Elastomers - Era Polymers

Elastomers - Era Polymers

Elastomers - Era Polymers

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

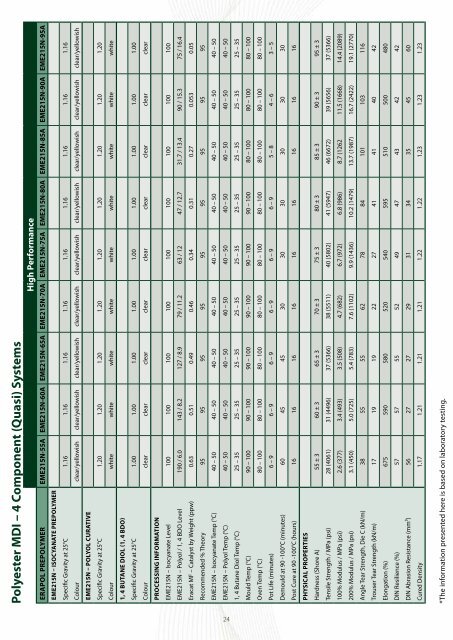

Polyester MDI – 4 Component (Quasi) Systems<br />

High Performance<br />

<strong>Era</strong>pol Prepolymer EME215N-55A EME215N-60A EME215N-65A EME215N-70A EME215N-75A EME215N-80A EME215N-85A EME215N-90A EME215N-95A<br />

EME215N – IsocyANATE Prepolymer<br />

Specific Gravity at 25°C 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16 1.16<br />

Colour clear/yellowish clear/yellowish clear/yellowish clear/yellowish clear/yellowish clear/yellowish clear/yellowish clear/yellowish clear/yellowish<br />

EME215N – Polyol Curative<br />

Specific Gravity at 25°C 1.20 1.20 1.20 1.20 1.20 1.20 1.20 1.20 1.20<br />

Colour white white white white white white white white white<br />

1, 4 Butane Diol (1, 4 BDO)<br />

Specific Gravity at 25°C 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00<br />

Colour clear clear clear clear clear clear clear clear clear<br />

Processing Information<br />

EME215N – Isocyanate Level 100 100 100 100 100 100 100 100 100<br />

EME215N – Polyol / 1, 4 BDO Level 190 / 6.0 143 / 8.2 127 / 8.9 79 / 11.2 63 / 12 47 / 12.7 31.7 / 13.4 90 / 15.3 75 / 16.4<br />

<strong>Era</strong>cat MF – Catalyst by Weight (ppw) 0.63 0.51 0.49 0.46 0.34 0.31 0.27 0.053 0.05<br />

Recommended % Theory 95 95 95 95 95 95 95 95 95<br />

EME215N – Isocyanate Temp (°C) 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50<br />

EME215N – Polyol Temp (°C) 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50 40 – 50<br />

1, 4 Butane Diol Temp (°C) 25 – 35 25 – 35 25 – 35 25 – 35 25 – 35 25 – 35 25 – 35 25 – 35 25 – 35<br />

Mould Temp (°C) 90 – 100 90 – 100 90 – 100 90 – 100 90 – 100 90 – 100 80 – 100 80 – 100 80 – 100<br />

Oven Temp (°C) 80 – 100 80 – 100 80 – 100 80 – 100 80 – 100 80 – 100 80 – 100 80 – 100 80 – 100<br />

Pot Life (minutes) 6 – 9 6 – 9 6 – 9 6 – 9 6 – 9 6 – 9 5 – 8 4 – 6 3 – 5<br />

Demould at 90 -100°C (minutes) 60 45 45 30 30 30 30 30 30<br />

Post Cure at 90 -100°C (hours) 16 16 16 16 16 16 16 16 16<br />

PhySICAL Properties<br />

Hardness (Shore A) 55 ± 3 60 ± 3 65 ± 3 70 ± 3 75 ± 3 80 ± 3 85 ± 3 90 ± 3 95 ± 3<br />

Tensile Strength / MPa (psi) 28 (4061) 31 (4496) 37 (5366) 38 (5511) 40 (5802) 41 (5947) 46 (6672) 39 (5656) 37 (5366)<br />

100% Modulus / MPa (psi) 2.6 (377) 3.4 (493) 3.5 (508) 4.7 (682) 6.7 (972) 6.8 (986) 8.7 (1262 11.5 (1668) 14.4 (2089)<br />

200% Modulus / MPa (psi) 3.1 (450) 5.0 (725) 5.4 (783) 7.6 (1102) 9.9 (1436) 10.2 (1479) 13.7 (1987) 16.7 (2422) 19.1 (2770)<br />

Angle Tear Strength, Die C (kN/m) 38 55 55 62 78 84 101 103 116<br />

Trouser Tear Strength (kN/m) 17 19 19 22 27 41 41 40 42<br />

Elongation (%) 675 590 580 520 540 595 510 500 480<br />

DIN Resilience (%) 57 57 55 52 49 47 43 42 42<br />

DIN Abrasion Resistance (mm³) 56 27 27 29 31 34 35 45 60<br />

Cured Density 1.17 1.21 1.21 1.21 1.22 1.22 1.23 1.23 1.23<br />

*The information presented here is based on laboratory testing.<br />

24