Mod Masterpiece - Left Seat

Mod Masterpiece - Left Seat

Mod Masterpiece - Left Seat

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

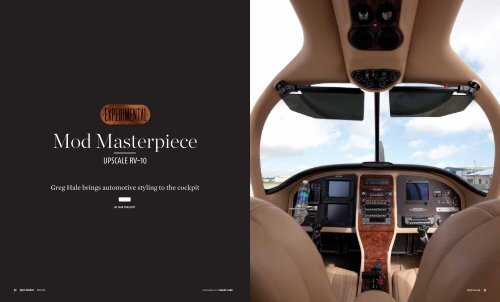

<strong>Mod</strong> <strong>Masterpiece</strong><br />

UPSCALE RV-10<br />

Greg Hale brings automotive styling to the cockpit<br />

BY Max Trescott<br />

32 Sport Aviation June 2011 PHOTOGRAPHY BY Brady Lane www.eaa.org 33

<strong>Mod</strong> <strong>Masterpiece</strong><br />

UPSCALE RV-10<br />

1. Environmental controls for the air conditioning are installed overhead.<br />

2. A smooth spinner without screws on the outside was accomplished with an internal<br />

flange inside the spinner with an attached backing plate.<br />

3. The $144 tail-mounted camera has a 170-degree field of view and is wired to the<br />

onboard computer for viewing in flight and for recording.<br />

4. A 7-inch retractable touch-screen computer plays DVDs or CDs. Software includes<br />

a weight and balance program Greg wrote and avionics manuals.<br />

1<br />

“The RV-10 impressed us since you could<br />

load four passengers and bags and be well<br />

within the maximum gross weight and CG.<br />

And as a homebuilt, it opened up a lot of<br />

possibilities for interior configurations not<br />

available on certified aircraft.”<br />

—Greg Hale<br />

When Greg Hale set out to<br />

build an RV-10, he had a<br />

simple vision: He wanted<br />

a cockpit interior that<br />

more closely resembled a<br />

Lexus than an airplane. By the time he finished,<br />

Greg made more than 25 major modifications,<br />

inside and out, from a custom nose spinner to<br />

a tail-mounted camera, all of which he details<br />

on his website. The result is perhaps the most<br />

highly modified RV-10 in the fleet and the 2011<br />

Sun ’n Fun Reserve Grand Champion kit plane.<br />

It’s no surprise the project blended the<br />

aviation and automotive worlds, as Greg has<br />

been rebuilding and customizing cars as<br />

long as he’s been flying. His first car was a<br />

1961 Volkswagen Karmann Ghia convertible.<br />

“It was made from two junked cars, and the<br />

paint job was done with Krylon spray paint,”<br />

Greg said. “I still have the spray cap indentation<br />

on my finger.”<br />

While building his car, he found a way to<br />

earn his private certificate by the age of 17<br />

for $550, which was cheap even in 1968. In<br />

college, Greg earned a bachelor’s degree in<br />

aeronautical technology and completed his<br />

A&P mechanic certificate.<br />

His career began in the engineering<br />

department at Beechcraft where he was<br />

responsible for the firewall forward<br />

of the Beech T-34C Mentor before<br />

becoming a production test pilot. After<br />

1,000 hours of flying for Beechcraft,<br />

he worked as a corporate pilot for several<br />

companies. During this time, he<br />

worked with friends to build his first<br />

airplane, a VariEze, in 1978. His career<br />

took him to the airlines, beginning<br />

with Republic Airlines, which through<br />

a series of acquisitions became<br />

Northwest and most recently Delta.<br />

“Once I started flying for the airlines, I<br />

got out of general aviation,” Greg said.<br />

Twelve years ago he earned his helicopter<br />

certificate in a Bell 47. “All of the<br />

old smells came back from learning to<br />

fly,” he said. He was hooked again.<br />

Greg built a one-man helicopter,<br />

a Revolution Mini 500, and it was<br />

his search in Tulsa for someone willing<br />

to share a hangar that led him to Al<br />

Howerton. Al was interested in building<br />

a Van’s RV-8 and at the time Greg<br />

was interested in a Globe Swift, but<br />

realized an RV-8 would be newer and<br />

faster. Their partnership blossomed<br />

from there.<br />

“We built the RV-8 as a fairly standard<br />

airplane in just nine months,” Greg<br />

said. Even so, it had a number of modifications,<br />

some of which found their way<br />

into the RV-10, too. The RV-8’s awardwinning<br />

paint scheme used 14 colors of<br />

automotive paint and was reminiscent<br />

of the street rods that Greg also likes to<br />

build. Over the years he has rebuilt a<br />

basket case 1967 Corvette coupe, customized<br />

a 1977 Toyota Corolla, and<br />

rebuilt a 1966 Mustang convertible for<br />

his wife, Kathy.<br />

Fiberglass Panel and Console<br />

Two years later Greg was ready to build<br />

again. “We were already sold on the<br />

Van’s aircraft, and the RV-10 impressed<br />

us since you could load four passengers<br />

and bags and be well within the<br />

maximum gross weight and CG. And<br />

as a homebuilt, it opened up a lot of<br />

possibilities for interior configurations<br />

not available on certified aircraft,” Greg<br />

said.<br />

As you enter Greg’s finished airplane,<br />

the dominant feature is the custom<br />

instrument panel and central console.<br />

“In 2004 we went to Oshkosh and the<br />

Chelton EFIS was the hottest thing,”<br />

Greg said. “So we decided to build the<br />

instrument panel around a pair of them.”<br />

The standard RV-10 instrument<br />

panel is a flat piece of aluminum, but<br />

since he wanted an interior that flowed<br />

together, Greg designed and built a custom-fit<br />

fiberglass panel with aluminum<br />

panel inserts to hold the avionics. Using<br />

his computer and inexpensive CAD<br />

(computer-aided design) software, he<br />

designed a wood panel to check for fit.<br />

Then he used the wood panel to create a<br />

mold for the final fiberglass panel.<br />

He got the idea for the fiberglass<br />

panel from Lancair and noted at that<br />

time, “Fiberglass instrument panels<br />

were not that readily available for other<br />

aircraft.” The central console, also<br />

made of fiberglass, flows up the center<br />

of the instrument panel, creating space<br />

for a central stack of avionics. That idea<br />

was borrowed from the Cirrus SR20<br />

and SR22.<br />

“The armrest for the console was<br />

made out of 2-inch-thick polyurethane<br />

foam. The base of the armrest is a 1/4-<br />

inch PVC foam lay-up,” Greg said. “I<br />

used the armrest base as a pattern to<br />

cut the 2-inch foam. The foam was<br />

bonded to the base, and then two layers<br />

of glass cloth were applied to foam.”<br />

The armrest was undersized to allow<br />

for a padded leather covering. It opens<br />

to reveal a glove box.<br />

Greg purchased a custom throttle<br />

quadrant from DJM Manufacturing<br />

and modified the throttle to add a “T”<br />

handle, similar to the throttle in the<br />

Cirrus SR22. He also made shorter prop<br />

and mixture levers.<br />

The central console covers the “tunnel,”<br />

a central passageway through which<br />

2 3<br />

4<br />

Instrument Panel Inserts<br />

The panels were made by Ideal Specialty in Tulsa from 1/8-inch<br />

aluminum. They were black anodized, and lettering was laseretched<br />

into the panels.<br />

The left panel contains:<br />

Dual Cheltons<br />

Advanced Flight Systems angle of attack indicator<br />

Rudder trim<br />

Dynon EFIS-D10A<br />

The right panel contains:<br />

Advanced Flight Systems engine monitor<br />

TruTrak autopilot<br />

Xenarc MDT-X7000 7-inch touch-screen VGA monitor<br />

DVD player<br />

The center avionics stack contains:<br />

Onboard computer<br />

Garmin GMA 340 audio panel<br />

Dual Garmin SL30 nav/comms<br />

Garmin GTX 330 transponder<br />

34 Sport Aviation June 2011 PHOTOGRAPHY BY Brady Lane<br />

www.eaa.org 35

<strong>Mod</strong> <strong>Masterpiece</strong><br />

UPSCALE RV-10<br />

Greg flies his RV-10 in formation alongside the RV-8 with the award-winning paint<br />

job that he built with Al.<br />

<strong>Mod</strong>ified RV-10 Specifications<br />

“I created flip-up doors<br />

like you’d find in<br />

street rods to cover the<br />

switches. Nobody was<br />

doing that in aircraft<br />

at the time.”<br />

—Greg Hale<br />

TOP: A flip-up door opens to reveal a series of<br />

swithes on the center console.<br />

<strong>Left</strong>: Greg connects the rudder pedals to the cables<br />

inside the “tunnel” with attachment bolts passing<br />

through “smiley face” slots.<br />

Right: Under the central console is the “tunnel”<br />

where fuel lines, rudder cables, air conditioning<br />

hoses, and avionics cables are routed out of view.<br />

fuel lines, cables from the pedals to the<br />

rudder, coaxial cables to antennas, and air<br />

conditioning hoses are routed out of view.<br />

In stock RV-10s, the rudder cables come out<br />

through the sides of the tunnel to connect<br />

to the pedals. But that didn’t fit with Greg’s<br />

vision for the interior.<br />

Instead, he kept the rudder cables<br />

inside of the tunnel and used a router to<br />

cut a “smiley face” slot on both sides of the<br />

tunnel near the rudder pedals. Attachment<br />

bolts pass through the slots to connect the<br />

rudder pedals’ vertical tubes to fittings<br />

inside the tunnel that connect to the rudder<br />

cables, while maintaining the cables’<br />

original length. A pair of cable covers, one<br />

with a larger diameter than the other, were<br />

slipped inside of each other and over each<br />

rudder cable to prevent the cables from<br />

contacting the air conditioning hoses.<br />

The control stick is from Infinity<br />

Aerospace. Switches on the stick control<br />

the flaps, roll/pitch trim, microphone,<br />

boost pump, engine start, and autopilot disconnect.<br />

The engine start switch goes to a<br />

Smart Start from TCW Technologies, the<br />

same company that makes the safety trim<br />

system used in the RV-10. With Smart Start,<br />

a separate activation switch is hidden in the<br />

airplane. After that switch is pushed, the<br />

pilot has one minute to start the airplane<br />

before the start circuit is deactivated. This<br />

protects against accidentally pressing the<br />

start switch with the engine running.<br />

It’s All About the Entertainment System<br />

Greg previously built a 1932 Ford Tudor<br />

Sedan street rod, and he chose a number<br />

of automotive parts and amenities for the<br />

RV-10, like seat belt harnesses, upholstery,<br />

cup holders, and an entertainment system.<br />

Particularly impressive is the plane’s<br />

in-dash computer and 7-inch touchscreen<br />

VGA monitor, designed for panel<br />

mounting in cars. The monitor, a Xenarc<br />

MDT-X7000, has a motorized display<br />

that retracts into the panel when it’s not<br />

in use. It contains a DVD drive that lets<br />

you view movies on the screen or play<br />

audio CDs. When switched to PC mode,<br />

its touch-screen works like a computer<br />

mouse, allowing you to click, select, and<br />

drag objects on the screen.<br />

Although Xenarc no longer sells the<br />

particular computer Greg installed, a similar<br />

one with a 160 GB drive, the Stealth<br />

LPC-460 computer, is available from<br />

another company. His software includes<br />

operating manuals for the avionics and an<br />

RV-10 weight and balance program that<br />

Greg wrote and gives away on his website.<br />

Slide-out silver cup holders, originally<br />

designed for cars, are installed on both<br />

sides of the instrument panel. Greg found<br />

that the pilot’s side cup holder is perfect<br />

for supporting his Apple iPad in a landscape<br />

orientation. He uses the iPad in<br />

flight primarily for instrument approach<br />

procedure charts.<br />

But he also likes to print out approach<br />

charts as a backup in case the aircraft loses<br />

power. To hold those charts and to have a<br />

place to write down ATIS information and<br />

IFR clearances, he designed and fabricated<br />

a removable desk. A Quick-Clamp universal<br />

clipboard from Sporty’s was modified<br />

for insertion into tubes installed in the console’s<br />

armrest storage compartment.<br />

Cruising in Comfort<br />

Greg liked the seat cushions supplied with<br />

the RV-10, but they didn’t evoke the Lexus<br />

feel he sought. So he used Chuck’s Auto<br />

Reupholstery, a local Tulsa interior shop, to<br />

build the seats, interior panels, and instrument<br />

panel eyebrow. The main interior<br />

covering is tan Ultraleather; tan Ultrasuede<br />

was used for the headliner and baggage<br />

area. None of the hardware attaching the<br />

interior is visible.<br />

“The idea for the back seats was to<br />

have them curve into the sidewalls to<br />

appear like one continuous molding.<br />

The back seat has a one-piece bottom<br />

and top, but is built to look like two separate<br />

seats,” Greg said. “Both seats are<br />

removable in case I need the area for<br />

cargo or for the annual inspection. The<br />

back support for the seat was made from<br />

1/4-inch PVC foam. Heat was applied<br />

to the top edge as the foam was bent to<br />

allow the seat back to cover the cabin<br />

support beam.”<br />

Greg chose to custom fit his seats with<br />

automotive inertial reel shoulder harnesses<br />

from <strong>Seat</strong>belt Pros. The front seat retractor<br />

attaches to the back of the front spar using doubler<br />

plates placed on both sides of the spar. An<br />

aluminum cover encloses the retractor front<br />

spar area. A fiberglass cover hides the shoulder<br />

harness for the front seats.<br />

For the back seats, the inertia reel was<br />

installed on the cabin cross bar. A plate<br />

added to the cross bar reinforces it at the<br />

inertia reel attachment points. A cover hides<br />

the inertia reels.<br />

To keep passengers comfortable, environmental<br />

controls are located on a switch panel<br />

cut into the overhead air conditioning duct. All<br />

heat controls are servo operated using controls<br />

from Perihelion Design that allow rheostats to<br />

control the servos positions.<br />

Most of the switches in the aircraft are<br />

hidden from view. “I created flip-up doors<br />

like you’d find in street rods to cover the<br />

switches,” Greg said. “Nobody was doing that<br />

in aircraft at the time.”<br />

Greg used fuses instead of circuit breakers<br />

to protect the electrical system, since<br />

circuit breakers were more expensive and<br />

didn’t go with the interior layout he had in<br />

mind. The fuse panels were installed on the<br />

left forward kick panel. A removable pocket<br />

hides the fuse panel from view. Lights and<br />

light controls are the same as those used<br />

in Cirrus aircraft, though the bulbs were<br />

changed from 28 to 12 volts.<br />

The baggage compartment contains a custom<br />

storage box for holding a roll of paper<br />

towels, 2 quarts of oil, fuel strainer, and tiedowns.<br />

The box is mounted in the aft bulkhead<br />

panel and recesses into the tail cone.<br />

The air conditioning return cover was not<br />

used in the final interior layout. Instead, a false<br />

upper bulkhead panel was installed 1 inch in<br />

front of the upper baggage compartment back<br />

panel to hide the return vent.<br />

<strong>Seat</strong>s: 4<br />

Length: 24 feet, 5 inches<br />

Wingspan: 31 feet, 9 inches<br />

Height: 8 feet, 8 inches<br />

Wing area: 148 square feet<br />

Performance<br />

55 percent power at 12,000 feet<br />

Firewall Forward<br />

The RV-10 is designed to accommodate engines<br />

ranging from 210 to 260 hp, and Greg chose<br />

the 260-hp Lycoming IO-540 engine. He<br />

mated it with a three-blade propeller from<br />

AeroComposites, noting he liked its larger<br />

blades better than other alternatives.<br />

The propeller included a spinner, which he<br />

modified to eliminate the screws on the outside.<br />

To do this, he fabricated an internal flange<br />

inside the spinner to which he attached a backing<br />

plate. The spinner close-outs are riveted to<br />

the backing plate.<br />

Since he selected an Airflow Systems air<br />

conditioning system, the cowling needed<br />

modification to reroute some of the hot air<br />

exiting the cowling away from the air conditioning<br />

condenser scoop. To minimize the<br />

amount of epoxy fill required, he recessed the<br />

Airflow Systems aluminum vent into the sides<br />

of the cowling. Epoxy and No. 407 filler were<br />

applied around the outside of the vent and<br />

over the rivets.<br />

Greg modified Van’s standard baffle kit<br />

to accommodate the air conditioning compressor.<br />

New attachment brackets were<br />

made, and the baffling on the forward left<br />

side was made removable to allow access to<br />

the compressor.<br />

He originally installed the fuel valve in<br />

the console, but he said, “I realized that it<br />

was 8 inches above the suggested position<br />

from Van’s. That could make it difficult for<br />

the fuel to gravity feed at low fuel tank levels.”<br />

To place the fuel valve lower, he purchased<br />

another valve from Andair with a 6-inch<br />

Empty weight: 1,848 pounds<br />

Max gross weight: 2,800 pounds<br />

Engine: Lycoming IO-540, 260 hp<br />

Propeller: Three-bladed AeroComposites<br />

Fuel capacity: 120 U.S. gallons<br />

RICH OF PEAK<br />

LEAN OF PEAK<br />

CRUISE 155 knots 151 knots<br />

FUEL BURN 12.5 gph 9 gph<br />

extension, resulting in it being an inch lower<br />

than Van’s standard installation.<br />

He replaced the standard induction filter<br />

with one developed by Rod Bower Aviation.<br />

It consists of a round aluminum can that<br />

encases the filter and a ram air valve that<br />

allows air to bypass the filter. On the ground,<br />

the ram air valve is closed so the engine<br />

receives filtered air. Greg modified the push/<br />

pull cable so that a Mac servo and a switch on<br />

the console control it.<br />

The first flight of the RV-10 was May 27,<br />

2010. In cruise, Greg runs the engine at 21<br />

inches of manifold pressure and 2300 rpm for<br />

55 percent power. That yields a cruise speed at<br />

12,000 feet of 155 knots when running rich of<br />

peak at 12.5 gph, or 151 knots when running lean<br />

of peak at 9 gph.<br />

Van’s Aircraft estimates the RV-10 can<br />

be built in 2,000 hours. Greg said he hadn’t<br />

added up the hours, but he worked on the<br />

plane for about six hours a day on each of<br />

the 14-18 days off he had each month when<br />

he was not flying for the airlines. Add that<br />

up over the five years he worked on the<br />

plane, and it’s likely Greg put in more than<br />

5,000 hours to construct his dream plane.<br />

Now that he has his Lycoming-powered<br />

Lexus with wings, it’s not surprising Greg’s next<br />

project is to fly the plane and have fun. If you’re<br />

wondering what he’s driving to get to the airport<br />

these days...it’s a tiny little Smart Car. “It<br />

saves me gas money so I can fly.”<br />

Max Trescott, EAA 531980, is an aviation author<br />

and publisher, and he was the 2008 National CFI of<br />

the Year. For more of his articles, go to www.MaxTrescott.com.<br />

For step-by-step explanations on Greg’s modifications and<br />

to see more build photos, visit www.SportAviation.org.<br />

36 Sport Aviation June 2011 PHOTOGRAPHY BY Brady Lane, John Dettor and courtesy of Greg Hale<br />

www.eaa.org 37