View brochure - JJ Smith

View brochure - JJ Smith

View brochure - JJ Smith

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

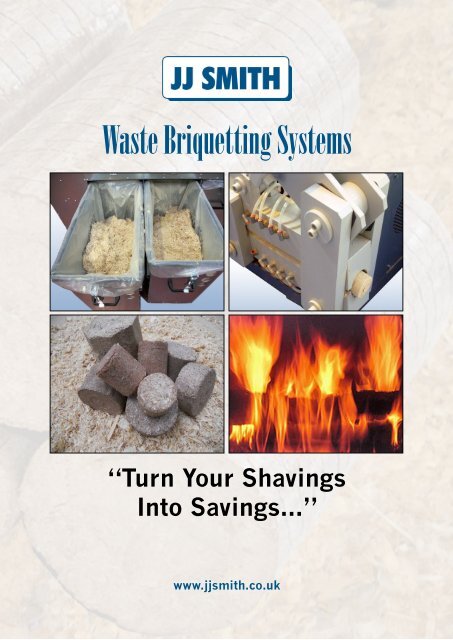

Waste Briquetting Systems<br />

“Turn Your Shavings<br />

Into Savings...”<br />

www.jjsmith.co.uk

Introduction<br />

Environmentally efficient ways of disposing of all types of waste has become increasingly more important<br />

in recent years. Many companies both large and small are now looking into the most economic forms of<br />

waste reduction and removal. This is particularly true of the woodworking sector who traditionally have large<br />

amounts of waste to dispose of. However one of the unique features of wood waste is that it lends itself to<br />

being recycled or re-used in a number of different forms, with one of the most popular being briquettes.<br />

What is Briquetting<br />

Briquetting your waste wood shavings and / or dust is essentially compressing the material into a cylindrical<br />

form. This is done through a dedicated briquetting machine which can be specified to suit the amount of<br />

waste that needs to be handled. Not only can these machines process woodwaste, they can also be used for<br />

cardboard, paper straw and in some cases waste metal shavings.<br />

Why Briquetting<br />

Unlike wood shavings and dust, briquettes are easy to handle and<br />

dispose of. They can be re-used within the factory in dedicated<br />

wood fired heaters or bagged and re-sold. Briquettes are<br />

recognised as being ideal to burn due to their high calorific value.<br />

Generally the larger the diameter briquettes burn longer and give<br />

out most heat. The Briquetting machines themselves are simple to<br />

operate and do not require regular operator intervention. They can<br />

be either filled manually or on request be directly linked to a dust<br />

extraction system. Companies who are able to recycle their waste<br />

in this way can greatly reduce their carbon foot print.<br />

Main Advantages Summary:<br />

• Reduce, remove, recycle.<br />

• Reduction of waste volume.<br />

• Savings on traditional methods of waste disposal and transport.<br />

• Briquettes ideal for burning due to high calorific value.<br />

• Machines can be specified to work with wood waste, paper or<br />

cardboard. (Note special machine specification maybe required)<br />

www.jjsmith.co.uk

Nazzareno ‘OL-D’ Series of Briquetting Presses<br />

The OL-D series of briquetting presses comprises<br />

of three different models, the 52, 62 and 72.<br />

While compact in design they are of heavy duty<br />

construction and are ideally suited to the small to<br />

medium size company who require a throughput of<br />

approximately 30kg to 100kg per hour. As standard<br />

the machine has an integral hydraulic power unit,<br />

hopper unit, electrical switch cabinet and a stainless<br />

steel plated extruder unit. These machines can<br />

work with a variety of different waste material<br />

including hardwood and softwood shavings/dust or<br />

a combination of both. Ideally the moisture content<br />

should be between 15 to 18%.<br />

Method Of Operation:<br />

The material to be processed is manually loaded in to the storage<br />

hopper, usually being emptied from waste extraction bags. It then<br />

gravitates down and is fed in to the worm screw which intern then<br />

feeds the waste in to the die head. Here it is compressed both<br />

vertically and horizontally by heavy duty hydraulic cylinders into its<br />

final compact cylindrical shape. The briquette density and length can<br />

be controlled by regulating the hydraulic clamping pressure and screw<br />

timer switch. On request other methods of loading the waste in to the<br />

hopper are available. These include via belt conveyor or directly from<br />

a waste extraction unit where the briquetting press can be positioned<br />

directly underneath.<br />

Optional Extras:<br />

• Sensor level indicator for automatic operation.<br />

• Briquette breaker (1000mm long) and head for interlinking<br />

briquettes to obtain briquettes of a length of 200mm - 300mm.<br />

• Inspection door on silo.<br />

• Inspection window on silo.<br />

• Oil cooling system.<br />

• Extruder cooling unit.<br />

• 10 Bag Carousel bagging unit.<br />

• Plastic bag sealing unit.<br />

Shredders, Pellet Plants and Combined Systems<br />

In addition to standard briquetting presses we are also able to offer<br />

dedicated woodwaste shredders, turnkey wood pellet biomass plants<br />

along with combined ‘all in one’ dust filter units complete with<br />

integrated wood briquetting press.<br />

www.jjsmith.co.uk

Technical Details<br />

Briquette<br />

Diameter<br />

50 60 70<br />

OL.D 52 OL.D 62 OL.D 72<br />

Loading bin Motor 1.5 + 0,75kw 1,5 + 0.75kw 2,2 +0.75kw<br />

Main Press motor 4kw 7.5kw 11kw<br />

Feeding bin diameter 900mm 900mm 900mm<br />

Feeding bin height 980mm 980mm 980mm<br />

Feeding bin capacity 0.6m3 0.6m3 0.6m3<br />

Hourly Throughput 30 - 50 kg/h 50 - 70 kg/h 70 - 100 kg/h<br />

Briquette diameter 50mm 60mm 70mm<br />

Briquette length Adjustable from 30 to 250mm Adjustable from 30 to 250mm Adjustable from 30 to 250mm<br />

Max moisture content of<br />

15 - 18 % 15 - 18% 15 - 18%<br />

product to be pressed<br />

Material particle size 0,5 - 8mm 0,5 - 8mm 0.5 - 8mm<br />

Machine size 1270 x 1750 x 1540mm 1270 x 1750 x 1540mm 1270 x 1750 x 1540mm<br />

Due to constant improvements the manufacturer reserves the right to alter the specification or appearance without prior notice.<br />

Moorgate Road, Knowsley Industrial Park, Kirkby, Liverpool L33 7DR<br />

Tel: 0151 548 9000 • Fax: 0151 549 1771<br />

E-mail: sales@jjsmith.co.uk • Website: www.jjsmith.co.uk