Elastomers - Era Polymers

Elastomers - Era Polymers

Elastomers - Era Polymers

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Properties of <strong>Era</strong>pol <strong>Elastomers</strong><br />

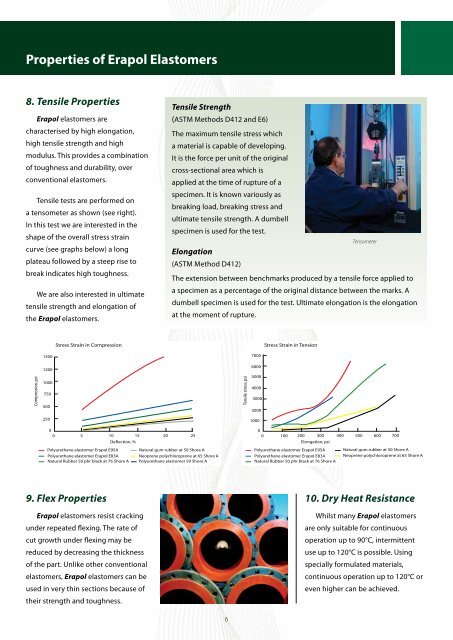

8. Tensile Properties<br />

<strong>Era</strong>pol elastomers are<br />

characterised by high elongation,<br />

high tensile strength and high<br />

modulus. This provides a combination<br />

of toughness and durability, over<br />

conventional elastomers.<br />

Tensile tests are performed on<br />

a tensometer as shown (see right).<br />

In this test we are interested in the<br />

shape of the overall stress strain<br />

curve (see graphs below) a long<br />

plateau followed by a steep rise to<br />

break indicates high toughness.<br />

We are also interested in ultimate<br />

tensile strength and elongation of<br />

the <strong>Era</strong>pol elastomers.<br />

Tensile Strength<br />

(ASTM Methods D412 and E6)<br />

The maximum tensile stress which<br />

a material is capable of developing.<br />

It is the force per unit of the original<br />

cross-sectional area which is<br />

applied at the time of rupture of a<br />

specimen. It is known variously as<br />

breaking load, breaking stress and<br />

ultimate tensile strength. A dumbell<br />

specimen is used for the test.<br />

Elongation<br />

(ASTM Method D412)<br />

Tensometer<br />

The extension between benchmarks produced by a tensile force applied to<br />

a specimen as a percentage of the original distance between the marks. A<br />

dumbell specimen is used for the test. Ultimate elongation is the elongation<br />

at the moment of rupture.<br />

Compression, psi<br />

Stress Stress Strain Strain in Compression<br />

1500 1500<br />

1200 1200<br />

Compression, psi<br />

1000 1000<br />

750 750<br />

500 500<br />

250 250<br />

Tensile stress, psi<br />

Stress Stress Strain Strain Tension in Tension<br />

7000 7000<br />

6000 6000<br />

5000 5000<br />

Tensile stress, psi<br />

4000 4000<br />

3000 3000<br />

2000 2000<br />

1000 1000<br />

0 0 5 5 10 10 15 15 20 20 25 25<br />

Deflection, Deflection, % %<br />

Polyurethane elastomer elastomer <strong>Era</strong>pol <strong>Era</strong>pol E95A E95A Natural Natural gum gum rubber rubber at 50 at Shore 50 Shore A A<br />

Polyurethane elastomer elastomer <strong>Era</strong>pol <strong>Era</strong>pol E83A E83A Neoprene Neoprene polychloroprene at 65 at Shore 65 Shore A A<br />

Natural Natural Rubber Rubber 50 phr 50 black phr black at 76 at Shore 76 Shore A A<br />

Polyurethane elastomer elastomer 50 Shore 50 Shore A A<br />

0 0 100 100200 200 300 300 400 400 500 500 600 600 700 700<br />

Elongation, Elongation, psi psi<br />

Polyurethane elastomer elastomer <strong>Era</strong>pol <strong>Era</strong>pol E95A E95A Natural Natural gum gum rubber rubber at 50 at Shore 50 Shore A A<br />

Polyurethane elastomer elastomer <strong>Era</strong>pol <strong>Era</strong>pol E83A E83A Neoprene Neoprene polychloroprene at 65 at Shore 65 Shore A A<br />

Natural Natural Rubber Rubber 50 phr 50 black phr black at 76 at Shore 76 Shore A A<br />

9. Flex Properties<br />

<strong>Era</strong>pol elastomers resist cracking<br />

under repeated flexing. The rate of<br />

cut growth under flexing may be<br />

reduced by decreasing the thickness<br />

of the part. Unlike other conventional<br />

elastomers, <strong>Era</strong>pol elastomers can be<br />

used in very thin sections because of<br />

their strength and toughness.<br />

10. Dry Heat Resistance<br />

Whilst many <strong>Era</strong>pol elastomers<br />

are only suitable for continuous<br />

operation up to 90°C, intermittent<br />

use up to 120°C is possible. Using<br />

specially formulated materials,<br />

continuous operation up to 120°C or<br />

even higher can be achieved.<br />

6