6-in.18.6 ppf<br />

CRA Liner was 5.92-in. (compared<br />

to a pre-expansion diameter of<br />

5.39 in.), while post-expansion<br />

burst and collapse were estimated<br />

at 7,000 psi and 4,000 psi,<br />

respectively. Overall liner length<br />

was reduced from 6,095 feet to<br />

5,869 feet as a natural result of<br />

the expansion process.<br />

!<br />

This success corresponds to the<br />

longest ever down hole tubular<br />

expansion with a record 1858m of<br />

tubing expanded in a single trip.<br />

Conducted in a NAM gas well in<br />

the Groningen field, this project<br />

involved the first commercial application<br />

of expandable 6” gas-tight<br />

premium connections <strong>VAM</strong> ET<br />

NA and expandable 13Cr seamless<br />

pipe. The field installation has been<br />

performed by ENVENTURE,<br />

a company specialised in the<br />

expansion technology.<br />

"This project is an excellent<br />

demonstration of the impact of<br />

Groningen field<br />

SET Technology," said Hans<br />

Bouman, Groningen Asset Manager<br />

for NAM. "Because of limitations<br />

in drilling additional wells in this<br />

field, we need to maximize the<br />

deliverability from existing wells<br />

to provide flexibility in meeting<br />

peak gas demand situations."<br />

"The ability to expand Cr13<br />

tubulars will allow us to do that<br />

by providing far greater production<br />

deliverability from highlycorrosive<br />

wells and allowing us to<br />

drill deeper than ever before,"<br />

Bouman added.<br />

Plans are now underway within<br />

NAM to initiate follow-up SET<br />

workover projects.<br />

!<br />

Inspection of<br />

the connection on site<br />

Expandable 13Cr<br />

seamless pipe on yard<br />

R&D breakthrough thanks<br />

to project organisation<br />

The design and conception of the<br />

gas tight expandable connection is<br />

the result of over two years of joint<br />

effort of Vallourec Mannesmann<br />

Oil & Gas and Shell International<br />

Exploration & Production.<br />

Research & Development activities<br />

have largely used computer works<br />

and laboratory testing facilities to<br />

elaborate new concept of tubular<br />

goods with performances enhanced<br />

by the expansion process itself.<br />

Before the production job, a fullscale<br />

system test was performed<br />

in a test well onshore. This appli-<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

!<br />

!<br />

!<br />

player<br />

market<br />

Combined loads with thermal cycles<br />

cation has provided ample learning<br />

opportunities in both the engineering<br />

and deployment of the<br />

SET systems.<br />

Due to the size and complexity of<br />

these Research & Development<br />

activities, a project organisation has<br />

been elaborated. Detailed project<br />

specifications, updated Planning,<br />

organigram and WBS have allowed<br />

efficient study progress toward<br />

common and clear final objectives.<br />

Revolutionary expandable<br />

tubulars and connectors<br />

The connections have proven<br />

satisfactory stability and tightness<br />

after expansion under various<br />

simulated well conditions, including<br />

compression, tension, thermal<br />

cycles, internal and external<br />

pressures. Besides, the metal/metal<br />

seal and the “Clean Well” option<br />

(Dope less solution) constitute<br />

a significant improvement in<br />

running procedure.<br />

The seamless tubes offer homogeneous<br />

toughness with very stringent<br />

mechanical properties for<br />

expansion without embrittlement.<br />

Solid Expansion Tubular (SET)<br />

Technology Principle<br />

Traditional drilling operations use progressively smaller casing<br />

diameters that telescope down to the reservoir objective. This<br />

limits the number of casing strings that can be deployed and<br />

restricts the wellbore cross-sectional area available for fluid<br />

flow.<br />

With expandable tubular technology, the operator runs casing<br />

into the wellbore normally, then expands it in situ by hydraulically<br />

pushing or pulling a specially designed mandrel, or pig,<br />

through the pipe (plastic deformation process known as cold<br />

drawing). The result is a minimal reduction in internal casing<br />

diameter from the previous string to the newly expanded string.<br />

Thus expandable tubular technology greatly increases the number<br />

of casing diameters available.<br />

This conservation of wellbore size allows operators to drill<br />

deeper wells, extend the length of deviat-ed wells and reach<br />

deepwater objectives previously thought impractical or impossible.<br />

The ability of expanded tubular systems to be deployed<br />

downhole permits operators to control problems associated<br />

with particular formations, including lost circulation, salt, water<br />

flow, subsidence and high temperature. By expanding tubulars<br />

inside existing casing, old wellbores can be repaired, depleted<br />

zones isolated and burst or collapse properties of existing casing<br />

enhanced.<br />

Expandable technology will change the basic design and<br />

construction of oil and gas wells. This may look as a threat for<br />

pipe manufacturers (reduction of the number of casings per<br />

well) but this can also be seen as a great challenge. This technology<br />

will create new applications and the manufacturer who will<br />

be a leader on this market will benefit of a significant<br />

differential advantage on competition, allowing increased<br />

market shares.<br />

13<br />

<strong>VAM</strong> ET NA Connection<br />

FEA simulation of the connection under expansion<br />

Principle of the Mono Diameter Application<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

!<br />

!<br />

!<br />

Spotlights<br />

VMUSA<br />

V & M STAR AND<br />

V & M TUBES CORP<br />

COMBINE THEIR<br />

OCTG SALES FORCES<br />

David Hamrick<br />

Ronny Clark<br />

David Hamrick, President of V & M Tubes Corp. will be the leader<br />

of the combined Sales Organization. In a new position reporting to<br />

David will be Ronny Clark, Vice President of OCTG Sales. Ronny,<br />

who used to be the General Sales Manager of V&M Star, will be<br />

responsible for all OCTG and Coupling Stock business. Each Sales<br />

Representative that is currently working for either organization, will<br />

be assigned as a single point of contact for our customers in all of<br />

our business dealings with V&M Star or V&M Tubes Corp.<br />

The new location for the group will be the current V & M Tubes<br />

Corp offices in the Post Oak area of Houston. We believe these<br />

changes will make it easier to do business with V & M, as we strive<br />

to be a complete source of seamless pipe to our customers.<br />

<strong>VAM</strong> SERVICES<br />

MORE THAN 100 <strong>VAM</strong> LICENSEES<br />

ALL AROUND THE WORLD<br />

We are pleased to announce that as of<br />

September 2002, we have now more than 100<br />

<strong>VAM</strong> licensees. More than ever, this allows our<br />

customers to have their accessories<br />

manufactured and their pipes maintained in<br />

increasing number of different countries,<br />

present date more than 40. This network<br />

permits us to have a strong presence in the<br />

market place and enables us improve the field<br />

support in order to fulfill the needs of our<br />

customers. As always all new licensees must<br />

meet required machining capabilities and<br />

pertinent criteria in relation to quality control<br />

procedures as demanded by <strong>VAM</strong> <strong>Services</strong>. The<br />

<strong>VAM</strong> <strong>Services</strong> team provides all the necessary<br />

training to support the evolution of the <strong>VAM</strong><br />

product line within this network and V&M<br />

Tubes has a commitment to continue to<br />

reinforce its capacity inline with the network<br />

and product line expansion.<br />

14<br />

VMOGUK<br />

<strong>VAM</strong> HP FOR SHELL EXPROS JANUS HPHT EXPLORA<br />

TION WELL<br />

Shell UK Exploration and Production (Shell Expro)<br />

are one of the leading North Sea Oil & Gas operators,<br />

with considerable experience of High Pressure, High<br />

Temperature gas condensate production. Vallourec<br />

Mannesmann Oil & Gas have worked closely with<br />

Shell Expro engineers to develop casing and tubing<br />

products that meet the very demanding technical<br />

challenges of HP.HT wells. A typical well architecture<br />

for the Shearwater field includes VM110SS and<br />

VM130CY steel grades, providing high strength and<br />

resistance to corrosive hydrogen sulphide. <strong>VAM</strong> HP<br />

and <strong>VAM</strong> TOP connections are the only ones qualified<br />

by Shell Expro for use in the production casing string.<br />

The connection chosen for the production tubing is<br />

<strong>VAM</strong> TOP HT. During manufacture of casing the wall<br />

thickness of each pipe is checked and the order is<br />

segregated into three groups. The thicker pipe is put<br />

into the well in areas where Shell engineers calculate<br />

that drill pipe wear will be most severe. Whenever<br />

Shell Expro drill a new HP.HTwell the V&M products<br />

are supported by <strong>VAM</strong> Field Service International who<br />

send dedicated engineers to help prepare the tubulars<br />

and to supervise offshore operations.<br />

Shell Expro’s confidence in our ability to meet their<br />

technical challenges was illustrated when, to meet a<br />

tight project window, they placed an order for 10,000<br />

feet of 10” diameter casing (a new size), before the<br />

connection design was validated. The design,<br />

qualification testing, manufacture, delivery and first<br />

field use of 10” x 73.9# VM130CY, <strong>VAM</strong> TOP-NB,<br />

was achieved within a nine month period. R&D testing<br />

has continued and shows the connection performance<br />

envelope to be beyond Shell Expro’s original<br />

requirements.<br />

<strong>VAM</strong> HP Coupling ready for surface<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E

<strong>VAM</strong> PREMIUM CONNECTIONS<br />

NEW SERIES OF BROCHURES ON <strong>VAM</strong> THREAD CONNECTIONS<br />

VALLOUREC & MANNESMANN TUBES' OCTG Division has recently brought<br />

out a new series of brochures on their patented <strong>VAM</strong> premium connections for oil and<br />

gas field tubulars. The 6- or 8-page leaflets contain all the important technical details,<br />

in particular dimension tables with the performance data for the relevant premium<br />

connections. So far, the series covers the following:<br />

• <strong>VAM</strong> TOP - TOP of the class<br />

• <strong>VAM</strong> TOP HC - Beyond the TOP in compression<br />

• <strong>VAM</strong> TOP HT - Beyond the TOP with torque<br />

• NEW <strong>VAM</strong> - The famous versatile premium<br />

• <strong>VAM</strong> ACE - Put an ACE in the hole<br />

• <strong>VAM</strong> HWST - The Heavy Weight champion<br />

• <strong>VAM</strong> FLJ - No gamble with the royal flush<br />

• <strong>VAM</strong> MUST - When success is a MUST<br />

All the brochures are available in English<br />

and can be obtained from<br />

VALLOUREC MANNESMANN OIL & GAS FRANCE<br />

130, rue de Silly, 92100 Boulogne - Fax: +33 1 4909-3713<br />

E-mail: hassna.belmalek@vmtubes.fr<br />

VMB<br />

5 LOGISTICS BASES<br />

OPENED BY VMB<br />

FOR PETROBRAS<br />

OPERATIONS<br />

After signing in April 2002<br />

a 5-year alliance contract with<br />

Petrobras, for the supply of<br />

OCTG and Line Pipe, VMB<br />

has opened until last December<br />

5 Logistic Bases close to<br />

Petrobras operations.<br />

These bases, located in Macaé<br />

(Rio de Janeiro), São Mateus<br />

(Espirito Santo), Salvador<br />

(Bahia), Natal (Rio Grande do<br />

Norte) and Aracajú (Sergipe),<br />

will manage the stock of<br />

tubular, as well as a just-in-time<br />

flow of material based on<br />

Petrobras needs.<br />

PRINVER<br />

QUALIFICATION ISO 9001-2000<br />

In 2002, drilling activity<br />

and pipe consumption<br />

in Mexico were good<br />

and in accordance with<br />

Budget.<br />

In premium<br />

connections, our<br />

target in market<br />

share was achieved<br />

and maintained at<br />

56 % of total<br />

Mexican market.<br />

Two new products were launched in the<br />

Mexican market: DINO <strong>VAM</strong> and <strong>VAM</strong><br />

SLIJ II.<br />

- DINO <strong>VAM</strong> to substitute BTC<br />

connections in 13 3/8 “ casing<br />

- <strong>VAM</strong> SLIJ II in 9 5/8”, 7” and 5” to be<br />

used in onshore deep wells,<br />

All together YTD (Dec-2002)<br />

represents 775 MT of pipe.<br />

Moreover, Prinver was qualified in ISO-<br />

9001, ver. 2000 and has been certificated<br />

in April 2003.<br />

FIRST ORDER OF<br />

13%CR TUBING<br />

FOR PETROBRAS<br />

VMB rolled and delivered in<br />

2002 its first order of tubing<br />

13%Cr to Petrobras, based on<br />

steel bars imported from<br />

Europe. Subsequently, VMB<br />

process was audited and<br />

qualified by the Mc Gregor<br />

inspection company, on behalf<br />

of Enterprise Oil, opening<br />

the way to future orders to be<br />

manufactured locally.<br />

15<br />

<strong>VAM</strong> PTS<br />

PARTICIPATION TO SPE 2002<br />

EXHIBITION<br />

<strong>VAM</strong> PTS once again participated as an<br />

exhibitor in the annual Society of Petroleum<br />

Engineers Technical Conference and<br />

Exhibition, held this year in San Antonio.<br />

Similar to the OTC in Houston, the SPE<br />

primarily attracts engineers from the oil and gas industry. This successful exhibit was a<br />

cooperative effort of <strong>VAM</strong> PTS, V&M USA and V&M Star. The focus for <strong>VAM</strong> PTS was<br />

<strong>VAM</strong> TOP in tubing sizes, which offers 100% pipe body compression with full gas tightness.<br />

VFSI IN BRAZIL<br />

Since the end of 2002,<br />

a team of four <strong>VAM</strong> Field<br />

Service engineers is available to<br />

serve any operator in South<br />

America. This new service will<br />

support VMB action to promote<br />

the <strong>VAM</strong> connection in Brazil<br />

and Latin America. The <strong>VAM</strong><br />

family is now extensively<br />

manufactured in Belo Horizonte,<br />

and will benefit from this 1st<br />

class support.<br />

V & M R E P O R T - O C T G D I V I S I O N S P E C I A L I S S U E