Pharmaceutical Spray Balls - Sani-Matic, Inc.

Pharmaceutical Spray Balls - Sani-Matic, Inc.

Pharmaceutical Spray Balls - Sani-Matic, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

B I O - P H A R M<br />

<strong>Pharmaceutical</strong> <strong>Spray</strong> <strong>Balls</strong><br />

Custom Engineered and Precision Drilled<br />

<strong>Sani</strong>-<strong>Matic</strong> <strong>Spray</strong> <strong>Balls</strong> are designed utilizing the latest technology to<br />

create a 3D model of the spray balls in your process vessels. This allows<br />

us to engineer the most effective static spray device and drill pattern<br />

to ensure proper coverage of all ports and surfaces.<br />

With decades of experience in spray technology and Bio-Pharm CIP<br />

applications, the <strong>Sani</strong>-<strong>Matic</strong> team understands the spray dynamics<br />

required to ensure proper flow rates, pressures and geometries.<br />

Why Choose <strong>Sani</strong>-<strong>Matic</strong><br />

<strong>Spray</strong> <strong>Balls</strong> and Supply Tubes<br />

• Custom engineered in 3D<br />

• Precision drilled on CNC machine<br />

• Pass Riboflavin testing the first time<br />

• Documented for future replacement<br />

Once the spray pattern and design have been<br />

determined, <strong>Sani</strong>-<strong>Matic</strong> manufactures the spray balls<br />

and supply tubes to deliver the solution. Orbital<br />

welding of the spray balls and custom patterns<br />

drilled with a CNC machine provide repeatable and<br />

consistent patterns.<br />

<strong>Sani</strong>tary tube welds use orbital welding wherever possible. All product contact<br />

welds are ground and polished to meet your interior finish requirements.<br />

Orbital welds are borescope inspected to meet ASME-BPE standards.<br />

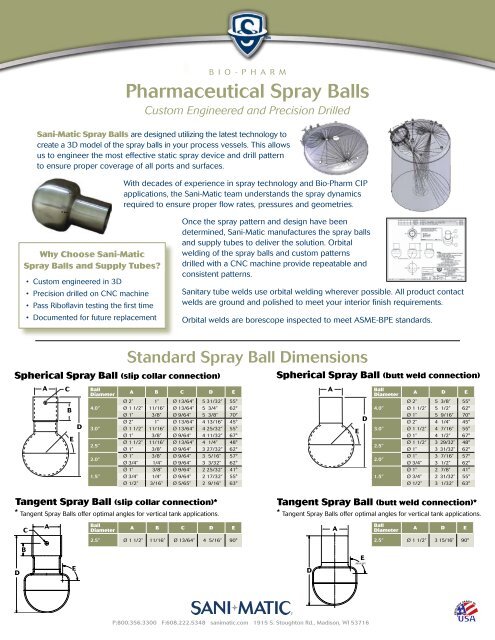

Spherical <strong>Spray</strong> Ball (slip collar connection)<br />

A<br />

C<br />

B<br />

E<br />

D<br />

Ball<br />

Diameter<br />

4.0”<br />

3.0”<br />

2.5”<br />

2.0”<br />

1.5”<br />

Standard <strong>Spray</strong> Ball Dimensions<br />

A B C D E<br />

Ø 2” 1” Ø 13/64” 5 31/32” 55°<br />

Ø 1 1/2” 11/16” Ø 13/64” 5 3/4” 62°<br />

Ø 1” 3/8” Ø 9/64” 5 3/8” 70°<br />

Ø 2” 1” Ø 13/64” 4 13/16” 45°<br />

Ø 1 1/2” 11/16” Ø 13/64” 4 25/32” 55°<br />

Ø 1” 3/8” Ø 9/64” 4 11/32” 67°<br />

Ø 1 1/2” 11/16” Ø 13/64” 4 1/4” 48°<br />

Ø 1” 3/8” Ø 9/64” 3 27/32” 62°<br />

Ø 1” 3/8” Ø 9/64” 3 5/16” 57°<br />

Ø 3/4” 1/4” Ø 9/64” 3 3/32” 62°<br />

Ø 1” 3/8” Ø 9/64” 2 25/32” 41°<br />

Ø 3/4” 1/4” Ø 9/64” 2 17/32” 55°<br />

Ø 1/2” 3/16” Ø 5/65” 2 9/16” 63°<br />

Spherical <strong>Spray</strong> Ball (butt weld connection)<br />

A<br />

E<br />

D<br />

Ball<br />

Diameter<br />

4.0”<br />

3.0”<br />

2.5”<br />

2.0”<br />

1.5”<br />

A D E<br />

Ø 2” 5 3/8” 55°<br />

Ø 1 1/2” 5 1/2” 62°<br />

Ø 1” 5 9/16” 70°<br />

Ø 2” 4 1/4” 45°<br />

Ø 1 1/2” 4 7/16” 55°<br />

Ø 1” 4 1/2” 67°<br />

Ø 1 1/2” 3 29/32” 48°<br />

Ø 1” 3 31/32” 62°<br />

Ø 1” 3 7/16” 57°<br />

Ø 3/4” 3 1/2” 62°<br />

Ø 1” 2 7/8” 41°<br />

Ø 3/4” 2 31/32” 55°<br />

Ø 1/2” 3 1/32” 63°<br />

Tangent <strong>Spray</strong> Ball (slip collar connection)*<br />

* Tangent <strong>Spray</strong> <strong>Balls</strong> offer optimal angles for vertical tank applications.<br />

D<br />

C<br />

B<br />

A<br />

E<br />

Ball<br />

Diameter<br />

A B C D E<br />

2.5” Ø 1 1/2” 11/16” Ø 13/64” 4 5/16” 90°<br />

Tangent <strong>Spray</strong> Ball (butt weld connection)*<br />

* Tangent <strong>Spray</strong> <strong>Balls</strong> offer optimal angles for vertical tank applications.<br />

D<br />

A<br />

E<br />

(MAX 90º)<br />

Ball<br />

Diameter<br />

A D E<br />

2.5” Ø 1 1/2” 3 15/16” 90°<br />

P:800.356.3300 F:608.222.5348 sanimatic.com 1915 S. Stoughton Rd., Madison, WI 53716

B I O - P H A R M<br />

Custom <strong>Spray</strong> Ball Nomenclature<br />

1 2 3 4 5 6 7 8 9<br />

SB GPM PSI Ra<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Selection Option Description<br />

Drill Pattern 3 Special <strong>Spray</strong> Pattern (diagram req’d)<br />

Ball Diameter<br />

Connection Size<br />

Connection Style<br />

Flow (GPM)<br />

**Max Flow Rate Chart<br />

Pressure (PSI)<br />

Finish (Ra)<br />

1.5 1.50” - round only<br />

2.0 2.00” - round only<br />

2.5 2.50” - round or tangential<br />

3.0 3.00” - round only<br />

4.0 4.00” - round only<br />

0.50” 0.50"<br />

0.75” 0.75"<br />

1.00” 1.00"<br />

1.50” 1.50"<br />

2.00” 2.00"<br />

2.50” 2.50"<br />

SC<br />

BW<br />

Custom<br />

Slip Collar (standard)<br />

Butt Weld<br />

Enter GPM (see chart at right)<br />

25 25 psi (standard)<br />

Custom<br />

Enter PSI (maximum 70 PSI)<br />

25 25 Ra/180 Grit<br />

15-20 15-20 Ra/240 Grit<br />

9-11 9-11 Ra/320 Grit<br />

Finish Option (EP) EP Electropolish (added to any finish)<br />

<strong>Spray</strong> Ball Design<br />

S<br />

T<br />

Spherical design<br />

Tangential design<br />

Calculate recommended<br />

minimum flow rate for cleaning<br />

of vertical process vessels<br />

D’ x 3GPM = <strong>Spray</strong> Ball GPM<br />

A minimum flow rate of 3 gallons/minute-foot (tank circumference) is<br />

suggested to produce the required flow of solution across vessel surfaces.<br />

Connection Size<br />

Maximum Flow<br />

0.50” 12 gpm<br />

0.75” 25 gpm<br />

1.00” 40 gpm<br />

1.50” 100 gpm<br />

2.00” 240 gpm<br />

2.50” 400 gpm<br />

Custom Supply Tube Nomenclature<br />

1 2 3 4 5 6 7 8<br />

ST<br />

Ra<br />

Double Ball Tee Nomenclature<br />

1 2 3 4 5 6 7<br />

DT<br />

Ra<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

Selection Option Description<br />

Tube<br />

Diameter<br />

Tank<br />

Connection<br />

Internal<br />

Connection<br />

External<br />

Connection<br />

Internal<br />

Length<br />

External<br />

Length<br />

Finish (Ra)<br />

Finish<br />

Option (EP)<br />

0.5 0.50”<br />

0.75 0.75”<br />

1.0 1.00”<br />

1.5 1.50”<br />

2.0 2.00”<br />

2.5 2.50”<br />

1.5 1.50” End Cap Tri-Clamp<br />

2.0 2.00” End Cap Tri-Clamp<br />

2.5 2.50” End Cap Tri-Clamp<br />

3.0 3.00” End Cap Tri-Clamp<br />

4.0 4.00” End Cap Tri-Clamp<br />

6.0 6.00” End Cap Tri-Clamp<br />

BW<br />

SC<br />

TC<br />

Flange<br />

Butt Weld (standard)<br />

Slip Collar<br />

Tri-Clamp Ferrule (standard)<br />

Flange<br />

Determined in design<br />

Determined in design<br />

25 25 Ra/180 Grit (standard)<br />

15-20 15-20 Ra/240 Grit<br />

9-11 9-11 RA/320 Grit<br />

EP<br />

Electropolish (added to any finish)<br />

6<br />

5<br />

1<br />

3<br />

4<br />

2<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Selection Option Description<br />

Tube<br />

Diameter<br />

0.5 0.50”<br />

0.75 0.75”<br />

1.0 1.00”<br />

1.5 1.50”<br />

2.0 2.00”<br />

Connection SC Slip Collar (standard)<br />

Ball<br />

Connection<br />

Leg Length<br />

Leg Length<br />

Finish (Ra)<br />

Finish<br />

Option (EP)<br />

SC<br />

BW<br />

Slip Collar (standard)<br />

Butt Weld<br />

Determined in design<br />

Determined in design<br />

25 25 Ra/180 Grit<br />

15-20 15-20 Ra/240 Grit<br />

9-11 9-11 Ra/320 Grit<br />

EP<br />

Electropolish<br />

(added to any finish)<br />

1<br />

(For Double Ball Tee,<br />

select Supply Tube<br />

from left)<br />

2<br />

4 5<br />

3<br />

BP-PSB-0311<br />

P:800.356.3300 F:608.222.5348 sanimatic.com 1915 S. Stoughton Rd., Madison, WI 53716