Oil Spill Detection - Simrad Professional Series

Oil Spill Detection - Simrad Professional Series

Oil Spill Detection - Simrad Professional Series

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

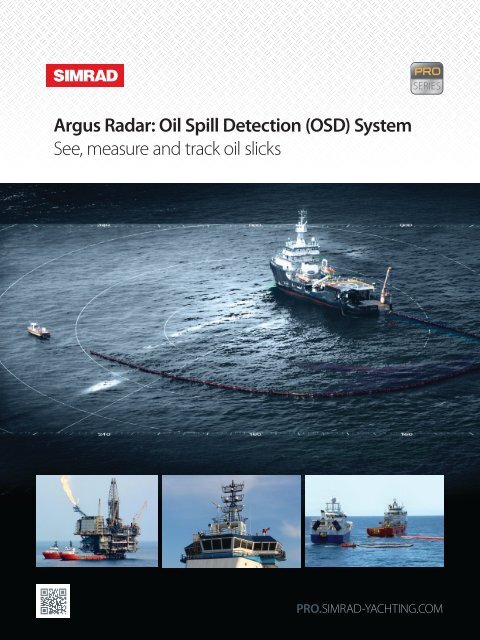

Argus Radar: <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> (OSD) System<br />

See, measure and track oil slicks

2<br />

<strong>Oil</strong> spill detection, response and recovery<br />

Early detection<br />

Early detection and the ability to mount an emergency response<br />

are essential should an oil spill occur. <strong>Oil</strong> spills are costly to the<br />

environment and the maritime industry, so oil spill prevention,<br />

detection and recovery are paramount.<br />

Having dedicated equipment permanently installed on your<br />

vessel that will allow you to accelerate the clean-up operation<br />

and contain the contaminated area is a necessity. The <strong>Simrad</strong><br />

ARGUS Radar <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> application is a must have, and<br />

this is a simple add-on to our standard type approved IMO/SOLAS<br />

navigational radar. The advanced hardware video processing<br />

function enables the detection and tracking of oil slicks.<br />

On-board with <strong>Simrad</strong> ARGUS<br />

The <strong>Simrad</strong> Argus <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> application works by receiving<br />

and processing signals in real-time from on-board transceivers.<br />

The water surface is usually dampened when it is contaminated<br />

by oil, so the backscatter of microwave radiation from these waves<br />

is unlike the rest of the sea. The radar is then able to highlight the<br />

dampening of the reflected microwave radiation on the radar<br />

display, thus calculating the size, position and drift (speed and<br />

course) of the oil spill. We let you see inside the oil spill!<br />

Looking inside the oil slick with your standard<br />

navigational radar<br />

Ships in regular operations can use the primary radar set as a<br />

traditional instrument for navigation, and the secondary radar<br />

display (interfaced to the primary radar) switched over to the<br />

advanced function of <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong>. We are among the first<br />

companies in the world to provide an oil detection application<br />

working in parallel with its IMO/SOLAS ARPA navigational radar.<br />

From the ship owners’ point of view, the most important benefit is<br />

the reduced maintenance costs in terms of installation, service and<br />

spare parts. In addition, the officers on watch don’t have to learn a<br />

new operating system, because the OSD functionality is part of the<br />

standard navigational radar system with the same user interface.<br />

The <strong>Simrad</strong> ARGUS <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> radar operates on the same<br />

hardware (not PC based) approved by the Federal Maritime and<br />

Hydrographic Agency in Germany (BSH), and is compliant with the<br />

European Maritime Directive (MED) and United Stated Coast Guard<br />

regulations. In a combined and integrated navigation and oil spill<br />

response and management bridge system, the stress of the officers<br />

on duty is drastically reduced by operating on the same userfriendly<br />

graphical man-machine interface.<br />

Long heritage and global support<br />

With over 60 years at the forefront of product innovation, we are<br />

one of the world’s most recognised brands in the field of marine<br />

electronics. This heritage provides a platform from which some of<br />

the most innovative products are engineered. Our OSD application<br />

is one that you can depend on to improve oil spill response<br />

capabilities, and should the need arise, our global service network<br />

of support engineers located in over 50 key ports around the world<br />

will deliver first class on-board service.<br />

Deepwater Horizon Response<br />

<strong>Professional</strong> <strong>Series</strong><br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Systems

<strong>Oil</strong> spill detection features<br />

3<br />

Main <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Features<br />

uu<br />

uu<br />

uu<br />

uu<br />

uu<br />

uu<br />

uu<br />

Ability to present oil concentration/thickness inside the<br />

oil slick pattern<br />

Automatic oil spot contour detection and area size<br />

calculation<br />

Assessment of the oil slick position, speed and direction<br />

Data recording of the operating history and instant<br />

screen dumps<br />

Instrumental maximum oil spill detection range up to<br />

12 Nm<br />

Real-time processed images with selectable integration<br />

time between 30 seconds up to 2 minutes<br />

Information display about wind conditions<br />

uu<br />

Ability to increase the antenna rotation speed up to 44<br />

revolutions per minute<br />

uu<br />

uu<br />

uu<br />

uu<br />

uu<br />

uu<br />

Ability to integrate external sensors and devices<br />

Capacity to interface and receive signals from two radar<br />

sensors and allows the operator to select the transceiver<br />

to be used for <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong>.<br />

Option to add an additional two radar sensors dedicated<br />

for oil spill<br />

Full master/slave interwsitchability with two additional<br />

navigational radar plants<br />

Superb video processing with 256 multicolour video<br />

levels providing sharp colour distinctions on screen<br />

System also provides special features such as Ice<br />

detection and Navigation mode, Small Target <strong>Detection</strong><br />

mode and Meteorology mode for storm tracking<br />

The OSD application shares the same hardware as the<br />

IMO/SOLAS APRPA navigational radar plant.<br />

Incorporate information about wind conditions to assist with<br />

oil slick speed and direction calculations.<br />

Look inside the oil slick with 256 multicolour video levels.<br />

Water contaminated by oil: low density = blue, high density = red<br />

Seamless interswitching between navigational and OSID radars.<br />

<strong>Professional</strong> <strong>Series</strong><br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Systems

4<br />

How the Argus <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> software works<br />

How it works<br />

In general, the operation of the marine radar is based on the<br />

physical phenomenon of backwards “scattering” of microwave<br />

radiation. When the microwave radiation waves strike an object,<br />

they are reflected in all directions. The signal is also partially<br />

radiated back towards the direction of origin (backscattering),<br />

generating an echo on the radar display. The wind causes the<br />

regular rise and fall of the water level: the sea waves.<br />

The presentation on the navigational radar screen is affected by<br />

the presence of the waves. The waves seen by a radar appear as<br />

an immeasurable amount of reflective objects that radiate back<br />

microwave energy in a completely chaotic and incoherent way<br />

over 360 degrees for several miles. The navigational radar has<br />

countermeasures to reduce this disturbance caused by waves and<br />

makes visible the possible targets.<br />

For the <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> functionality it is vice versa. Echoes<br />

from particular waves are required. Ripples, called capillary waves,<br />

appear on smooth water when the wind blows due to the friction<br />

of air flowing over the sea surface.<br />

The echoes from the sea surface, in terms of microwave radiation,<br />

meet the law of the surface reflectivity.<br />

The microwave radiation reflectivity<br />

depends on the angle of incidence, the<br />

roughness and the dielectric constant<br />

properties of the sea surface. The<br />

suppression of the capillary waves by oil<br />

viscosity reduces the surface roughness.<br />

The different dielectric constant of the oil<br />

results in less radar backscatter.<br />

The returning signal from an area contaminated by oil is slightly<br />

dampened by both of these factors working simultaneously.<br />

The excellent capability of the <strong>Simrad</strong> Argus <strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong><br />

radar, thanks to an advanced real-time signal processing, is able to<br />

highlight the dampening of the reflected microwave radiation on<br />

the radar display.<br />

Vertical Polarization Antennas<br />

When discussing microwave energy propagation and scattering,<br />

the polarization of the radiation is an important property.<br />

Although imagery in both vertical and horizontal polarizations<br />

can be used for slick detection, the vertical imagery is preferred<br />

for dedicated oil spill radar sensors. In general, it offers a stronger<br />

clutter background than other polarization choices, generating an<br />

improved contrast with the oil contaminated areas.<br />

However, in spite of the fact that vertical polarizations are more<br />

sensitive than horizontal for slick detection, there are only<br />

disadvantages in their use for navigational radars.<br />

<strong>Simrad</strong> Argus OSD display is available in three different configurations to suit any vessel:<br />

The deck configuration provides an<br />

optional display deck stand which can<br />

also house the electronic cabinet.<br />

Two different options available :<br />

• Desk-Top Cabinet for 26“ with Pedestal<br />

• Desk-Top Cabinet for 23“ / Adapter<br />

Frame kit for 19” Monitor / Pedestal<br />

The modular configuration with<br />

monitor, keyboard and ARPA electronic<br />

cabinet supplied as three separate<br />

modules which can be flush mounted<br />

into the bridge console to the customers´<br />

preference.<br />

The table top configuration where<br />

the monitor and key-board are housed<br />

into an ergonomic console while the<br />

electronics are contained in a separate<br />

bulkhead mounted cabinet.<br />

<strong>Professional</strong> <strong>Series</strong><br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Systems

Looking inside the oil slick<br />

5<br />

Vessels towing oil recovery<br />

booms into place<br />

Spot area of oil<br />

concentration<br />

<strong>Oil</strong> spot area =<br />

10.38km2<br />

<strong>Oil</strong> volume =<br />

326,592 barrels<br />

<strong>Oil</strong> thickness = 5mm<br />

Vessel spilling oil<br />

Spot contour<br />

showing outline<br />

of oil spill<br />

Colour gradients to<br />

show oil density<br />

<strong>Professional</strong> <strong>Series</strong><br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Systems

6<br />

System diagrams<br />

Navigation and oil response Bridge Solution<br />

X Band Antenna Group<br />

X Band<br />

6 and 9 Ft<br />

12 or 25 kW<br />

and HSC<br />

Additional two radar sensors<br />

for oil spill (optional)<br />

Navigation Radar<br />

<strong>Oil</strong> <strong>Spill</strong> Radar<br />

2nd Station<br />

Interswitch<br />

Bridge Network (Lan)<br />

to ECDIS<br />

interfaced to OTHER RADAR BRAND<br />

BASIC SOLUTION<br />

Existing X Band Radar System<br />

X Band Antenna Group<br />

ALPHA RIB<br />

(Radar Interface Board)<br />

X Band<br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Display<br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Display<br />

<strong>Professional</strong> <strong>Series</strong><br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Systems

Technical specifications<br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> operational mode<br />

7<br />

Display<br />

Monitors<br />

Radar picture<br />

Resolution<br />

19” LCD TFT<br />

23” LCD TFT<br />

27” LCD TFT<br />

>250 mm (12” PPI)<br />

>320 mm (16” PPI)<br />

1280x1024<br />

1600x1200<br />

Day/Night modes<br />

Head, Course and North Up<br />

Course and North Up<br />

Up to 50% of range scales in use<br />

0.25; 0.5; 0.75; 1.5; 3; 6; 12 nm<br />

3 m on 0.75 nm range scale<br />

Presentation modes<br />

Relative motion (RM)<br />

True motion (TM)<br />

Off-centering<br />

Range scales<br />

Range resolution<br />

Azimuth resolution 0.1°<br />

Trackball<br />

Polar and Geographical coordinates<br />

continuously displayed<br />

Diagnostic<br />

On-line diagnostic programs<br />

<strong>Oil</strong> slick tracking facilities<br />

Acquisition<br />

Manual<br />

Tracking<br />

Manual with automatic dead-reckoning<br />

Operating history<br />

UTC, Range/Bearing, Speed/Course,<br />

Latitude/Longitude, Area, Volume and<br />

Thickness. Transferable via USB<br />

Memory stick or network.<br />

<strong>Oil</strong> slick vectors<br />

Four time integration filters<br />

Metric measurement of oil<br />

OSD threshold<br />

<strong>Oil</strong> slick contour<br />

Search mode<br />

Anchored mode<br />

Spot area<br />

Volume<br />

<strong>Oil</strong> thickness<br />

Data recording<br />

AIS facilities<br />

Presentation<br />

Safe checking<br />

Auto acquisition/<br />

Guard zones<br />

Visualize the potential vectors of patches of<br />

oil<br />

The longer the filter length, the more evident<br />

the presence of oil will be<br />

Choose between Nautic or Metric units of<br />

measurement<br />

Modify the video color palette threshold<br />

within the monitoring window of the oil<br />

patch for more accurate calculation of the<br />

surface area of the patch<br />

Highlights the outline of the oil slick<br />

The monitoring window maintains its position<br />

relative to the ship<br />

The oil spill monitoring window will remain<br />

anchored at its true geographical position<br />

Expressed in m2/km. Spot area indicates the<br />

surface of the oil patch<br />

Presumed volume of oil expressed in barrels<br />

Manual setting of presumed thickness of oil<br />

patch for greater accuracy in calculating the<br />

volume of oil<br />

The following oil patch area data can be<br />

recorded -area, date and time, geographical<br />

position of the patch barycentre, speed and<br />

direction<br />

Up to 300 targets chosen as the nearest to<br />

own ship<br />

All 300 targets in sleep or activated stated<br />

Same zones as described for ARPA facilities<br />

Mapping<br />

Operator compiled maps up to 120 segments plus symbols and text strings<br />

with selectable colours and line styles.<br />

Map stabilisation<br />

Relative, true (Dead Reckoning) or<br />

geographic<br />

Map storage<br />

By Name , on a built-in non volatile<br />

memory.<br />

Transferable via USB Memory stick<br />

Map adjustment<br />

Position and Orientation<br />

Graphic functions<br />

Alarms<br />

Data readout<br />

OSD target data<br />

AIS target data<br />

Own ship data<br />

<strong>Oil</strong> spill area<br />

<strong>Oil</strong> spot volume<br />

System setting<br />

True or relative time adjustable vectors<br />

Target identification number, track-ball<br />

marker and true marks.<br />

AIS identification number, ship names or<br />

call signs.<br />

Time adjustable past position plots<br />

Own ship shape and activated AIS target<br />

shape on lower range scales.<br />

Range/Bearing, Speed/Course and<br />

Latitude/Longitude.<br />

Ship Name, MMSI, Call Sign, Range/<br />

bearing, speed/course, CPA/TCPA and<br />

Latitude/Longitude, Type, Status,<br />

Destination, ETA, ship size, AIS class.<br />

Heading, Speed/Course water or ground<br />

stabilized, wind speed and direction, Geo<br />

graphic position and UTC time.<br />

Automated calculation of the oil spot area<br />

in Km² or m².<br />

Computed calculation of the oil spot<br />

volume in barrels.<br />

<strong>Oil</strong> Slick Thickness.<br />

Alarms<br />

Acoustic and visual warning for: System and<br />

external interface sensors (EPFS and AIS)<br />

failures.<br />

Inputs<br />

Gyro heading<br />

Analog, synchro or stepper<br />

Digital Fast NMEA (IEC 61162-2)<br />

Speed log<br />

Analog: PIT or two axis log<br />

Digital: NMEA (IEC 61162-1)<br />

EPFS Serial Interface NMEA (IEC 61162-1)<br />

Wind Serial Interface NMEA (IEC 61162-1)<br />

AIS Serial Interface NMEA (IEC 61162-1)<br />

Output Serial Interface NMEA 0183 (IEC 61162-1)<br />

RATTM - RAOSD – RARSD – RAALR –<br />

RATLB – RATTD sentences<br />

Four USB 2.0 port.<br />

Rules references<br />

Type testing in IMO Resolution A.813 (19), accordance with A.694 (17),<br />

MSC192 (79), MSC 36 (63), IMO Circ. S/N 217<br />

and specified standards:<br />

IEC 60945 (General Requirements)<br />

IEC 62388 (Performance Requirements)<br />

IEC 61162-1/2 (NMEA Interface)<br />

X-Band Radar Up-mast<br />

Peak Power (kW) 12 or 25<br />

Pulse length (nsec) 60 – 250 - 800<br />

PRF (Hz) 3000-1500-750<br />

Antenna model 6X 9X 12X<br />

Gain (dB) 29 31 32,5<br />

Horizontal beam width at -3 dB (°) 1,3 0,9 0,7<br />

Vertical beam width at -3 dB (°) 22 22 22<br />

Weight of Antenna (kg) 40 44 49<br />

(incl. Pedestal with Transceiver)<br />

Nominal Rotation speed (RPM) 22 or 44<br />

Environmental Options<br />

Different PRF set:<br />

Upon Customer request<br />

Heaters: For very cold environment (< -25° C)<br />

<strong>Professional</strong> <strong>Series</strong><br />

<strong>Oil</strong> <strong>Spill</strong> <strong>Detection</strong> Radar Systems

OUR Heritage: ESTABLISHED IN 1947.<br />

With more than 60 years of maritime expertise invested in delivering solutions to the<br />

professional market, we have unique knowledge to support professional customers<br />

with cost effective navigation solutions.<br />

Contact us:<br />

Navico Americas: Tel: +1 832 377 9578 Email: sales.americas@navico.com<br />

Navico Asia Pacific: Tel: +64 9 925 4500 Email: sales.apacnz@navico.com<br />

Navico EMEA: Tel: +44 1794 510010 Email: sales.emea@navico.com<br />

985-10557-001