Volume1 - Aventura

Volume1 - Aventura

Volume1 - Aventura

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

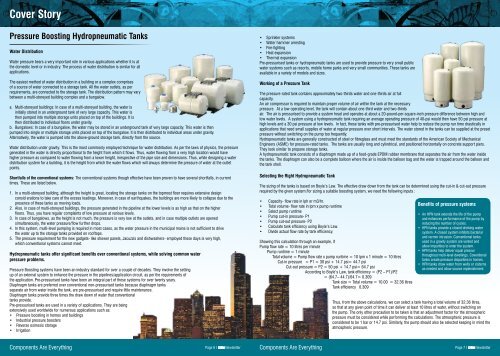

Cover Story<br />

Pressure Boosting Hydropneumatic Tanks<br />

Water Distribution<br />

Water pressure bears a very important role in various applications whether it is at<br />

the domestic level or in industry. The process of water distribution is similar for all<br />

applications.<br />

The easiest method of water distribution in a building or a complex comprises<br />

of a source of water connected to a storage tank. All the water outlets, as per<br />

requirements, are connected to the storage tank. The distribution pattern may vary<br />

between a multi-storeyed building complex and a bungalow.<br />

a. Multi-storeyed buildings: In case of a multi-storeyed building, the water is<br />

initially stored in an underground tank of very large capacity. This water is<br />

then pumped into multiple storage units placed on top of the buildings. It is<br />

then distributed to individual floors under gravity.<br />

b. Bungalows: In case of a bungalow, the water may be stored in an underground tank of very large capacity. This water is then<br />

pumped into single or multiple storage units placed on top of the bungalow. It is then distributed to individual areas under gravity.<br />

Alternatively, the water is pumped into the above-ground storage tank, directly from the source.<br />

Water distribution under gravity: This is the most commonly employed technique for water distribution. As per the laws of physics, the pressure<br />

generated in the water is directly proportional to the height from which it flows. Thus, water flowing from a very high location would have<br />

higher pressure as compared to water flowing from a lower height, irrespective of the pipe size and dimensions. Thus, while designing a water<br />

distribution system for a building, it is the height from which the water flows which will always determine the pressure of water at the outlet<br />

points.<br />

Shortfalls of the conventional systems: The conventional systems though effective have been proven to have several shortfalls, in current<br />

times. These are listed below.<br />

1. In a multi-storeyed building, although the height is great, locating the storage tanks on the topmost floor requires extensive design<br />

consid erations to take care of the excess loadings. Moreover, in case of earthquakes, the buildings are more likely to collapse due to the<br />

presence of these tanks as moving loads.<br />

2. Also, in case of multi-storeyed buildings, the pressure generated in the pipeline at the lower levels is as high as that on the higher<br />

floors. Thus, you have regular complaints of low pressure at various levels.<br />

3. In case of bungalows, as the height is not much, the pressure is very low at the outlets, and in case multiple outlets are opened<br />

simultaneously, the water pressure/flow further drops.<br />

4. In this system, multi-level pumping is required in most cases, as the water pressure in the municipal mains is not sufficient to drive<br />

the water up to the storage tanks provided on rooftops.<br />

5. The pressure requirement for the new gadgets- like shower panels, Jacuzzis and dishwashers- employed these days is very high,<br />

which conventional systems cannot meet.<br />

Hydropneumatic tanks offer significant benefits over conventional systems, while solving common water<br />

pressure problems.<br />

Pressure Boosting systems have been an industry standard for over a couple of decades. They involve the setting<br />

up of an external system to enhance the pressure in the pipelines/application circuit, as per the requirements of<br />

the application. Pre-pressurised tanks have been an integral part of these systems for over twenty years.<br />

Diaphragm tanks are preferred over conventional non-pressurised tanks because diaphragm tanks<br />

separate air from water inside the tank, are pre-pressurised and require little maintenance.<br />

Diaphragm tanks provide three times the draw down of water that conventional<br />

tanks provide.<br />

Pre-pressurised tanks are used in a variety of applications. They are being<br />

extensively used worldwide for numerous applications such as:<br />

• Pressure boosting in homes and buildings<br />

• Industrial pressure boosters<br />

• Reverse osmosis storage<br />

• Irrigation<br />

• Sprinkler systems<br />

• Water hammer arresting<br />

• Fire-fighting<br />

• Heat expansion<br />

• Thermal expansion<br />

Pre-pressurised tanks or hydropneumatic tanks are used to provide pressure to very small public<br />

water systems such as resorts, mobile home parks and very small communities. These tanks are<br />

available in a variety of models and sizes.<br />

Working of a Pressure Tank<br />

The pressure-rated tank contains approximately two-thirds water and one-thirds air at full<br />

capacity.<br />

An air compressor is required to maintain proper volume of air within the tank at the necessary<br />

pressure. At a low operating level, the tank will contain about one-third water and two-thirds<br />

air. The air is pressurised to provide a system head and operates at about a 20-pound-per-square-inch pressure difference between high and<br />

low water levels. A system using a hydropneumatic tank requiring an average operating pressure of 40-psi would then have 50 psi pressure at<br />

high levels and a 30 psi pressure at low levels. In fact, these tanks with pre-pressurised water help to reduce the pump run time drastically in<br />

applications that need small supplies of water at regular pressure over short intervals. The water stored in the tanks can be supplied at the preset<br />

pressure without switching on the pump too frequently.<br />

Hydropneumatic tanks are generally constructed of steel or fibreglass and must meet the standards of the American Society of Mechanical<br />

Engineers (ASME) for pressure-rated tanks. The tanks are usually long and cylindrical, and positioned horizontally on concrete support piers.<br />

They look similar to propane storage tanks.<br />

A hydropneumatic tank consists of a diaphragm made up of a food-grade EPDM rubber membrane that separates the air from the water inside<br />

the tanks. The diaphragm can also be a complete balloon where the air is inside the balloon bag and the water is trapped around the balloon and<br />

the tank shell.<br />

Selecting the Right Hydropneumatic Tank<br />

The sizing of the tanks is based on Boyle’s Law. The effective draw down from the tank can be determined using the cut-in & cut-out pressure<br />

required by the given system.For sizing a suitable boosting system, we need the following inputs :<br />

• Capacity- flow rate in lph or m3/hr.<br />

• Total volume- flow rate in lpm x pump runtime<br />

• Select pump runtime<br />

• Pump cut-in pressure- P1<br />

• Pump cut-out pressure- P2<br />

• Calculate tank efficiency using Boyle’s Law.<br />

• Divide actual flow rate by tank efficiency.<br />

Showing this calculation through an example, if<br />

Pump flow rate = 10 litres per minute<br />

Pump runtime = 1 minute<br />

Total volume = Pump flow rate x pump runtime = 10 lpm x 1 minute = 10 litres<br />

Cut-in pressure = P1 = 30 psi + 14.7 psi= 44.7 psi<br />

Cut-out pressure = P2 = 50 psi + 14.7 psi= 64.7 psi<br />

According to Boyle’s Law, tank efficiency = (P2 – P1)/P2<br />

= (64.7– 44.7)/64.7= 0.309<br />

Tank size = Total volume = 10.00 = 32.36 litres<br />

Tank efficiency 0.309<br />

Benefits of pressure systems<br />

• An HPN tank extends the life of the pump<br />

and enhances performance of the pump by<br />

reducing the number of cycles.<br />

• HPN tanks provide a closed drinking water<br />

system. A closed system inhibits bacterial<br />

and vermin intrusion. Conventional tanks<br />

used in a gravity system are vented and<br />

allow impurities to enter the system.<br />

• HPN tanks help deliver equal pressur<br />

throughout multi-level dwellings. Coventional<br />

tanks create pressure disparities in homes.<br />

• HPN tanks draw water from wells or cisterns<br />

as needed and allow source replenishment.<br />

Thus, from the above calculations, we can select a tank having a total volume of 32.36 litres,<br />

so that at any given point of time it can deliver at least 10 litres of water, without switching on<br />

the pump. The only other precaution to be taken is that an adjustment factor for the atmospheric<br />

pressure must be considered while performing the calculations. The atmospheric pressure is<br />

considered to be 1 bar or 14.7 psi. Similarly, the pump should also be selected keeping in mind the<br />

atmospheric pressure.<br />

Components Are Everything<br />

Components Are Everything<br />

Page 6 I OEM Newsletter Page 7 I OEM Newsletter