in2Pro Talon Manipulator Brochure - InTest Corporation

in2Pro Talon Manipulator Brochure - InTest Corporation

in2Pro Talon Manipulator Brochure - InTest Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

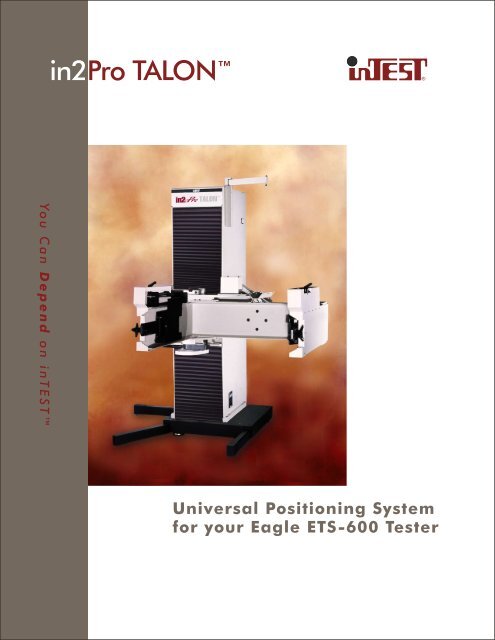

<strong>in2Pro</strong> TALON ®<br />

You Can Depend on inTEST<br />

Universal Positioning System<br />

for your Eagle ETS-600 Tester

Get Maximum Performance<br />

from Your Eagle ETS-600<br />

The <strong>in2Pro</strong> <strong>Talon</strong>: built to deliver maximum throughput from<br />

your Eagle ETS-600 Tester. From its solid stance, to the speed<br />

and convenience of seven motions, to its high precision and<br />

rugged, inTEST dependability, the <strong>Talon</strong> is ready to boost<br />

production on your test floor.<br />

Faster, Easier Set-Ups<br />

The <strong>Talon</strong> gives you remarkably quick and easy test set-ups. The standard version’s<br />

motions are adjusted manually for greater speed, while operator movement is kept<br />

to an absolute minimum with easy-to-reach controls and locks. All motions are<br />

independently adjustable, except naturally integrated test head theta and in/out<br />

motions.<br />

2<br />

4<br />

Extra Margins of Safety<br />

The highly stable unloaded <strong>in2Pro</strong> <strong>Talon</strong> will maintain its solid footing even with<br />

no counterweights in place. And the <strong>Talon</strong>’s Impulse Load is designed with a factor<br />

of safety equal to five times Rated Load. This is significantly greater than competitive<br />

units, whose Impulse Load capability is typically only two times the Rated Load.<br />

1<br />

Optional Motorized Motion<br />

The <strong>Talon</strong> offers optional motorized motion for even easier test set-ups. Conveniently<br />

controlled by pushbuttons on a handheld pendant, these include both the up/down<br />

and twist (or “rotation”) motions. Because the test head is captured at the center<br />

of gravity, the motorized <strong>Talon</strong> can use low-torque, clutched motors for greater test<br />

floor safety.<br />

3<br />

inTEST Dependability<br />

The <strong>in2Pro</strong> <strong>Talon</strong> is manufactured with high-strength, aircraft-quality aluminum<br />

and steel. Its high-precision, high-load bearings are lightly loaded versus design<br />

capacity, to ensure ease of movement and extended service life. Like every inTEST<br />

positioning system, the <strong>in2Pro</strong> <strong>Talon</strong> is a summary of state-of-the-art, precision<br />

craftsmanship and rugged, durable design, backed up by the best global service<br />

in the industry. It’s one more reason you can depend on inTEST.<br />

7 Adjustable Motions for Fast Positioning<br />

Glide Up/Down<br />

Glide Side to Side<br />

Swing<br />

Twist (”Rotation”)<br />

on column

Convenient control pendant<br />

for motorized version<br />

Full motion control for easy test set-ups<br />

Glide Up/Down<br />

On column, provides a vertical stroke<br />

of 44”; independently lockable.<br />

1<br />

6<br />

6<br />

2<br />

Glide Side-to-Side<br />

On column, provides 8.6” of motion;<br />

independently lockable.<br />

3<br />

Swing<br />

On column, provides a full 90° of<br />

motion; independently lockable.<br />

5<br />

5<br />

4<br />

Twist<br />

On column, provides 270° of rotation;<br />

independently lockable.<br />

Tumble<br />

On cradle, provides ± 5° of motion;<br />

fixed with common lock handles.<br />

5<br />

6<br />

Glide In/Out and<br />

Test Head Theta<br />

On cradle, provides 2.6” of glide in/out<br />

motion and ± 5° of test head theta<br />

motion; fixed with common lock<br />

handles.<br />

Glide In/Out<br />

Tumble<br />

Test Head Theta<br />

in cradle

<strong>in2Pro</strong> TALON<br />

50-50059-025 4/02<br />

75.28 (191 cm) 72.66 (185 cm)<br />

Lifting Capability<br />

73.50<br />

(187 cm)<br />

44.50 (113 cm) 47.25 (120 cm)<br />

Rated Load: 22,500 inch-pounds (Test Head<br />

Weight x Distance from column to test head<br />

cg.). Impulse Load: 5x Rated Load<br />

Typical test head weight range: 200 – 450 lb.<br />

inTEST <strong>Corporation</strong><br />

Corporate Headquarters<br />

7 Esterbrook Lane<br />

Cherry Hill, NJ 08003 USA<br />

Tel (856) 424 6886<br />

Fax (856) 751 1222<br />

inTEST <strong>Corporation</strong><br />

1275 Lawrence Station Road<br />

Sunnyvale, CA 94089 USA<br />

Tel (408) 747 5901<br />

Fax (408) 747 5910<br />

inTEST <strong>Corporation</strong><br />

Temptronic<br />

4 Commercial Street<br />

Sharon, MA 02067 USA<br />

Tel (781) 688 2300<br />

Fax (781) 688 2301<br />

Axis Travel Motorized<br />

Glide Side-to-Side 8.6 in. (218.44 mm) manual<br />

Glide In/Out 2.6 in. (66.04 mm) manual<br />

Cradle Swing 90° manual<br />

Glide Up/Down 44 in. (1,117.6 mm) optional<br />

Twist (”Rotation”) 270° with ± 5° compliance optional<br />

Tumble ± 5° manual<br />

Test Head Theta ± 5° manual<br />

• Test Head is counter-balanced with column weights.<br />

• Each axis can be left floating or it can be locked in position with a<br />

brake.<br />

• In Manual Mode, each axis requires no more than 22 lb. (10 kg)<br />

force to move it through its entire travel.<br />

• Options Include:<br />

- Motorized motions: up/down and twist (both operated by handheld<br />

control pendant).<br />

- Black, bellows-style cable cover (shown in photos).<br />

• System features an integrated cable management harness.<br />

• Optional motors are operated from push-buttons on a hand-held<br />

Control Pendant.<br />

Electrical (motorized)<br />

100-240 VAC, 50/60 Hz, 600 W<br />

Design Integration Across the Entire MDI<br />

For dependable performance and maximum uptime, all the parts of<br />

your MDI Assembly (<strong>Manipulator</strong>, Docking, and Interface) must work<br />

together seamlessly. Contact your inTEST representative for information<br />

on inTEST’s Docking and Interface equipment. Our Design Integration<br />

Program assures you of design-matched components across the entire<br />

MDI.<br />

inTEST Limited<br />

11-12 Thame Park Business Centre<br />

Wenman Road<br />

Thame Oxfordshire<br />

OX9 3XA United Kingdom<br />

Tel +44 184 421 7525<br />

Fax +44 184 421 7798<br />

inTEST KK<br />

1-13-4 Kita-Otsuka<br />

Nihon Seimei Otsuka Building<br />

Toshima-Ku, Tokyo 170-0004<br />

Japan<br />

Tel +81 3-5961-4881<br />

Fax +81 3-5961-4883<br />

inTEST PTE Ltd<br />

Block 4010 TechPlace 1<br />

#05-01/02 Ang Mo Kio Ave 10<br />

Singapore 569626<br />

Tel +65 6552-2404<br />

Fax +65 6552-2414<br />

inTEST GmbH<br />

Gewerbeparking 18<br />

D-15299 Muellrose<br />

Germany<br />

Tel +49-33606-77700<br />

Fax +49-33606-77701<br />

<strong>Manipulator</strong>, Docking, and<br />

Interface Solutions<br />

www.intest.com<br />

TEMPTRONIC<br />

CORPORATION<br />

an inTEST Company<br />

Thermal Test Solutions<br />

www.temptronic.com