MELT INDEXER (TWELVINDEX) - Garello & De Giosa snc

MELT INDEXER (TWELVINDEX) - Garello & De Giosa snc

MELT INDEXER (TWELVINDEX) - Garello & De Giosa snc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Melt fl ow systems are used to test the fl ow characteristics<br />

of various polymers.<br />

This melt-fl ow index is an automatic model to determine<br />

the fl uidity index of thermoplastic materials<br />

exposed to heat.<br />

<strong>MELT</strong> <strong>INDEXER</strong><br />

(<strong>TWELVINDEX</strong>)<br />

This test method covers measurement of the rate of<br />

extrusion of molten resins through a die of a specifi ed<br />

length and diameter under prescribed conditions of<br />

temperature, load and piston position in the barrel as<br />

the timed mea-surement is being made.<br />

Based on this analysis, it is possible to calculate the<br />

breaking stretching ratio, which improves controls on<br />

incoming materials.<br />

Therefore melt strength properties are an important<br />

aid for plastic producers - it helps them to evaluate the<br />

material quality before production and to determinate<br />

the best para-meters in advance.<br />

The instrument carries out a volumetric procedure<br />

(MVI) and, by means of an optical system, determines<br />

the volume of the material extruded at a pre-set time.<br />

Three models are available :<br />

• MFI extrusion plastometer, melt index tester<br />

• TwelVindex with automatic cutting device and serial<br />

interface<br />

• MeP equipment for the characterisation of melted<br />

plastics materials with automatic cutting device<br />

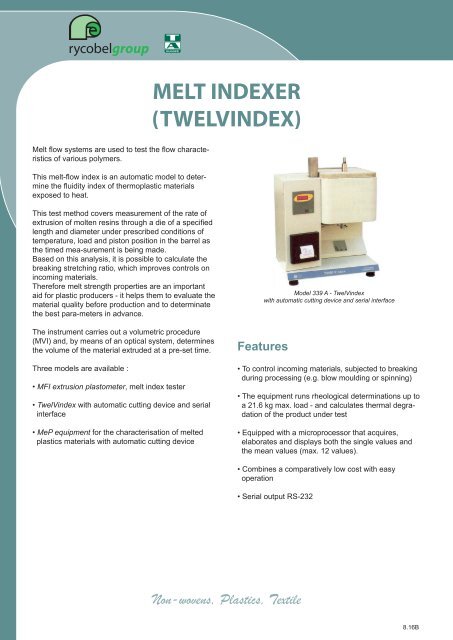

Model 339 A - TwelVindex<br />

with automatic cutting device and serial interface<br />

Features<br />

• To control incoming materials, subjected to breaking<br />

during processing (e.g. blow moulding or spinning)<br />

• The equipment runs rheological determinations up to<br />

a 21.6 kg max. load - and calculates thermal degradation<br />

of the product under test<br />

• Equipped with a microprocessor that acquires,<br />

elaborates and displays both the single values and<br />

the mean values (max. 12 values).<br />

• Combines a comparatively low cost with easy<br />

operation<br />

• Serial output RS-232<br />

Non-wovens, Plastics, Textile<br />

8.16B

Physical specifications<br />

Dimensions<br />

33 x 25 x 63 cm (LxWxH)<br />

Net Weight<br />

36 kg<br />

Options<br />

• Hasteloy test chamber, piston and die<br />

for determinations of corrosive materials<br />

• Personal computer and printer<br />

• Software and cable<br />

• Different mass<br />

Performance data<br />

Temperature range<br />

From ± 50 °C to + 400 °C<br />

Thermal control<br />

PID digital thermoregulator governed by a<br />

microprocessor and equipped with a four LED<br />

digital display, 0.1 °C resolution and keyboard for<br />

temperature setting<br />

Thermal stability<br />

0.2 °C in the heating area<br />

Heating system<br />

Two resistance set<br />

Power supply<br />

220 V, 50/60 Hz, single phase<br />

Standards<br />

ASTM D1238, D2116, D3369, BS 2782/105C,<br />

AFNOR T 51/016, ISO 1133, DIN 53735, UNI 5640<br />

Agent<br />

Cardboard<br />

Packaging<br />

Plastics<br />

Pulp<br />

Non-wovens<br />

Paper<br />

Printing Inks<br />

Textile<br />

Nijverheidslaan 47 8540 <strong>De</strong>erlijk Belgium<br />

Tel.: +32(0)56.78.21.70 Fax: +32(0)56.77.30.40<br />

Email: info@rycobel.be Website: www.rycobel.be